Research progress on thermally conductive polymer matrix composites reinforced by three-dimensional network fillers

-

摘要: 聚合物在超导技术、航天航空、电子电路、动力电池、换热器等领域的应用十分广泛。随着器件的小型化、密集化和高功率,对于整体的散热要求越来越高,但是聚合物作为器件和设备粘接、封装等工艺的关键材料,热导率仅为0.2 W/(m∙K),完全不能满足目前的散热需求,因此亟需提升聚合物的导热性能。由于在聚合物基体中构建连续的导热路径能极大提高聚合物的导热系数,往往能提高数倍或数十倍,因此采用三维网络填料增强聚合物导热性能是最为常用的一种方法之一。本文主要对用构建三维网络填料来增强高分子材料的导热性能的相关研究进行了整理,以制备方式的不同,将其归类为自组装法、相分离法、模板法、取向分布法等方法。最后,从制备方法的热导率提高值、可行性、稳定性等方面进行了总结分析,并对三维网络填料增强的聚合物基导热复合材料的未来发展前景进行了展望。Abstract: Polymer materials find wide applications in various fields such as superconducting technology, aerospace, electronic circuits, power batteries, heat exchangers, among others. With the increasing demands for miniaturization, densification, and high power of devices, the overall heat dissipation requirements have escalated. However, polymers, serving as crucial materials in device encapsulation and bonding processes, exhibit a low thermal conductivity of only 0.2 W/(m∙K), which falls significantly short of current heat dissipation needs. Therefore, there is an urgent need to enhance the thermal conductivity of polymers. Constructing continuous thermal pathways within the polymer matrix has been shown to significantly improve the thermal conductivity, often increasing it several times or even tens of times. Hence, utilizing three-dimensional network fillers to reinforce the thermal conductivity of polymers stands out as one of the most commonly employed methods. Accordingly, this paper organizes relevant studies on enhancing the thermal conductivity of polymeric materials through the construction of three-dimensional network fillers. Based on different preparation methods, these are categorized into self-assembly, phase-separation, template-methods, oriented-distribution methods, among others. Finally, a summary analysis is provided from aspects such as the increase in thermal conductivity values due to preparation methods, feasibility, stability, and prospects for the future development of polymer-based thermally conductive composites reinforced by three-dimensional network fillers.

-

Key words:

- thermal conductivity /

- composites /

- polymer /

- 3-dimensional reinforcement /

- inorganic filler

-

Material Thermal conductivity/

(W·(m∙K)−1)Low-density polyethylene (LDPE) 0.33 Polypropylene (PP) 0.14 Polystyrene (PS) 0.04-0.14 Polyethylene terephthalate (PET) 0.29 Polymethyl methacrylate (PMMA) 0.15-0.25 Polytetrafluoroethylene (PTFE) 0.25 Polyvinyl chloride (PVC) 0.12-0.17 Polyetheretherketone (PEEK) 0.25 Polycarbonate (PC) 0.19 Polybutylene terephthalate (PBT) 0.25 Polysulfone (PSU) 0.22 Polyvinylidene difluoride (PVDF) 0.19 Thermoplastic polyimide (TPI) 0.1 Epoxy (EP) 0.17-0.21 Nylon 6, 6 0.25 Urethane base thermoplastic elastomer (TPU) 0.19 Poly(dimethylsiloxane) (PDMS) 0.25 表 2 室温下部分金属与碳纳米管、碳纤维、石墨、石墨烯的导热系数[10, 16-17, 36, 44-46]

Table 2. Thermal conductivity of some metals and carbon nanotubes, carbon fiber, graphite, and graphene at room temperature[10, 16-17, 36, 44-46]

Material Thermal conductivity/(W·(m∙K)−1)) Gold 345 Silver 450 Copper 483 Nickle 158 Aluminum 204 Tungsten 142 Carbon nanotubes 1000-4000 Carbon fibers 300-1000 Graphene 2000-6000 Graphite 100-400 表 3 常温下部分导热填料的导热系数[10, 16-17, 36, 44-46]

Table 3. Thermal conductivities of some thermally conductive fillers at room temperature[10, 16-17, 36, 44-46]

Material Thermal conductivity/

(W·(m∙K)−1)Silicon nitride (Si3N4) 103-200 Boron nitride (BN) 29-300 Hexagonal boron nitride (hBN) 185-300 Aluminum nitride (AlN) 100-300 Silicon carbide (SiC) 120-611 Alumina (Al2O3) 20-29 Zinc oxide (ZnO) 60 Beryllium oxide (BeO) 260 Magnesium oxide (MgO) 25-30 Diamond 2000 表 4 不同方法所制备的导热填料三维网络增强聚合物基复合材料汇总表

Table 4. Summary of three-dimensional network reinforced polymer matrix composites prepared by different methods

Preparation method Filler Matrix Filling rate Thermal conductivity/

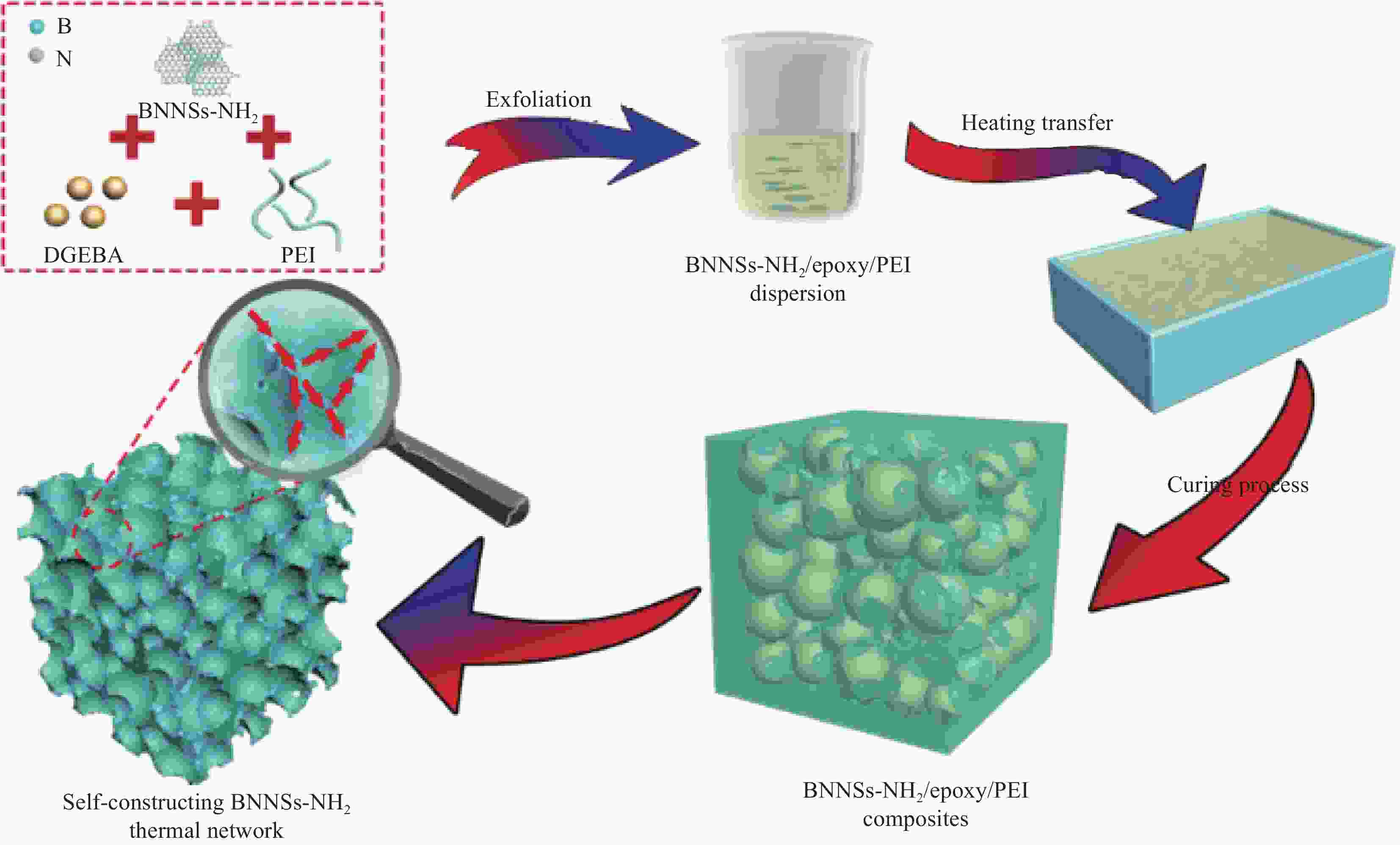

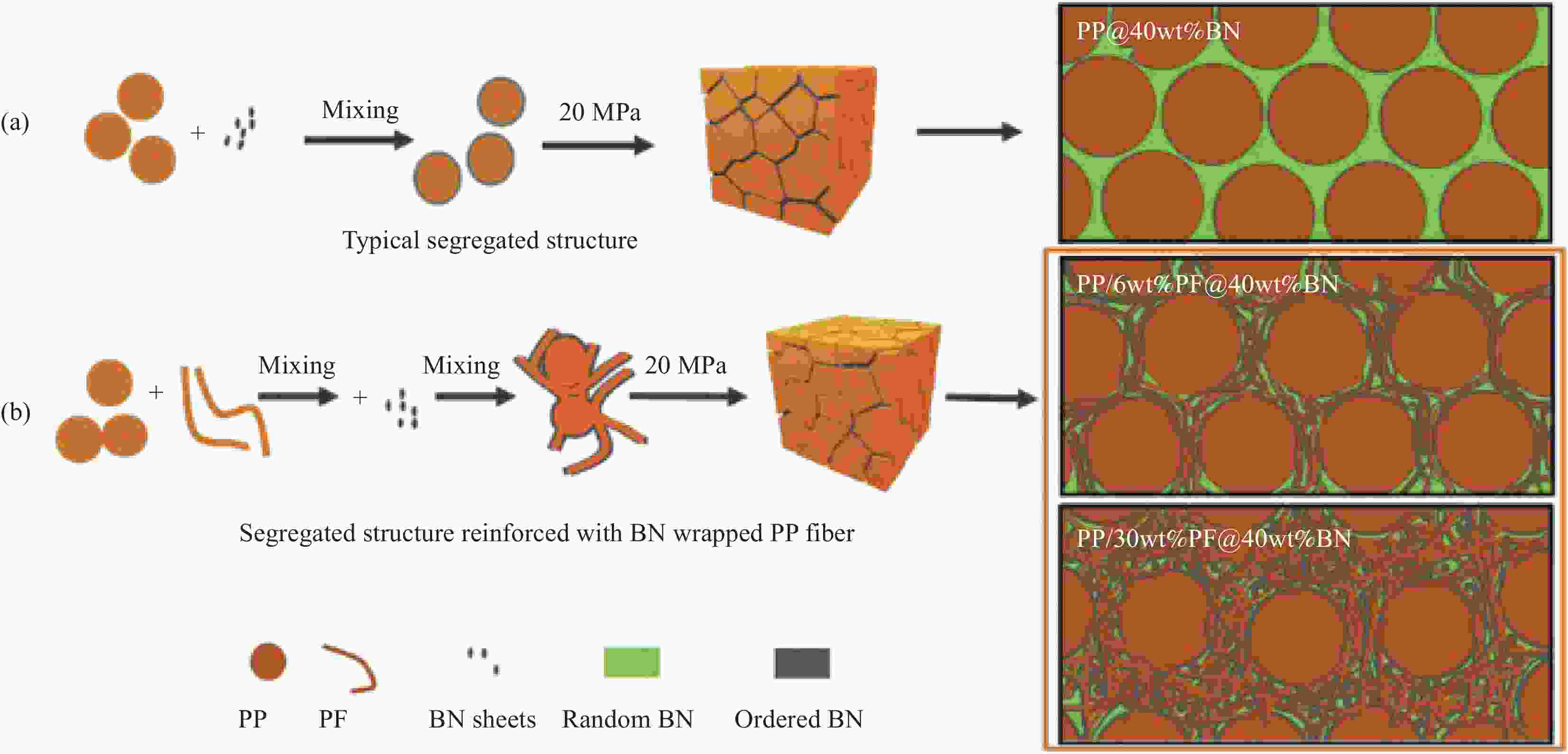

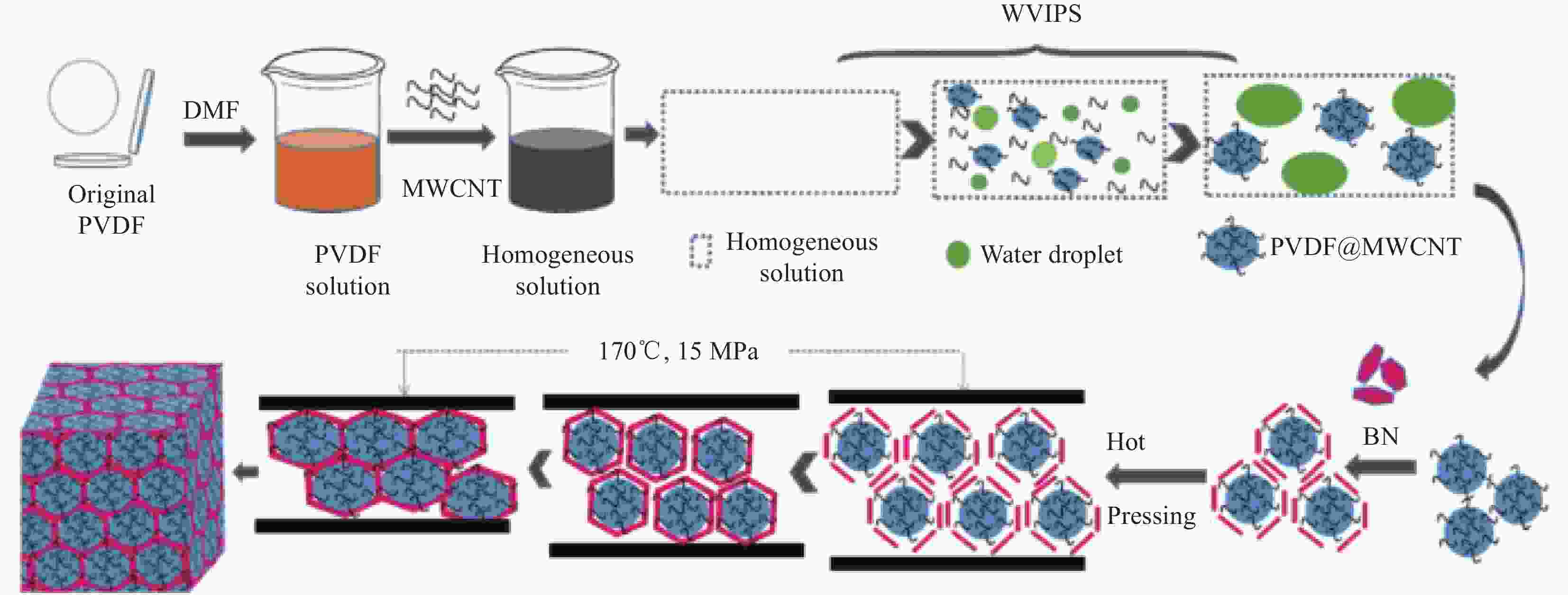

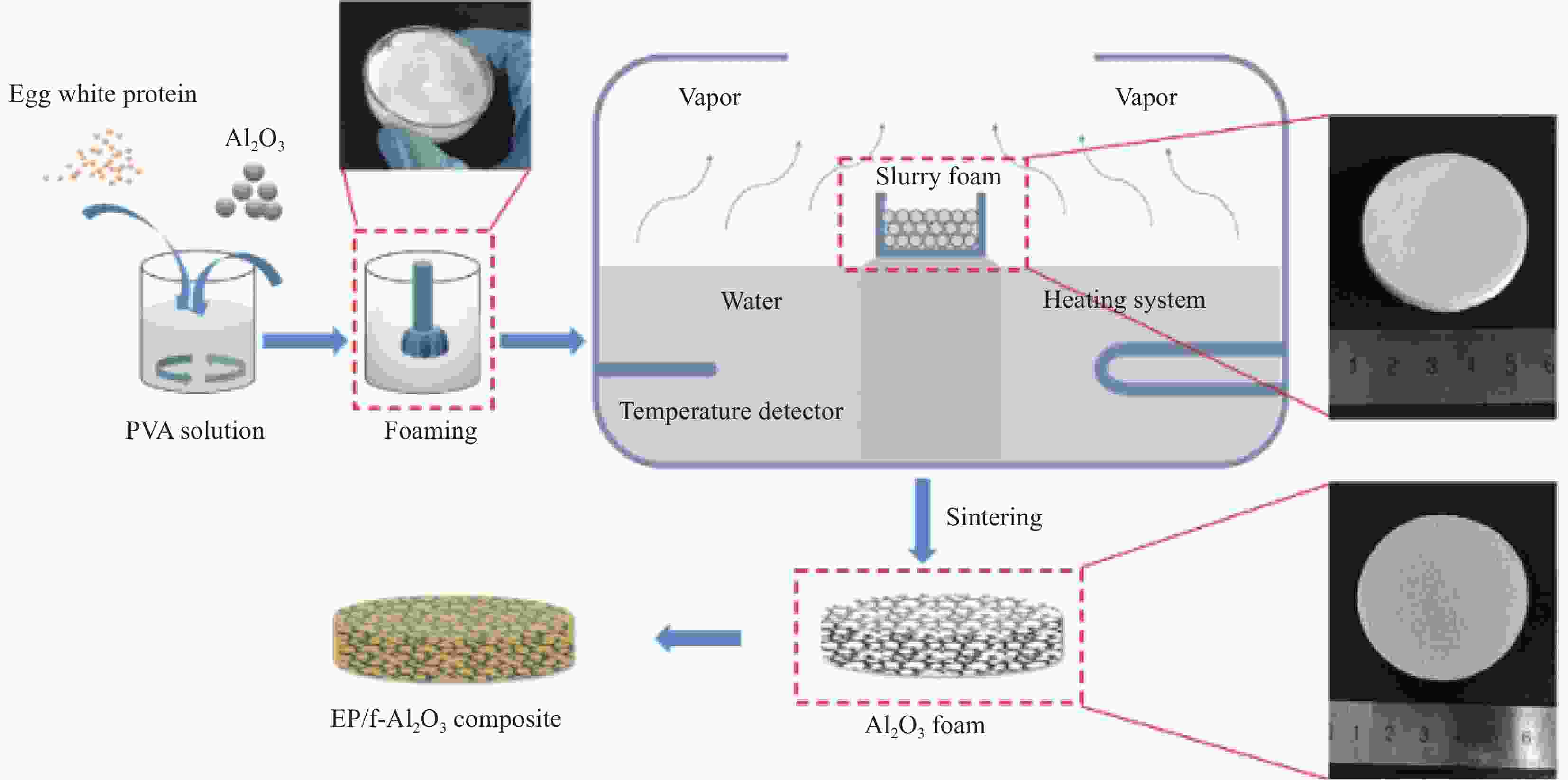

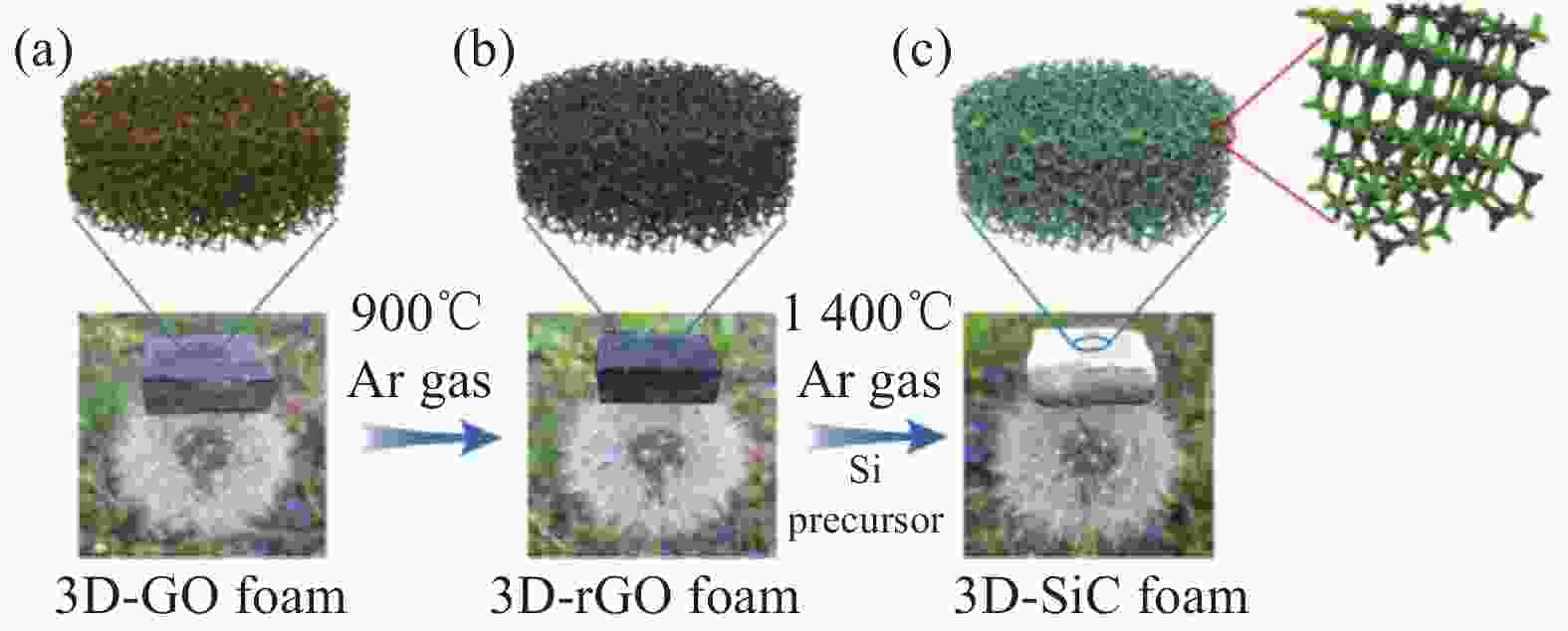

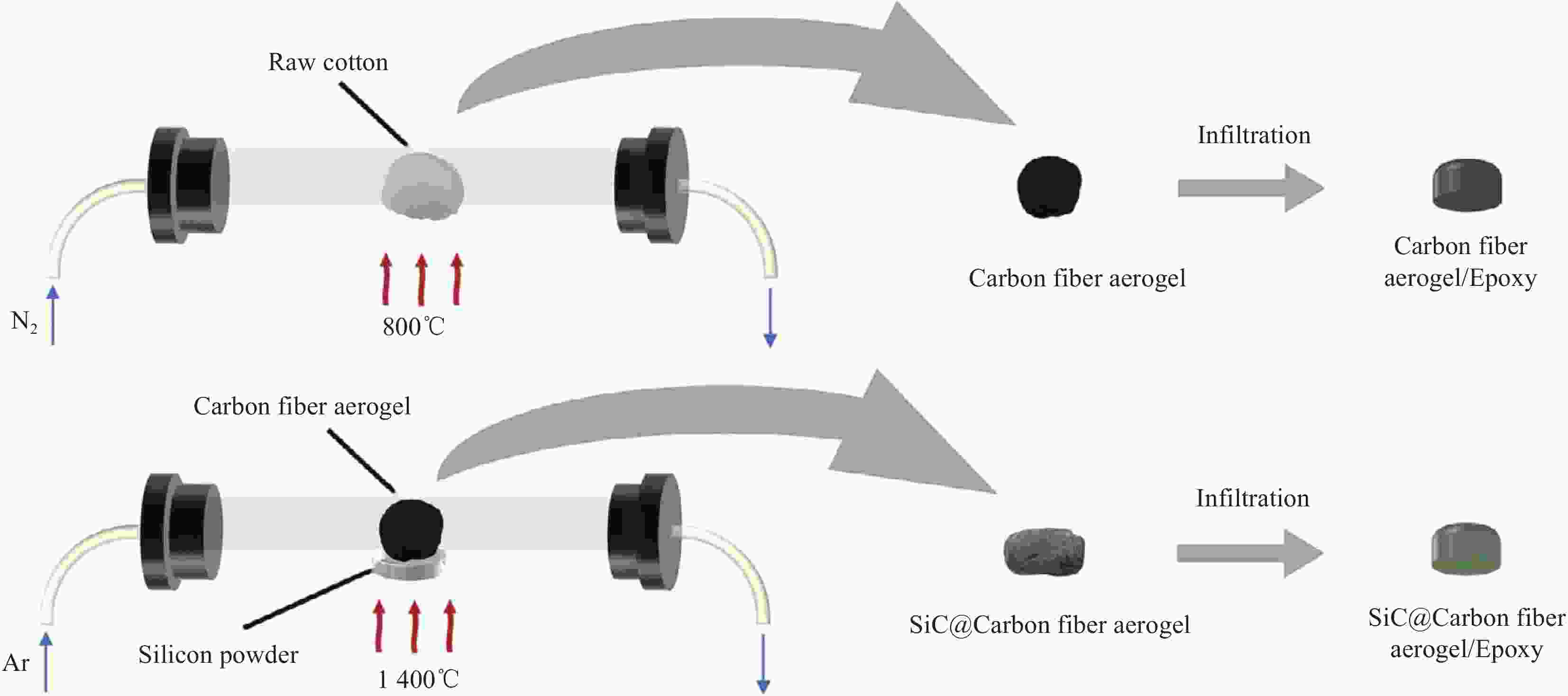

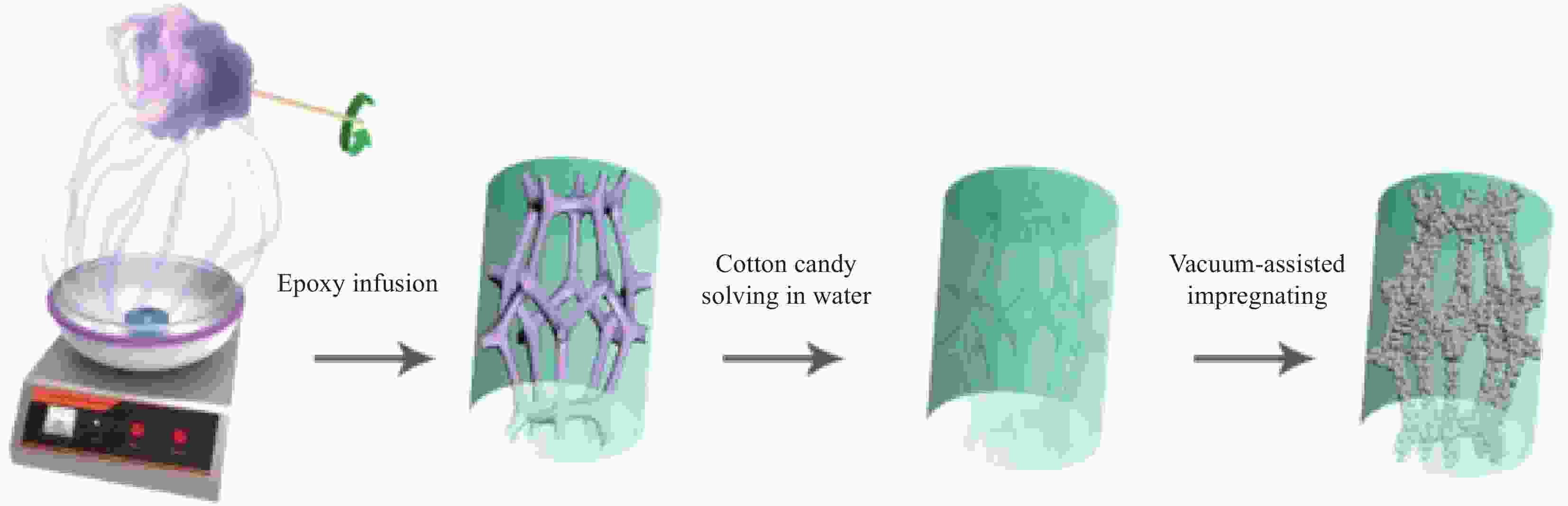

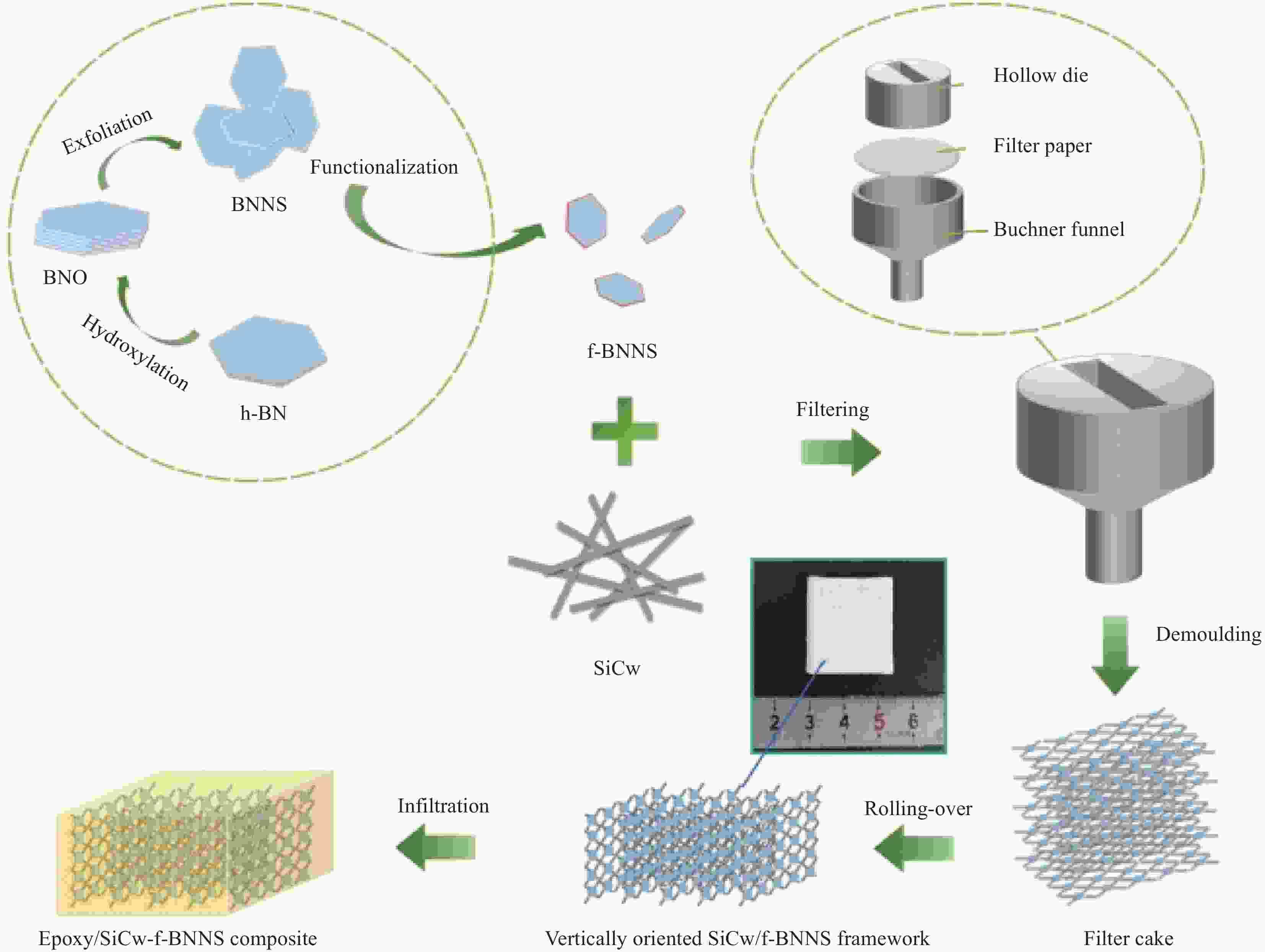

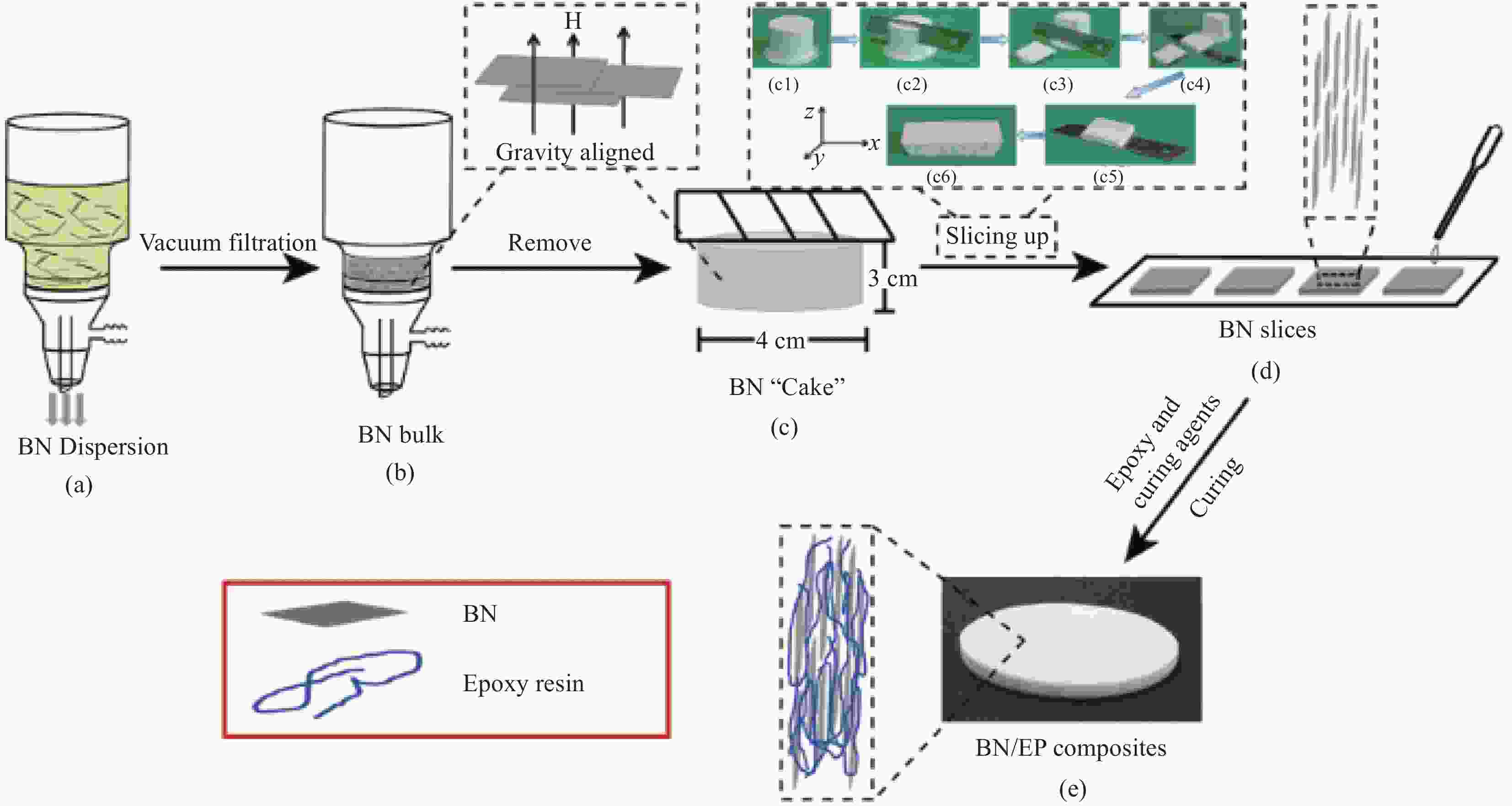

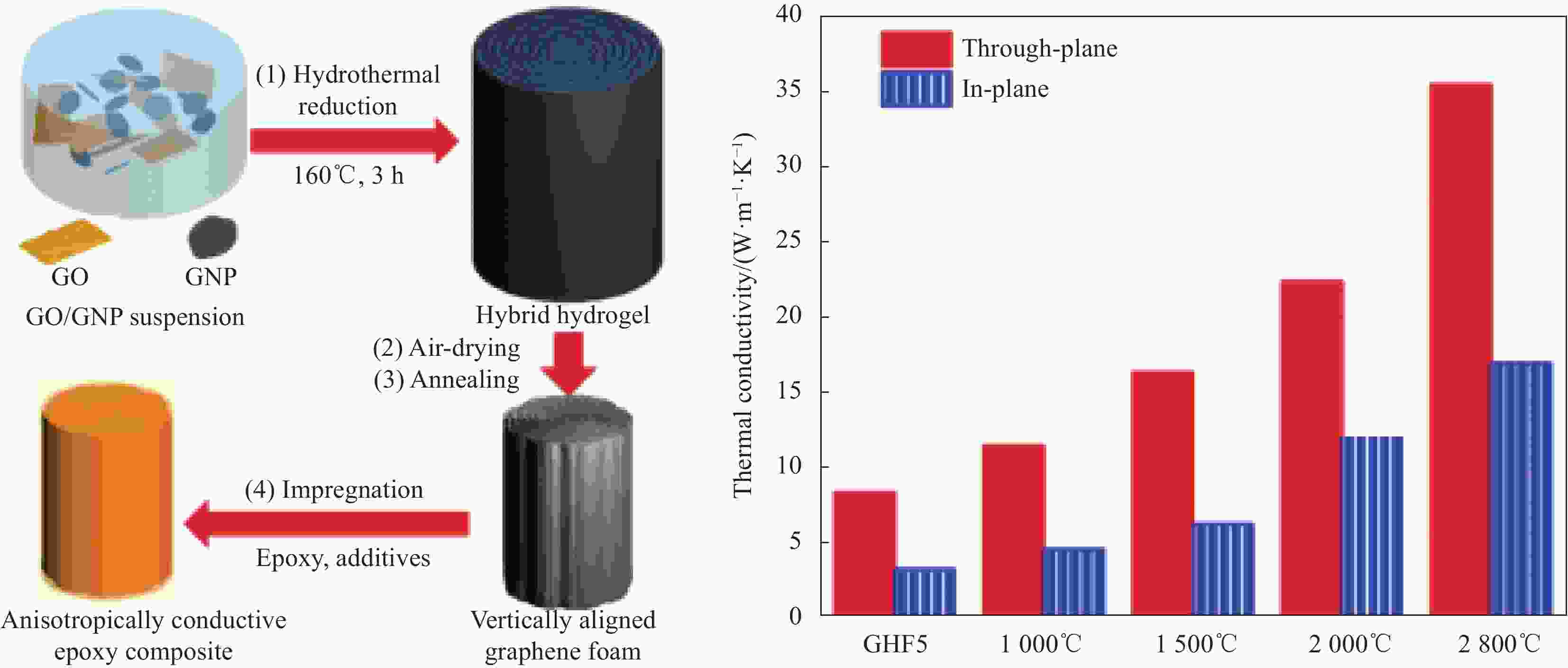

(W∙(m∙K)−1)Notes Self-assembly method Graphene[82] Epoxy 19wt% 35.5 Thermal reduction Graphene/SiC nanowires[83] Epoxy 0.092vol% 0.64 Phase-separation method Graphene[86] Epoxy/PES 10wt% 0.71 Reaction induced phase separation hBN[87] Epoxy/PES 10wt% 0.52 BNNS-NH2[88] Epoxy/PEI 1wt% 0.37 hBN[89] PP/PS 50wt% 5.57 Hot pressing Template method BNNS[92] Epoxy 9.29vol% 2.85 Ice-template hBN[94] PVDF 21wt% 1.23 Salt-template Hollow BN microbeads[95] Epoxy 65.6vol% 17.61 Al2O3[99] Epoxy 23.32vol% 2.58 Foam-template BNNS/melamine[100] Epoxy 1.1vol% 0.6 Graphene[102] Epoxy 0.14vol% 0.52 SiC nanowires[103] Epoxy 3.91vol% 0.43 Polymer removal Al2O3/T-ZnOw[104] Epoxy 17.7vol% 1.97 C felt/Cu[105] Epoxy 29.34vol% 30.69 Template conversion SiC[106] Epoxy 6.52vol% 10.26 Cotton candy/Al2O3[109] Epoxy 36.20vol% 3.17 Orientation-distribution method SiC nanowires/f-BNNS[110] Epoxy 21.9vol% 4.22 Vacuum filtration BNMS[111] Epoxy 44vol% 9 BNNS[58] Epoxy 15vol% 6.07 Bidirectional freezing Notes: PES—Polyethersulfone; BNMS— -

[1] 孙颖颖. 高分子复合材料导热性能的调控机制研究[D]. 北京: 华北电力大学, 2018.SUN Yingying. Study on the regulatory mechanism of thermal conductivity of polymer composites[D]. Beijing: North China Electric Power University, 2018(in Chinese). [2] 曾小亮. 功能化有机基板材料的制备、结构表征及其性能研究[D]. 北京: 中国科学院大学, 2017.ZENG Xiaoliang. Preparation, structural characterization and properties of functionalized organic substrates[D]. Beijing: University of Chinese Academy of Sciences, 2017(in Chinese). [3] 虞锦洪. 高导热聚合物复合材料的制备与性能研究[D]. 上海: 上海交通大学, 2012.YU Jinhong. Preparation and properties of polymer composites with high thermal conductivity[D]. Shanghai: Shanghai Jiao Tong University, 2012(in Chinese). [4] T'JOEN C, PARK Y, WANG Q, et al. A review on polymer heat exchangers for HVAC&R applications[J]. International Journal of Refrigeration, 2009, 32(5): 763-779. [5] 周文英, 丁小卫. 导热高分子材料[M]. 北京: 国防工业出版社, 2014.ZHOU Wenying, DING Xiaowei. Heat conducting polymer material[M]. Beijing: National Defense Industry Press, 2014(in Chinese). [6] 仝兴存. 电子封装先进热管理材料[M]. 安兵, 吕卫平, 吴懿平, 译. 北京: 国防工业出版社, 2016.TONG Xing. Advanced thermal management materials for electronic packaging[M]. Translated by AN Bing, LU Weiping, WU Yiping. Beijing: National Defense Industry Press, 2016(in Chinese). [7] HUANG X Y, JIANG P K, TANAKA T. A review of dielectric polymer composites with high thermal conductivity[J]. IEEE Electrical Insulation Magazine, 2011, 27(4): 8-16. doi: 10.1109/MEI.2011.5954064 [8] VADIVELU M A, KUMAR C R, JOSHI G M. Polymer composites for thermal management: A review[J]. Composite Interfaces, 2016, 23(9): 847-872. [9] BURGER N, LAACHACHI A, FERRIOL M, et al. Review of thermal conductivity in composites: Mechanisms, parameters and theory[J]. Progress in Polymer Science, 2016, 61: 1-28. [10] CHEN H Y, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science, 2016, 59: 41-85. doi: 10.1016/j.progpolymsci.2016.03.001 [11] RAZEEB K M, DALTON E, CROSS G L W, et al. Present and future thermal interface materials for electronic devices[J]. International Materials Reviews, 2017, 63(1): 1-21. [12] WU S F, YAN T, KUAI Z H, et al. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review[J]. Energy Storage Materials, 2020, 25: 251-295. doi: 10.1016/j.ensm.2019.10.010 [13] HE R, SCHIERNING G, NIELSCH K. Thermoelectric devices: A review of devices, architectures, and contact optimization[J]. Advanced Materials Technologies, 2018, 3(4): 1700256. doi: 10.1002/admt.201700256 [14] ZHI C Y, BANDO Y, TERAO T, et al. Towards thermoconductive, electrically insulating polymeric composites with boron nitride nanotubes as fillers[J]. Advanced Functional Materials, 2009, 19(12): 1857-1862. doi: 10.1002/adfm.200801435 [15] ZHANG T, WU X F, LUO T F. Polymer nanofibers with outstanding thermal conductivity and thermal stability: Fundamental linkage between molecular characteristics and macroscopic thermal properties[J]. The Journal of Physical Chemistry C, 2014, 118(36): 21148-21159. doi: 10.1021/jp5051639 [16] EBADI-DEHAGHANI H, NAZEMPOUR M. Thermal conductivity of nanoparticles filled polymers[M]//HASHIM A. Smart Nanoparticles Technology. Rijeka: In Tech, 2012: 519-540. [17] HAN Z D, FINA A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review[J]. Progress in Polymer Science, 2011, 36(7): 914-944. doi: 10.1016/j.progpolymsci.2010.11.004 [18] KIM G H, LEE D, SHANKER A, et al. High thermal conductivity in amorphous polymer blends by engineered interchain interactions[J]. Nature Materials, 2015, 14(3): 295-300. doi: 10.1038/nmat4141 [19] HENRY A, CHEN G. High thermal conductivity of single polyethylene chains using molecular dynamics simulations[J]. Physical Review Letters, 2008, 101(23): 235502. doi: 10.1103/PhysRevLett.101.235502 [20] LIU J, YANG R G. Length-dependent thermal conductivity of single extended polymer chains[J]. Physical Review B, 2012, 86(10): 104307. doi: 10.1103/PhysRevB.86.104307 [21] JEONG I, KIM C B, KANG D G, et al. Liquid crystalline epoxy resin with improved thermal conductivity by intermolecular dipole-dipole interactions[J]. Journal of Polymer Science, Part A: Polymer Chemistry, 2019, 57(6): 708-715. [22] KIM K, YOO M, AHN K, et al. Thermal and mechanical properties of AlN/BN-filled PVDF composite for solar cell backsheet application[J]. Ceramics International, 2015, 41(1): 179-187. doi: 10.1016/j.ceramint.2014.08.056 [23] ZHANG X, ZHANG J, XIA L, et al. Simple and consecutive melt extrusion method to fabricate thermally conductive composites with highly oriented boron nitrides[J]. ACS Applied Materials & Interfaces, 2017, 9(27): 22977-22984. [24] SONG W L, WANG P, CAO L, et al. Polymer/boron nitride nanocomposite materials for superior thermal transport performance[J]. Angewandte Chemie-International Edition, 2012, 51(26): 6498-6501. [25] YANG J, TANG L S, BAO R Y, et al. An ice-templated assembly strategy to construct graphene oxide/boron nitride hybrid porous scaffolds in phase change materials with enhanced thermal conductivity and shape stability for light-thermal-electric energy conversion[J]. Journal of Materials Chemistry A, 2016, 4(48): 18841-18851. doi: 10.1039/C6TA08454K [26] CHEN J, HUANG X, SUN B, et al. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability[J]. ACS Nano, 2019, 13(1): 337-345. [27] WANG R, CHENG H, GONG Y, et al. Highly thermally conductive polymer composite originated from assembly of boron nitride at an oil-water interface[J]. ACS Applied Materials & Interfaces, 2019, 11(45): 42818-42826. [28] VU M C, CHOI W K, LEE S G, et al. High thermal conductivity enhancement of polymer composites with vertically aligned silicon carbide sheet scaffolds[J]. ACS Applied Materials & Interfaces, 2020, 12(20): 23388-23398. [29] VOLKOV A N, ZHIGILEI L V. Heat conduction in carbon nanotube materials: Strong effect of intrinsic thermal conductivity of carbon nanotubes[J]. Applied Physics Letters, 2012, 101(4): 043113. doi: 10.1063/1.4737903 [30] HE J, WANG H, SU Z, et al. Designing poly(vinylidene fluoride)-silicon carbide nanowire composite structures to achieve high thermal conductivity[J]. ACS Applied Polymer Materials, 2019, 1(11): 2807-2818. doi: 10.1021/acsapm.9b00218 [31] CHEN J, HUANG X Y, ZHU Y K, et al. Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability[J]. Advanced Functional Materials, 2017, 27(5): 1604754. doi: 10.1002/adfm.201604754 [32] LI A, ZHANG C, ZHANG Y F. Thermal conductivity of graphene-polymer composites: Mechanisms, properties, and applications[J]. Polymers, 2017, 9(12): 437. [33] CHEN J, HUANG X, SUN B, et al. Vertically aligned and interconnected boron nitride nanosheets for advanced flexible nanocomposite thermal interface materials[J]. ACS Applied Materials & Interfaces, 2017, 9(36): 30909-30917. [34] HUANG X Y, IIZUKA T, JIANG P K, et al. Role of interface on the thermal conductivity of highly filled dielectric epoxy/AlN composites[J]. The Journal of Physical Chemistry C, 2012, 116(25): 13629-13639. doi: 10.1021/jp3026545 [35] UETANI K, HATORI K. Thermal conductivity analysis and applications of nanocellulose materials[J]. Science and Technology of Advanced Materials, 2017, 18(1): 877-892. doi: 10.1080/14686996.2017.1390692 [36] KAUSAR A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review[J]. Polymer-Plastics Technology and Materials, 2020, 59(8): 895-909. doi: 10.1080/25740881.2019.1708103 [37] BIGG D M. Thermally conductive polymer compositions[J]. Polymer Composites, 1986, 7(3): 125-140. doi: 10.1002/pc.750070302 [38] TAVMAN I H. Thermal and mechanical properties of aluminum powder filled high-density polyethylene composites[J]. Journal of Applied Polymer Science, 1996, 62(12): 2161-2167. doi: 10.1002/(SICI)1097-4628(19961219)62:12<2161::AID-APP19>3.0.CO;2-8 [39] MAMUNYA Y P, DAVYDENKO V V, PISSIS P, et al. Electrical and thermal conductivity of polymers filled with metal powders[J]. European Polymer Journal, 2002, 38(9): 1887-1897. [40] SIDHU S S, KUMAR S, BATISH A. Metal matrix composites for thermal management: A review[J]. Critical Reviews in Solid State & Materials Sciences, 2015, 41(2): 132-157. [41] CONRADO F, PAVESE M. A continuous 3D-graphene network to overcome threshold issues and contact resistance in thermally conductive graphene nanocomposites[J]. Journal of Nanomaterials, 2017, 2017: 8974174. doi: 10.1155/2017/8974174 [42] SONG W L, WANG W, VECA L M, et al. Polymer/carbon nanocomposites for enhanced thermal transport properties-carbon nanotubes versus graphene sheets as nanoscale fillers[J]. Journal of Materials Chemistry, 2012, 22(33): 17133-17139. doi: 10.1039/c2jm32469e [43] NAN C W, LIU G, LIN Y H, et al. Interface effect on thermal conductivity of carbon nanotube composites[J]. Applied Physics Letters, 2004, 85(16): 3549-3551. doi: 10.1063/1.1808874 [44] SINGH A K, PANDA B P, MOHANTY S, et al. Recent developments on epoxy-based thermally conductive adhesives (TCA): A review[J]. Polymer-Plastics Technology and Engineering, 2017, 57(9): 903-934. [45] HANSSON J, NILSSON T M J, YE L L, et al. Novel nanostructured thermal interface materials: A review[J]. International Materials Reviews, 2017, 63(1): 22-45. [46] CHUNG D D L. Materials for thermal conduction[J]. Applied Thermal Engineering, 2001, 21(16): 1593-1605. doi: 10.1016/S1359-4311(01)00042-4 [47] OHASHI M, KAWAKAMI S, YOKOGAWA Y, et al. Spherical aluminum nitride fillers for heat-conducting plastic packages[J]. Journal of the American Ceramic Society, 2005, 88(9): 2615-2618. doi: 10.1111/j.1551-2916.2005.00456.x [48] YU S Z, HING P, HU X. Thermal conductivity of polystyrene-aluminum nitride composite[J]. Composites Part A: Applied Science and Manufacturing, 2002, 33(2): 289-292. [49] TIAN X, PAN T, DENG B, et al. Synthesis of sandwich-like nanostructure fillers and their use in different types of thermal composites[J]. ACS Applied Materials & Interfaces, 2019, 11(43): 40694-40703. [50] ZHANG C, HUANG R, WANG Y, et al. Self-assembled boron nitride nanotube reinforced graphene oxide aerogels for dielectric nanocomposites with high thermal management capability[J]. ACS Applied Materials & Interfaces, 2020, 12(1): 1436-1443. [51] ZHANG Y, ZHANG T D, LIU L Z, et al. Sandwich-structured PVDF-based composite incorporated with hybrid Fe3O4@BN nanosheets for excellent dielectric properties and energy storage performance[J]. The Journal of Physical Chemistry C, 2018, 122(3): 1500-1512. doi: 10.1021/acs.jpcc.7b10838 [52] HU J, HUANG Y, YAO Y, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN[J]. ACS Applied Materials & Interfaces, 2017, 9(15): 13544-13553. [53] ZHANG H, HUANG R, LI Y, et al. Optimization of boron nitride sphere loading in epoxy: Enhanced thermal conductivity and excellent electrical insulation[J]. Polymers (Basel), 2019, 11(8): 1335. [54] DU C, LI M, CAO M, et al. Mussel-inspired and magnetic co-functionalization of hexagonal boron nitride in poly(vinylidene fluoride) composites toward enhanced thermal and mechanical performance for heat exchangers[J]. ACS Applied Materials & Interfaces, 2018, 10(40): 34674-34682. [55] CHEN J, WEI H, BAO H, et al. Millefeuille-inspired thermally conductive polymer nanocomposites with overlapping BN nanosheets for thermal management applications[J]. ACS Applied Materials & Interfaces, 2019, 11(34): 31402-31410. [56] ZHANG X L, SHEN L Y, WU H, et al. Enhanced thermally conductivity and mechanical properties of polyethylene (PE)/boron nitride (BN) composites through multistage stretching extrusion[J]. Composites Science and Technology, 2013, 89: 24-28. doi: 10.1016/j.compscitech.2013.09.017 [57] HU Z R, WANG S, LIU Y C, et al. Constructing a layer-by-layer architecture to prepare a transparent, strong, and thermally conductive boron nitride nanosheet/cellulose nanofiber multilayer film[J]. Industrial & Engineering Chemistry Research, 2020, 59(10): 4437-4446. [58] HAN J K, DU G L, GAO W W, et al. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network[J]. Advanced Functional Materials, 2019, 29(13): 1900412. doi: 10.1002/adfm.201900412 [59] ZHANG C, HUANG R J, WANG Y G, et al. Aminopropyltrimethoxysilane-functionalized boron nitride nanotube based epoxy nanocomposites with simultaneous high thermal conductivity and excellent electrical insulation[J]. Journal of Materials Chemistry A, 2018, 6(42): 20663-20668. doi: 10.1039/C8TA07435F [60] WU K, FANG J, MA J, et al. Achieving a collapsible, strong, and highly thermally conductive film based on oriented functionalized boron nitride nanosheets and cellulose nanofiber[J]. ACS Applied Materials & Interfaces, 2017, 9(35): 30035-30045. [61] HE D, WANG Y, SONG S, et al. Significantly enhanced dielectric performances and high thermal conductivity in poly(vinylidene fluoride)-based composites enabled by SiC@SiO2 core-shell whiskers alignment[J]. ACS Applied Materials & Interfaces, 2017, 9(51): 44839-44846. [62] FENG Y Z, HU J, XUE Y, et al. Simultaneous improvement in the flame resistance and thermal conductivity of epoxy/Al2O3 composites by incorporating polymeric flame retardant-functionalized graphene[J]. Journal of Materials Chemistry A, 2017, 5(26): 13544-13556. doi: 10.1039/C7TA02934A [63] EVERY A G, TZOU Y, HASSELMAN D P H, et al. The effect of particle size on the thermal conductivity of ZnS/diamond composites[J]. Acta Metallurgica et Materialia, 1992, 40(1): 123-129. [64] ROY A K, FARMER B L, VARSHNEY V, et al. Importance of interfaces in governing thermal transport in composite materials: Modeling and experimental perspectives[J]. ACS Applied Materials & Interfacess, 2012, 4(2): 545-563. [65] YANG J K, YANG Y, WALTERMIRE S W, et al. Enhanced and switchable nanoscale thermal conduction due to van der Waals interfaces[J]. Nature Nanotechnology, 2012, 7(2): 91-95. doi: 10.1038/nnano.2011.216 [66] 张驰. 高导热环氧树脂复合材料的设计、制备及性能调控[D]. 北京: 中国科学院大学, 2021.ZHANG Chi. Design, preparation and property control of epoxy resin composites with high thermal conductivity[D]. Beijing: University of Chinese Academy of Sciences, 2021(in Chinese). [67] KIRKPATRICK S. Percolation and conduction[J]. Reviews of Modern Physics, 1973, 45: 574-588. doi: 10.1103/RevModPhys.45.574 [68] NAN C W. Physics of inhomogeneous inorganic materials[J]. Progress in Materials Science, 1993, 37(1): 1-116. doi: 10.1016/0079-6425(93)90004-5 [69] SHANTE V K S, KIRKPATRICK S. An introduction to percolation theory[J]. Advances in Physics, 1971, 20(85): 325-357. [70] WARZOHA R J, FLEISCHER A S. Heat flow at nanoparticle interfaces[J]. Nano Energy, 2014, 6: 137-158. doi: 10.1016/j.nanoen.2014.03.014 [71] NAN C W, BIRRINGER R, CLARKE D R, et al. Effective thermal conductivity of particulate composites with interfacial thermal resistance[J]. Journal of Applied Physics, 1997, 81(10): 6692-6699. [72] KAPITZA P L. The study of heat transfer in helium ii[J]. Journal of Physics-USSR, 1941, 4(181): 114-153. [73] YU J H, HUANG X Y, WU C, et al. Interfacial modification of boron nitride nanoplatelets for epoxy composites with improved thermal properties[J]. Polymer, 2012, 53(2): 471-480. doi: 10.1016/j.polymer.2011.12.040 [74] AGAR Y, UNO T. Thermal conductivity of polymer filled with carbon materials: Effect of conductive particle chains on thermal conductivity[J]. Journal of Applied Polymer Science, 1985, 30(5): 2225-2235. [75] MAI V D, LEE D I, PARK J H, et al. Rheological properties and thermal conductivity of epoxy resins filled with a mixture of alumina and boron nitride[J]. Polymers (Basel), 2019, 11(4): 597. [76] WANG Z D, CHENG Y H, WANG H K, et al. Sandwiched epoxy-alumina composites with synergistically enhanced thermal conductivity and breakdown strength[J]. Journal of Materials Science, 2017, 52(8): 4299-4308. doi: 10.1007/s10853-016-0511-6 [77] LEUNG S N, KHAN M O, CHAN E, et al. Synergistic effects of hybrid fillers on the development of thermally conductive polyphenylene sulfide composites[J]. Journal of Applied Polymer Science, 2013, 127(5): 3293-3301. doi: 10.1002/app.37941 [78] JI C, YAN C Z, WANG Y, et al. Thermal conductivity enhancement of CNT/MoS2/graphene-epoxy nanocomposites based on structural synergistic effects and interpenetrating network[J]. Composites Part B: Engineering, 2019, 163: 363-370. doi: 10.1016/j.compositesb.2018.11.005 [79] XIAO Y J, WANG W Y, LIN T, et al. Largely enhanced thermal conductivity and high dielectric constant of poly(vinylidene fluoride)/boron nitride composites achieved by adding a few carbon nanotubes[J]. The Journal of Physical Chemistry C, 2016, 120(12): 6344-6355. doi: 10.1021/acs.jpcc.5b12651 [80] 苏政. 取向结构聚合物基导热材料的设计、制备与性能研究[D]. 合肥: 中国科技大学, 2019.SU Zheng. Design, preparation and properties of oriented polymer based thermal conductivity materials[D]. Hefei: University of Science and Technology of China, 2019(in Chinese). [81] 肖超. 三维导热网络的构筑及其环氧树脂复合材料性能研究 [D]. 合肥: 中国科技大学, 2020.XIAO Chao. Construction of three-dimensional thermal conductivity network and study on properties of epoxy resin composites[D]. Hefei: University of Science and Technology of China, 2020(in Chinese). [82] AN F, LI X, MIN P, et al. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities[J]. ACS Applied Materials & Interfaces, 2018, 10(20): 17383-17392. [83] HE J, WANG H, SU Z, et al. Thermal conductivity and electrical insulation of epoxy composites with graphene-SiC nanowires and BaTiO3[J]. Composites Part A: Applied Science and Manufacturing, 2019, 117: 287-298. doi: 10.1016/j.compositesa.2018.10.031 [84] ZHANG F, FENG Y Y, QIN M M, et al. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite[J]. Advanced Functional Materials, 2019, 29(25): 1901383. doi: 10.1002/adfm.201901383 [85] ZHAO X T, WU W, DRUMMER D, et al. SiC nanowires bridged graphene aerogels with a vertically aligned structure for highly thermal conductive epoxy resin composites and their mechanism[J]. ACS Applied Electronic Materials, 2023, 5(5): 2548-2557. doi: 10.1021/acsaelm.3c00015 [86] ZHANG Y W, SHEN Y C, SHI K X, et al. Constructing a filler network for thermal conductivity enhancement in epoxy composites via reaction-induced phase separation[J]. Composites Part A: Applied Science and Manufacturing, 2018, 110: 62-69. doi: 10.1016/j.compositesa.2018.04.009 [87] GAO C, ZHU Z H, SHEN Y C, et al. Efficient construction of boron nitride network in epoxy composites combining reaction-induced phase separation and three-roll milling[J]. Composites Part B: Engineering, 2020, 198: 108232. doi: 10.1016/j.compositesb.2020.108232 [88] JIN X L, LI W Z, LIU Y Y, et al. Self-constructing thermal conductive filler network via reaction-induced phase separation in BNNSs/epoxy/polyetherimide composites[J]. Composites Part A: Applied Science and Manufacturing, 2020, 130: 105727. doi: 10.1016/j.compositesa.2019.105727 [89] LI X, LI C H, ZHANG X M, et al. Simultaneously enhanced thermal conductivity and mechanical properties of PP/BN composites via constructing reinforced segregated structure with a trace amount of BN wrapped PP fiber[J]. Chemical Engineering Journal, 2020, 390: 124563. doi: 10.1016/j.cej.2020.124563 [90] LIU B C, LI Y B, FEI T, et al. Highly thermally conductive polystyrene/polypropylene/boron nitride composites with 3D segregated structure prepared by solution-mixing and hot-pressing method[J]. Chemical Engineering Journal, 2020, 385: 123829. doi: 10.1016/j.cej.2019.123829 [91] ZHANG P, DING X, WANG Y Y, et al. Segregated double network enabled effective electromagnetic shielding composites with extraordinary electrical insulation and thermal conductivity[J]. Composites Part A: Applied Science and Manufacturing, 2019, 117: 56-64. doi: 10.1016/j.compositesa.2018.11.007 [92] ZENG X, YAO Y, GONG Z, et al. Ice-templated assembly strategy to construct 3D boron nitride nanosheet networks in polymer composites for thermal conductivity improvement[J]. Small, 2015, 11(46): 6205-6213. [93] ZHANG J G, WANG H, ZHANG T X, et al. Vertically-oriented graphene-boron nitride skeletons using graphene oxide as inorganic adhesives for high-efficiency thermal conduction of polymeric composites with electrical insulation and compressibility[J]. Composites Science and Technology, 2023, 233: 109915. doi: 10.1016/j.compscitech.2023.109915 [94] CHEN X, LIM J S K, YAN W, et al. Salt template assisted BN scaffold fabrication toward highly thermally conductive epoxy composites[J]. ACS Applied Materials & Interfaces, 2020, 12(14): 16987-16996. [95] XIAO C, TANG Y L, CHEN L, et al. Preparation of highly thermally conductive epoxy resin composites via hollow boron nitride microbeads with segregated structure[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 330-340. doi: 10.1016/j.compositesa.2019.03.044 [96] GUO H, ZHAO H, NIU H, et al. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications[J]. ACS Nano, 2021, 15(4): 6917-6928. [97] ZHANG C Y, DENG K Y, LI X Z, et al. Thermally conductive 3D-printed carbon-nanotube-filled polymer nanocomposites for scalable thermal management[J]. ACS Applied Nano Materials, 2023, 6(14): 13400-13408. doi: 10.1021/acsanm.3c02067 [98] LUO F B, YANG S G, YAN P P, et al. Orientation behavior and thermal conductivity of liquid crystal polymer composites based on three-dimensional printing[J]. Composites Part A: Applied Science and Manufacturing, 2022, 160: 107059. doi: 10.1016/j.compositesa.2022.107059 [99] XIAO C, CHEN L, TANG Y L, et al. Three dimensional porous alumina network for polymer composites with enhanced thermal conductivity[J]. Composites Part A: Applied Science and Manufacturing, 2019, 124: 105511. doi: 10.1016/j.compositesa.2019.105511 [100] WANG X W, WU P Y. Melamine foam-supported 3D interconnected boron nitride nanosheets network encapsulated in epoxy to achieve significant thermal conductivity enhancement at an ultralow filler loading[J]. Chemical Engineering Journal, 2018, 348: 723-731. doi: 10.1016/j.cej.2018.04.196 [101] XIAO Y Y, BAI D Y, XIE Z P, et al. Flexible copper foam-based phase change materials with good stiffness-toughness balance, electro-to-thermal conversion ability and shape memory function for intelligent thermal management[J]. Composites Part A: Applied Science and Manufacturing, 2021, 146: 106420. doi: 10.1016/j.compositesa.2021.106420 [102] ZHOU H, WANG H, DU X, et al. Facile fabrication of large 3D graphene filler modified epoxy composites with improved thermal conduction and tribological performance[J]. Carbon, 2018, 139: 1168-1177. doi: 10.1016/j.carbon.2018.07.059 [103] XIAO C, CHEN L, TANG Y L, et al. Enhanced thermal conductivity of silicon carbide nanowires (SiCw)/epoxy resin composite with segregated structure[J]. Composites Part A: Applied Science and Manufacturing, 2019, 116: 98-105. doi: 10.1016/j.compositesa.2018.10.023 [104] WU B Y, CHEN R Y, FU R L, et al. Low thermal expansion coefficient and high thermal conductivity epoxy/Al2O3/T-ZnOw composites with dual-scale interpenetrating network structure[J]. Composites Part A: Applied Science and Manufacturing, 2020, 137: 105993. doi: 10.1016/j.compositesa.2020.105993 [105] XU F, CUI Y X, BAO D, et al. A 3D interconnected Cu network supported by carbon felt skeleton for highly thermally conductive epoxy composites[J]. Chemical Engineering Journal, 2020, 388: 124287. doi: 10.1016/j.cej.2020.124287 [106] XUE Y M, ZHOU X, ZHAN T Z, et al. Densely interconnected porous BN frameworks for multifunctional and isotropically thermoconductive polymer composites[J]. Advanced Functional Materials, 2018, 28(29): 1801205. doi: 10.1002/adfm.201801205 [107] VU M C, THIEU N A T, CHOI W K, et al. Ultralight covalently interconnected silicon carbide aerofoam for high performance thermally conductive epoxy composites[J]. Composites Part A: Applied Science and Manufacturing, 2020, 138: 106028. doi: 10.1016/j.compositesa.2020.106028 [108] ZHOU Z R, HUANG R J, LIU H M, et al. Fabrication of thermal conductivity enhanced polymer composites with three-dimensional networks based on natural cotton[J]. Polymer Composites, 2022, 43(3): 1832-1843. doi: 10.1002/pc.26501 [109] WU Y, YE K, LIU Z, et al. Cotton candy-templated fabrication of three-dimensional ceramic pathway within polymer composite for enhanced thermal conductivity[J]. ACS Applied Materials & Interfaces, 2019, 11(47): 44700-44707. [110] XIAO C, GUO Y J, TANG Y L, et al. Epoxy composite with significantly improved thermal conductivity by constructing a vertically aligned three-dimensional network of silicon carbide nanowires/boron nitride nanosheets[J]. Composites Part B: Engineering, 2020, 187: 107855. doi: 10.1016/j.compositesb.2020.107855 [111] YU C P, ZHANG J, LI Z, et al. Enhanced through-plane thermal conductivity of boron nitride/epoxy composites[J]. Composites Part A: Applied Science and Manufacturing, 2017, 98: 25-31. doi: 10.1016/j.compositesa.2017.03.012 [112] LIU H B, HUANG Z Y, CHEN T, et al. Construction of 3D MXene/silver nanowires aerogels reinforced polymer composites for extraordinary electromagnetic interference shielding and thermal conductivity[J]. ChemicalEngineering Journal, 2022, 427: 131540. doi: 10.1016/j.cej.2021.131540 [113] WANG J, YANG C, MA D Z, et al. Magnetically oriented 3D-boron nitride nanobars enable efficient heat dissipation for 3D-integrated power packaging[J]. ACS Applied Nano Materials, 2023, 6(19): 18508-18517. doi: 10.1021/acsanm.3c03969 [114] ZHAN C, CUI W Z, LI L J, et al. Dual-aligned carbon nanofiber scaffolds as heat conduction path to enhance thermal conductivity of polymer composites[J]. Composites Science and Technology, 2023, 231: 109823. doi: 10.1016/j.compscitech.2022.109823 -

下载:

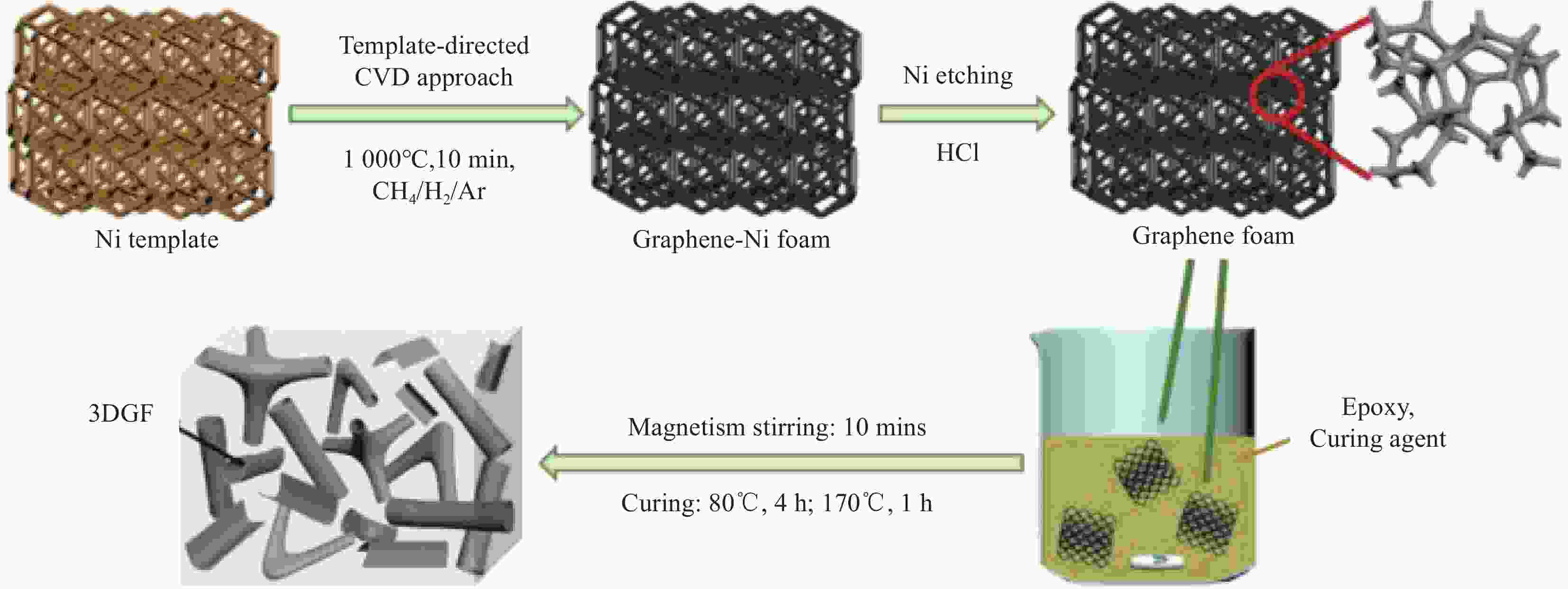

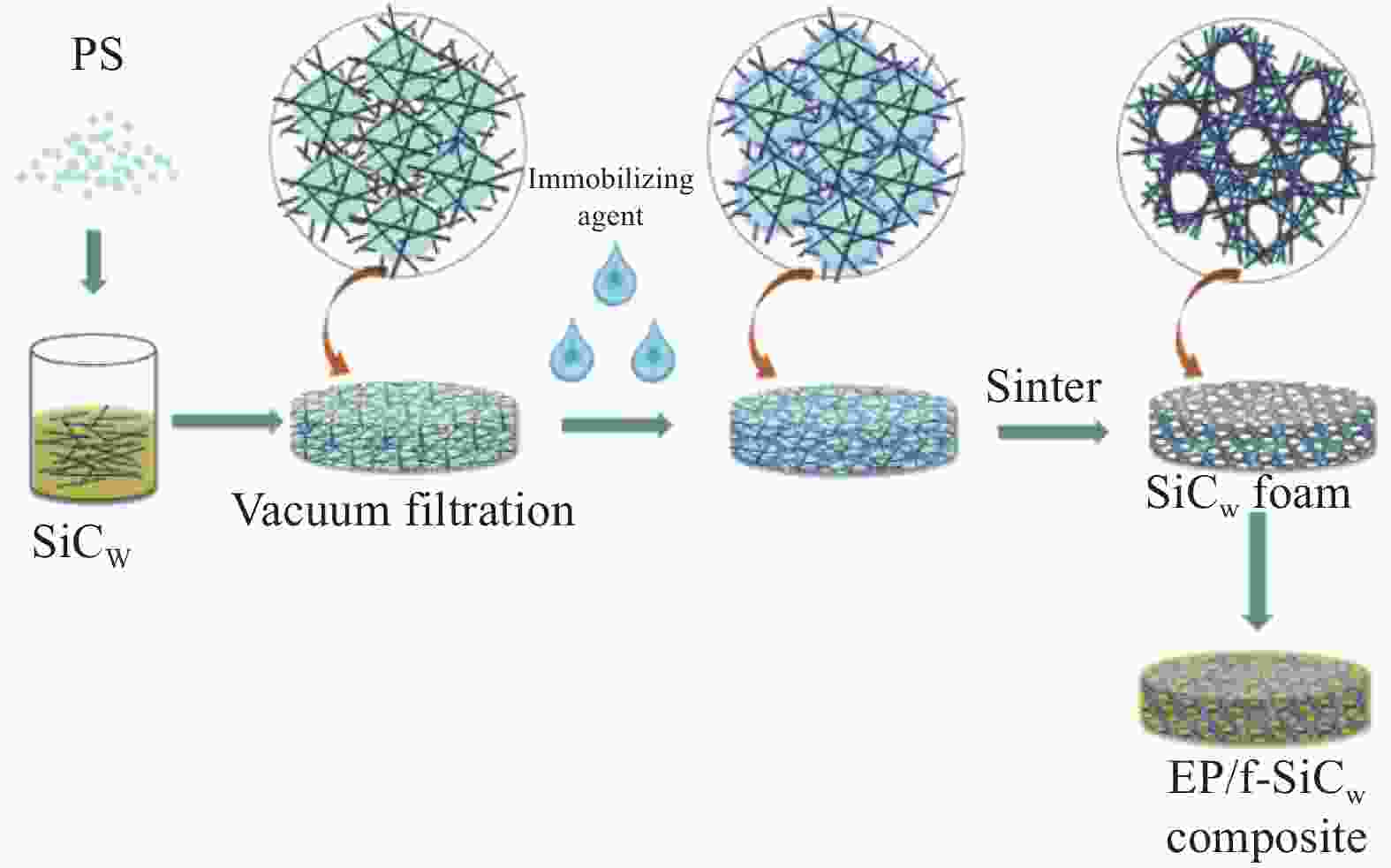

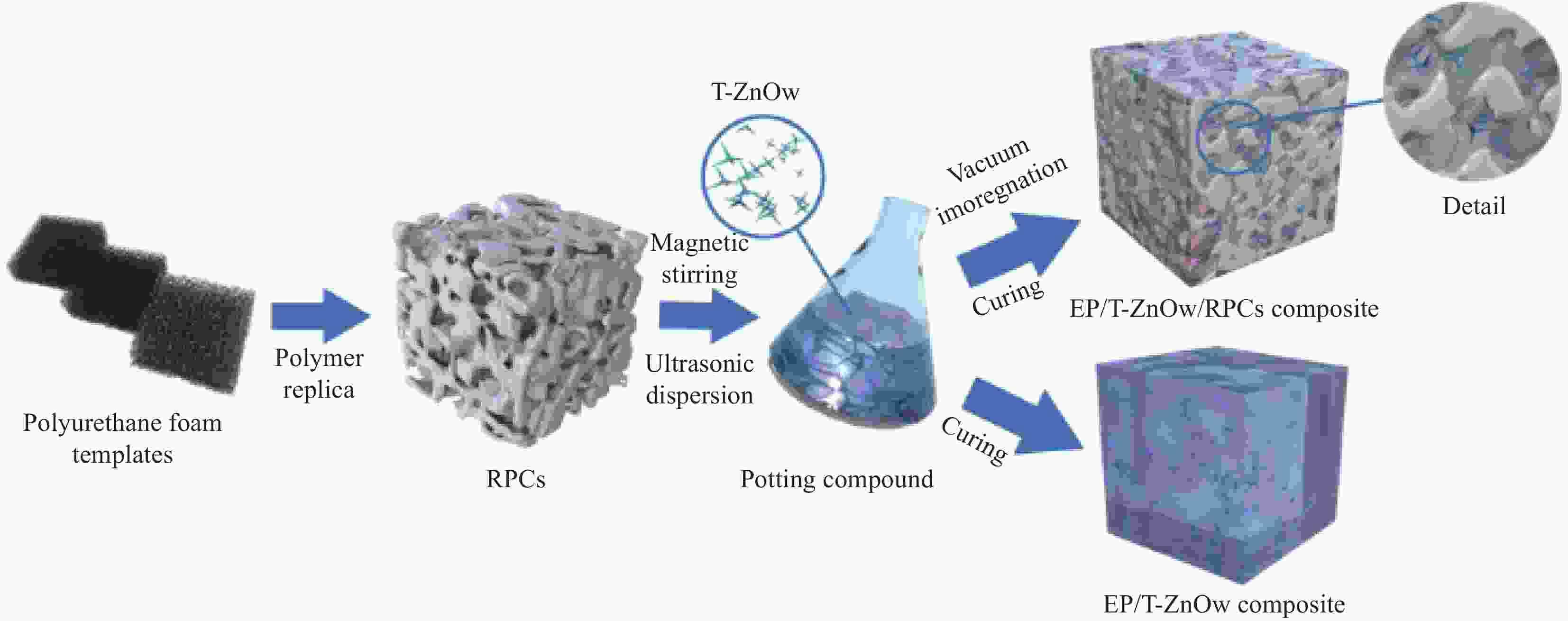

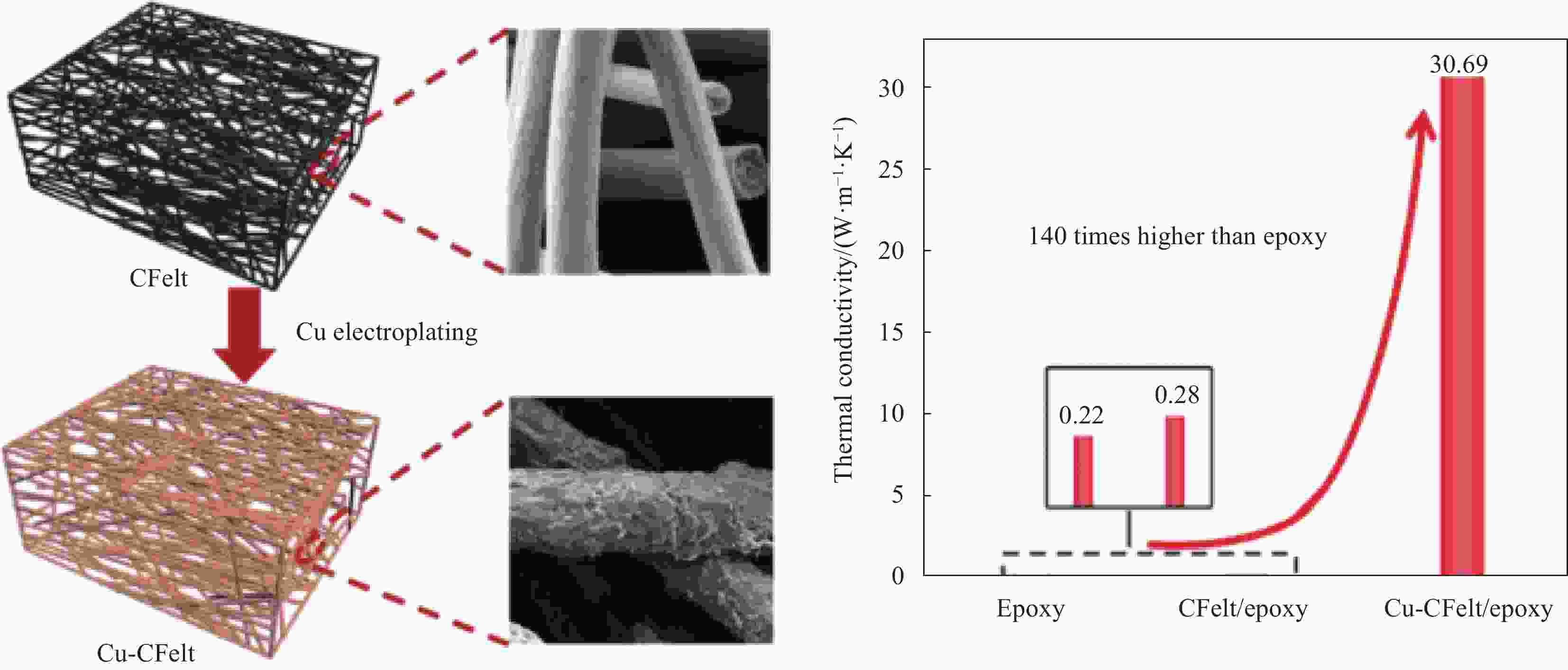

下载: