Review of numerical simulation research on fiber reinforced composite bar/cable

-

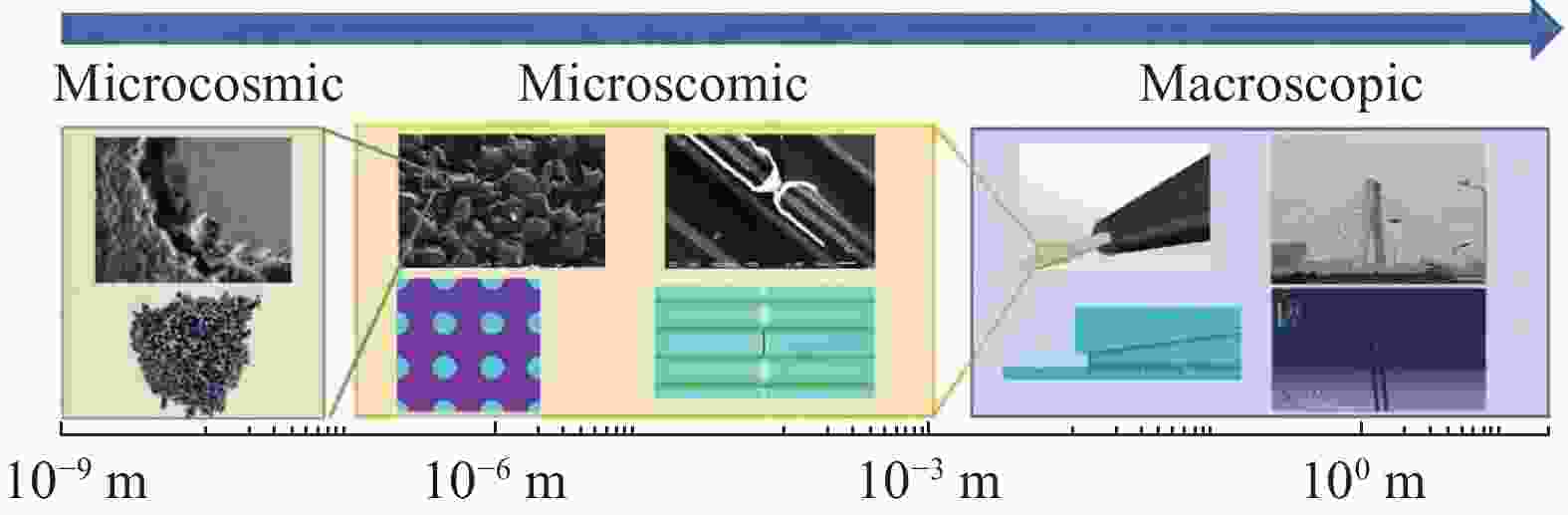

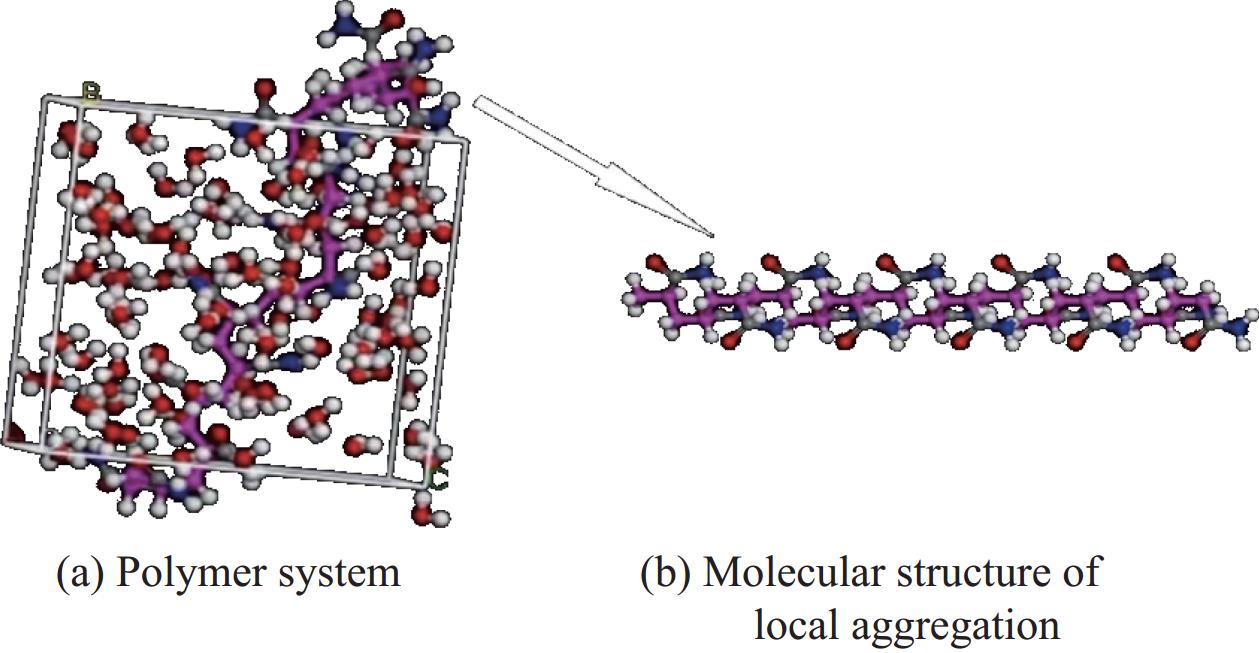

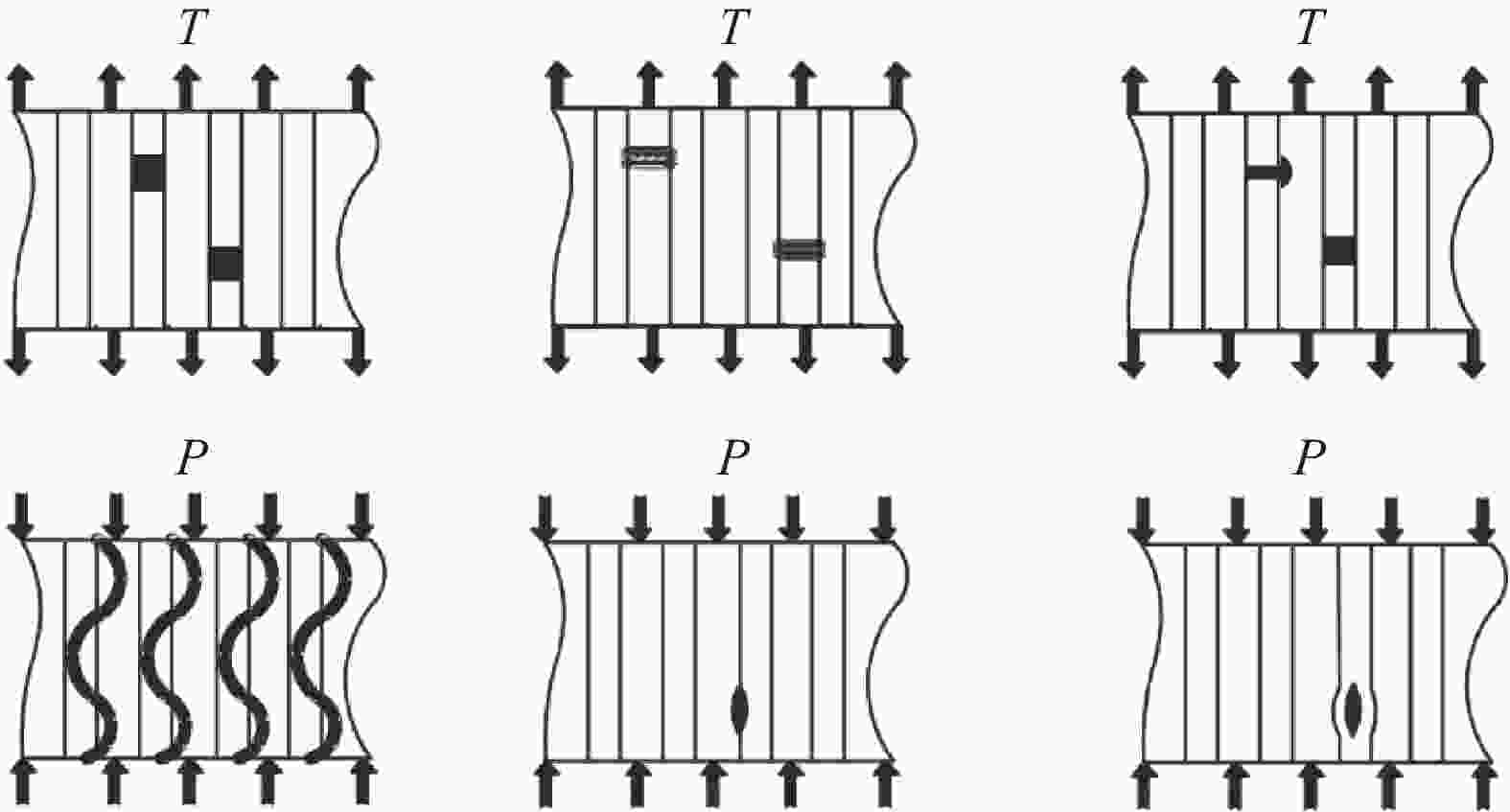

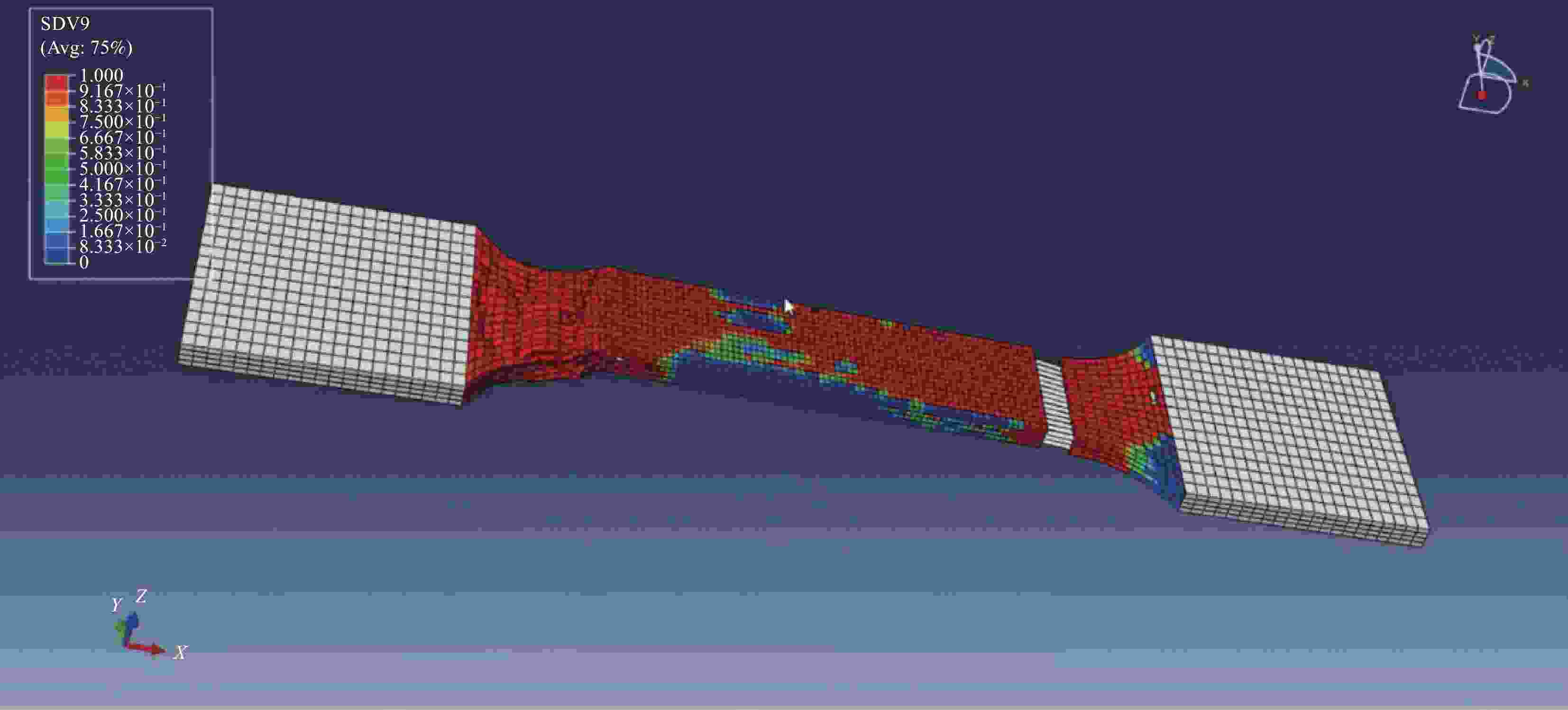

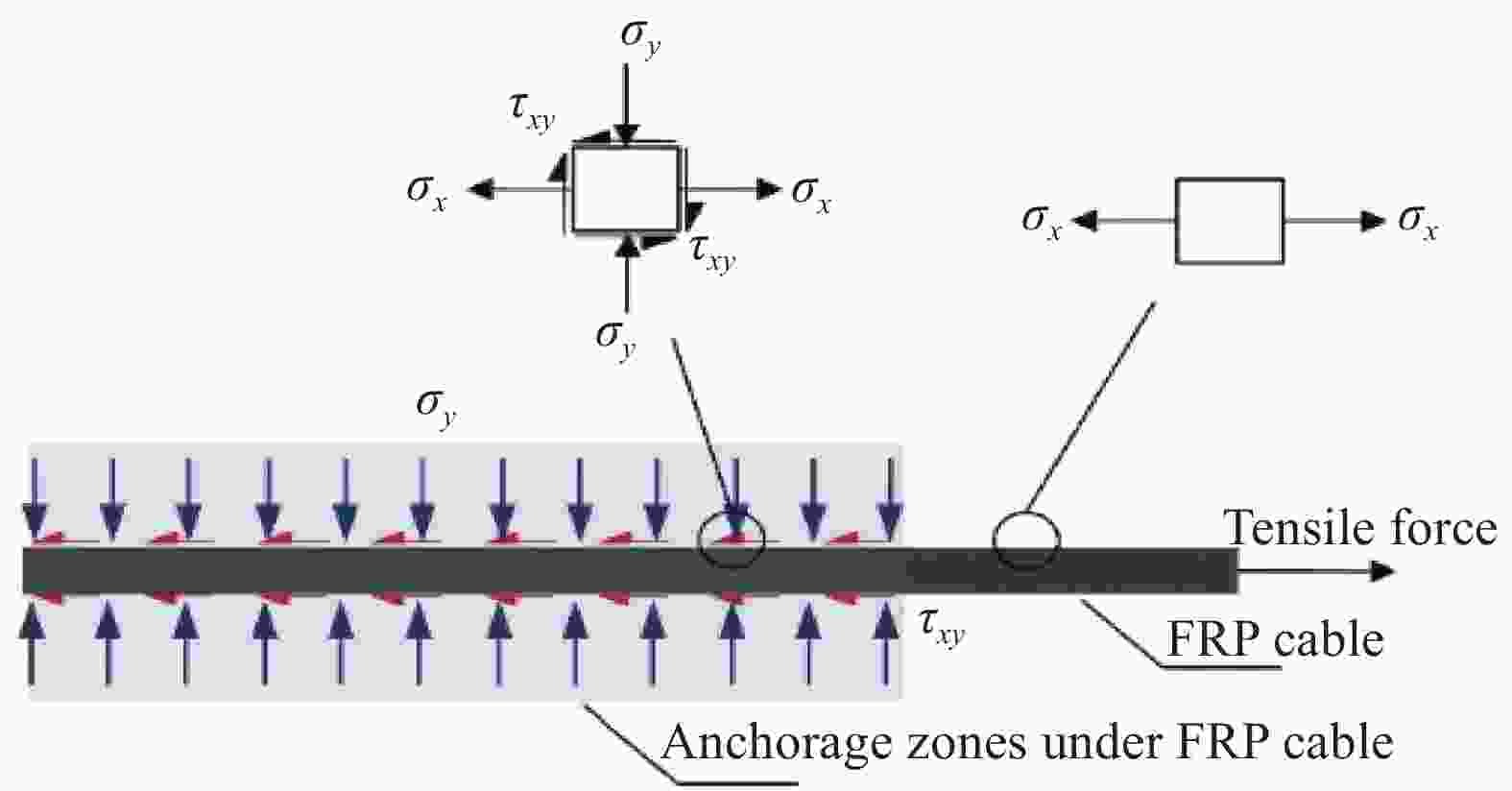

摘要: 纤维增强树脂基复合材料(FRP)是由纤维和树脂基体组合而成的一种材料,在各种领域中拥有广泛的应用。利用数值模拟方法可以更加简单、精确地预测FRP筋/拉索性能,从而加快设计效率、减少试验工作量,因此大量学者针对FRP筋/拉索进行了数值模拟研究。本文主要介绍了单向纤维增强聚合物复合材料的模拟控制因素和需求,在微观、细观和宏观尺度下研究FRP的理论模型和分析方法,提出了在不同尺度下对FRP筋/拉索进行数值模拟的不足之处及数值模拟在微观、细观和宏观层面中的应用。重点论述了不同尺度数值模拟方法在FRP筋/拉索中的应用和最新多尺度数值研究进展及FRP筋/拉索在锚固区的数值模拟方法及现状,最后简要阐述了FRP筋/拉索数值模拟在未来可能的研究发展方向。为建立精细化FRP筋/拉索损伤和性能预测模型发展提供参考。Abstract: Fiber reinforced resin matrix composite (FRP) is a material composed of fibers and resin matrix, which has a wide range of applications in various fields. The use of numerical simulation methods can more easily and accurately predict the performance of FRP bars/cables, thereby accelerating design efficiency and reducing experimental workload. Therefore, a large number of scholars have conducted numerical simulation research on FRP bars/cables. This article mainly introduces the simulation control factors and requirements of unidirectional fiber reinforced polymer composites, studies the theoretical models and analysis methods of FRP at micro, micro, and macro scales, proposes the shortcomings of numerical simulation of FRP bars/cables at different scales, and the application of numerical simulation at micro, micro, and macro levels. The focus is on the application of different scale numerical simulation methods in FRP bars/cables, as well as the latest progress in multi-scale numerical research, as well as the numerical simulation methods and current status of FRP bars/cables in the anchorage zone. Finally, a brief explanation is given of the possible research and development directions of FRP bar/cable numerical simulation in the future. To provide reference for the development of refined FRP reinforcement/cable damage and performance prediction models.

-

Key words:

- FRP structure /

- numerical simulation /

- multi scale analysis /

- finite element method /

- durability

-

表 1 不同尺度方法的适用性与局限性

Table 1. Applicability and limitations of different scale methods

Different scale methods Applicability Limitation Microscopic methods (1) Consider the microstructure, shape, position, and material properties of fibers and matrix; (2) It can reflect the fine structure of composite materials in detail and truthfully; (3) Can more clearly and intuitively demonstrate the transformation characteristics of composite material molecular models (1) Difficulty in accurately fitting with the experimental process, unable to obtain accurate experimental data for argumentation; (2) Too many factors to consider, complex parameters such as modeling node elements, and complex calculation process Mesoscopic methods (1) Reduced the number of nodes and units, reducing the difficulty of modeling; (2) Compared with macroscopic methods, it has added the function of strain, stress, and failure analysis for each layer and interlayer of composite materials; (3) Can establish the relationship between the strength of composite materials and the properties, content, microstructure and other parameters of component materials (1) Expanded the research scale, reduced workload, and reduced accuracy; (2) Due to the different environments and failure modes of different structures, the research process may be slightly cumbersome Macroscopic methods Starting from experiments and analyzing the mechanical properties of composite materials, the feasibility of research is higher (1) There will be many ideal conditions set during the experimental process, and there may be errors in the experimental data; (2) Unable to consider issues such as strain, stress, and failure analysis between composite layers -

[1] WAN B L, JIANG C, WU Y F. Effect of defects in externally bonded FRP reinforced concrete[J]. Construction and Building Materials, 2018, 172: 63-76. doi: 10.1016/j.conbuildmat.2018.03.217 [2] 范向前, 刘决丁, 胡少伟, 等. FRP加固混凝土研究现状与展望[J]. 混凝土, 2019(12): 156-160.FAN Xiangqian, LIU Jueding, HU Shaowei, et al. Research status and prospects of FRP reinforced concrete[J]. Concrete, 2019(12): 156-160(in Chinese). [3] 张鑫, 代清利, 李伟, 等. FRP复合材料在道路路面裂缝安全处治中的运用[J]. 城市建设理论研究, 2023(23): 147-149.ZHANG Xin, DAI Qingli, LI Wei, et al. The application of FRP composite materials in safe treatment of road surface cracks[J]. Urban Construction Theory Research, 2023(23): 147-149(in Chinese). [4] 袁方, 赵修远. FRP筋-钢筋增强ECC-混凝土组合柱抗震性能研究[J]. 工程力学, 2021, 38(8): 55-65.YUAN Fang, ZHAO Xiuyuan. Research on seismic performance of FRP reinforced ECC concrete composite columns[J]. Engineering Mechanics, 2021, 38(8): 55-65(in Chinese). [5] 白娜妮. 单向纤维复合材料疲劳性能数值模拟方法[D]. 北京: 北京科技大学, 2023.BAI Nani. Numerical simulation method for fatigue performance of unidirectional fiber composite materials[D]. Beijing: Beijing University of Science and Technology, 2023(in Chinese). [6] 刘杰. 基于FRP的钢桥箱梁疲劳损伤加固方法研究[D]. 南京: 东南大学, 2020.LIU Jie. Research on fatigue damage reinforcement method for steel bridge box girders based on FRP[D]. Nanjing: Southeast University, 2020(in Chinese). [7] 贾瀚翔, 吴超, 夏林祥, 等. 纤维增强复合材料疲劳性能研究进展[J]. 新技术新工艺, 2023(8): 5-9.JIA Hanxiang, WU Chao, XIA Linxiang, et al. Research progress on fatigue performance of fiber-reinforced composite materials[J]. New Technology and Process, 2023(8): 5-9(in Chinese). [8] YE Y J, ZHENG K G, HUA K Q. Rate-dependent multiaxial life prediction for polyamide-6 considering ratchetting: Semi-empirical and physics-informed machine learning models[J]. International Journal of Fatigue, 2022, 163: 107086. doi: 10.1016/j.ijfatigue.2022.107086 [9] TAO C C, ZHANG C, JI H L, et al. Fatigue damage characterization for composite laminates using deep learning and laser ultrasonic[J]. Composites Part B: Engineering, 2021, 216: 108816. doi: 10.1016/j.compositesb.2021.108816 [10] 刘志明, 陈静芬, 毛欢, 等. 纤维增强复合材料混合模式分层破坏数值模拟研究[J]. 应用力学学报, 2023, 40(3): 545-557.LIU Zhiming, CHEN Jingfen, MAO Huan, et al. Numerical simulation of mixed mode delamination failure in fiber reinforced composite materials[J]. Journal of Applied Mechanics, 2023, 40(3): 545-557(in Chinese). [11] 魏志远. 碳纤维编织复合材料变形与内部损伤精细化测量与数值模拟[D]. 保定: 河北大学, 2021.WEI Zhiyuan. Fine measurement and numerical simulation of deformation and internal damage in carbon fiber woven composite materials[D]. Baoding: Hebei University, 2021(in Chinese). [12] 杨玉娥, 张文习. 碳纤维复合材料的无损检测综述[J]. 济南大学学报(自然科学版), 2015(6): 471-476.YANG Yu'e, ZHANG Wenxi. Review of non-destructive testing of carbon fiber composite materials[J]. Journal of Jinan University (Natural Science Edition), 2015(6): 471-476(in Chinese). [13] 文琼华, 孟江燕, 龚楚, 等. 碳纤维增强树脂基复合材料孔隙率检测方法的分析比较[J]. 玻璃钢/复合材料, 2016(7): 32-37.WEN Qionghua, MENG Jiangyan, GONG Chu, et al. Analysis and comparison of porosity detection methods for carbon fiber reinforced resin matrix composites[J]. Fiber Glass/Composite Materials, 2016(7): 32-37(in Chinese). [14] 闫清峰, 张纪刚. 纤维增强复合材料在土木工程中的应用与发展[J]. 科学技术与工程, 2021, 21(36): 15314-15322.YAN Qingfeng, ZHANG Jigang. Application and development of fiber reinforced composite materials in civil engineering[J]. Science and Technology and Engineering, 2021, 21(36): 15314-15322(in Chinese). [15] 梅葵花, 李宇, 贾文科, 等. 纤维增强复合材料缆索锚固系统研究与应用进展[J]. 土木工程学报, 2023, 56(4): 83-102.MEI Kuihua, LI Yu, JIA Wenke, et al. Research and application progress of fiber reinforced composite cable anchorage system[J]. China Civil Engineering Journal, 2023, 56(4): 83-102(in Chinese). [16] CHEN Z P, QIN W H, LIANG Y H, et al. Axial compressive performance of seawater sea sand concrete-filled CFRP-stainless steel tube short columns[J]. Construction and Building Materials, 2023, 369: 130501. doi: 10.1016/j.conbuildmat.2023.130501 [17] 吴超, 吴瑞东, 蒋金桥, 等. 土木工程应用中碳纤维/环氧树脂界面在环境影响下退化的分子模拟研究进展[J]. 复合材料学报, 2020, 37(12): 2941-2952.WU Chao, WU Ruidong, JIANG Jinqiao, et al. Recent advances in understanding environmental effects on degradation of carbon fiber/epoxy matrix interface in civil engineering applications via molecular simulation[J]. Acta Materiae Compositae Sinica, 2020, 37(12): 2941-2952(in Chinese). [18] WU C, WU R D, TAM L H. Understanding degradation of fiber/matrix interface under environmental effects using molecular simulation[C]//10th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, CICE 2021. Istanbul: Lecture Notes in Civil Engineering, 2022, 198: 2096-2108. [19] WU R D, WANG X Q, ZHAO D Y, et al. Degradation of fiber/matrix interface under various environmental and loading conditions: Insights from molecular simulations[J]. Construction and Building Materials, 2023, 390: 131101. doi: 10.1016/j.conbuildmat.2023.131101 [20] 刘颖红林. 纤维增强复合材料损伤演化声发射量化表征方法研究[D]. 大庆: 东北石油大学, 2022.LIU Yinghonglin. Research on quantitative characterization method of acoustic emission for damage evolution of fiber reinforced composite materials[D]. Daqing: Northeast Petroleum University, 2022(in Chinese). [21] 章中才. 基于正交数值试验与GA-BP算法的玻纤筋参数优化及预测研究[D]. 西安: 西安建筑科技大学, 2022.ZHANG Zhongcai. Research on optimization and prediction of fiberglass reinforcement parameters based on orthogonal numerical experiments and GA-BP algorithm[D]. Xi'an: Xi'an University of Architecture and Technology, 2022(in Chinese). [22] 杨步云, 肖明, 罗宁, 等. 锚杆剪切过程中的受力机理分析[J]. 华中科技大学学报(自然科学版), 2019, 47(3): 127-132.YANG Buyun, XIAO Ming, LUO Ning, et al. Analysis of the stress mechanism during the shearing process of bolts[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2019, 47(3): 127-132(in Chinese). [23] 周小燚, 钱盛域, 王能威, 等. FRP工程结构多尺度不确定性分析研究进展[J]. 中国公路学报, 2023, 36(1): 97-113.ZHOU Xiaoyi, QIAN Shengyu, WANG Nengwei, et al. Research progress on multi-scale uncertainty analysis of FRP engineering structures[J]. Chinese Journal of Highway Engineering, 2023, 36 (1): 97-113(in Chinese). [24] 朱德举, 沈琰, 李晟, 等. 考虑内部缺陷的FRP拉索力学行为仿真分析[J]. 湖南大学学报(自然科学版), 2022, 49(1): 85-93.ZHU Deju, SHEN Yan, LI Sheng, et al. Simulation analysis of mechanical behavior of FRP cables considering internal defects[J]. Journal of Hunan University (Natural Science Edition), 2022, 49(1): 85-93(in Chinese). [25] 黄梅, 潘静雯, 江剑, 等. 纤维增强复合材料中多分层损伤的识别研究[J]. 复合材料科学与工程, 2021(5): 21-30.HUANG Mei, PAN Jingwen, JIANG Jian, et al. Identification of multi layered damage in fiber reinforced composite materials[J]. Composite Materials Science and Engineering, 2021(5): 21-30(in Chinese). [26] 詹超, 马晓静, 张芝芳. 纤维增强复合材料梁的分层损伤识别[J]. 玻璃钢/复合材料, 2017(9): 5-12.ZHAN Chao, MA Xiaojing, ZHANG Zhifang. Identification of delamination damage in fiber reinforced composite beams[J]. Fiber Glass/Composite Materials, 2017(9): 5-12(in Chinese). [27] 高嘉琪. 不同表面特性FRP筋与海水海砂混凝土粘结性能试验研究[D]. 大连: 大连理工大学, 2022.GAO Jiaqi. Experimental study on the bonding performance between FRP bars with different surface characteristics and seawater sand concrete[D]. Dalian: Dalian University of Technology, 2022(in Chinese). [28] ZHANG P, ZHANG S, GAO D, et al. Influence of rib parameters on mechanical properties and bond behavior in concrete of fiber-reinforced polymer rebar[J]. Advances in Structural Engineering, 2020, 24(1): 196-208. [29] SOLYOM S, BALÁZS G L. Bond of FRP bars with different surface characteristics[J]. Construction and Building Materials, 2020, 264: 119839. [30] 张羽, 傅丰, 郑吉丰, 等. 基于试验验证下的FRP筋与混凝土粘结滑移界面关系有限元模型的建立方法[J/OL]. 建筑结构: 1-11[2024-01-21].ZHANG Yu, FU Feng, ZHENG Jifeng, et al. Method for establishing a finite element model of the bond slip interface relationship between FRP bars and concrete based on experimental verification [J/OL]. Building Structure: 1-11[2024-01-21](in Chinese). [31] 尹世平, 李雨珊, 刘运超. FRP筋与全珊瑚骨料海水混凝土粘结性能数值模拟[J]. 应用基础与工程科学学报, 2023, 31(1): 210-223.YIN Shiping, LI Yushan, LIU Yunchao. Numerical simulation of bonding performance between FRP bars and seawater concrete with coral aggregate[J]. Journal of Applied Fundamentals and Engineering Science, 2023, 31(1): 210-223(in Chinese). [32] 赵卫平, 肖建庄. 带肋钢筋与混凝土间粘结滑移本构模型[J]. 工程力学, 2011, 28(4): 164-171.ZHAO Weiping, XIAO Jianzhuang. Bond slip constitutive model between ribbed steel bars and concrete[J]. Engineering Mechanics, 2011, 28(4): 164-171(in Chinese). [33] 褚天舒. 基于耐久性的FRP筋-混凝土构件粘结滑移本构关系研究[D]. 镇江: 江苏大学, 2018.CHU Tianshu. Study on the bond-slip constitutive relationship between FRP reinforcement and concrete members based on durability[D]. Zhenjiang: Jiangsu University, 2018(in Chinese). [34] SOORIYAARACHCHI H, PILAKOUTAS K, BYARS E. Tension stiffening behavior of GFRP-reinforced concrete[J]. Special Publication, 2005, 230: 975-990. [35] VILANOVA I, TORRES L, BAENA M, et al. Experimental study of tension stiffening in GFRP RC tensile members under sustained load[J]. Engineering Structures, 2014, 79: 390-400. doi: 10.1016/j.engstruct.2014.08.037 [36] RIMKUS A, BARROS J A O, GRIBNIAK V, et al. Mechanical behavior of concrete prisms reinforced with steel and GFRP bar systems[J]. Composite Structures, 2019, 220: 273-288. doi: 10.1016/j.compstruct.2019.03.088 [37] 贾道光. 考虑GFRP筋拉伸性能劣化的GFRP筋-钢筋双层配筋墩柱抗震性能研究[D]. 哈尔滨: 哈尔滨工程大学, 2021.JIA Daoguang. Research on seismic performance of GFRP reinforced double layer reinforced pier columns considering the deterioration of tensile performance of GFRP reinforcement[D]. Harbin: Harbin Engineering University, 2021(in Chinese). [38] 吴刚, 罗云标, 吴智深, 等. 钢-连续纤维复合筋(SFCB)力学性能试验研究与理论分析[J]. 土木工程学报, 2010, 43(3): 53-61.WU Gang, LUO Yunbiao, WU Zhishen, et al. Experimental study and theoretical analysis on the mechanical properties of steel continuous fiber composite reinforcement (SFCB)[J]. China Civil Engineering Journal, 2010, 43(3): 53-61(in Chinese). [39] MU Y N, SHI L, ZHANG Z. Studies and improvements on modal pushover analysis and application on bridge[J]. Advanced Materials Research, 2010, 163-167: 4076-4082. doi: 10.4028/www.scientific.net/AMR.163-167.4076 [40] GUO F, AL-SAADI S, SINGH RAMAN R S, et al. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment[J]. Corrosion Science, 2018, 141: 1-13. doi: 10.1016/j.corsci.2018.06.022 [41] 周小祥. 复合材料板冲击拉伸性能的实验研究与数值模拟[D]. 西安: 西北工业大学, 2005.ZHOU Xiaoxiang. Experimental study and numerical simulation of impact tensile properties of composite plates[D]. Xi'an: Northwest University of Technology, 2005(in Chinese). [42] 郝仙娟, 许有纯, 舒营. FRP材料动态本构模型综述[J]. 低温建筑技术, 2022, 44(4): 21-24, 29.HAO Xianjuan, XU Youchun, SHU Ying. Overview of dynamic constitutive models for FRP materials[J]. Low Temperature Architecture Technology, 2022, 44(4): 21-24, 29(in Chinese). [43] LUO S D, WANG Y, WANG G T, et al. Hybrid spray-coating, laser-scribing and ink-dispensing of graphene sensors/arrays with tunable piezoresistivity for in situ monitoring of composites[J]. Carbon, 2018, 139: 437-444. [44] 张新越, 欧进萍. FRP加筋混凝土短柱受压性能试验研究[J]. 西安建筑科技大学学报(自然科学版), 2006(4): 467-472, 485.ZHANG Xinyue, OU Jinping. Experimental study on compressive performance of FRP reinforced concrete short columns[J]. Journal of Xi'an University of Architecture and Technology (Natural Science Edition), 2006(4): 467-472, 485(in Chinese). [45] 周健南, 孔新立, 王鹏, 等. CFRP加固素混凝土拱压缩性能数值模拟[J]. 陆军工程大学学报, 2022, 1(1): 80-88.ZHOU Jiannan, KONG Xinli, WANG Peng, et al. Numerical simulation of compressive performance of CFRP reinforced plain concrete arches[J]. Journal of Army Engineering University, 2022, 1(1): 80-88(in Chinese). [46] 任振华, 曾宪桃, 孙浚博. 内嵌 CFRP筋加固宽缺口混凝土梁内力解析与试验研究[J]. 工程力学, 2019, 36(4): 117-124.REN Zhenhua, ZENG Xiantao, SUN Junbo. Analysis and experimental study of internal forces in reinforced wide gap concrete beams with embedded CFRP reinforcement[J]. Engineering Mechanics, 2019, 36(4): 117-124(in Chinese). [47] 徐可. 混合配筋高强混凝土梁受弯性能试验研究及数值模拟[D]. 镇江: 江苏大学, 2020.XU Ke. Experimental research and numerical simulation on the flexural performance of high-strength concrete beams with mixed reinforcement[D]. Zhenjiang: Jiangsu University, 2020(in Chinese). [48] 张智梅, 魏久燚. 钢筋与FRP筋混杂配筋混凝土梁的抗弯性能[J]. 上海大学学报(自然科学版), 2022, 28(4): 678-688.ZHANG Zhimei, WEI Jiuyi. Flexural performance of concrete beams with mixed reinforcement of steel bars and FRP bars[J]. Journal of Shanghai University (Natural Science Edition), 2022, 28(4): 678-688(in Chinese). [49] MUSTAFA S A A, HASSAN H A. Behavior of concrete beams reinforced with hybrid steel and FRP composites[J]. HBRC Journal, 2018, 14(3): 300-308. [50] 蒋祖发. FRP筋ECC梁受弯性能研究[D]. 郑州: 郑州大学, 2021.JIANG Zufa. Research on the flexural performance of FRP reinforced ECC beams[D]. Zhengzhou: Zhengzhou University, 2021(in Chinese). [51] 刘水, 汪昕, 吴智深. FRP筋-钢筋混合配筋混凝土受弯构件短期刚度计算方法[J/OL]. 工程力学: 1-11[2023-12-07].LIU Shui, WANG Xin, WU Zhishen. Short term stiffness calculation method for FRP reinforced concrete flexural members with mixed reinforcement[J/OL]. Engineering Mechanics: 1-11[2023-12-07](in Chinese). [52] 高丹盈, 赵军, BRAHIM B. 玻璃纤维聚合物筋混凝土梁裂缝和挠度的特点及计算方法[J]. 水利学报, 2001, 32(8): 53-58.GAO Danying, ZHAO Jun, BRAHIM B. Characteristics and calculation methods of cracks and deflections in concrete beams reinforced with glass fiber polymer reinforcement[J]. Journal of Hydraulic Engineering, 2001, 32(8): 53-58(in Chinese). [53] DAVOOD M, MARYAM M A. Effect of confining of boundary elements of slender RC shear wall by FRP composites and stirrups[J]. Engineering Structures, 2012, 41: 1-13. doi: 10.1016/j.engstruct.2012.03.019 [54] 朱虹, 张继文. 预应力FRP筋增强RC梁受弯破坏模式研究[J]. 土木建筑与环境工程, 2012, 34(5): 97-101.ZHU Hong, ZHANG Jiwen. Research on the flexural failure mode of prestressed FRP reinforced RC beams[J]. Journal of Civil and Environmental Engineering, 2012, 34(5): 97-101(in Chinese). [55] JIN L, YU W X, DU X L, et al. Meso-scale modelling of the size effect on dynamic compressive failure of concrete under different strain rates[J]. International Journal of Impact Engineering, 2019, 125: 1-12. [56] 王自柯, 段建新, 赵军, 等. FRP筋在不同腐蚀环境下的层间剪切性能劣化试验[J/OL]. 复合材料学报: 1-14[2023-11-24].WANG Zike, DUAN Jianxin, ZHAO Jun, et al. Deterioration test of interlayer shear performance of FRP reinforcement under different corrosive environments[J/OL]. Acta Materiae Compositae Sinica: 1-14[2023-11-24](in Chinese). [57] 王自柯. FRP筋在模拟海水-海砂混凝土孔溶液浸泡下的耐久性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Zike. Durability study of FRP reinforcement under simulated seawater sea sand concrete pore solution immersion[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [58] 庞育阳, 吕远晨, 王强. 氯盐侵蚀环境下液体橡胶改性CFRP-钢界面耐久性[J/OL]. 复合材料学报:1-15[2024-02-04].PANG Yuyang, LYU Yuanchen, WANG Qiang. Interfacial durability of liquid rubber modified CFRP-steel under chloride salt erosion[J/OL]. Acta Materiae Compositae Sinica: 1-15[2024-02-04](in Chinese). [59] DE LORENZIS L, TENG J G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures[J]. Composites Part B: Engineering, 2007, 38(2): 119-143. doi: 10.1016/j.compositesb.2006.08.003 [60] 袁良柱, 苗春贺, 单俊芳, 等. 冲击下混凝土试样应变率效应和惯性效应探讨[J]. 爆炸与冲击, 2022, 42(1): 18-30.YUAN Liangzhu, MIAO Chunhe, SHAN Junfang, et al. Discussion on strain rate effect and inertia effect of concrete specimens under impact[J]. Explosion and Shock Waves, 2022, 42(1): 18-30(in Chinese). [61] SOLIMAN S M, EL-SALAKAWY E, BENMOKRANE B. Bond performance of near-surface-mounted FRP bars[J]. Journal of Composites for Construction, 2011, 15(1): 103-111. doi: 10.1061/(ASCE)CC.1943-5614.0000150 [62] PENG B, LI Q, FENG X Q, et al. Effect of shear stress on adhesive contact with a generalized Maugis-Dugdale cohesive zone model[J]. Journal of the Mechanics and Physics of Solids, 2021, 148: 104275. doi: 10.1016/j.jmps.2020.104275 [63] 曹吉星. 钢纤维混凝土的动态本构模型及其有限元方法[D]. 成都: 西南交通大学, 2018.CAO Jixing. Dynamic constitutive model and finite element method of steel fiber reinforced concrete[D]. Chengdu: Southwest Jiaotong University, 2018(in Chinese). [64] LIU T, XIAO Y. Impact behavior of CFRP-strip-wrapped RC beams without stirrups[J]. Journal of Composites for Construction, 2017, 21(5): 04017035. doi: 10.1061/(ASCE)CC.1943-5614.0000815 [65] LIU T, LIU T, KANG T H K, et al. Impact testing of reinforced concrete beams shear-strengthened with fiber-reinforced polymer wraps[J]. ACI Structural Journal, 2020, 117(3): 297-310. [66] 卢娟. 冲击荷载下CFRP增强钢筋混凝土梁的动力性能及界面粘结机制研究[D]. 广州: 广州大学, 2023.LU Juan. Research on the dynamic performance and interface bonding mechanism of CFRP reinforced concrete beams under impact load[D]. Guangzhou: Guangzhou University, 2023(in Chinese). [67] ZHU H, WANG Q, DAI J G, et al. Innovative additional aluminum alloy ribs anchorage for improving the bond reliability of pretensioned CFRP bar: A feasibility study[J]. Composite Structures, 2022, 280: 114817. [68] 崔兆发. 冻融及疲劳荷载耦合作用下BFRP-混凝土界面粘结性能研究[D]. 长春: 吉林建筑大学, 2023.CUI Zhaofa. Study on the bonding performance of BFRP concrete interface under the coupling effect of freeze-thaw and fatigue loads[D]. Changchun: Jilin University of Architecture, 2023(in Chinese). [69] TOUMPANAKI E, RAMAGE M. Cyclic loading of glued-in FRP rods in timber: Experimental and analytical study[J]. Journal of Composites for Construction, 2022, 26(2): 0001182. [70] 彭哲琦, 汪昕, 吴智深. FRP拉索静力及蠕变性能的多尺度预测[J]. 中国公路学报, 2022, 35(2): 98-105.PENG Zheqi, WANG Xin, WU Zhishen. Multi scale prediction of static and creep properties of FRP cables[J]. China Journal of Highway and Transport, 2022, 35(2): 98-105(in Chinese). [71] 石康乐, 何朗, 朱四荣, 等. 基于基因表达式编程的FRP蠕变分析与预测[J]. 武汉理工大学学报, 2022, 44(7): 1-9.SHI Kangle, HE Lang, ZHU Sirong, et al. Analysis and prediction of FRP creep based on gene expression programming[J]. Journal of Wuhan University of Technology, 2022, 44(7): 1-9(in Chinese). [72] 张尧. 纤维增强树脂基复合材料弯曲蠕变分析及其细观模型研究[D]. 武汉: 武汉理工大学, 2023.ZHANG Yao. Bending creep analysis and mesoscopic model study of fiber reinforced resin matrix composite materials[D]. Wuhan: Wuhan University of Technology, 2023(in Chinese). [73] 董志强, 吴刚. FRP筋增强混凝土结构耐久性能研究进展[J]. 土木工程学报, 2019, 52(10): 1-19, 29DONG Zhiqiang, WU Gang. Research progress on durability performance of FRP reinforced concrete structures[J]. China Civil Engineering Journal, 2019, 52(10): 1-19, 29(in Chinese). [74] 王伟, 薛伟辰. 碱环境下GFRP筋拉伸性能加速老化试验研究[J]. 建筑材料学报, 2012, 15(6): 760-766.WANG Wei, XUE Weichen. Research on accelerated aging test of tensile properties of GFRP reinforcement in alkaline environment[J]. Journal of Building Materials, 2012, 15(6): 760-766(in Chinese). [75] AL-SALLOUM Y A, EL-GAMAL S, ALMUSALLAM T H, et al. Effect of harsh environmental conditions on the tensile properties of GFRP bars[J]. Composites Part B: Engineering, 2013, 45(1): 835-844. [76] 付凯, 薛伟辰. 人工海水环境下GFRP筋抗拉性能加速老化试验[J]. 建筑材料学报, 2014, 17(1): 35-41.FU Kai, XUE Weichen. Accelerated aging test on tensile properties of GFRP bars under artificial seawater environment[J]. Journal of Building Materials, 2014, 17(1): 35-41(in Chinese). [77] 于志力. FRP筋与海水海砂混凝土界面粘结耐久性研究[D]. 大连: 大连理工大学, 2023.YU Zhili. Study on the durability of interface bonding between FRP reinforcement and seawater sand concrete[D]. Dalian: Dalian University of Technology, 2023(in Chinese). [78] FENG B, WANG X, WU Z S, et al. Performance of anchorage assemblies for CFRP cables under fatigue loads[J]. Structures, 2021, 29: 947-953. [79] FENG P, ZHANG P, MENG X M, et al. Mechanical analysis of stress distribution in a carbon fiber-reinforced polymer rod bonding anchor[J]. Polymers, 2014, 6(4): 1129-1143. doi: 10.3390/polym6041129 [80] 李扬, 贾丽君. 基于Tsai-wu准则的CFRP拉索粘结型锚具的仿真分析[J]. 重庆交通大学学报(自然科学版), 2020, 39(1): 60-66.LI Yang, JIA Lijun. Simulation analysis of CFRP cable bonded anchorage based on Tsai-wu criterion[J]. Journal of Chongqing Jiaotong University (Natural Science Edition), 2020, 39(1): 60-66(in Chinese). [81] 王文广. FRP抗剪加固混凝土梁锚固效果的有限元分析[D]. 大连: 大连理工大学, 2019.WANG Wenguang. Finite element analysis of anchorage effect of FRP shear strengthening concrete beams[D]. Dalian: Dalian University of Technology, 2019(in Chinese). [82] 刘浪. 预应力BFRP锚杆设计与锚固性能研究[D]. 南京: 东南大学, 2022.LIU Lang. Design and anchoring performance research of prestressed BFRP anchor rods[D]. Nanjing: Southeast University, 2022(in Chinese). [83] 冯博. 大吨位FRP拉索锚固体系及长期性能研究[D]. 南京: 东南大学, 2020.FENG Bo. Research on large tonnage FRP cable anchorage system and long term performance[D]. Nanjing: Southeast University, 2020(in Chinese). [84] 熊文, 肖汝诚, CAI C S, 等. 基于力学与造价的CFRP-钢组合拉索斜拉桥设计理论[J]. 中国公路学报, 2012, 25(4): 97-106.XIONG Wen, XIAO Rucheng, CAI C S, et al. Design theory of CFRP steel composite cable-stayed bridge based on mechanics and cost[J]. China Journal of Highway and Transport, 2012, 25(4): 97-106(in Chinese). [85] 周建超. 基于高性能材料超大跨径混合梁斜拉桥的结构方案及力学性能[D]. 长沙: 湖南大学, 2021.ZHOU Jianchao. Structural scheme and mechanical properties of ultra long span hybrid beam cable-stayed bridges based on high-performance materials[D]. Changsha: Hunan University, 2021(in Chinese). [86] NANNI A, BAKIS C E, DIXON T O. Performance of FRP tendon-anchor systems for prestressed concrete structures[J]. PCI Journal, 1996, 41(1): 34-43. doi: 10.15554/pcij.01011996.34.44 [87] 余锐锋. GFRP/CFRP混杂纤维筋土层锚杆的锚固机制与设计方法研究[D]. 镇江: 江苏大学, 2022.YU Ruifeng. Research on the anchoring mechanism and design method of GFRP/CFRP hybrid fiber reinforced soil anchor rods[D]. Zhenjiang: Jiangsu University, 2022(in Chinese). [88] WANG Y L, WANG Y S, WAN B L, et al. Properties and mechanisms of self-sensing carbon nanofibers/epoxy composites for structural health monitoring[J]. Composite Structures, 2018, 200: 669-678. [89] ABED F, OUCIF C, AWERA Y, et al. FE modeling of concrete beams and columns reinforced with FRP composites[J]. Defence Technology, 2021, 17(1): 1-14. [90] TAM L H, ZHOU A, YU Z C, et al. Understanding the effect of temperature on the interfacial behavior of CFRP-wood composite via molecular dynamics simulations[J]. Composites Part B: Engineering, 2017, 109: 227-237. doi: 10.1016/j.compositesb.2016.10.030 [91] TAM L H, JIANG J Q, YU Z C, et al. Molecular dynamics investigation on the interfacial shear creep between carbon fiber and epoxy matrix[J]. Applied Surface Science, 2021, 537: 148013. [92] WU C, JIANG J, TAM L H, et al. An atomistic study of creep deformation in fiber/matrix interface[C]//ICCM22 2019. Melbourne: VIC, 2019: 2526-2535. [93] TAM L H, WU R D, MINKENG M A N, et al. Understanding creep behavior of carbon fiber/epoxy interface via molecular dynamics simulation[J]. Mechanics of Advanced Materials and Structures, 2023, 30(19): 4052-4064. [94] 杨清瑞. 侵蚀离子环境下FRP/混凝土界面劣化机制与性能调控的分子动力学研究[D]. 青岛: 青岛理工大学, 2022.YANG Qingrui. Molecular dynamics study on the degradation mechanism and performance control of FRP/concrete interface under corrosive ion environment[D]. Qingdao: Qingdao University of Technology, 2022(in Chinese). [95] TAM L H, MINKENG M A N, LAU D, et al. Molecular interfacial shearing creep behavior of carbon fiber/epoxy matrix interface under moisture condition[J]. Engineering Fracture Mechanics, 2023, 282: 109177. [96] TAM L H, HE L, WU C. Molecular dynamics study on the effect of salt environment on interfacial structure, stress, and adhesion of carbon fiber/epoxy interface[J]. Composite Interfaces, 2019, 26(5): 431-447. [97] TAM L H, ZHOU A, WU C. Nanomechanical behavior of carbon fiber/epoxy interface in hygrothermal conditioning: A molecular dynamics study[J]. Materials Today Communications, 2019, 19: 495-505. [98] TAM L H, ZHOU A, ZHANG R X, et al. Effect of hygrothermal environment on traction-separation behavior of carbon fiber/epoxy interface[J]. Construction and Building Materials, 2019, 220: 728-738. [99] LAU D, JIAN W, YU Z, et al. Nano-engineering of construction materials using molecular dynamics simulations: Prospects and challenges[J]. Composites Part B: Engineering, 2018, 143: 282-291. [100] GUNES O, LAU D, TUAKTA C, et al. Ductility of FRP-concrete systems: Investigations at different length scales[J]. Construction and Building Materials, 2013, 49: 915-925. [101] 杨强, 解维华, 孟松鹤, 等. 复合材料多尺度分析方法与典型元件拉伸损伤模拟[J]. 复合材料学报, 2015, 32(3): 617-624.YANG Qiang, XIE Weihua, MENG Songhe, et al. Multi-scale analysis method of composites and damage simulation of typical component under tensile load[J]. Acta Materiae Compositae Sinica, 2015, 32(3): 617-624(in Chinese). [102] 陈玉丽, 马勇, 潘飞, 等. 多尺度复合材料力学研究进展[J]. 固体力学学报, 2018, 39(1): 1-68. doi: 10.19636/j.cnki.cjsm42-1250/o3.2017.030CHEN Yuli, MA Yong, PAN Fei, et al. Research progress in multi-scale composite material mechanics[J]. Chinese Journal of Solid Mechanics, 2018, 39(1): 1-68(in Chinese). doi: 10.19636/j.cnki.cjsm42-1250/o3.2017.030 [103] 苏畅. FRP筋性能设计及其增强海水海砂混凝土构件长期性能研究[D]. 南京: 东南大学, 2021.SU Chang. Performance design of FRP bars and long-term performance study of reinforced seawater sand concrete components[D]. Nanjing: Southeast University, 2021(in Chinese). [104] 王川, 欧进萍. GFRP筋酸碱盐腐蚀老化实验研究[J]. 防灾减灾工程学报, 2010, 30(S1): 373-377.WANG Chuan, OU Jinping. Experimental study on acid alkali salt corrosion and aging of GFRP tendons[J]. Journal of Disaster Prevention and Mitigation Engineering, 2010, 30(S1): 373-377(in Chinese). [105] 芦思羽, 陈德, 吴昊. FRP-混凝土界面动态剪切滑移模型[J/OL]. 工程力学: 1-13[2023-04-07].LU Siyu, CHEN De, WU Hao. FRP concrete interface dynamic shear slip model[J/OL]. Engineering Mechanics: 1-13[2023-04-07](in Chinese). [106] CHEN Z L, WANG J, CHEN J Y, et al. Responses of concrete-filled FRP tubular and concrete-filled FRP-steel double skin tubular columns under horizontal impact[J]. Thin-Walled Structures, 2020, 155: 106941. [107] 谭力豪. FRP螺旋条带部分包裹混凝土柱轴压力学性能试验研究[D]. 广州: 广东工业大学, 2020.TAN Lihao. Experimental study on the axial compressive performance of partially wrapped concrete columns with FRP spiral strips[D]. Guangzhou: Guangdong University of Technology, 2020(in Chinese). [108] 翟可仪. GFRP筋与超高性能混凝土(UHPC)粘结性能研究[D]. 广州: 广东工业大学, 2022.ZHAI Keyi. Study on the bonding performance between GFRP reinforcement and ultra high performance concrete (UHPC)[D]. Guangzhou: Guangdong University of Technology, 2022(in Chinese). [109] 吴镇铎. FRP筋增强ECC桥面连接板工作机制及受力特性研究[D]. 广州: 华南理工大学, 2020.WU Zhenduo. Research on the working mechanism and stress characteristics of FRP reinforced ECC bridge deck connection plates[D]. Guangzhou: South China University of Technology, 2020(in Chinese). [110] 史健喆. 海洋环境下BFRP筋体外预应力加固钢筋混凝土梁长期性能研究[D]. 南京: 东南大学, 2020.SHI Jianzhe. Long term performance study of reinforced concrete beams strengthened with BFRP tendons externally prestressed in marine environments[D]. Nanjing: Southeast University, 2020(in Chinese). [111] LIU B, JIANG H, HUANG Y, et al. Atomic-scale finite element method in multiscale compotation with applications to carbon nanotubes[J]. Physical Review B, 2005, 72(3): 035435 doi: 10.1103/PhysRevB.72.035435 [112] 李军平, 刘宝瑞, 童军, 等. 纤维增强复合材料递阶多尺度分析方法综述[C]//北京力学会第二十八届学术年会论文集(上). 北京: 北京力学会, 2022: 7.LI Junping, LIU Baorui, TONG Jun, et al. Summary of hierarchical multiscale analysis methods for fiber-reinforced composite materials[C]//Proceedings of the 28th Academic Annual Meeting of the Beijing Society of Mechanics (Part 1). Beijing: Beijing Society of Mechanics, 2022: 7(in Chinese). [113] 彭哲琦. 大跨结构用FRP拉索多尺度精细化性能预测及结构分析[D]. 南京: 东南大学, 2021.PENG Zheqi. Multi scale refined performance prediction and structural analysis of FRP cables for large-span structures[D]. Nanjing: Southeast University, 2021(in Chinese). [114] 欧云福. 玄武岩纤维增强复合材料的多尺度力学性能研究[D]. 长沙: 湖南大学, 2017.OU Yunfu. Study on multiscale mechanical properties of basalt fiber reinforced composite materials[D]. Changsha: Hunan University, 2017(in Chinese). [115] 张如灏. 考虑初始缺陷的三维玄武岩纤维复合材料多尺度渐进损伤分析[D]. 长春: 吉林大学, 2023.ZHANG Ruhao. Multiscale progressive damage analysis of three-dimensional basalt fiber composite materials considering initial defects[D]. Changchun: Jilin University, 2023(in Chinese). -

下载:

下载: