Recent advances in the nanocellulose-based humidity-responsive smart devices

-

摘要: 纳米纤维素来源广泛、绿色可再生,作为纤维素衍生材料,由于其特殊的结构特性,使其具有高机械强度、高结晶度、大比表面积等特点。基于纳米纤维素的湿度响应智能器件因其丰富的亲水基团(例如羟基和羧基)而显示出出色的响应性能,因此纳米纤维素可以作为一种湿度敏感材料来制备高性能湿度响应智能器件。本文介绍了纳米纤维素的分类、来源及湿度响应智能器件的分类及响应原理,重点阐述了不同纳米纤维素在湿度响应智能器件方面的制备及应用,总结了不同类型纳米纤维素与导电材料复合的湿度响应智能器件的性能及优缺点,最后对纳米纤维素基湿度响应智能器件的研究应用存在的问题与挑战进行归纳总结,以期为纳米纤维素基复合材料在湿度响应智能器件中的发展提供理论支持。Abstract: Nanocellulose is an abundant, eco-friendly, and renewable resource, as a cellulose-derived material, it is characterized by high mechanical strength, high crystallinity, and large specific surface area due to its special structural properties. Nanocellulose-based humidity-responsive smart devices show excellent sensitivity and fast response due to its abundant hydrophilic groups (such as hydroxyl and carboxyl groups). Nanocellulose can be used as a humidity sensitive material to prepare high-performance humidity-responsive smart devices. This paper provides a concise overview of nanocellulose, its classification, and sources, along with an exploration of the classification and response principle of humidity responsive smart devices. The primary focuses lie in the application of nanocellulose within the context of humidity-responsive smart devices, and summarized the performance, advantages and disadvantages of different types of humidity responsive smart devices composited with nanocellulose and conductive materials. Finally, this paper conclude the problems and challenges in the potential research applications of nanocellulose-based humidity-responsive smart devices, aiming to offer theoretical support for the advancement of nanocellulose-based composites in humidity-responsive smart devices.

-

Key words:

- nanocellulose /

- humidity response /

- sensors /

- actuators /

- flexible composites

-

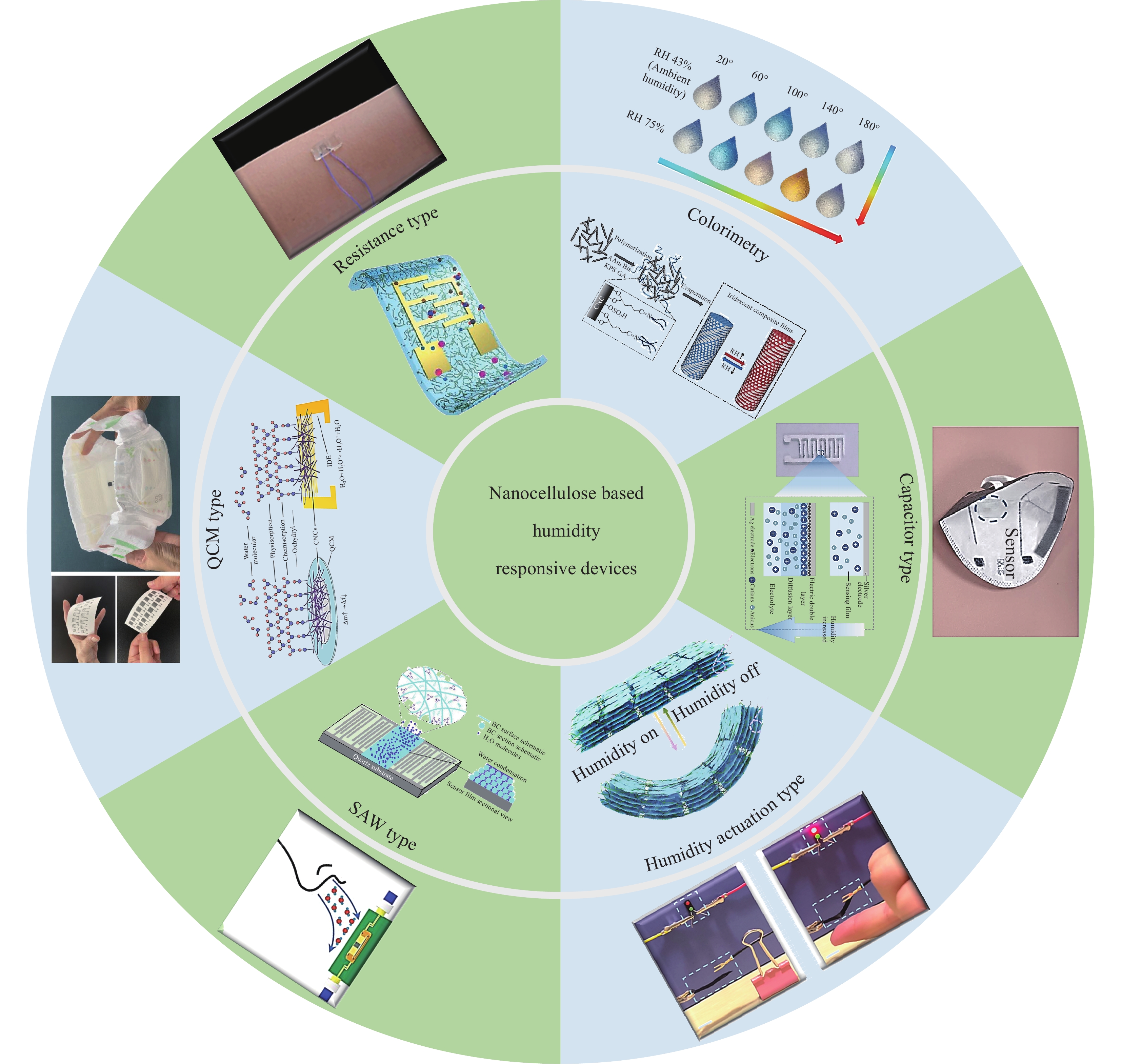

图 1 纳米纤维素基湿度响应器件的多功能应用

QCM—Quartz crystal microbalance; SAW—Surface acoustic wave; RH—Relative humidity; BC—Bacterial cellulose; CNC—Cellulose nanocrystal; IDE- Interdigital electrode; AAm—Acrylamide; KPS—Potassium persulfate; GA—Glutaraldehyde; ∆m—Mass change of the QCM sensor; ∆f—Frequency shift of the QCM sensor

Figure 1. Multifunctional applications of nanocellulose-based humidity-responsive devices

图 2 在92% 相对湿度(RH)下2, 2, 6, 6-四甲基哌啶-1-氧自由基氧化纤维素纳米纤维(TCNF)-Na+0.37 μm/还原氧化石墨烯(rGO)双层致动器在自主开关照明设备中的应用方案[54]:(a)关闭状态:电路断开;通电状态:电路连接;(b)在4个连续周期中灯的振荡开关状态随时间变化的曲线

Figure 2. Application scheme of the 2, 2, 6, 6-tetramethyl-1-piperidinoxyl oxidized cellulose nanofibers (TCNF)-Na+0.37 μm/reduced graphene oxide (rGO) bilayer actuator in an autonomous on-and-off lighting device at 92%RH[54]: (a) Off-state: The electric circuit is open; On-state: The electronic circuit is connected; (b) Plot of the oscillating on-and-off states of the lamp as a function of time for four successive cycles

图 3 基于纤维素纳米纤维-MXene-单宁酸(CNF-MXene-TA-II)复合薄膜致动器的概念验证智能服装[55]:((a), (a'))由复合薄膜致动器组成的具有功能性双半月襟翼的智能服装湿度响应和电加热图;(b)响应湿度;(c)皮肤和运动服之间随时间变化的内部湿度和皮肤表面的温度;(d)在5 V供电电压下的双半月瓣的光学照片和相应的红外图像;(e)不同条件下的皮肤表面温度:裸露的皮肤、普通的棉质运动服和基于复合薄膜致动器的运动服;(f)基于复合薄膜致动器的运动服和普通棉质运动服的水蒸气透过率测试

∆RH—Skin surface humidity; ∆T—Skin surface temperature

Figure 3. Proof-of-concept smart garment based on the cellulose nanofiber-MXene-tannic acid (CNF-MXene-TA-II) composite film actuator[55]: ((a), (a')) Diagram of humidity response and electric heating of the smart garment with functional double semilunar flaps composed of the composite film actuator; (b) Response to humidity; (c) Time-dependent internal humidity between the skin and sportswear and the temperature on the skin surface; (d) Optical photographs and corresponding infrared images of double semilunar flaps at a supplied voltage of 5 V; (e) Skin surface temperature of various conditions: Bare skin, normal cotton sportswear, and composite film actuator-based sportswear; (f) Water vapor transmission rate test of composite film actuator-based sportswear and normal cotton sportswear

图 4 纤维素纳米晶体/聚丙烯酸(CNC/PAA10)彩虹涂层的防伪效果:(a)单图案防伪实验;(b)双图案防伪效果;(c)三图案防伪结果[71]

Figure 4. Anticounterfeiting effects of cellulose nanocrystal/polyacrylic acid (CNC/PAA10) iridescent coating: (a) Single pattern anticounterfeiting experiment; (b) Double patterns anticounterfeiting effect; (c) Three patterns anticounterfeiting result[71]

图 5 基于聚多巴胺修饰的MXene/细菌纤维素纳米纤维复合膜(PDMM/BCNF)致动器的多功能智能设备的概念演示[78]:(a)具有高导电性的PDMM/BCNF薄膜可以用作湿气刺激的控制开关,无需用手指接触开关即可开启LED灯;(b) PDMM/BCNF薄膜可以用作“起重机”吊起物体,也可以作为“机械臂”在湿度梯度下运输货物的“叉车”

R—Resistance; VD—Light-emitting diode

Figure 5. Concept demonstrations of multifunctional smart devices based on polydopamine-modified MXene/bacterial cellulose nanofiber (PDMM/BCNF) actuators[78]: (a) PDMM/BCNF film with high-conductivity can be used as a control switch for moisture stimulation, enabling the turning on of the LED light without physical touch of the switch with your finger; (b) PDMM/BCNF film can be used as a "crane" to lift objects, or a "forklift" to transport cargos under humidity gradients as a "robotic arm"

表 1 基于纤维素复合材料的湿敏传感器件的测试参数对比

Table 1. Comparison of test parameters of cellulose composite-based moisture-sensitive sensor devices

Moisture sensitive material Response calculation Range of RH Sensitivity Response time Recovery time Ref. CNF/PVA/rGO — 30%-98% 0.198/%RH,

0.347/%RH— — [47] CNF/Gr — 15%-99% — 45 s 33 s [48] CNF/CNTs — 11%-95% — 330 s 377 s [49] CNF/CNTs — 11%-95% — 321 s 435 s [50] CNF/CNTs — 11%-95% — 333 s 523 s [51] CNF/GOQD — 11%-97% 51840.91 pF/%RH 30 s 11 s [53] CNF/GO/CNTs — 30%-70% — 0.8 s 2 s [31] CNF/ionic liquid — 11%-95% 27.95 pF/%RH 43 s ~1 s [29] CNF/PEG — 20%-90% — 265 s 490 s [79] CNF/MXene/PDA — 40%-90% — 7 s 21 s [80] CNF/MXene — 11%-97% — 232 s 438 s [81] CNC/GO — 25%-90% — 90 min 35 min [58] CNC — 11.3%-97.3% — 60 s 15 s [59] CNC — 11%-94% — 7 s 2 s [60] CNC — 11.3%-97.3% — 68 s 4 s [61] CNC/ND — 11.3%-97.3% 54.1 Hz/%RH 6 s (55%-11.3%RH)

19 s (55%-97%RH)8 s (55%-11.3%RH)

3 s (55%-97%RH)[62] CNC/CNTs/GO — — — — — [63] CNC/TiO2 — 11%-95% — 22 s 13 s [30] CNC/PAM — 11%-97% — 2-3 min — [69] CNC — 43%-99% — — — [71] BC — 5%-97% — 89-119 s 53-62 s [75] BC — 30%-93% — 12 s 5 s [76] BC — 11.3%-93% — 76 s 39 s [77] Notes: The response calculation is used to evaluate the sensors performance; Sensitivity is the ratio of the output change to the input change in steady state operation; Response and recovery time are defined as the durations required by a sensor to achieve 90% of the total change in response during adsorption and desorption of H2O molecules; CNF—Cellulose nanofiber; CNC—Cellulose nanocrystal; BC—Bacterial cellulose; PVA—Polyvinyl alcohol; rGO—Reduced graphene oxide; Gr—Graphene; CNTs—Carbon nanotubes; GOQD—Graphene oxide quantum dots; GO—Graphene oxide; PEG—Poly(ethylene glycol); PDA—Polydopamine; ND—Nanodiamond; PAM—Polyacrylamide; ΔR—Resistance change (RRH–R0), R0—Initial resistance at 15%RH, RRH—Resistance at target RH[48]; ΔI = IRH–I0, IRH, I0—Corresponding instantaneous current at the target humidity and the initial current at 11%RH, respectively[49-51, 81]; C1—Capacitance value measured at RH1, C2—Capacitance obtained at RH2[29]; R0—Resistance of the sample at 11%RH, RRH—Resistance upon exposure to the target RH condition[30]; ΔI = IRH–I0; I0—Initial current through the sensors at 11.3%RH, IRH—Actual current under different target humidity values[77]. -

[1] KUMAR R, AL-DOSSARY O, KUMAR G, et al. Zinc oxide nanostructures for NO2 gas sensor applications: A review[J]. Nano-Micro Letters, 2015, 2: 97-120. [2] LI Z X, WANG J, XU Y J, et al. Green and sustainable cellulose-derived humidity sensors: A review[J]. Carbohydrate Polymers, 2021, 270: 118385. doi: 10.1016/j.carbpol.2021.118385 [3] PU W, WEI F, YAO L, et al. A review of humidity-driven actuator: Toward high response speed and practical applications[J]. Journal of Materials Science, 2022, 57(26): 12202-12235. doi: 10.1007/s10853-022-07344-z [4] WANG Y, HUANG J. Recent advancements in flexible humidity sensors[J]. Journal of Semiconductors, 2020, 41(4): 040401. doi: 10.1088/1674-4926/41/4/040401 [5] RESHMY R, PHILIP E, PAUL S A, et al. Nanocellulose-based products for sustainable applications—Recent trends and possibilities[J]. Reviews in Environmental Science and Bio/Technology, 2020, 19: 779-806. doi: 10.1007/s11157-020-09551-z [6] SHAHROKHIAN S, NADERI L, GHALKHANI M. Nanocellulose/carbon nanoparticles nanocomposite film modified electrode for durable and sensitive electrochemical determination of metoclopramide[J]. Electroanalysis, 2015, 27(11): 2637-2644. doi: 10.1002/elan.201500266 [7] NAJEEB M A, AHMAD Z, SHAKOOR R A. Organic thin-film capacitive and resistive humidity sensors: A focus review[J]. Advanced Materials Interfaces, 2018, 5(21): 1800969. doi: 10.1002/admi.201800969 [8] ARMAN KUZUBASOGLU B. Recent studies on the humidity sensor: A mini review[J]. ACS Applied Electronic Materials, 2022, 4(10): 4797-4807. doi: 10.1021/acsaelm.2c00721 [9] YADAV A. Classification and applications of humidity sensors: A review[J]. International Journal for Research in Applied Science and Engineering Technology, 2018, 6(4): 3686-3699. doi: 10.22214/ijraset.2018.4616 [10] FILIPPIDOU M K, CHATZICHRISTIDI M, CHATZANDROULIS S. A fabrication process of flexible IDE capacitive chemical sensors using a two step lift-off method based on PVA patterning[J]. Sensors and Actuators B: Chemical, 2019, 284: 7-12. doi: 10.1016/j.snb.2018.12.095 [11] LIU M Q, WANG C, KIM N Y. High-sensitivity and low-hysteresis porous MIM-type capacitive humidity sensor using functional polymer mixed with TiO2 microparticles[J]. Sensors, 2017, 17(2): 284-294. doi: 10.3390/s17020284 [12] YU H, LIANG J G, WANG C, et al. Target properties optimization on capacitive-type humidity sensor: Ingredients hybrid and integrated passive devices fabrication[J]. Sensors and Actuators B: Chemical, 2021, 340: 129883 doi: 10.1016/j.snb.2021.129883 [13] ZHANG D, WANG M, TANG M, et al. Recent progress of diversiform humidity sensors based on versatile nanomaterials and their prospective applications[J]. Nano Research, 2023, 16(10): 11938-11958. [14] 苏云鹏. 适用于人体呼吸检测的SAW湿度传感器研究[D]. 天津: 天津理工大学, 2020.SU Yunpeng. Research on SAW humidity sensor suitable for human breath detection[D]. Tianjin: Tianjin University of Technology, 2020(in Chinese). [15] ZHENG F, LI M, LI C, et al. Wireless surface acoustic wave humidity sensor with chitosan/porous cyclodextrin-TiO2 composites for monitoring air and human respiration[J]. Sensors and Actuators B: Chemical, 2023, 379: 133235. doi: 10.1016/j.snb.2022.133235 [16] LE X, LIU Y, PENG L, et al. Surface acoustic wave humidity sensors based on uniform and thickness controllable graphene oxide thin films formed by surface tension[J]. Microsystems & Nanoengineering, 2019, 5(1): 36-45. [17] MEMON M M, HONGYUAN Y, PAN S, et al. Surface acoustic wave humidity sensor based on hydrophobic polymer film[J]. Journal of Electronic Materials, 2022, 51(10): 5627-5634. doi: 10.1007/s11664-022-09791-5 [18] LI X, TAN Q, QIN L, et al. A high-sensitivity MoS2/graphene oxide nanocomposite humidity sensor based on surface acoustic wave[J]. Sensors and Actuators A: Physical, 2022, 341: 113573. doi: 10.1016/j.sna.2022.113573 [19] OLSSON A L J, QUEVEDO I R, HE D, et al. Using the quartz crystal microbalance with dissipation monitoring to evaluate the size of nanoparticles deposited on surfaces[J]. ACS Nano, 2013, 7(9): 7833-7843. doi: 10.1021/nn402758w [20] YAN H, GUO S, WU F, et al. Carbon atom hybridization matters: Ultrafast humidity response of graphdiyne oxides[J]. Angewandte Chemie International Edition, 2018, 57(15): 3922-3926. doi: 10.1002/anie.201709417 [21] ZHAO X, CHEN X D, LIU F, et al. An ultrafast QCM humidity sensor for respiratory monitoring outside a mask[J]. Sensors and Actuators B: Chemical, 2022, 371: 132396. doi: 10.1016/j.snb.2022.132396 [22] 辛丽平. 基于光学传感器的检测技术在制浆造纸中的应用研究[D]. 广州: 华南理工大学, 2015.XIN Liping. Optical sensing based technology applied to pulp and paper related measurements[D]. Guangzhou: South China University of Technology, 2015(in Chinese). [23] 王啸卿. 二氧化钛基薄膜型光学湿度传感器研究[D]. 南京: 南京信息工程大学, 2020.WANG Xiaoqing. Study on titanium dioxide based thin film optical humidity sensor[D]. Nanjing: Nanjing University of Information Science and Technology, 2020(in Chinese). [24] SIKARWAR S, YADAV B C. Opto-electronic humidity sensor: A review[J]. Sensors and Actuators A: Physical, 2015, 233: 54-70. doi: 10.1016/j.sna.2015.05.007 [25] 李玉林. 光学湿度传感器技术及相关专利分析[J]. 工业技术创新, 2017, 4(1): 183-185.LI Yulin. Optical humidity sensoring technology and analysis on its related patents[J]. Industrial Technology Innovation, 2017, 4(1): 183-185(in Chinese). [26] ZENG J, ZHANG Y, ZENG T, et al. Anisotropic plasmonic nanostructures for colorimetric sensing[J]. Nano Today, 2020, 32: 100855 doi: 10.1016/j.nantod.2020.100855 [27] 郑一帆. 基于聚乙烯醇/蒽体系的致动器的制备和性能研究[D]. 上海: 东华大学, 2022.ZHENG Yifan. Prepration and properties of actuators based on poly(vinyl alcohol)/anthracene system[D]. Shanghai: Donghua University, 2022(in Chinese). [28] FANG Z Q, HOU G Y, CHEN C J, et al. Nanocellulose-based films and their emerging applications[J]. Current Opinion in Solid State and Materials Science, 2019, 23(4): 100764. doi: 10.1016/j.cossms.2019.07.003 [29] HOU Z, MA Z, GUAN X, et al. A cellulose nanofiber capacitive humidity sensor with high sensitivity and fast recovery characteristics[J]. Chemosensors, 2022, 10(11): 464-474. doi: 10.3390/chemosensors10110464 [30] WU J, CHEN Y, SHEN W, et al. Highly sensitive, flexible and transparent TiO2/nanocellulose humidity sensor for respiration and skin monitoring[J]. Ceramics International, 2023, 49(2): 2204-2214. doi: 10.1016/j.ceramint.2022.09.187 [31] WEI J, JIA S, GUAN J, et al. Robust and highly sensitive cellulose nanofiber-based humidity actuators[J]. ACS Applied Materials & Interfaces, 2021, 13(45): 54417-54427. [32] ZHAO G, HUANG Y, MEI C, et al. Chiral nematic coatings based on cellulose nanocrystals as a multiplexing platform for humidity sensing and dual anticounterfeiting[J]. Small, 2021, 17(50): 2103936. doi: 10.1002/smll.202103936 [33] YOSHIDA A, WANG Y F, TACHIBANA S, et al. Printed, all-carbon-based flexible humidity sensor using a cellulose nanofiber/graphene nanoplatelet composite[J]. Carbon Trends, 2022, 7: 100166. doi: 10.1016/j.cartre.2022.100166 [34] ABRAHAM E, DEEPA B, POTHAN L A, et al. Extraction of nanocellulose fibrils from lignocellulosic fibers: A novel approach[J]. Carbohydrate Polymers, 2011, 86: 1468-1475. doi: 10.1016/j.carbpol.2011.06.034 [35] DEEPA B, ABRAHAM E, CORDEIRO N, et al. Utilization of various lignocellulosic biomass for the production of nanocellulose: A comparative study[J]. Cellulose, 2015, 22: 1075-1090. doi: 10.1007/s10570-015-0554-x [36] AN X Y, CHENG D, SHEN J, et al. Nanocellulose materials: Research/production activities and applications[J]. Journal of Bioresources and Bioproducts, 2017, 2(2): 45-49. [37] RUIZ-PALOMERO C, SORIANO M L, VALCARCEL T, et al. Sulfonated nanocellulose for the efficient dispersive micro solid-phase extraction and determination of silver nanoparticles in food products[J]. Journal of Chromatography A, 2016, 1428: 352-358. doi: 10.1016/j.chroma.2015.06.023 [38] YANG X, SHI K Y, ZHITOMIRSKY I, et al. Cellulose nanocrystal aerogels as universal 3D lightweight substrates for supercapacitor materials[J]. Advanced Materials, 2015, 27: 6104-6109. doi: 10.1002/adma.201502284 [39] VOLOVA T G, PRUDNIKOVA S V, SUKOVATYI A G, et al. Production and properties of bacterial cellulose by the strain Komagataeibacter xylinus B-12068[J]. Applied Microbiology and Biotechnology, 2018, 102: 7417-7428. doi: 10.1007/s00253-018-9198-8 [40] KIM H J, ROY S, RHIM J W. Effects of various types of cellulose nanofibers on the physical properties of the CNF-based films[J]. Journal of Environmental Chemical Engineering, 2021, 9(5): 106043. doi: 10.1016/j.jece.2021.106043 [41] 朱晓东, 杜昀怡, 原续波, 等. 细菌纤维素的最新研究进展[J]. 高分子通报, 2022, 277(5): 17-26.ZHU Xiaodong, DU Yunyi, YUAN Xubo, et al. Recent progress on bacterial cellulose[J]. Chinese Polymer Bulletin, 2022, 277(5): 17-26(in Chinese). [42] CHARREAU H, CAVALLO E, FORESTI M L. Patents involving nanocellulose: Analysis of their evolution since 2010[J]. Carbohydrate Polymers, 2020, 237: 116039. doi: 10.1016/j.carbpol.2020.116039 [43] TRACHE D, THAKUR V K, BOUKHERROUB R. Cellulose nanocrystals/graphene hybrids—A promising new class of materials for advanced applications[J]. Nanomaterials, 2020, 10: 1523. doi: 10.3390/nano10081523 [44] DUFRESNE A. Nanocellulose processing properties and potential applications[J]. Current Forestry Reports, 2019, 5: 76-89. doi: 10.1007/s40725-019-00088-1 [45] KIM H C, PANICKER P S, KIM D, et al. High-strength cellulose nanofiber/graphene oxide hybrid filament made by continuous processing and its humidity monitoring[J]. Scientific Reports, 2021, 11(1): 13611. doi: 10.1038/s41598-021-93209-5 [46] WANG Y, HOU S, LI T, et al. Flexible capacitive humidity sensors based on ionic conductive wood-derived cellulose nanopapers[J]. ACS Applied Materials & Interfaces, 2020, 12(37): 41896-41904. [47] XU S M, YU W J, YAO W L, et al. Nanocellulose-assisted dispersion of graphene to fabricate poly(vinyl alcohol)-graphene nanocomposite for humidity sensing[J]. Composites Science and Technology, 2016, 131: 67-76. doi: 10.1016/j.compscitech.2016.05.014 [48] GONG L, FU H, LIU L, et al. Construction and performance of a nanocellulose-graphene-based humidity sensor with a fast response and excellent stability[J]. ACS Applied Polymer Materials, 2022, 4(5): 3656-3666. [49] ZHU P H, LIU Y, FANG Z Q, et al. A flexible and highly sensitive humidity sensor based on cellulose nanofibers and carbon nanotubes composite film[J]. Langmuir, 2019, 35(14): 4834-4842. doi: 10.1021/acs.langmuir.8b04259 [50] ZHU P H, OU H J, KUANG Y D, et al. Cellulose nanofiber/carbon nanotube dual network-enabled humidity sensor with high sensitivity and durability[J]. ACS Applied Materials & Interfaces, 2020, 12(29): 33229-33238. [51] ZHU P, KUANG Y, WEI Y, et al. Electrostatic self-assembly enabled flexible paper-based humidity sensor with high sensitivity and superior durability[J]. Chemical Engineering Journal, 2021, 404: 127105. doi: 10.1016/j.cej.2020.127105 [52] SOLIN K, BORGHEI M, SEL O, et al. Electrically conductive thin films based on nanofibrillated cellulose: Interactions with water and applications in humidity sensing[J]. ACS Applied Materials & Interfaces, 2020, 12(32): 36437-36448. [53] HUANG L J, YANG Y T, TI P, et al. Graphene oxide quantum dots attached on wood-derived nanocellulose to fabricate a highly sensitive humidity sensor[J]. Carbohydrate Polymers, 2022, 288: 119312. [54] HÉRALY F, ZHANG M, ÅHL A, et al. Nanodancing with moisture: Humidity-sensitive bilayer actuator derived from cellulose nanofibrils and reduced graphene oxide[J]. Advanced Intelligent Systems, 2022, 4(1): 2100084. doi: 10.1002/aisy.202100084 [55] WEI J, JIA S, WEI J, et al. Tough and multifunctional composite film actuators based on cellulose nanofibers toward smart wearables[J]. ACS Applied Materials & Interfaces, 2021, 13(32): 38700-38711. [56] LAGERWALL J P F, SCHÜTZ C, SALAJKOVA M, et al. Cellulose nanocrystal-based materials: From liquid crystal self-assembly and glass formation to multifunctional thin films[J]. NPG Asia Materials, 2014, 6(1): e80. doi: 10.1038/am.2013.69 [57] SADASIVUNI K K, KAFY A, ZHAI L, et al. Transparent and flexible cellulose nanocrystal/reduced graphene oxide film for proximity sensing[J]. Small, 2015, 11(8): 994-1002. doi: 10.1002/smll.201402109 [58] KAFY A, AKTHER A, SHISHIR I R, et al. Cellulose nanocrystal/graphene oxide composite film as humidity sensor[J]. Sensors and Actuators A: Physical, 2016, 247: 221-226. doi: 10.1016/j.sna.2016.05.045 [59] YAO Y, HUANG X, ZHANG B, et al. Facile fabrication of high sensitivity cellulose nanocrystals based QCM humidity sensors with asymmetric electrode structure[J]. Sensors and Actuators B: Chemical, 2020, 302: 127192. doi: 10.1016/j.snb.2019.127192 [60] ZHENG Z, TANG C, YEOW J T W. A high-performance CMUT humidity sensor based on cellulose nanocrystal sensing film[J]. Sensors and Actuators B: Chemical, 2020, 320: 128596. doi: 10.1016/j.snb.2020.128596 [61] CHEN Q, YAO Y, HUANG X, et al. Simulation analysis and experimental verification for sensitivity of IDE-QCM humidity sensors[J]. Sensors and Actuators B: Chemical, 2021, 341: 129992. doi: 10.1016/j.snb.2021.129992 [62] CHEN Q, MAO K, YAO Y, et al. Nanodiamond/cellulose nanocrystals composite-based acoustic humidity sensor[J]. Sensors and Actuators B: Chemical, 2022, 373: 132748. doi: 10.1016/j.snb.2022.132748 [63] WANG H Q, LUO H S, ZHOU H K, et al. Dramatically enhanced strain- and moisture-sensitivity of bioinspired fragmentized carbon architectures regulated by cellulose nanocrystals[J]. Chemical Engineering Journal, 2018, 345: 452-461. doi: 10.1016/j.cej.2018.04.003 [64] LIANG H L, BAY M M, VADRUCCI R, et al. Roll-to-roll fabrication of touch-responsive cellulose photonic laminates[J]. Nature Communications, 2018, 9(1): 4632-4638. doi: 10.1038/s41467-018-07048-6 [65] ZHANG Y P, CHODAVARAPU V P, KIRK A G, et al. Structured color humidity indicator from reversible pitch tuning in self-assembled nanocrystalline cellulose films[J]. Sensors and Actuators B: Chemical, 2013, 176: 692-697. doi: 10.1016/j.snb.2012.09.100 [66] LIZUNDIA E, NGUYEN T D, VILAS J L, et al. Chiroptical, morphological and conducting properties of chiral nematic mesoporous cellulose/polypyrrole composite films[J]. Journal of Materials Chemistry A, 2017, 5(36): 19184-19194. doi: 10.1039/C7TA05684B [67] KOSE O, TRAN A, LEWIS L, et al. Unwinding a spiral of cellulose nanocrystals for stimuli-responsive stretchable optics[J]. Nature Communications, 2019, 10(1): 510-516. doi: 10.1038/s41467-019-08351-6 [68] XIONG R, YU S, KANG S, et al. Integration of optical surface structures with chiral nanocellulose for enhanced chiroptical properties[J]. Advanced Materials, 2020, 32(2): 1905600. doi: 10.1002/adma.201905600 [69] LU T, PAN H, MA J, et al. Cellulose nanocrystals/polyacrylamide composites of high sensitivity and cycling performance to gauge humidity[J]. ACS Applied Materials & Interfaces, 2017, 9(21): 18231-18237. [70] ADSTEDT K, POPENOV E A, PIERCE K J, et al. Chiral cellulose nanocrystals with intercalated amorphous polysaccharides for controlled iridescence and enhanced mechanics[J]. Advanced Functional Materials, 2020, 30(49): 2003597. doi: 10.1002/adfm.202003597 [71] ZHAO G, HUANG Y, MEI C, et al. Chiral nematic coatings based on cellulose nanocrystals as a multiplexing platform for humidity sensing and dual anticounterfeiting[J]. Small, 2021, 17(50): 2103936. [72] ZHU Q, JIN Y, WANG W, et al. Bioinspired smart moisture actuators based on nanoscale cellulose materials and porous, hydrophilic EVOH nanofibrous membranes[J]. ACS Applied Materials & Interfaces, 2018, 11(1): 1440-1448. [73] TORRES F G, ARROYO J J, TRONCOSO O P. Bacterial cellulose nanocomposites: An all-nano type of material[J]. Materials Science and Engineering: C, 2019, 98: 1277-1293. doi: 10.1016/j.msec.2019.01.064 [74] GORGIEVA S, TRCEK J. Bacterial cellulose: Production, modification and perspectives in biomedical applications[J]. Nanomaterials, 2019, 9(10): 1352-1371. doi: 10.3390/nano9101352 [75] HU W, CHEN S, ZHOU B, et al. Highly stable and sensitive humidity sensors based on quartz crystal microbalance coated with bacterial cellulose membrane[J]. Sensors and Actuators B: Chemical, 2011, 159(1): 301-306. doi: 10.1016/j.snb.2011.07.014 [76] WANG J L, GUO Y J, LI D J, et al. Bacterial cellulose coated ST-cut quartz surface acoustic wave humidity sensor with high sensitivity, fast response and recovery[J]. Smart Materials and Structures, 2020, 29(4): 045037. doi: 10.1088/1361-665X/ab7842 [77] MA H, LI X, LOU J, et al. Strong bacterial cellulose-based films with natural laminar alignment for highly sensitive humidity sensors[J]. ACS Applied Materials & Interfaces, 2022, 14(2): 3165-3175. [78] YANG L, CUI J, ZHANG L, et al. A moisture-driven actuator based on polydopamine-modified MXene/bacterial cellulose nanofiber composite film[J]. Advanced Functional Materials, 2021, 31(27): 2101378. doi: 10.1002/adfm.202101378 [79] SYROVÝ T, MARONOVÁ S, KUBERSKÝ P, et al. Wide range humidity sensors printed on biocomposite films of cellulose nanofibril and poly(ethylene glycol)[J]. Journal of Applied Polymer Science, 2019, 136(36): 47920. doi: 10.1002/app.47920 [80] CAO J, ZHOU Z, SONG Q, et al. Ultrarobust Ti3C2T x MXene-based soft actuators via bamboo-inspired mesoscale assembly of hybrid nanostructures[J]. ACS Nano, 2020, 14(6): 7055-7065. doi: 10.1021/acsnano.0c01779 [81] HAN M, SHEN W. Nacre-inspired cellulose nanofiber/MXene flexible composite film with mechanical robustness for humidity sensing[J]. Carbohydrate Polymers, 2022, 298: 120109. doi: 10.1016/j.carbpol.2022.120109 -

下载:

下载: