Preparation of honeycomb porous carbon nanofibers via electro-blowing spinning and investigation of their supercapacitor performance

-

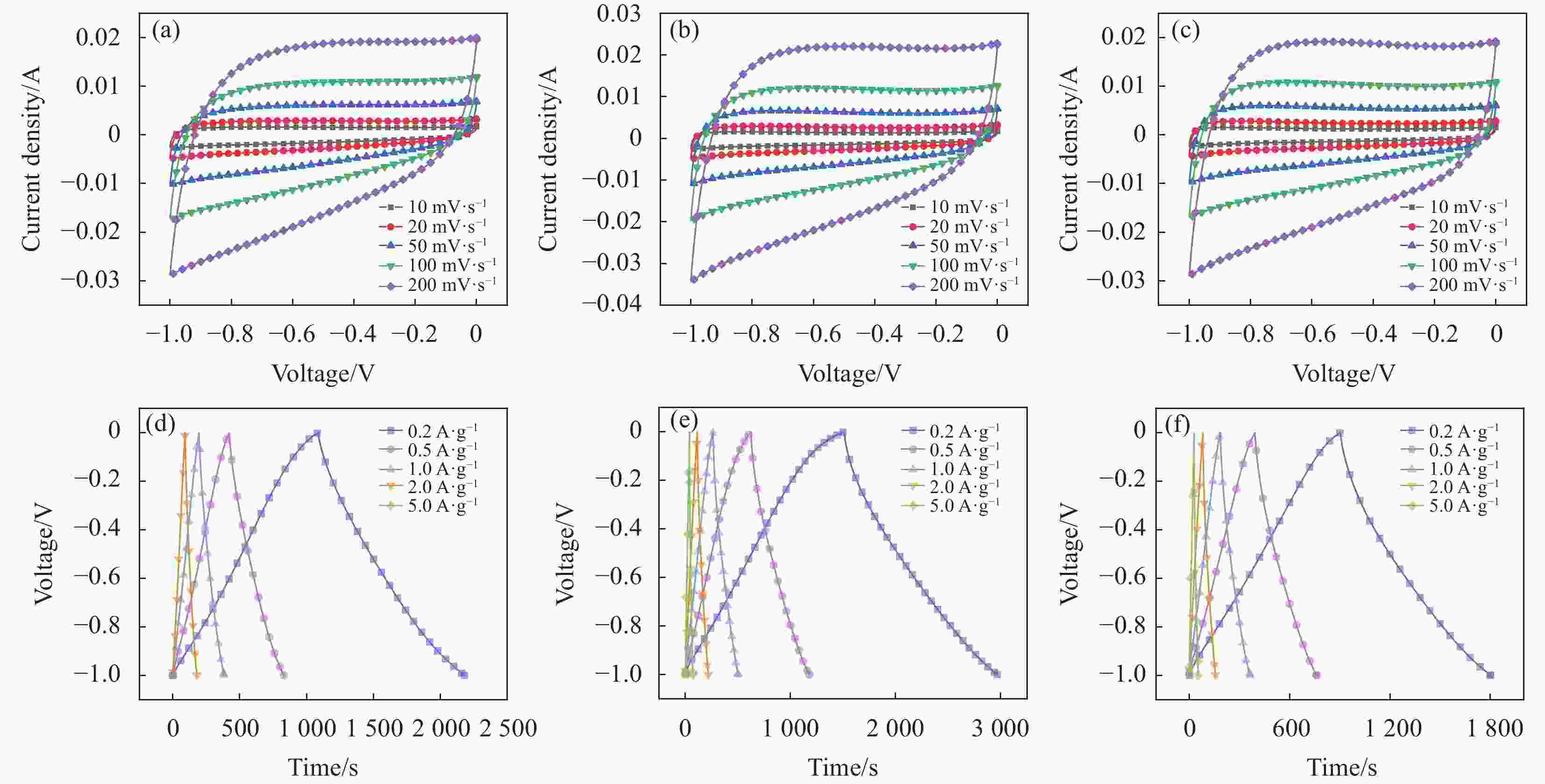

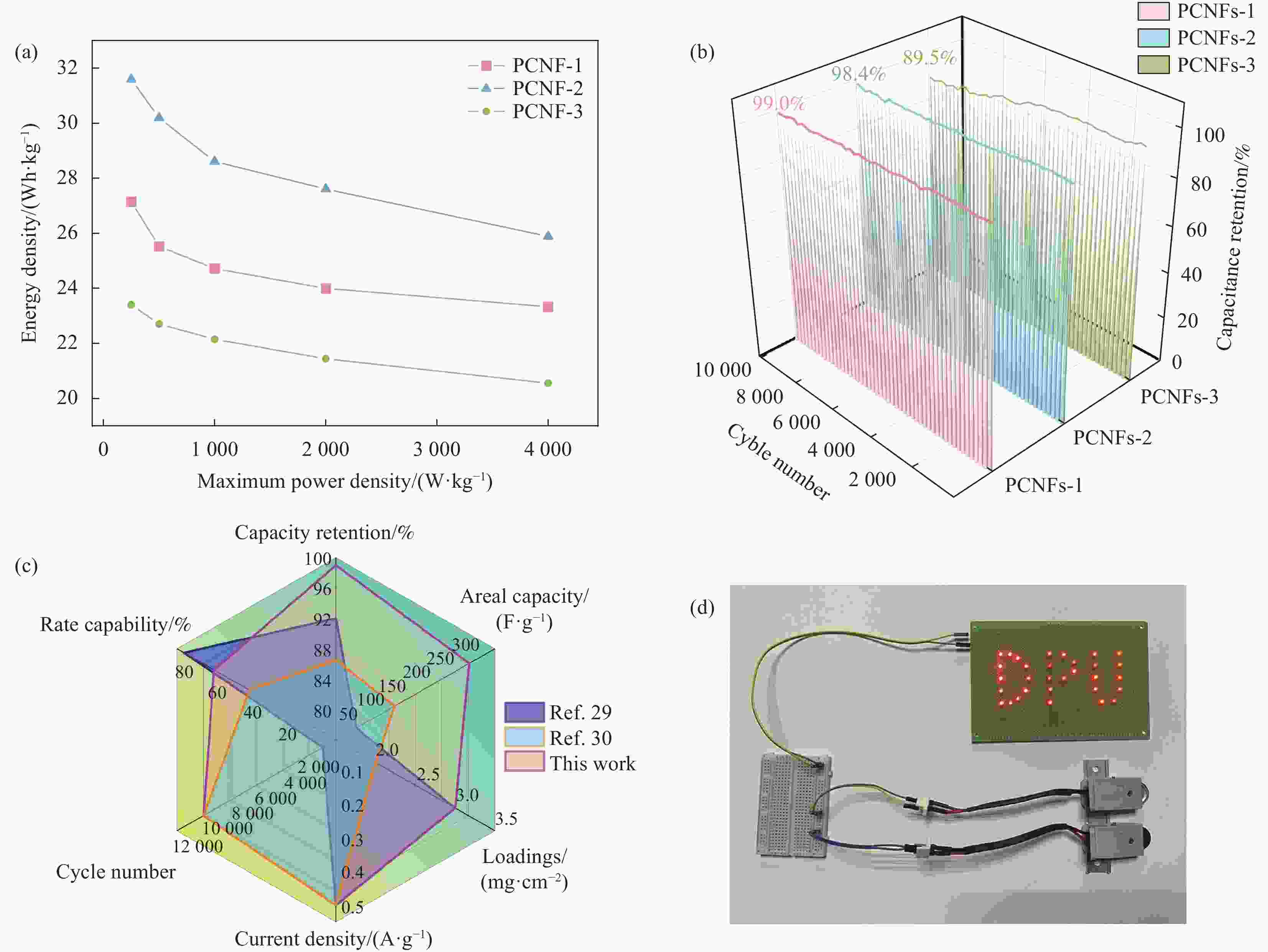

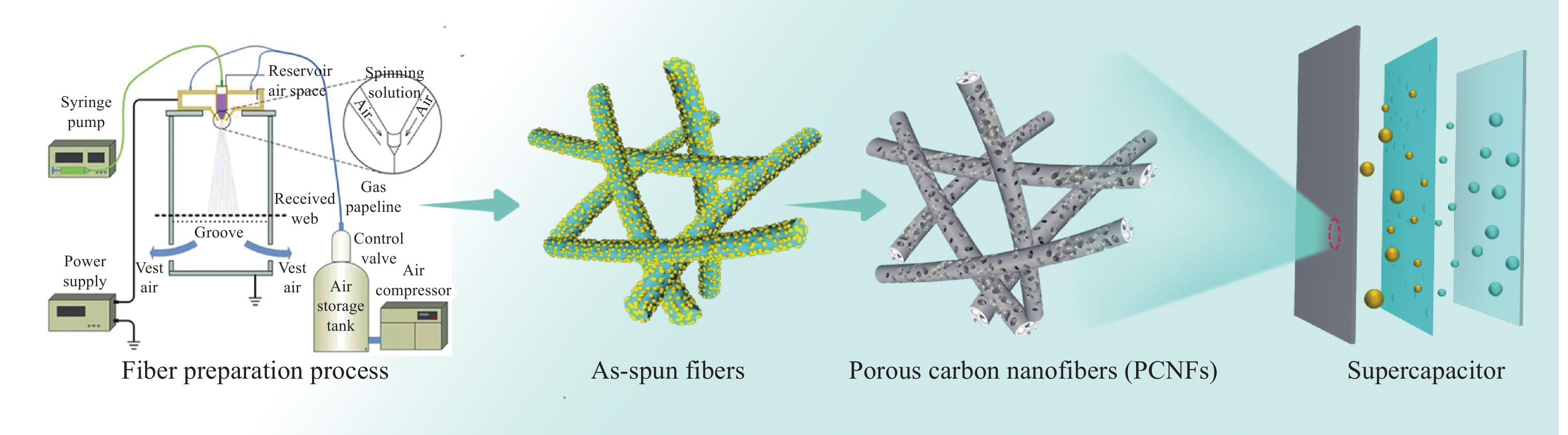

摘要: 一维多孔碳纳米纤维具有比表面积高、长径比大、电子传输高效等特点,成为超级电容器电极材料的热门选择。利用静电溶液喷射纺丝技术,以聚乙烯吡咯烷酮(PVP)为成碳高聚物,聚四氟乙烯乳液(PTFE)为制孔剂,结合高温碳化工艺得到蜂窝多孔碳纳米纤维超级电容器电极材料。通过SEM、TEM、Raman、XRD和BET等测试对制备的电极材料形貌和结构进行了表征,并分析了制孔剂含量对纤维形貌、孔结构及电化学性能的影响。结果表明:当纺丝液中PVP∶PTFE质量比为1∶10时,制备的电极材料具有最大的比表面积165 m²/g;在0.5 A·g−1电流密度下,其比电容值高达277.5 F·g−1;在二电极体系中,其功率密度为250 W/kg时,能量密度可达31.6 W·h/kg;经10000圈充放电循环后,其电容保持率可达98.4%,展示出了良好的电容性能和循环性能。这种独特的高孔隙率蜂窝多孔碳纳米纤维电极材料能够为电荷存储提供充足的活性位点,同时为电子/离子的快速传输提供便利通道,对高性能超级电容器电极材料的开发具有一定参考和指导意义。Abstract: One-dimensional porous carbon nanofibers have become a popular choice for supercapacitor electrode materials due to their high specific surface area, large aspect ratio, and efficient electron transport. In this study, honeycomb porous carbon nanofibers were synthesized using electrospinning technique, where polyvinylpyrrolidone (PVP) served as the carbon precursor and polytetrafluoroethylene (PTFE) emulsion acted as the pore-forming agent, followed by a high-temperature carbonization process. The morphology and structure of the prepared electrode materials were characterized using SEM, TEM, Raman spectroscopy, XRD, and Brunauer-Emmett-Teller (BET) analysis. Furthermore, the influence of pore-forming agent content on the fiber morphology, pore structure, and electrochemical performance was investigated. The results revealed that when the mass ratio of PVP∶PTFE in the spinning solution was 1∶10, the resulting electrode material exhibited the maximum specific surface area of 165 m²/g. Moreover, at a current density of 0.5 A·g−1, it achieved a high specific capacitance of 277.5 F·g−1. In a two-electrode system, the power density reached 250 W/kg, resulting in an energy density of 31.6 W·h/kg. Additionally, after 10000 charge-discharge cycles, the capacitance retention remained as high as 98.4%, indicating excellent capacitive and cycling performance of the fabricated electrode material. Such a unique porous carbon nanofibers electrode material with its high porosity and honeycomb-like structure can offer abundant active sites for charge storage and provide convenient pathways for fast electron/ion transport, which holds significant reference and guidance for the development of high-performance supercapacitor electrode materials.

-

图 2 不同PVP与PTFE质量比的初生纤维SEM图像: (a) 1∶5;(b) 1∶10;(c) 1∶15;蜂窝多孔碳纤维电镜和透射图: (d) PCNFs-1;(e) PCNFs-2;(f) PCNFs-3;(g) PCNFs-2纤维截面SEM图像;(h) 蜂巢电子照片

Figure 2. SEM images of as-spun fibers with different mass ratios of PVP and PTFE: (a) 1∶5; (b) 1∶10; (c) 1∶15; SEM and TEM images of PCNF: (d) PCNFs-1; (e) PCNFs-2; (f) PCNFs-3; (g) Cross section SEM image of PCNFs-2; (h) Digital image of honeycomb

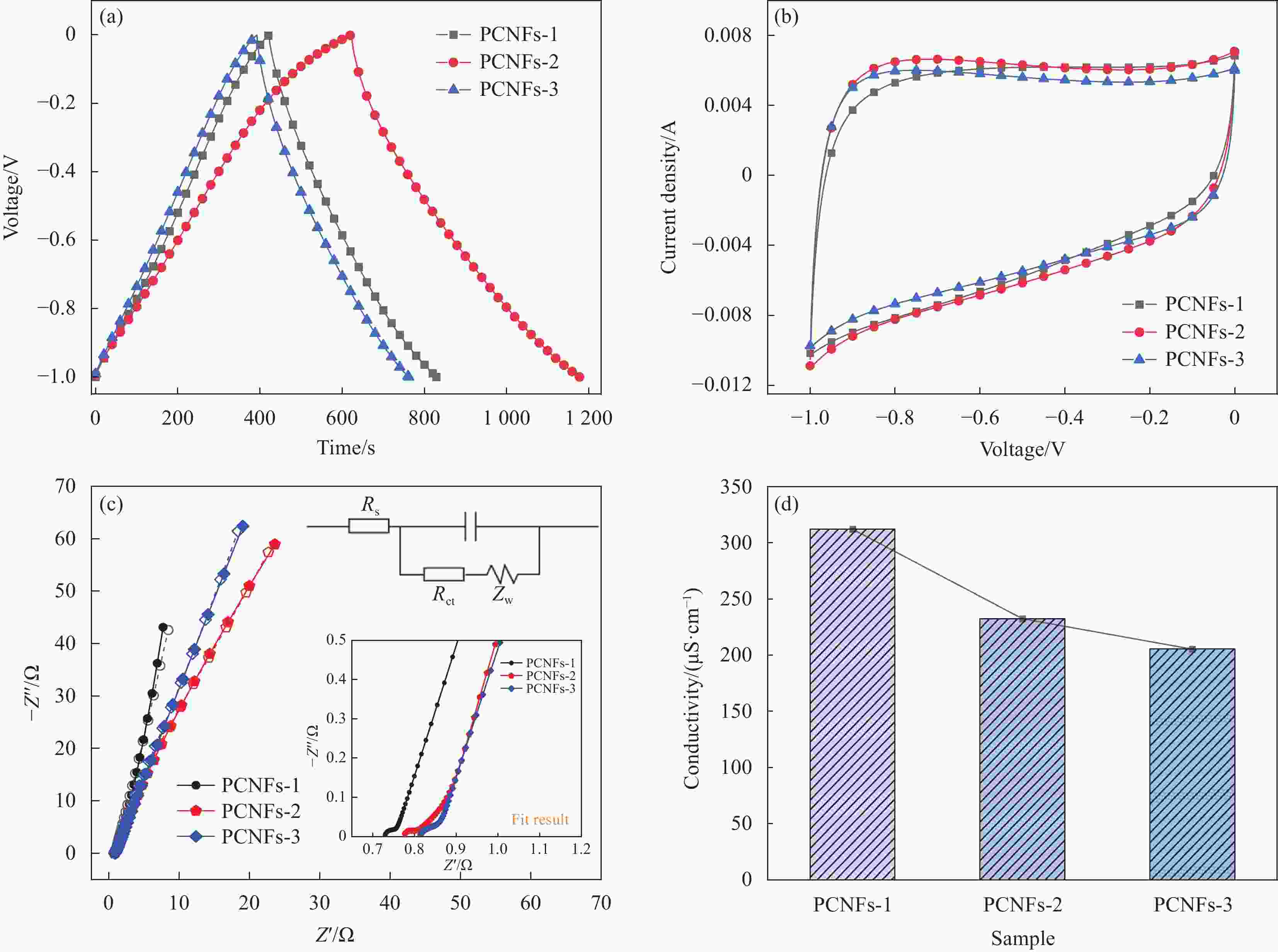

图 5 蜂窝多孔碳纳米纤维: (a) 0.5 A·g−1电流密度下的GCD曲线;(b) 50 mV·s−1扫描速率下的CV曲线;(c) 奈奎斯特曲线及等效电路图;(d) 电导率变化图

Figure 5. Honeycomb porous carbon nanofibers: (a) GCD curves at a current density of 0.5 A·g−1; (b) CV curves at a scanning rate of 50 mV·s−1; (c) Nyquist plots and equivalent circuit; (d) Conductivity variation diagram

图 6 PCNFs-1、PCNFs-2、PCNFs-3蜂窝多孔碳纳米纤维:(a)功率密度-能量密度关系;(b)电极材料循环稳定性;(c) 指标对比雷达图[29-30];(d)纽扣电池点亮 LED 电路板的数码照片

Figure 6. PCNFs-1, PCNFs-2, PCNFs-3 honeycomb porous carbon nanofibers: (a) Power density-energy density relationship; (b) Electrode material cycling stability; (c) Index comparison radar chart[29-30]; (d) Digital photo of button cell light LED circuit board

表 1 不同聚乙烯吡咯烷酮(PVP)与聚四氟乙烯(PTFE)质量比的蜂窝多孔碳纳米纤维

Table 1. Honeycomb porous carbon nanofibers with different mass ratio of polyvinylpyrrolidone (PVP) to polytetrafluoroethylene (PTFE)

m(PVP)∶m(PTFE) PCNFs-1 1∶5 PCNFs-2 1∶10 PCNFs-3 1∶15 Note: m(PVP)∶m(PTFE)—Mass ratio of PVP to PTFE. -

[1] YANG Y Q, BREMNER S, MENICTAS C, et al. Modelling and optimal energy management for battery energy storage systems in renewable energy systems: A review[J]. Renewable and Sustainable Energy Reviews, 2022, 167: 112671. doi: 10.1016/j.rser.2022.112671 [2] LYU Y F, GENG X W, LUO W M, et al. Review on influence factors and prevention control technologies of lithium-ion battery energy storage safety[J]. Journal of Energy Storage, 2023, 72: 108389. doi: 10.1016/j.est.2023.108389 [3] KIRUTHIKA S, SNEHA N, GUPTA R. Visibly transparent supercapacitors[J]. Journal of Materials Chemistry A, 2023, 11(10): 4907-4936. doi: 10.1039/D2TA07836H [4] MUZAFFAR A, AHAMED M B, DESHMUKH K, et al. A review on recent advances in hybrid supercapacitors: Design, fabrication and applications[J]. Renewable and Sustainable Energy Reviews, 2019, 101: 123-145. doi: 10.1016/j.rser.2018.10.026 [5] LAMBA P, SINGH P, SINGH P, et al. Recent advancements in supercapacitors based on different electrode materials: Classifications, synthesis methods and comparative performance[J]. Journal of Energy Storage, 2022, 48: 103871. doi: 10.1016/j.est.2021.103871 [6] LYU S, MA L Y, SHEN X Y, et al. Recent design and control of carbon materials for supercapacitors[J]. Journal of Materials Science, 2021, 56(3): 1919-1942. doi: 10.1007/s10853-020-05351-6 [7] QIU C J, JIANG L L, GAO Y G, et al. Effects of oxygen-containing functional groups on carbon materials in supercapacitors: A review[J]. Materials & Design, 2023, 230: 111952. [8] NANDI D, MOHAN V B, BHOWMICK A K, et al. Metal/metal oxide decorated graphene synthesis and application as supercapacitor: A review[J]. Journal of Materials Science, 2020, 55(15): 6375-6400. doi: 10.1007/s10853-020-04475-z [9] YAN J A, LI S H, LAN B B, et al. Rational design of nanostructured electrode materials toward multifunctional supercapacitors[J]. Advanced Functional Materials, 2020, 30(2): 1902564. doi: 10.1002/adfm.201902564 [10] FAN P Z, YE C W, XU L. One-dimensional nanostructured electrode materials based on electrospinning technology for supercapacitors[J]. Diamond and Related Materials, 2023, 134: 109803. [11] WEI Q L, XIONG F Y, TAN S S, et al. Porous one-dimensional nanomaterials: Design, fabrication and applications in electrochemical energy storage[J]. Advanced Materials, 2017, 29(20): 1602300. doi: 10.1002/adma.201602300 [12] GUPTA D, VARGHESE B S, SURESH M, et al. Nanoarchitectonics: Functional nanomaterials and nanostructures—A review[J]. Journal of Nanoparticle Research, 2022, 24(10): 196. doi: 10.1007/s11051-022-05577-2 [13] FENG P X, WANG H, HUANG P P, et al. Nitrogen-doped lignin-derived porous carbons for supercapacitors: Effect of nanoporous structure[J]. Chemical Engineering Journal, 2023, 471: 144817. [14] WANG X, ZHANG X Y, FU G T, et al. Recent progress of electrospun porous carbon-based nanofibers for oxygen electrocatalysis[J]. Materials Today Energy, 2021, 22: 100850. doi: 10.1016/j.mtener.2021.100850 [15] DENG J, LI M M, WANG Y. Biomass-derived carbon: Synthesis and applications in energy storage and conversion[J]. Green Chemistry, 2016, 18(18): 4824-4854. doi: 10.1039/C6GC01172A [16] YIN J A, ZHANG W L, ALHEBSHI N A, et al. Synthesis strategies of porous carbon for supercapacitor applications[J]. Small Methods, 2020, 4(3): 1900853. doi: 10.1002/smtd.201900853 [17] YANG D S, BHATTACHARJYA D, INAMDAR S, et al. Phosphorus-doped ordered mesoporous carbons with different lengths as efficient metal-free electrocatalysts for oxygen reduction reaction in alkaline media[J]. Journal of the American Chemical Society, 2012, 134(39): 16127-16130. doi: 10.1021/ja306376s [18] WANG H, YAO L, ZUO H M, et al. Fabrication of porous carbon nanofibers from polymer blends using template method for electrode-active materials in supercapacitor[J]. Molecules, 2023, 28(5): 2228. doi: 10.3390/molecules28052228 [19] NADAF A, GUPTA A, HASAN N, et al. Recent update on electrospinning and electrospun nanofibers: Current trends and their applications[J]. RSC Advances, 2022, 12(37): 23808-23828. doi: 10.1039/D2RA02864F [20] XU H Z, YAGI S, ASHOUR S, et al. A review on current nanofiber technologies: Electrospinning, centrifugal spinning, and electro-centrifugal spinning[J]. Macromolecular Materials and Engineering, 2023, 308(3): 2200502. doi: 10.1002/mame.202200502 [21] LI Y, ZHU J D, CHENG H, et al. Developments of advanced electrospinning techniques: A critical review[J]. Advanced Materials Technologies, 2021, 6(11): 2100410. doi: 10.1002/admt.202100410 [22] LI L, LIU X L, WANG G, et al. Research progress of ultrafine alumina fiber prepared by sol-gel method: A review[J]. Chemical Engineering Journal, 2021, 421: 127744. doi: 10.1016/j.cej.2020.127744 [23] ZHOU X H, SONG K H, LI Z H, et al. The excellent catalyst support of Al2O3 fibers with needle-like mullite structure and HMF oxidation into FDCA over CuO/Al2O3 fibers[J]. Ceramics International, 2019, 45(2): 2330-2337. doi: 10.1016/j.ceramint.2018.10.148 [24] SCHUEPFER D B, BADACZEWSKI F, GUERRA-CASTRO J M, et al. Assessing the structural properties of graphitic and non-graphitic carbons by Raman spectroscopy[J]. Carbon, 2020, 161: 359-372. doi: 10.1016/j.carbon.2019.12.094 [25] ELANTHAMILAN E, SRIRAM B, RAJKUMAR S, et al. Couroupita guianansis dead flower derived porous activated carbon as efficient supercapacitor electrode material[J]. Materials Research Bulletin, 2019, 112: 390-398. doi: 10.1016/j.materresbull.2018.12.028 [26] PINZÓN C M J, DE AQUINO J M, FREITAS R G, et al. A comprehensive study about the influence of pore structures of carbon-based electrode materials on the charge-storage processes of water-in-salt based supercapacitors[J]. Journal of Energy Storage, 2023, 62: 106858. doi: 10.1016/j.est.2023.106858 [27] TAN J A, LI Z H, YE M X, et al. Nanoconfined space: Revisiting the charge storage mechanism of electric double layer capacitors[J]. ACS Applied Materials & Interfaces, 2022, 14(33): 37259-37269. [28] ZHANG M, ZHOU W J, HUANG W W. Characterization methods of organic electrode materials[J]. Journal of Energy Chemistry, 2021, 57: 291-303. doi: 10.1016/j.jechem.2020.08.054 [29] PANG S Y, LIN L Y, SHEN Y Q, et al. Surface activated commercial carbon cloth as superior electrodes for symmetric supercapacitors[J]. Materials Letters, 2022, 315: 131985. doi: 10.1016/j.matlet.2022.131985 [30] ZHENG Y L, WANG H L, SUN S J, et al. Sustainable nitrogen-doped carbon electrodes for use in high-performance supercapacitors and Li-ion capacitors[J]. Sustainable Energy & Fuels, 2020, 4(4): 1789-1800. -

下载:

下载: