Progress in research and application of special wettable composite materials based on in situ polymerization

-

摘要: 本文总结了基于原位聚合构造特殊润湿性复合材料的最新进展,首先介绍了基于特殊润湿性的机制及自然界中的特殊润湿性现象,指出人工构造特殊润湿性复合材料的常见方法,举例说明了各类方法的优势与缺陷,并指出原位聚合法构造特殊润湿性复合材料的原理及其优势。其次,以原位聚合法为核心,讨论了3种类型的特殊润湿性复合材料构造现状,包括特殊润湿性涂层复合材料、特殊润湿性纤维复合材料、特殊润湿性多孔复合材料。同时还讨论了原位聚合构造特殊润湿性复合材料在油水分离、水雾收集、液滴操控等领域的应用现状,对其作用机制、材料类型、应用性能进行了综述。最后总结了原位聚合构造特殊润湿性复合材料目前面对的挑战和未来前景。Abstract: In this paper, the latest development of special wettable composite materials based on in situ polymerization is summarized. Firstly, the mechanism of special wettability and special wettable phenomenon in nature are introduced, the common methods of constructing special wettable composite materials are pointed out, and the advantages and disadvantages of these methods are illustrated with examples. Secondly, three types of special wettable composite materials are discussed based on in situ polymerization, it includes special wettable coating composite materials, special wettable fiber composite materials and special wettable porous composite materials. At the same time, the application of special wettable composite materials constructed by in situ polymerization in the fields of oil-water separation, water mist collection and droplet control is also discussed, the mechanism of action, material type and application performance were reviewed. Finally, the challenges and prospects of special wettable composite materials constructed by in-situ polymerization are summarized.

-

Key words:

- in situ polymerization /

- special wettability /

- surface /

- polymer /

- composite materials

-

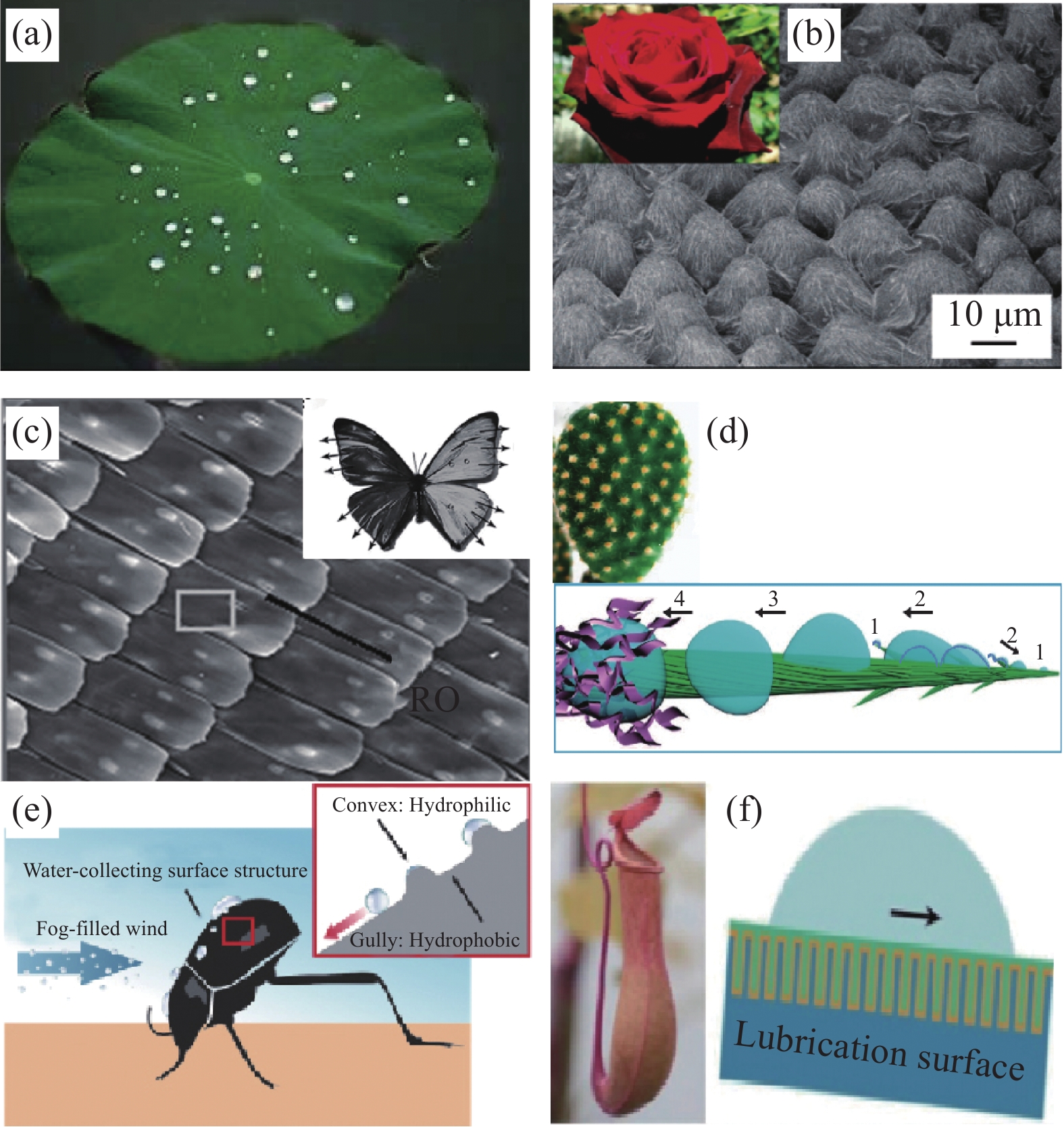

图 1 自然界中的特殊润湿现象:(a)荷叶表面[1];(b)玫瑰花瓣[2];(c)蝴蝶翅膀[3];(d)仙人掌刺[4];(e)沙漠甲虫背甲[5];(f)猪笼草内表面[6-7]

RO—Rolling orientationally

Figure 1. Special wettability in nature: (a) Lotus leaf surface[1]; (b) Rose petals[2]; (c) Butterfly wings[3]; (d) Cactus thorn[4]; (e) Desert beetle carapace[5]; (f) Pitcher grass inner surface[6-7]

图 2 (a)基于SiC、多巴胺(DOPA)、十八胺(ODA)的超疏水莫来石织物制备过程示意图[34];(b)基于异佛尔酮二异氰酸酯(IPDI)、SiO2及聚(脲-甲醛)纳米颗粒(PUF NPs)的超疏水微胶囊制备示意图[35]

Figure 2. (a) Schematic illustration of superhydrophobic mullite fabric based on SiC, dopamine (DOPA) and octadecylamine (ODA)[34]; (b) Preparation of superhydrophobic microcapsules based on isophorone diisocyanate (IPDI) , SiO2 and poly(urea formaldehyde) nanoparticles (PUF NPs)[35]

图 3 (a)基于甲基三氯硅烷(MTS)、过乙烯基三氯硅烷(VTS)的3种超疏水聚酯(PET)纤维结构制备路径示意图[40];(b)基于纤维素乙酸酯(CA)、含氟聚苯并噁嗪(F-PBZ)、多聚甲醛单体/SiO2纳米颗粒(BAF-tfa/SiO2 NPs)的静电纺超疏水/超亲油纳米纤维膜合成示意图[41]

Figure 3. (a) Diagram of the preparation path for three types of superhydrophobic polyester (PET) fiber structures based on methyl trichlorosilane (MTS) and polyvinyl trichlorosilane (VTS)[40]; (b) Diagram of electrospinning superhydrophobic/superhydrophilic nanofiber membranes based on cellulose acetate (CA), fluorinated polybenzoxazine (F-PBZ), paraformaldehyde/SiO2 nanoparticles (BAF-tfa/SiO2 NPs)[41]

图 4 (a) 基于纤维素纳米纤维与壳聚糖气凝胶基质(m-CNS)、(3-巯基丙基)三甲氧基硅烷(MPTMS)、聚二甲基硅氧烷(PDMS)的超疏水复合气凝胶(P-CNS)制造过程图解[47];(b) 基于DOPA、N-(3, 4-二羟基苯乙基)丙烯酰胺(DBDOPA)的超疏水聚氨酯(PU)海绵合成示意图[48];(c) 基于聚乙烯醇(PVA)、海藻酸钠(SA)、苯胺单体及硫酸铵溶液(APS)浸泡的超亲水复合气凝胶制备过程示意图[49]

Figure 4. (a) Diagram of superhydrophobic composite aerogel (P-CNS) based on cellulose nanofibers and chitosan aerogel matrix (m-CNS), (3-mercaptopropyl) trimethoxysilane (MPTMS) and polydimethylsiloxane (PDMS)[47]; (b) Diagram of superhydrophobic polyurethane (PU) sponge synthesis based on DOPA and N-(3, 4-dihydroxyphenylethyl) acrylamide (DBDOPA)[48]; (c) Schematic illustration of the preparation process for superhydrophilic composite aerogel based on polyvinyl alcohol (PVA), sodium alginate (SA) , aniline momomer and ammonium sulfate solution (APS) immersion

图 5 (a)超疏水共轭微孔聚合物涂层海绵(CMP@sponges)制备及其连续油水分离示意图[64];(b)超疏水不锈钢网(SSW)的原位热聚合 (ISTP)制备过程及其油水分离应用[65]

Figure 5. (a) Schematic illustration for superhydrophobic conjugated microporous polymer-coated sponges (CMP@sponges) and its schematic diagram of continuous oil-water separation[64]; (b) In situ thermal polymerization (ISTP) preparation of superhydrophobic stainless steel mesh (SSW) and its application in oil-water separation[65]

图 6 (a) 基于二乙烯苯(DVB)的超疏水聚二乙烯苯织物(PDVB@fabric)制备过程示意图;原始织物(b)和PDVB@fabric (c)的SEM图像(右上角插图为相应的水接触角(WCA)光学图像);(d) 具有不对称润湿性的Janus织物制备路线图[69];(e) 磁性可变形超疏水织物的制备路径图[70]

Figure 6. (a) Schematic illustration for preparation process of superhydrophobic polydivinylbenzene fabric (PDVB@fabric) based on diethylene benzene (DVB); SEM images of original fabric (b) and PDVB@fabric (c) (Inset on the top right are the corresponding WCA optical photos); (d) Schematic illustration of Janus fabric with asymmetric wettability[69]; (e) Schematic illustration of magnetic deformable superhydrophobic fabric[70]

图 7 (a) 基于F-PBZ、4, 4-(六氟异丙基)二苯酚(BAF)、SiO2 NPs、ODA的超疏水薄膜制备路径及单体合成路线示意图[76];(b) 电纺聚氨酯(PU-E)、多层纳米薄片(MXene)、DOPA修饰的聚多巴胺(PDA) Janus膜(PU-E/MXene@PDA-PU)制备过程示意图;(c) 当水滴滴在Janus膜的疏水层和反向上时Janus膜实时定向水传输现象[77]

Figure 7. (a) Schematic illustration of the preparation path and monomer synthesis route of superhydrophobic films based on F-PBZ, 4, 4-(hexafluoroisopropyl)diphenol (BAF), SiO2 NPs and ODA[76]; (b) Schematic diagram of electrospun polyurethane (PU-E), multi-layer nanosheets (MXene), DOPA modified polydopamine (PDA) Janus film (PU-E/MXene@PDA-PU); (c) Real-time directional water transport phenomena of the Janus membrane when waterdroplets were dripped on its hydrophobic layer and the reverse direction[77]

图 8 基于3-氨基丙基三乙氧基硅烷(AEMO)、甲基丙烯酸甲酯共聚丙烯酸3-(三甲氧基甲硅烷基)丙酯(MMA-co-KH570)修饰的智能pH响应织物的合成过程及其在可控油水分离中的应用示意图[79]

Figure 8. Schematic illustration of intelligent pH responsive fabric modified with 3-aminopropyltriethoxysilane (AEMO) and methyl methacrylate co polyacrylic acid 3-(trimethoxysilyl) propyl ester (MMA-co-KH570) and it applications in controllable oil/water separation[79]

图 9 基于抗坏血酸(VC)及氧气等离子体处理的三氟甲基/氧化铜智能自修复超疏水棉织物制备示意图(a)及其表面氧气等离子体蚀刻高温自愈示意图(b)[80]

Figure 9. Schematic illustration of intelligent self-healing superhydrophobic cotton fabric based on ascorbic acid (VC) and oxygen plasma treatment (a) and its surface oxygen plasma etching with high temperature self-healing (b)[80]

表 1 特殊润湿性复合材料的制备方法比较

Table 1. Comparison of preparation methods for special wettable composite materials

Method Material Principle Advantage Disadvantage Ref. Femtosecond laser Superhydrophobic memory surface Femtosecond laser directly treats the surface of the material to form micro-columns Simple, stability High equipment cost [8] Etching Aluminum plate superhydrophobic surface Chemical etching aluminum plate structure roughness, and then use low surface energy reagent modification Fast, stable Perfluorinated compounds are used [9] Template Underwater super hydrophobic oil film A hydrophilic casting solution is used to form a film on a polytetrafluoroethylene substrate Simple operation,

not harsh application conditionsUnstable, the product

is prone to structural damage, which has certain requirements for the synthesis system[10] Sol-gel Superhydrophobic coating The low surface energy precursor and the roughness component are mixed in the liquid phase to form the gel Good chemical uniformity and uniform microscale distribution Poor durability and

high cost[11] Induced deposition Superhydrophobic/

superhydrophilic patternUnder the action of laser, thin films are formed on the glass substrate, and regular repeated geometric patterns are formed

by depositionHigh speed and

wear resistanceIt needs to be carried out at high temperatures, and

some substrates cannot withstand it, which poses risks[12]

Layer by layer self-assemblyLubricating superhydrophobic patterned surfaces Through the strong interaction of the components in the solution, low surface energy compounds are driven to spontaneously associate and form superhydrophobic surfaces on the substrate Simple operation

and high product controllabilityMultiple steps, time-consuming [13] In-situ polymerization Superhydrophobic cotton fabric Based on the thermal initiation and non volatility of ionic liquid precursors, a

sturdy polymer layer can be in-situ generated in an air atmosphere and

coated onto the fabricSimple and convenient operation, low cost,

and strong product durability

It is difficult to regulate the polymerization accurately[14] 表 2 油水分离用特殊润湿性复合材料性能对比

Table 2. Performance comparison of special wettability composite materials for oil-water separation

Material Contact angle Separation object Separation efficiency Separation flux/(L·m−2·s−1) Ref. CMP@sponges WCA/OCA: 153.92°/0° Diesel oil/water, Gasoline/water, Toluene/water emulsion 98.98%-99.81% 10.2-16.3 [64] Superhydrophobic SSM WCA/OCA: 158°/0° n-hexane/water 99.8% 15.65 [65] P(MMA-co-GMA) membrane WCA/OCA: 0°/150° (Underwater) n-hexane in water emulsion 98.3% 90 [66] SP-PVDF membrane WCA/OCA: 168.4°/

162.3° (Underoil)n-hexane in water emulsion,

n-hexane, water in n-hexane emulsion99.4% 484.8/599.3 [67] Notes: WCA—Water contact angle; OCA—Oil contact angle; P(MMA-co-GMA)—Poly(methyl methacrylate-co-glycidyl methacrylate); SP-PVDF—Silica decoration-poly(vinylidene fluoride). -

[1] 江雷. 从自然到仿生的超疏水纳米界面材料[J]. 化工进展, 2003(12): 1258-1264. doi: 10.3321/j.issn:1000-6613.2003.12.002JIANG Lei. Super hydrophobic nano interface materials from nature to bionics[J]. Chemical Progress, 2003(12): 1258-1264(in Chinese). doi: 10.3321/j.issn:1000-6613.2003.12.002 [2] 高党鸽, 李鹏宇, 苏莹, 等. 特殊润湿性油水分离材料的研究进展[J]. 精细化工, 2021, 38(9): 1746-1756. doi: 10.13550/j.jxhg.20210326GAO Dangge, LI Pengyu, SU Ying, et al. Research progress of special wetting oil-water separation materials[J]. Fine Chemical Industry, 2021, 38(9): 1746-1756(in Chinese). doi: 10.13550/j.jxhg.20210326 [3] BARTHLOTT W, NEINHUIS C. Purity of the sacred lotus, or escape from contamination in biological surfaces[J]. Planta, 1997, 202: 1-8. doi: 10.1007/s004250050096 [4] ZHENG Y M, GAO X F, JIANG L. Directional adhesion of superhydrophobic butterfly wings[J]. Soft Matter, 2007, 3: 178-182. [5] FENG L, ZHANG Y N, XI J M, et al. Petal effect: A superhydrophobic state with high adhesive force[J]. Langmuir, 2008, 24: 4114-4119. doi: 10.1021/la703821h [6] JU J, BAI H, ZHENG Y M, et al. A multistructural and multi-functional integrated fog collection system in cactus[J]. Nature Communications, 2012, 3: 1247-1252. doi: 10.1038/ncomms2253 [7] 陈杰, 史素青, 宫永宽, 等. 特殊润湿表面制备方法及表面形貌研究进展[J]. 涂料工业, 2021, 51(8): 75-82. doi: 10.12020/j.issn.0253-4312.2021.8.75CHEN Jie, SHI Suqing, GONG Yongkuan, et al. Research progress in preparation methods and surface morphology of special wetted surfaces[J]. Paint Industry, 2021, 51(8): 75-82(in Chinese). doi: 10.12020/j.issn.0253-4312.2021.8.75 [8] XUE B, QING Y, YAO F, et al. Superhydrophobicity-memory surfaces prepared by a femtosecond laser[J]. Chemical Engineering Journal, 2020, 383: 123143. doi: 10.1016/j.cej.2019.123143 [9] EIHAM A, AKBAR E, SAEED R B. Investigation of chemical etching and surface modification effect on the superhydrophobic, self-cleaning and corrosion behaviour of aluminium substrate[J]. Bulletin of Materials Science, 2022, 45 (4): 1-7. [10] TANG M, KOFI S, CHRISTIE S, et al. Fabrication of a novel underwater-superoleophobic/hydrophobic composite membrane for robust anti-oil-fouling membrane distillation by the facile breath figures templating method[J]. Journal of Membrane Science, 2021, 617: 118666. doi: 10.1016/j.memsci.2020.118666 [11] RA'NA R H, ZAHRA R, HOSSEIN Y, et al. Tuning up sol-gel process to achieve highly durable superhydrophobic coating[J]. Surfaces and Interfaces, 2022, 33, 102282. doi: 10.1016/j.surfin.2022.102282 [12] NASTARAN B, SAEID A, BABAK J. Hybrid superhydrophobic/hydrophilic patterns deposited on glass by laser-induced forward transfer method for efficient water harvesting[J]. Journal of Colloid and Interface Science, 2022, 625: 383-396. [13] JIAO L, TONG J Y, WU Y X, et al. Self-assembly of supraparticles on a lubricated-superamphiphobic patterned surface[J]. Applied Surface Science, 2022, 576: 151684. doi: 10.1016/j.apsusc.2021.151684 [14] LEE S, PARK C H . Conductivity, superhydrophobicity and mechanical properties of cotton fabric treated with polypyrrole by in-situ polymerization using the binary oxidants ammonium peroxodisulfate and ferric chloride[J]. Textile Research Journal, 2019, 89(12): 2376-2394. [15] ZHU Z P, ZHENG S, PENG S, et al. Superlyophilic interfaces and their applications[J]. Advanced Materials, 2017, 29(45): 1-13. [16] HOU Y Y, LIU M M, ZHANG L P, et al. Matchstick-like metal-organic framework-based superwetting materials for efficient multiphase liquid separation via filtration or adsorption[J]. Separation and Purification Technology, 2020, 240: 116598. [17] SRIJITA N, ARITR G, TAPAS K M. Hydrophilic and superhydrophilic self-cleaning coatings by morphologically varying ZnO microstructures for photovoltaic and glazing applications[J]. ACS Omega, 2020, 5(2): 1033-1039. doi: 10.1021/acsomega.9b02758 [18] LIU Y, WANG X, ZHANG Y H, et al. In-situ generation of hydrated nanoparticles on commercial stainless steel mesh for durable superhydrophilicity and self-cleaning[J]. Materials & Design, 2018, 157: 284-293. [19] LU J W, ZHU X T, MIAO X, et al. An unusual superhydrophilic/superoleophobic sponge for oil-water separation[J]. Frontiers of Materials Science, 2020, 14: 341-350. doi: 10.1007/s11706-020-0516-6 [20] LUO W P, YU B, XIAO D B, et al. Biomimetic superhydrophobic hollowed-out pyramid surface based on self-assembly[J]. Materials, 2018, 11(5): 813. [21] HUANG M L, SI Y, TANG X M, et al. Gravity driven separation of emulsified oil-water mixtures utilizing in situ polymerized superhydrophobic and superoleophilic nanofibrous membranes[J]. Journal of Materials Chemistry A, 2013, 1: 14071-14074. doi: 10.1039/c3ta13385k [22] XU J S, GAO Z. Alumina-pillared α-zirconium phosphate prepared by in-situ polymerization method[J]. Microporous and Mesoporous Materials, 1998, 24: 213-222. [23] JENNY F, CATHERINE G, LAURENT C, et al. Properties of polymer/clay interphase in nanoparticles synthesized through in-situ polymerization processes[J]. Polymer, 2010, 50(21): 4462-4471. [24] ZHU S R, XIE K B, LIN Q L, et al. Experimental determination of surface energy for high-energy surface: A review[J]. Advances in Colloid and Interface Science, 2023, 315: 102905. doi: 10.1016/j.cis.2023.102905 [25] RABIA N, ASIF A Q, UMER M, et al. Development of polyaniline/ethylene propylene diene monomer rubber (PANI/EPDM) conductive blend by in situ polymerization technique[J]. Journal of Materials Science-Materials in Electronics, 2022, 33: 14805-14815. [26] WANG S, LEI K, WANG Z Y, et al. Metal-based phase change material (PCM) microcapsules/nanocapsules: Fabrication, thermophysical characterization and application[J]. Chemical Engineering Journal, 2022, 438: 135559. doi: 10.1016/j.cej.2022.135559 [27] CHEN Y X, BAI W B, CHEN J P, et al. In-situ intercalation of montmorillonite/urushiol titanium polymer nanocomposite for anti-corrosion and anti-aging of epoxy coatings[J]. Progress in Organic Coatings, 2022, 165: 106738. doi: 10.1016/j.porgcoat.2022.106738 [28] ISHAMOL S, DIDDO D, MARTIN W, et al. Mechanistically novel frontal-inspired in situ photopolymerization: An efficient electrode electrolyte interface engineering method for high energy lithium metal polymer batteries[J]. Energy & Environmental Materials, 2022, 6(6): 12469. [29] ZUO Y C, WANG Y M, XU S M, et al. Superhydrophobic double-layer coating for efficient heat dissipation and corrosion protection[J]. Chemical Engineering Journal, 2019, 326: 638-649. [30] HE Q, WANG J W, WANG G F, et al. Construction of a durable superhydrophobic flame-retardant coating on the PET fabrics[J]. Materials & Design, 2023, 233: 112258. [31] XIE H, WEI J F, DUAN S Y, et al. Non-fluorinated and durable photothermal superhydrophobic coatings based on attapulgite nanorods for efficient anti-icing and deicing[J]. Chemical Engineering Journal, 2022, 428: 132585. doi: 10.1016/j.cej.2021.132585 [32] XIONG Z, YU H Y, GONG X. Designing photothermal superhydrophobic pet fabrics via in situ polymerization and 1, 4-conjugation addition reaction[J]. Langmuir, 2022, 38(28): 8708-8718. [33] TIAN N, CHEN K, WEI J F, et al. Robust superamphiphobic fabrics with excellent hot liquid repellency and hot water vapor resistance[J]. Langmuir, 2022, 38(18): 5891-5899. [34] LIU D Z, WANG A Z, WANG G, et al. Silicon carbide nanowire modified mullite fabric hierarchical structure applied as a stable and self-cleaning superhydrophobic material[J]. Materials & Design, 2021, 15(210): 110044. [35] LUO W J, SUN D W, CHE S S, et al. Robust microcapsules with durable superhydrophobicity and superoleophilicity for efficient oil-water separation[J]. ACS Applied Materials & Interfaces, 2020, 51(12): 57547-57559. [36] CHEN C, LIN K G, WU M M, et al. Micro-nano dual-scale all-polymer particles for construction of superwetting surface with controllable wettability and hot-water-repellency[J]. Chemical Engineering Journal, 2022, 445: 136810. doi: 10.1016/j.cej.2022.136810 [37] ZHAO H, LIN X X, LU S C, et al. Anti-mold, self-cleaning superhydrophobic bamboo fiber/polypropylene composites with mechanical durability[J]. Frontiers in Chemistry, 2023, 11: 1150635. [38] JI X H, JI W H, SEPIEDH P, et al. Novel superhydrophobic core-shell fibers/epoxy coatings with self-healing anti-corrosion properties in both acidic and alkaline environments[J]. Reactive & Functional Polymers, 2023, 187: 105574. [39] YANZUR M A, RIZAFIZAH O, FARAH H A, et al. Superhydrophobic modification of sansevieria trifasciata natural fibres: A promising reinforcement for wood plastic composites[J]. Polymers, 2023, 15(3): 594. [40] XI Y N, LIU K X, WANG F Q, et al. Construction of hierarchically hollow micro-nanostructured surface on polyester via in-situ chlorosilane polymerization and its superhydrophobicity[J]. Polymer, 2021, 233: 124189. doi: 10.1016/j.polymer.2021.124189 [41] SHANG Y W, SI Y. An in situ polymerization approach for the synthesis of superhydrophobic and superoleophilic nanofibrous membranes for oil-water separation[J]. Nanoscale, 2012, 4: 7847-7854. doi: 10.1039/c2nr33063f [42] MA W J, ZHANG M J, LIU Z C, et al. Fabrication of highly durable and robust superhydrophobic-superoleophilic nanofibrous membranes based on a fluorine-free system for efficient oil/water separation[J]. Journal of Membrane Science, 2019, 570-571: 303-313. doi: 10.1016/j.memsci.2018.10.035 [43] KANG L, SHI L J, ZENG Q, et al. Melamine resin-coated lignocellulose fibers with robust superhydrophobicity for highly effective oil/water separationvolume[J]. Separation and Purification Technology, 2021, 279: 119737. [44] SHEYDA K, KOUROSH K, NAHID H. Super-hydrophilic/oleophobic chitosan/acrylamide hydrogel: An efficient water/oil separation filter[J]. Advanced Composites and Hybrid Materials, 2020, 3: 167-176. doi: 10.1007/s42114-020-00150-8 [45] LI J, SHAO Y J, SONG W, et al. Ultrahigh solar vapor evaporation rate of super-hydrophilic aerogel by introducing environmental energy and convective flow[J]. Chemical Engineering Journal, 2023, 466: 143281. doi: 10.1016/j.cej.2023.143281 [46] LUO J, MA Y, LIU Y F, et al. Construction of superhydrophobic ZIF-90/melamine sponge with highly stable puncture structure for sustainable oil spill removal from seawater[J]. Microporous and Mesoporous Materials, 2023, 355: 112563. doi: 10.1016/j.micromeso.2023.112563 [47] ZHANG M L, JIANG S, LI M M, et al. Superior stable, hydrophobic and multifunctional nanocellulose hybrid aerogel via rapid UV induced in-situ polymerization[J]. Carbohydrate Polymers, 2022, 288: 119370. doi: 10.1016/j.carbpol.2022.119370 [48] JIN L Q, GAO Y S, HUANG Y P, et al. Mussel-inspired and in situ polymerization-modified commercial sponge for efficient crude oil and organic solvent adsorption[J]. ACS Applied Materials & Interfaces, 2022, 14(2): 2663-2673. [49] YAN J Y, ZHANG Z, SHI Y X, et al. An anti-oil-fouling superhydrophilic composite aerogel for solar saline alkali water desalination[J]. New Journal of Chemistry, 2022, 46: 14479-14489. doi: 10.1039/D2NJ01743A [50] GAO A L, LIU F, XIONG Z, et al. Tunable adhesion of superoleophilic/superhydrophobic poly(lactic acid) membrane for controlled-release of oil soluble drugs[J]. Journal of Colloid and Interface Science, 2017, 505: 49-58. doi: 10.1016/j.jcis.2017.05.071 [51] ZHENG W W, HUANG J Y, LI S H, et al. Advanced materials with special wettability toward intelligent oily wastewater remediation[J]. ACS Applied Materials & Interfaces, 2021, 13(1): 67-87. [52] HUANG P K, WU F, SHEN B, et al. Biomimetic porous polypropylene foams with special wettability properties[J]. Composites Part B: Engineering, 2020, 190: 107927. doi: 10.1016/j.compositesb.2020.107927 [53] HOU L L, WANG N, WU J, et al. Bioinspired superwettability electrospun micro/nanofibers and their applications[J]. Advanced Functional Materials, 2018, 28(49): 1801114. doi: 10.1002/adfm.201801114 [54] XIANG B, LIU Q Q, SUN Q, et al. Recent advances in eco-friendly fabrics with special wettability for oil/water separation[J]. Chemical Communications, 2022, 58: 13413-13438. doi: 10.1039/D2CC05780H [55] FENG L D, GAO Y, HOU X, et al. Phytic acid and graphene oxide functionalized sponge with special-wettability and electronegativity for oil-in-water emulsion separation in single-step[J]. Journal of Hazardous Materials, 2022, 435: 129003. doi: 10.1016/j.jhazmat.2022.129003 [56] LI L, XU Z Z, SUN W, et al. Bio-inspired membrane with adaptable wettability for smart oil/water separation[J]. Journal of Membrane Science, 2020, 598: 117661. doi: 10.1016/j.memsci.2019.117661 [57] BALRAJ K T, ADITYA K. Robust and durable superhydrophobic steel and copper meshes for separation of oil-water emulsions[J]. Progress in Organic Coatings, 2019, 133: 316-324. [58] ZHANG S F, CHEN S P, LI H Q, et al. Superhydrophobic, flame-retardant and magnetic polyurethane sponge for oil-water separation[J]. Journal of Environmental Chemical Engineering, 2022, 10(3): 107580. [59] GAO H P, CHANG S Y, LIU Y, et al. Interlaced wetting surfaces with switchable wettability for manipulating underwater oil droplets[J]. Chemical Engineering Journal, 2022, 437(1): 135007. [60] MUSADDAQ A, MUHAMMAD T N, MICHAL P, et al. Surface wettability of vertical harps for fog collection[J]. Surfaces and Interfaces, 2022, 30: 101842. [61] LI K Q, XIANG J M, ZHOU J L, et al. Self-healing and wear resistance stable superhydrophobic composite coating with electrothermal and photothermal effects for anti-icing[J]. Progress in Organic Coatings, 2023, 177: 107415. [62] KABIZ F, KUMARAN K, ABU S F M, et al. Review of MXenes as a component in smart textiles and an adsorbent for textile wastewater remediation[J]. Chinese Chemical Letters, 2024, 35(2): 108533. [63] FEI Y S, TAN Y J, DENG Y Y, et al. In situ construction strategy for three-dimensional Janus cellulose aerogel with highly efficient oil-water separation performance: From hydrophobicity to asymmetric wettability[J]. Green Chem, 2022, 24: 7074-7081. doi: 10.1039/D2GC02275C [64] XU L, ZANG Y, XIAO J J, et al. Superhydrophobic conjugated microporous polymer-coated sponges: Synthesis and application for highly efficient oil/water separation and the recovery of palladiumions[J]. Separation and Purification Technology, 2021, 261: 118291. doi: 10.1016/j.seppur.2020.118291 [65] JIANG B, ZHANG H J, ZHANG L H, et al. Novel one-step, in situ thermal polymerization fabrication of robust superhydrophobic mesh for efficient oil/water separation[J]. Industrial & Engineering Chemistry Research, 2017, 56(41): 11817-11826. [66] DENG Y, ZHANG G W, BAI R B, et al. Fabrication of superhydrophilic and underwater superoleophobic membranes via an in situ crosslinking blend strategy for highly efficient oil/water emulsion separation[J]. Journal of Membrane Science, 2019, 569: 60-70. doi: 10.1016/j.memsci.2018.09.069 [67] ZHU Y Y, LU Y Q, SHI Y X, et al. Amphiphilic super-wetting membranes from direct immobilization of nanoparticles by in-situ polymerization and ionic cross-linking during phase inversion[J]. Journal of Membrane Science, 2021, 635: 119469. doi: 10.1016/j.memsci.2021.119469 [68] MUHAMMAD A R, AHMED S, MOHSEN S, et al. Novel concept for water scarcity quantification considering nonconventional and virtual water resources in arid countries: Application in gulf cooperation council countries[J]. Science of the Total Environment, 2023, 882: 163473. doi: 10.1016/j.scitotenv.2023.163473 [69] ZHU R F, LIU M M, HOU Y Y, et al. Biomimetic fabrication of Janus fabric with asymmetric wettability for water purification and hydrophobic/hydrophilic patterned surfaces for fog harvesting[J]. ACS Applied Materials & Interfaces, 2020, 12(44): 50113-50125. [70] LI D K, HUANG J X, HAN G C, et al. A facile approach to achieve bioinspired PDMS@Fe3O4 fabric with switchable wettability for liquid transport and water collection[J]. Journal of Materials Chemistry A, 2018, 6(45): 22741-22748. doi: 10.1039/C8TA08993K [71] SON C H, JI B Q, PARK J K, et al. A magnetically actuated superhydrophobic ratchet surface for droplet manipulation[J]. Micromachines, 2021, 12(3): 325. doi: 10.3390/mi12030325 [72] ZHANG S, LI W, WANG W, et al. Paper-based dual-mode liquid manipulation system: Oil/water separation and time-lapse droplet switch[J]. Chemical Engineering Journal, 2022, 427: 131606. doi: 10.1016/j.cej.2021.131606 [73] LIU M, LI C H, PENG Z L, et al. Simple but efficient method to transport droplets on arbitrarily controllable paths[J]. Langmuir, 2022, 38(12): 3917-3924. [74] WAN T, WANG B, HAN Q, et al. A review of superhydrophobic shape-memory polymers: Preparation, activation, and applications[J]. Applied Materials Today, 2022, 29: 101665. [75] YANG C, ZENG Q H, HUANG J X, et al. Droplet manipulation on superhydrophobic surfaces based on external stimulation: A review[J]. Advances in Colloid and Interface Science, 2022, 306: 102724. doi: 10.1016/j.cis.2022.102724 [76] AIKIFA R, SI Y, DING B, et al. Fabrication of superhydrophobic films with robust adhesion and dual pinning state via in situ polymerization[J]. Journal of Colloid and Interface Science, 2013, 395: 256-262. doi: 10.1016/j.jcis.2012.11.030 [77] HU M M, WU J, TIAN B Y, et al. Janus membrane decorated by mxene multilayered nanoflakes for wet-thermal management[J]. ACS Applied Nano Materials, 2022, 5(5): 7344-7356. doi: 10.1021/acsanm.2c01282 [78] BAI X, GOU X D, ZHANG J L, et al. A review of smart superwetting surfaces based on shape-memory micro/nanostructures[J]. Small, 2023, 19: 2206463. [79] QU M N, LIU Q, HE J M, et al. A multifunctional superwettable material with excellent pH-responsive for controllable in situ separation multiphase oil/water mixture and efficient separation organics system[J]. Applied Surface Science, 2020, 515: 145991. doi: 10.1016/j.apsusc.2020.145991 [80] LI W L, LIU K X, ZHANG Y X, et al. A facile strategy to prepare robust self-healable superhydrophobic fabrics with self-cleaning, anti-icing, UV resistance, and antibacterial properties[J]. Chemical Engineering Journal, 2022, 446: 137195. doi: 10.1016/j.cej.2022.137195 [81] YANG M, ZOU W Z, LUO H, et al. Bright-white hydrogels for on-demand passive cooling[J]. Science China Chemistry, 2023, 66: 1511-1519. doi: 10.1007/s11426-023-1548-0 [82] LIANG F, LIU D X, DONG S R, et al. Facile construction of polyzwitterion membrane via assembly of graphene oxide-based core-brush nanosheet for high-efficiency water permeation[J]. Journal of Membrane Science, 2022, 644: 120150. doi: 10.1016/j.memsci.2021.120150 [83] QI F F, MA T Y, LIU Y, et al. 3D superhydrophilic polypyrrole nanofiber mat for highly efficient adsorption of anionic azo dyes[J]. Microchemical Journal, 2020, 159: 105389. doi: 10.1016/j.microc.2020.105389 -

下载:

下载: