Bonding properties of UHPC-high strength rebar based on beam test

-

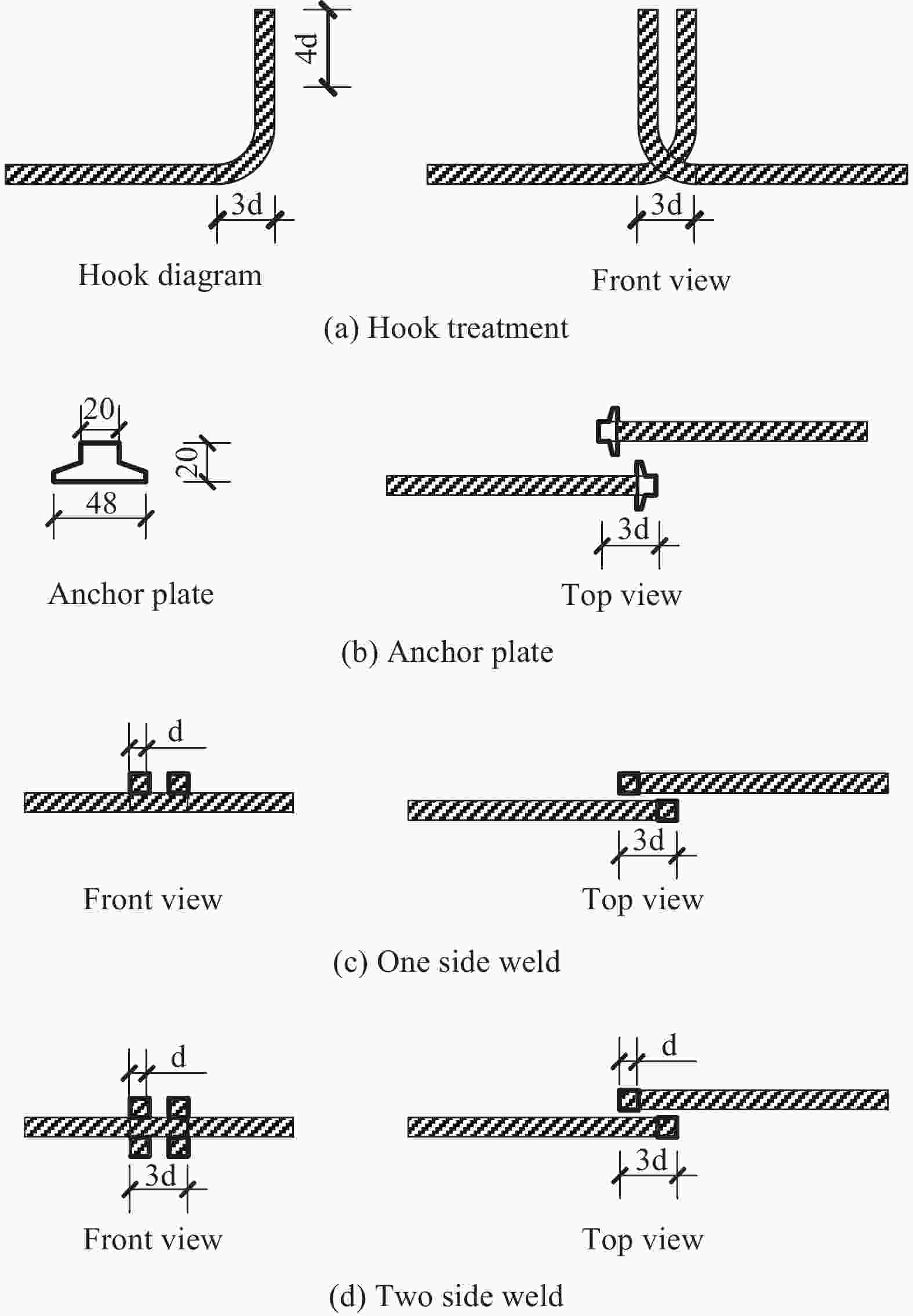

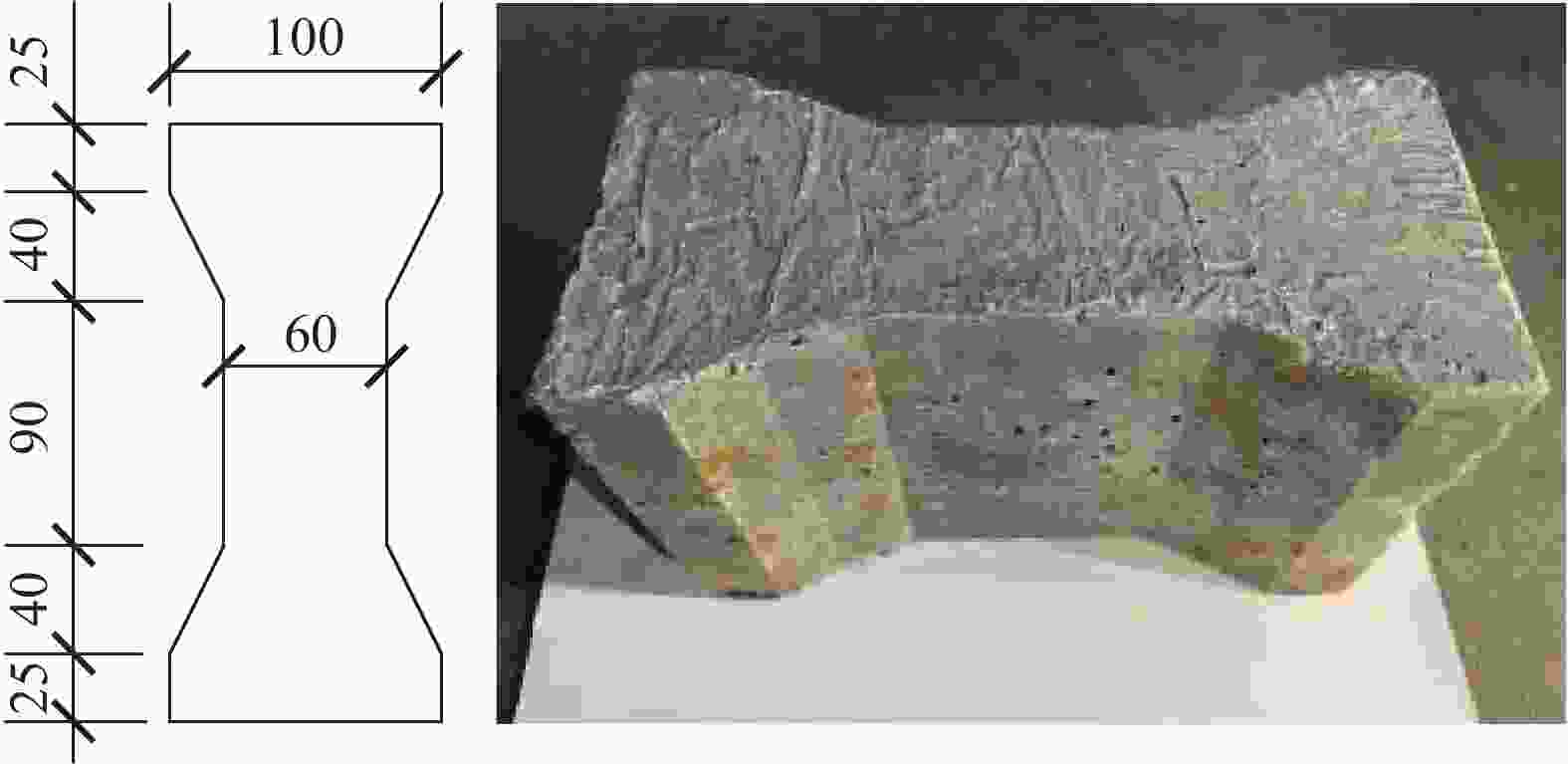

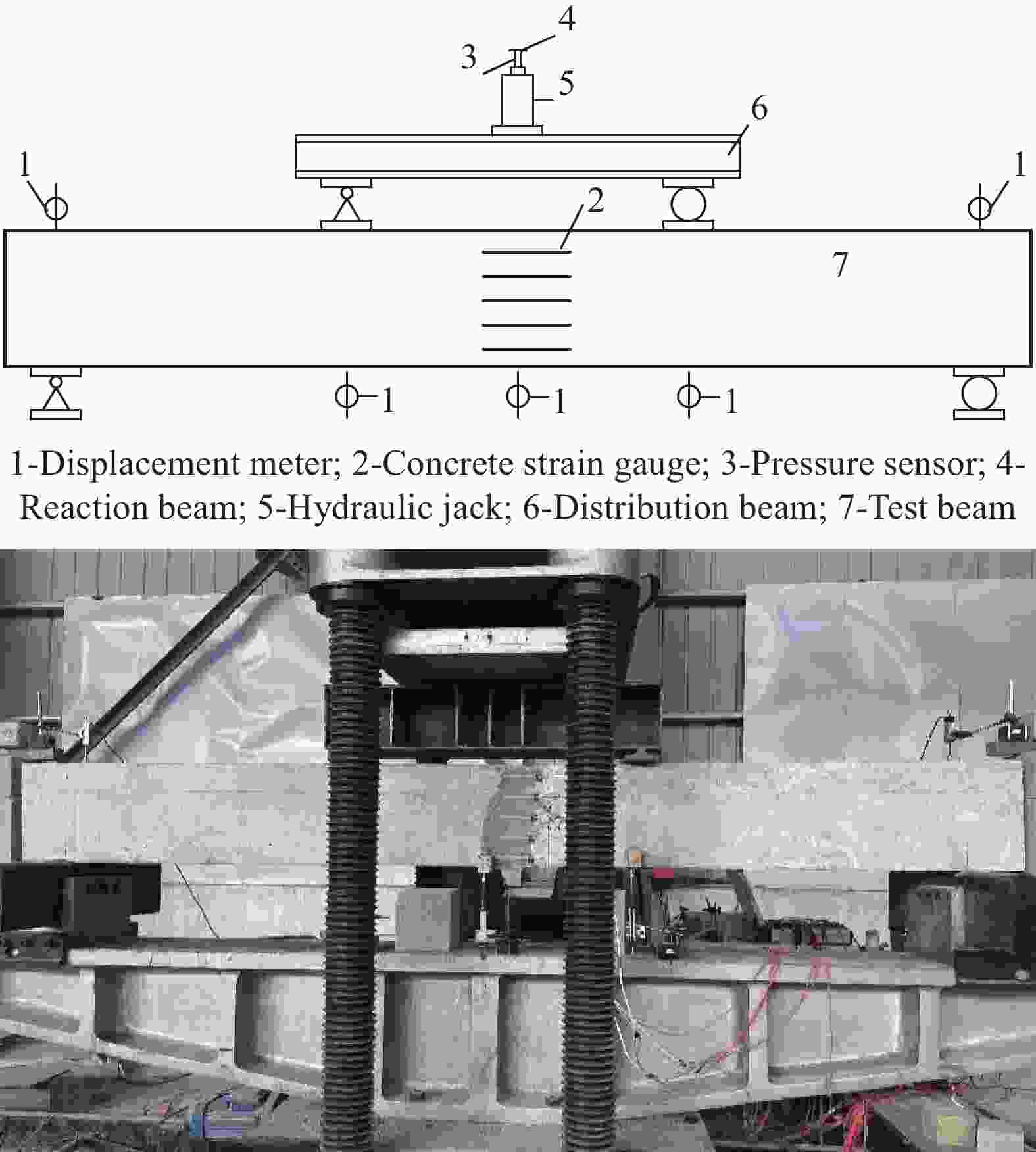

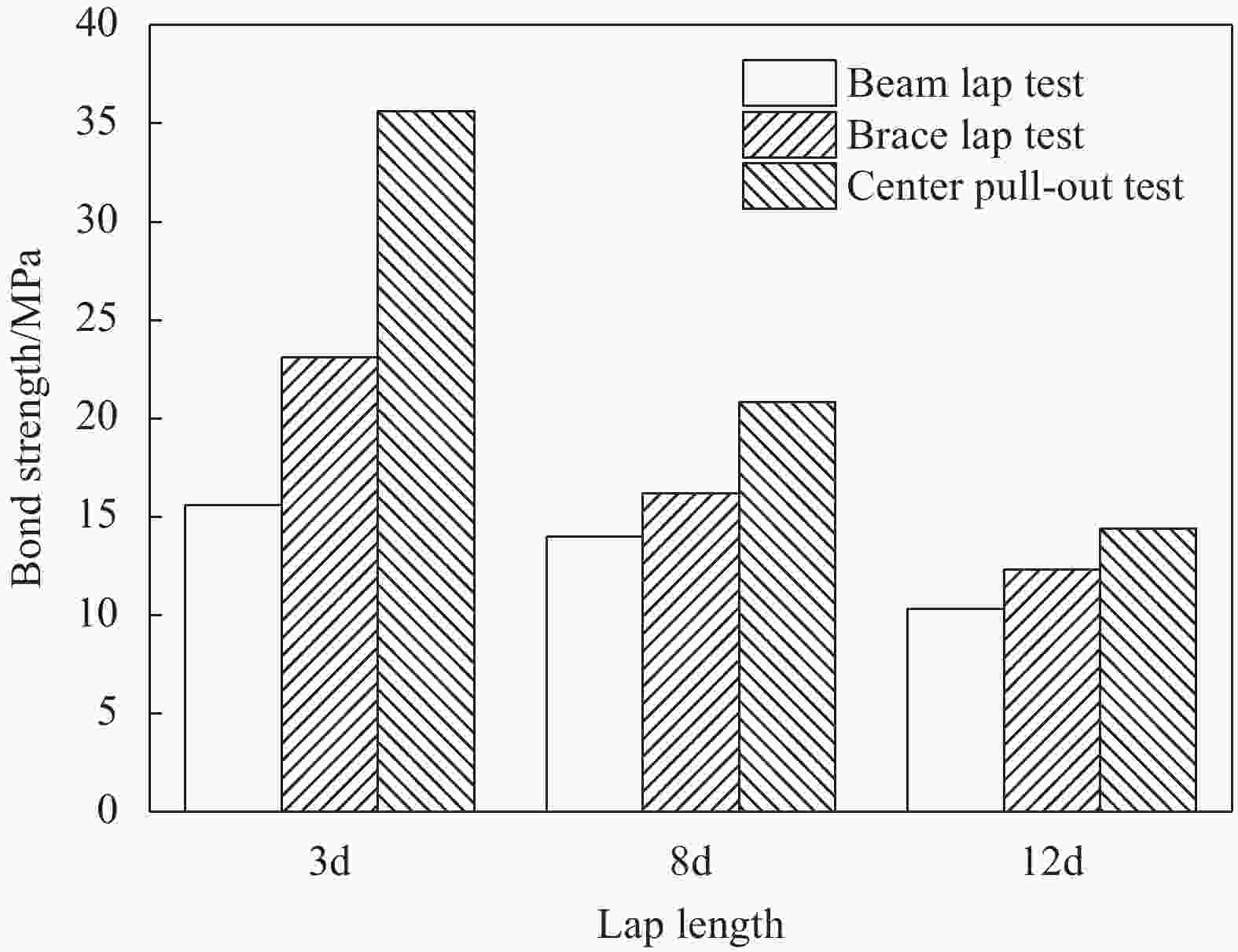

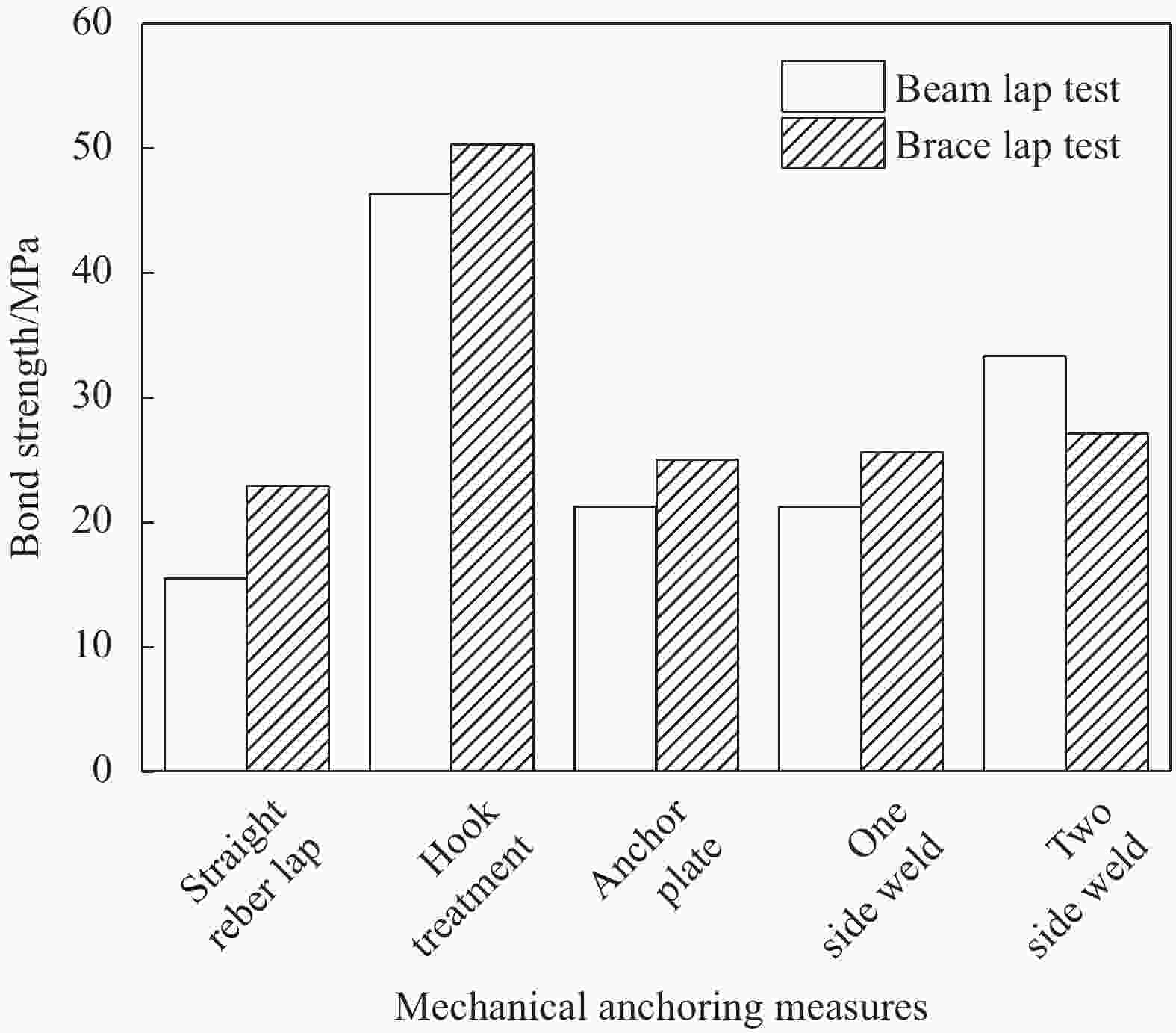

摘要: 为了研究高强钢筋与超高性能混凝(Ultra-high-performance concrete, UHPC) 的黏结性能,通过梁式搭接试验,设计制作了9根搭接梁,分析了钢筋搭接长度、钢纤维掺量、机械锚固措施对搭接梁中高强钢筋与UHPC黏结性能的影响。结果表明:采用UHPC连接的搭接梁,搭接段受拉钢筋与混凝土具有更优异的黏结性能;随着钢筋搭接长度的增加,搭接梁的峰值荷载提高,但平均黏结强度逐渐减小;搭接梁的峰值荷载和黏结强度随着钢纤维掺量的增大而增大;采用机械锚固措施处理后的搭接梁,具有更高的峰值荷载和黏结强度,其中采用弯钩处理的搭接梁峰值荷载和黏结强度提升最为明显,分别提高了212.4%,199.4%,并且搭接钢筋发生屈服。根据搭接梁达到峰值荷载时轴力和弯矩的平衡条件,计算出搭接梁中钢筋的最大拉应力,进一步建立钢筋与UHPC平均黏结强度的计算方法,并与中心拉拔试验,对拉搭接试验结果进行对比。Abstract: To study the bonding properties of high-strength steel bars and ultra-high-performance concrete (UHPC), nine groups of lap beams were designed and fabricated. The influences of specific variables on the bonding properties were analyzed, including lap length, steel fiber volume content, and mechanical anchoring measures. The experimental results show that the tensile steel bars in the lap section of the lap beams connected with UHPC have better performance on the bonding properties with concrete. Increasing the lap length promotes peak load but the average bonding strength of the lap beams on the contrary. With the increase of steel fiber volume content, the peak load and bond strength of the lap beams increase. Mechanical anchoring adopted lap beams show a higher peak load and bonding strength, where bent hooks treated lap beam shows the highest enhancement, with peak load and bond strength improved by 212.4% and 199.4%, respectively, and it is worth mentioning that the hooked lap steel bars yielded. Based on the equilibrium condition of axial force and bending moment at the peak point, the maximum tensile stress of the steel bar in the lap beam was calculated. A calculation method of the average bonding strength between the steel bar and UHPC was then established. The proposed method calculation results were compared with the centre pull-out test and brace lap test results subsequently.

-

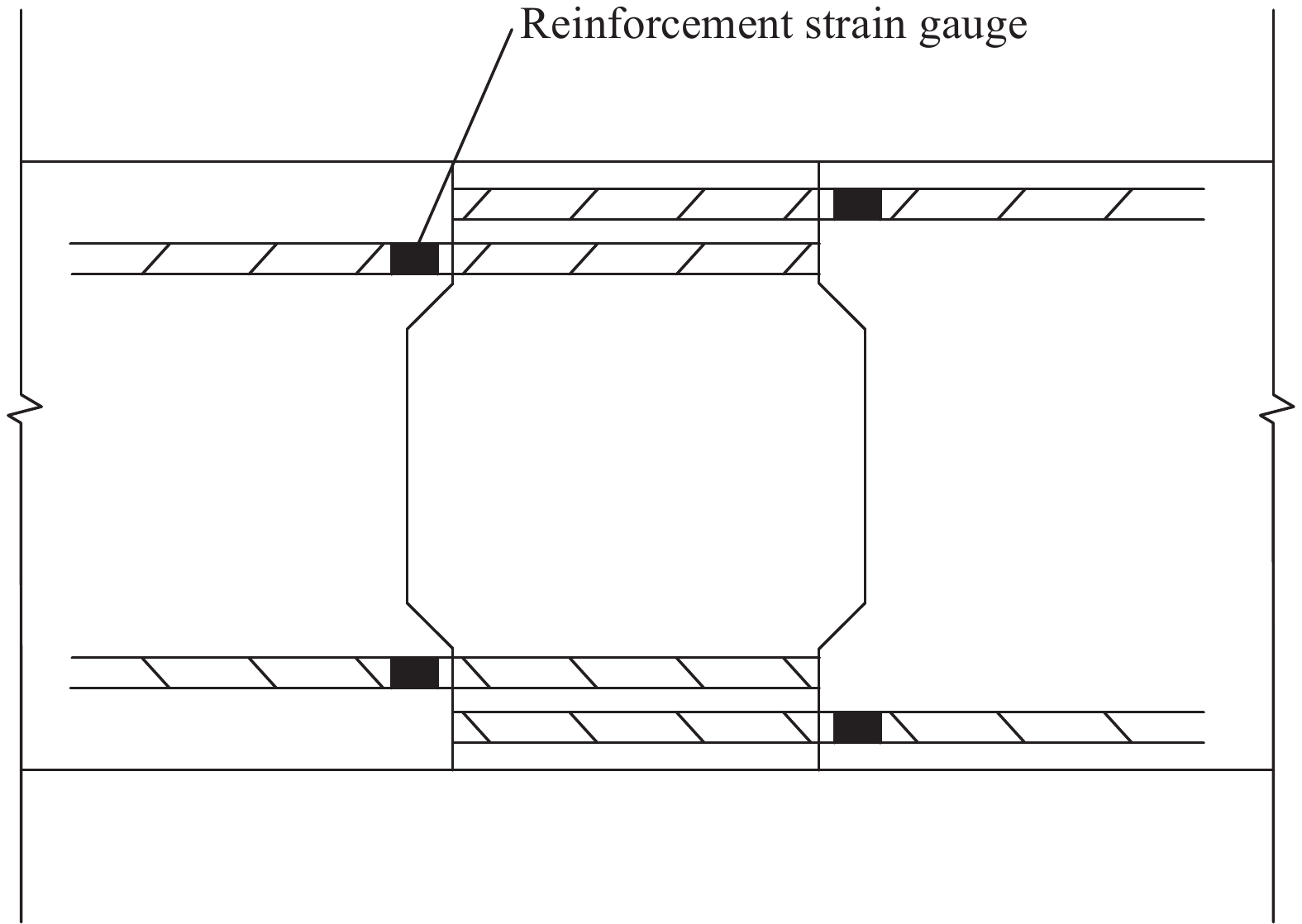

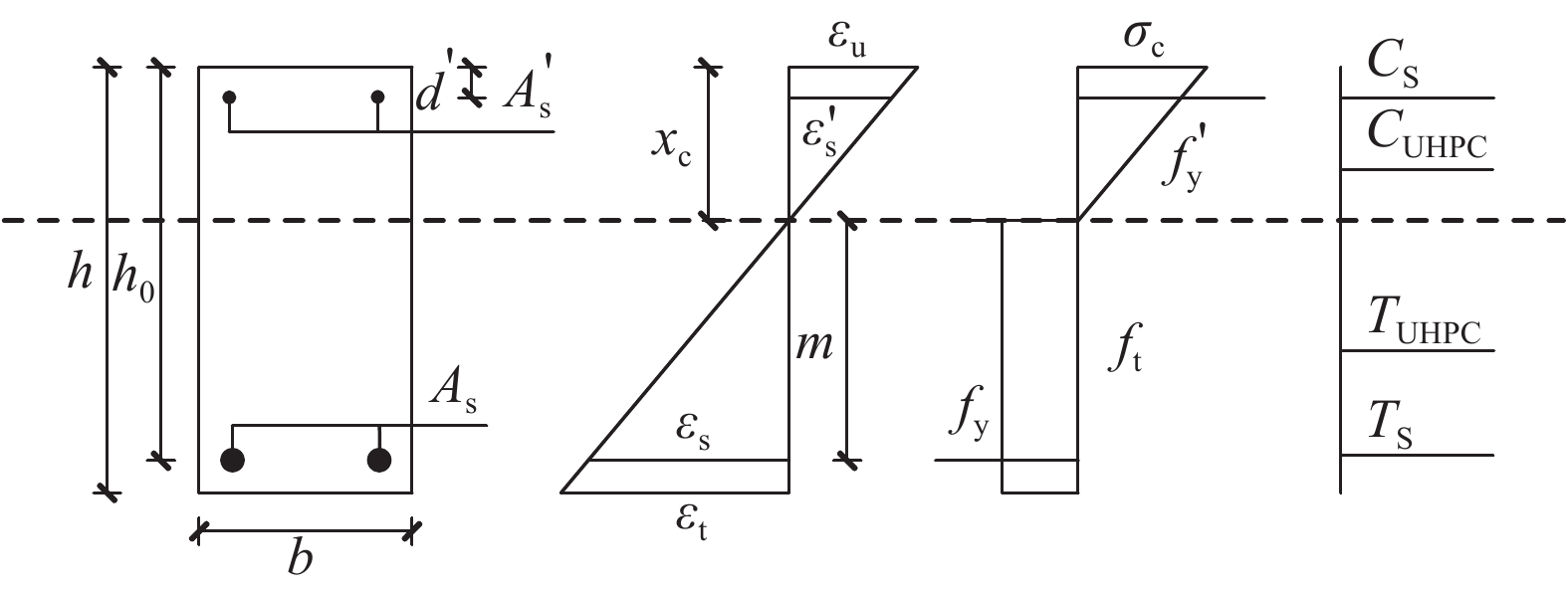

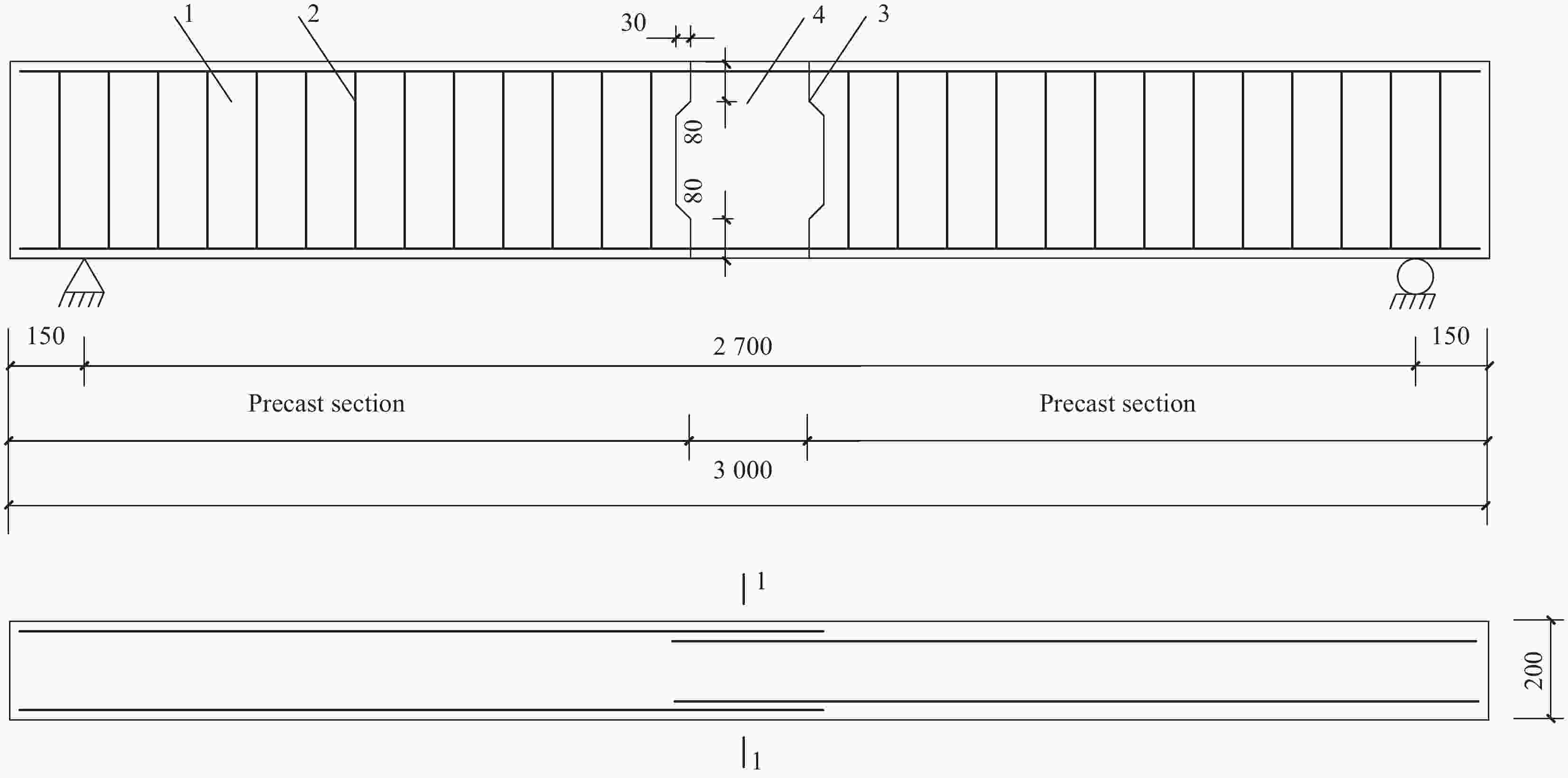

图 12 钢筋应力计算示意图

Figure 12. Schematic diagram of reinforcement stress calculation

$ h $-Lap beam section height; $ {h_{\text{0}}} $-Effective height of lap beam section; $ {d'} $-Distance from the point of action of the combined forces of the compression reinforcement to the outer edge of the beam; $ {A_{\text{s}}} $-Cross-sectional area of tensile reinforcement; $ {A_{\text{s}}^{\prime}} $-Cross-sectional area of compression reinforcement; $ {x_{\text{c}}} $-Height of compression zone of beam section; $ m $-The depth of the extreme UHPC tensile fiber below the neutral axis; $ {\varepsilon _{\text{t}}} $-Calculated tensile strain of UHPC; $ {\varepsilon _{\text{u}}} $-Compressive strain of UHPC at the extreme compression fiber; $ {\varepsilon _{\text{s}}} $-Actual strain in tensile reinforcement; $ {\varepsilon _{\text{s}}^{\prime}} $-Actual strain in compression reinforcement; $ {f_{\text{y}}} $-Yield stress of tensile reinforcement; $ {f_{\text{y}}^{\prime}} $-Yield stress of compression reinforcement; $ {f_{\text{t}}} $-Measured uniaxial tensile strength of dumbbell specimens; $ {\sigma _{\text{c}}} $-Compressive stress of UHPC at the extreme compression fiber; $ {T_{\text{s}}} $-Combined force of tensile reinforcement; $ {T_{{\text{UHPC}}}} $-Combined force of UHPC in the tension zone; $ {C_{\text{s}}} $-Combined force of compression reinforcement; $ {C_{{\text{UHPC}}}} $-Combined pressure of UHPC in the pressure zone

表 1 梁式搭接试验试件参数设计及钢筋应力计算结果

Table 1. Parameter design of beam lap test specimen and results of reinforcement stress calculation

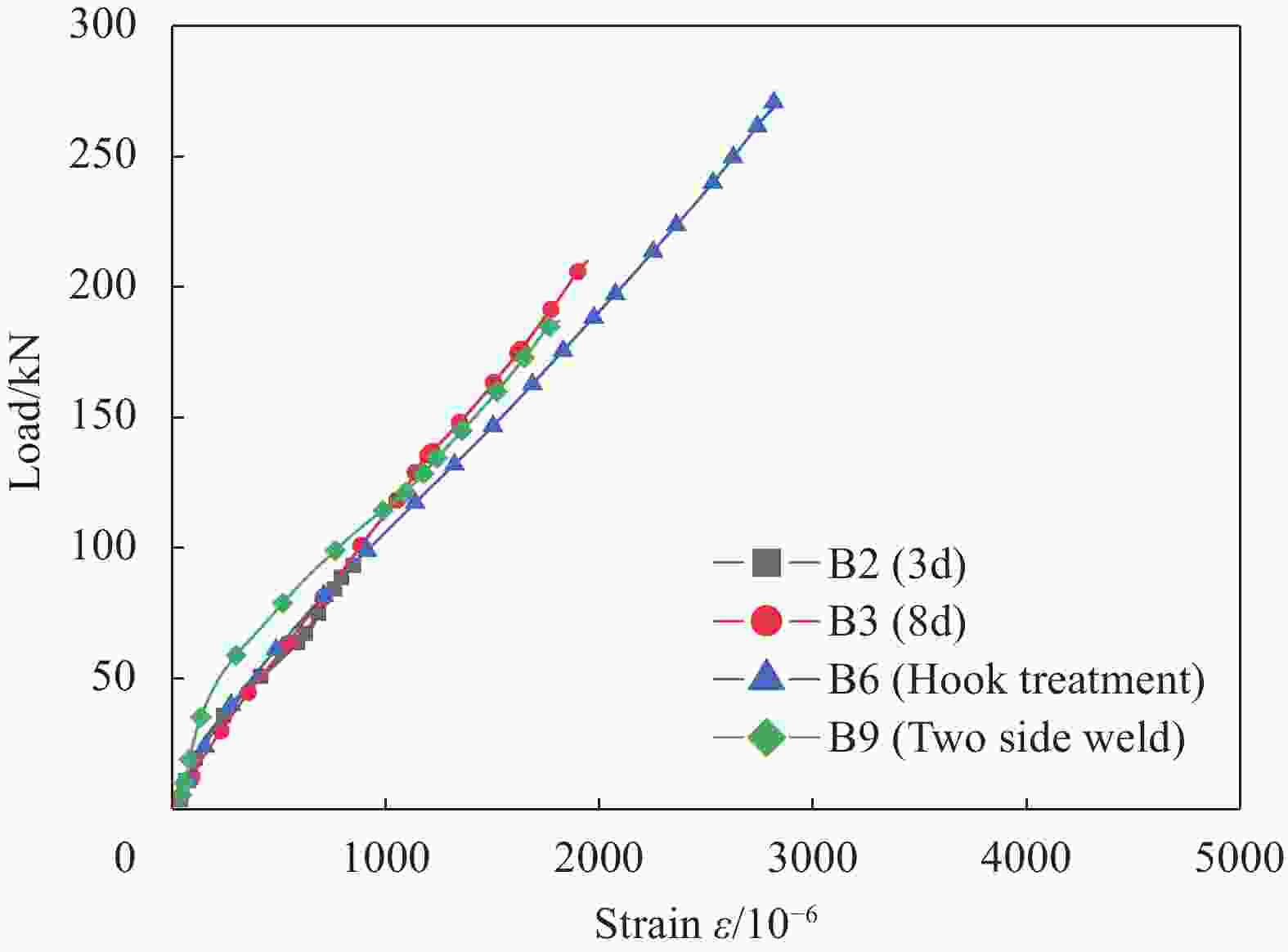

Number Type L Lap form Vf/% Peak load /kN fs/MPa Yield or not B1

B2C80

UHPC3d

3dStraight rebar lap

Straight rebar lap2%

2%23.5

95.2-

187Not

NotB3 UHPC 8d Straight rebar lap 2% 207.8 449 Not B4 UHPC 12d Straight rebar lap 2% 231.1 494 Not B5 UHPC 3d Straight rebar lap 3% 145.3 302 Not B6 UHPC 3d Hook treatment 2% 297.4 560 Yield B7 UHPC 3d Anchor plate 2% 124.1 257 Not B8 UHPC 3d One side weld 2% 124.3 257 Not B9 UHPC 3d Two side weld 2% 188.0 403 Not Notes: Type-Type of post-cast concrete in lap section; L-Lap length; d-Steel bar diameter; Lap form-Different mechanical anchorage measures; Vf-Fibre volume fraction; fs-Calculated tensile strength of rebar. 表 2 UHPC材料性能

Table 2. Material properties of UHPC

Vf/% fcu/MPa fc/MPa ft/MPa 2 123.3 113.2 6.22 3 135.6 122.7 7.01 Notes: fcu-Cubic compressive strength; fc-Prismatic compressive strength; ft-Tensile strength. 表 3 钢筋力学性能

Table 3. Mechanical properties of reinforcement

Strength grade Diameter/

mmYield strength/

MPaUltimate strength/

MPaHPB300 8 357 529 HRB500 20 560 715 表 4 UHPC-高强钢筋梁式试验对比

Table 4. Test comparison of UHPC-high strength rebar beam lap test

Number Type L Vf/% Lap form Center pull-out test Brace lap test Beam lap test τu2/τu1 τu3/τu2 τu1/MPa Failure mode τu2/MPa Failure mode τu3/MPa Failure mode B1

B2C80

UHPC3d

3d0%

2%Straight rebar lap

Straight rebar lap19.2

35.6SPF

SPF12.1

23.1SPF - BOF 0.63 - SPF 15.6 BOF 0.65 0.68 B3 UHPC 8d 2% Straight rebar lap 20.8 SPF 16.2 SPF 14.0 BOF 0.78 0.86 B4 UHPC 12d 2% Straight rebar lap 14.4 RF 12.3 RF 10.3 BOF 0.85 0.84 B5 UHPC 3d 3% Straight rebar lap 49.7 SPF 27.6 SPF 25.2 BOF 0.56 0.91 B6 UHPC 3d 2% Hook treatment - - 50.7 RF 46.7 BEF - 0.92 B7 UHPC 3d 2% Anchor plate - - 25.2 SPF 21.4 BOF - 0.85 B8 UHPC 3d 2% One side weld - - 27.1 SPF 21.4 BOF - 0.79 B9 UHPC 3d 2% Two side weld - - 28.4 SPF 33.6 BOF - 1.18 Notes: All the above specimens are made of HRB500 grade rebar, diameter is 20 mm, the concrete protective layer is 1.5d; τu1-Bond strength obtained by center poll-out test, τu2-Bond strength obtained by brace lap test, τu3-Bond strength obtained by beam lap test; SPF and RF represent the splitting pull-out failure and steel bar rupture failure respectively; BOF and BEF represent the bonding failure of steel bars and the bending failure of lap beams respectively. 表 5 UHPC-高强钢筋搭接长度计算

Table 5. Lap length calculation of UHPC-high strength rebar

Lap length Vf/% Mechanical anchoring measures 3% Straight

rebar lapHook treatment Anchor plate One side weld lsy 9.8d 11.6d 6.7d 9.4d 8.6d lsu 13.7d 16.0d 10.9d 13.6d 12.6d Notes: lsy-Minimum lap length of steel bar yield; lsu-Minimum lap length of steel bar rupture. -

[1] 邵旭东, 樊伟, 黄政宇. 超高性能混凝土在结构中的应用[J]. 土木工程学报, 2021, 54(1): 1-13.Shao Xudong, Fan Wei, Huang Zhengyu. Application of ultra-high-performance concrete in engineering structures[J]. China Civil Engineering Journal, 2021, 54(1): 1-13(in Chinese). [2] 陈宝春, 季韬, 黄卿维, 等. 超高性能混凝土研究综述[J]. 建筑科学与工程学报, 2014, 31(3): 1-24. doi: 10.3969/j.issn.1673-2049.2014.03.002Chen Baochun, Ji Tao, Huang Qingwei, et al. Review of research on ultra-high-performance concrete[J]. Joural of Architecture and Civil Engineering, 2014, 31(3): 1-24(in Chinese). doi: 10.3969/j.issn.1673-2049.2014.03.002 [3] LI J, WU Z, SHI C, et al. Durability of ultra-high performance concrete- A review[J]. Construction and Building Materials, 2020, 255: 119296. doi: 10.1016/j.conbuildmat.2020.119296 [4] TSIOTSIAS K, PANTAZOPOULOU S J. Bond behavior of high-performance fiber reinforced concrete (HPFRC) under direct tension pullout[J]. Engineering Structures, 2021, 243: 112701. doi: 10.1016/j.engstruct.2021.112701 [5] KOOK K H, SHIN H O, KWAHK I J, et al. Bond characteristics of ultra high performance concrete[J]. Journal of the Korea Concrete Institute, 2010, 22(6): 753-760. doi: 10.4334/JKCI.2010.22.6.753 [6] DENG E F, ZHANG Z, ZHANG C X, et al. Experimental study on flexural behavior of UHPC wet joint in prefabricated multi-girder bridge[J]. Engineering Structures, 2023, 275: 115314. doi: 10.1016/j.engstruct.2022.115314 [7] LI L, JIANG Z. Flexural Behavior and Strut-and-tie model of joints with headed bar details connecting precast members[J]. Perspectives in Science, 2016, 7: 253-260. doi: 10.1016/j.pisc.2015.11.041 [8] JIANG H, HU Z, FENG J, et al. Flexural behavior of UHPC-filled longitudinal connections with non-contacting lap-spliced reinforcements for narrow joint width[J]. Structures, 2022, 39: 620-636. doi: 10.1016/j.istruc.2022.03.017 [9] DAGENAIS M A, MASSICOTTE B. Tension lap splices strengthened with ultrahigh-performance fiber-reinforced concrete[J]. Journal of Materials in Civil Engineering, 2015, 27(7): 04014206. doi: 10.1061/(ASCE)MT.1943-5533.0001169 [10] 冯军骁, 郑七振, 龙莉波, 等. 超高性能混凝土连接的预制梁受弯性能试验研究[J]. 工业建筑, 2017, 47(8): 59-65.Feng Junxiao, Zheng Qizhen, Long Libo, et al. Experimental studies of flexural behavior of precast ultra-high-performance concrete beam[J]. Industrial Construction, 2017, 47(8): 59-65(in Chinese). [11] ALKAYSI M, EL-TAWIL S. Factors affecting bond development between ultra high performance concrete (UHPC) and steel bar reinforcement[J]. Construction and Building Materials, 2017, 144: 412-422. doi: 10.1016/j.conbuildmat.2017.03.091 [12] BAE B I, CHOI H K, CHOI C S. Bond stress between conventional reinforcement and steel fibre reinforced reactive powder concrete[J]. Construction and Building Materials, 2016, 112: 825-835. doi: 10.1016/j.conbuildmat.2016.02.118 [13] HU A, LIANG X, SHI Q. Bond characteristics between high-strength bars and ultrahigh-performance concrete[J]. Journal of Materials in Civil Engineering, 2020, 32(1): 04019323. doi: 10.1061/(ASCE)MT.1943-5533.0002919 [14] 梁芮, 黄远. 高强钢筋与超高性能混凝土黏结性能试验研究[J]. 建筑结构学报, 2022, 43(9): 294-302.Liang Rui, Huang Yuan. Experimental study on the bond performance between high strength steel rebar and ultra-high-performance concrete[J]. Journal of Building Structures, 2022, 43(9): 294-302(in Chinese). [15] 邓宗才, 袁常兴. 高强钢筋与活性粉末混凝土黏结性能的试验研究[J]. 土木工程学报, 2014, 47(3): 69-78.Deng Zongcai, Yuan Changxing. Experimental study on bond capability between high strength rebar and reactive powder concrete[J]. China Civil Engineering Journal, 2014, 47(3): 69-78(in Chinese). [16] 韩方玉, 刘建忠, 刘加平, 等. 基于超高性能混凝土的钢筋锚固性能研究[J]. 材料导报, 2019, 33(S1): 244-248.Hang Fangyu, Liu Jiangzhong, Liu Jiaping, et al. Study on anchorage behavior of steel bar in ultra-high-performance concrete[J]. Materials Reports, 2019, 33(S1): 244-248(in Chinese). [17] 李艳艳, 赵银磊, 武凯, 王权. 高强钢筋与超高性能混凝土混凝土粘结性能及可靠度分析[J/OL]. 工程力学.Li Yan-yan, Zhao Yin-lei, Wu Kai, Wang Quan, Bond property and reliability analysis between high strength rebar and ultra-high-performance concrete. Engineering Mechanics.(in Chinese) [18] LAGIER F, MASSICOTTE B, CHARRON J P. Bond strength of tension lap splice specimens in UHPFRC[J]. Construction and Building Materials, 2015, 93: 84-94. doi: 10.1016/j.conbuildmat.2015.05.009 [19] 方志, 陈潇, 张门哲, 等. 活性粉末混凝土中带肋钢筋搭接性能试验研究[J]. 土木工程学报, 2019, 52(3): 20-28+49.Fang Zhi, Chen Xiao, Zhang Menzhe, et al. Experimental study on performance of lap-spliced ribbed steel bars in reactive powder concrete[J]. China Civil Engineering Journal, 2019, 52(3): 20-28+49(in Chinese). [20] 马福栋, 邓明科, 孙宏哲, 等. 变形钢筋/超高性能混凝土搭接黏结性能[J]. 复合材料学报, 2021, 38(11): 3912-3924.Ma Fudong, Deng Mingke, Sun HongZhe. et al. Bond behavior of deformed steel bars lap-splice in ultra-high- performance concrete[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3912-3924(in Chinese). [21] AL-QURAISHI H, AL-FARTTOOSI M, ABDULKHUDHUR R. Tension lap splice length of reinforcing bars embedded in reactive powder concrete (RPC)[J]. Structures, 2019, 19: 362-368. doi: 10.1016/j.istruc.2018.12.011 [22] RONANKI V S, AALETI S, VALENTIM D B. Experimental investigation of bond behavior of mild steel reinforcement in UHPC[J]. Engineering Structures, 2018, 176: 707-718. doi: 10.1016/j.engstruct.2018.09.031 [23] HUNG C C, YUEN T Yp, HUANG C W, 等. Tension lap splices in UHPC beams: Influence of rebar size, steel fibers, splice length, and coarse aggregate[J]. Journal of Building Engineering, 2022, 55: 104716. [24] 梁芮, 黄远. 超高性能混凝土与钢筋劈裂黏结强度试验研究[J/OL]. 建筑结构学报.Liang Rui, Huang Yuan. Experimental study on bond splitting strength of ultra-high-performance concrete with steel bars[J]. Journal of Building Structures. (in Chinese) [25] 邱明红, 邵旭东, 胡伟业, 等. 钢筋UHPC矩形截面受弯构件的钢筋应力简化计算[J]. 中国公路学报, 2021, 34(8): 106-116.Qiu Minghong, Shao Xudong, Hu Weiye, et al. Siplified calculation of reinforcement stress in reinforced UHPC bending members with rectangular sections[J]. China J. Highw. Transp, 2021, 34(8): 106-116(in Chinese). [26] 徐明雪, 梁兴文, 汪萍, 等. 超高性能混凝土梁正截面受弯承载力理论研究[J]. 工程力学, 2019, 36(8): 70-78. doi: 10.6052/j.issn.1000-4750.2018.06.0307Xu Mingxue, Liang Xingwen, Wang Ping, et al. Theoretical Investigation on Normal Section Flexura; Capacity of UHPC Beams[J]. Engineering Mechanics, 2019, 36(8): 70-78(in Chinese). doi: 10.6052/j.issn.1000-4750.2018.06.0307 [27] 靳梦娜. 高强钢筋与超高性能混凝土黏结性能试验研究[D]. 西安建筑科技大学, 2022Jin Mengna. Experimental study on bonding performance concrete between high strength steel bar and ultra-high-performance concrete[D]. Xi’an University of Architecture and Technology, 2022. (in Chinese) -

点击查看大图

点击查看大图

计量

- 文章访问数: 99

- HTML全文浏览量: 77

- 被引次数: 0

下载:

下载: