Preparation of nano-modified cement-based thermoelectric composite and its self-power supply behaviors engineered cathodic protection for offshore structure

-

摘要: 经略海洋及双碳背景下,用阴极防护(CP)技术提升海工结构服役寿命具有重要意义,然而需外加电源额外驱动。为此本文先用水热法合成纳米二氧化锰(nMnO2),然后与碳纳米管(CNTs)复掺水泥砂浆体系中,制备纳米水泥基热电复合材料(NTEC);最后将20个NTEC串联成1套热电发电模块,并结合电化学方法综合评价基于温差发电的NTEC热电模块直接用作海工结构钢筋CP系统电流供给源的可行性。结果表明:复掺有0.2wt%CNTs与5.0wt%nMnO2的NTEC试件的热电系数、热电功率因数可分别达3612 μV/℃和301.4 μW·m−1·℃−2,本征力学强度与耐久抗渗性得到保障;施加基于NTEC温差发电的CP,钢筋的腐蚀电位正移,腐蚀概率显著降低;施加基于NTEC热电模块的CP后能使钢筋腐蚀电流密度降低3个数量级,腐蚀电荷转移得到了抑制,腐蚀速率大为降低,实现海工结构钢筋CP的自供能,同时保障了其用作保护层的强度与耐久性。

-

关键词:

- 海工结构 /

- 阴极防护自供能 /

- 纳米水泥基热电复合材料 /

- 温差发电性能 /

- 电化学性能

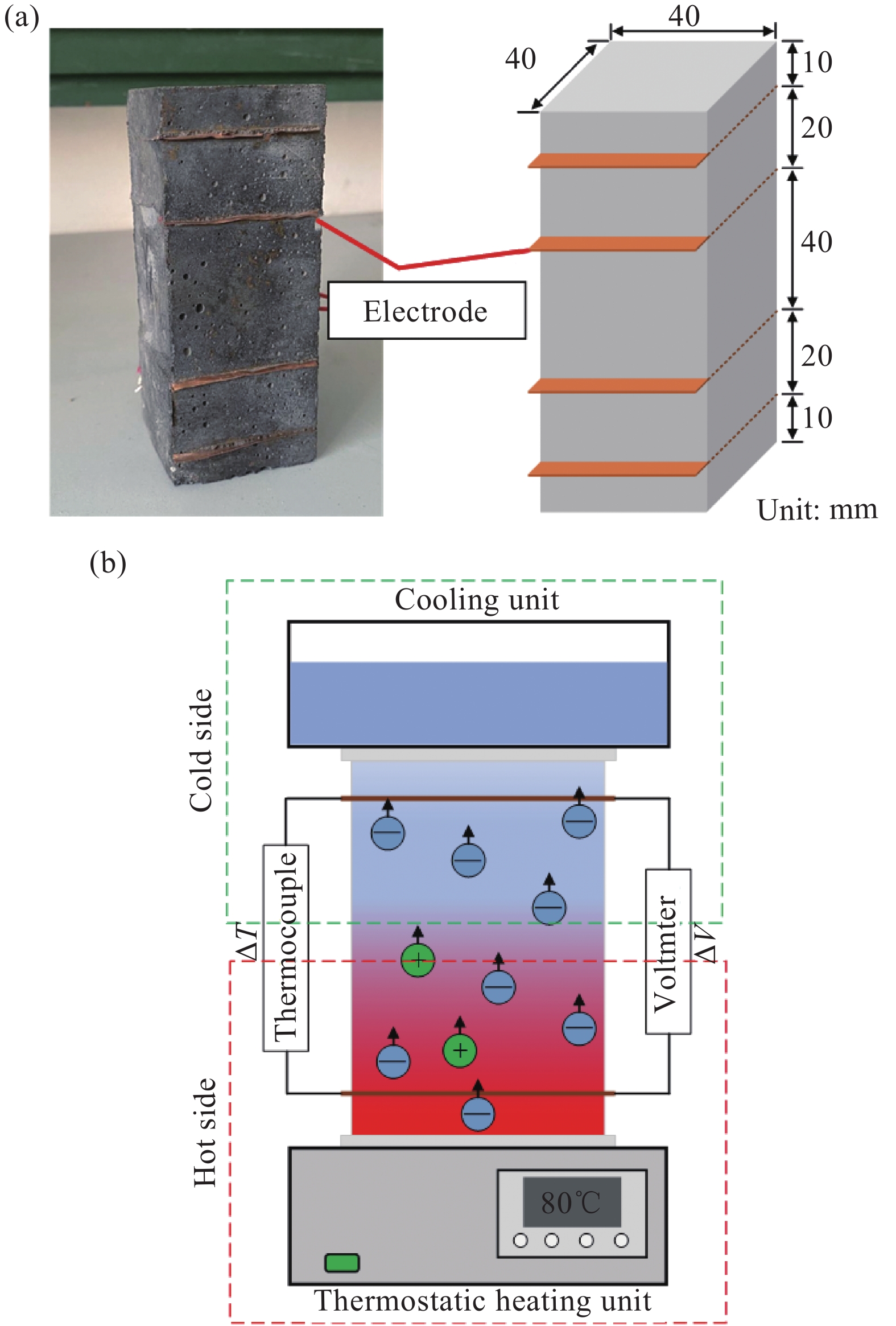

Abstract: Under the background of strategic ocean and double-carbon, it is important to use cathodic protection (CP) technology to enhance the service life of offshore structures. However, it requires additional power supply for extra drive. Here, nano-size nMnO2 was synthesized by hydrothermal method, and then was mixed into cement mortar along with carbon nanotubes (CNTs) to prepare nano-modified cement-based thermoelectric composites (NTEC). 20 NTECs were connected in series to form a set of thermoelectric power generation module, and combined with electrochemical methods to comprehensively evaluate the feasibility of NTEC thermoelectric module based on differential temperature power generation directly serving as a current supply source for the reinforcement CP system of offshore structure. Results show that: The thermoelectric coefficient and thermoelectric power factor of NTEC specimens doped with 0.2wt%CNTs and 5.0wt%nMnO2 can be up to 3612 μV/℃, and 301.4 μW·m−1·℃−2, respectively. The intrinsic mechanical strength and anti-permeability are accordingly guaranteed. Applying the CP based on the temperature difference power generation of NTEC, the corrosion potential of the reinforcement bar positively shifts, and the probability of corrosion is significantly reduced. Applying the CP based on the NTEC thermoelectric module the corrosion current density of the reinforcement is reduced by 3 orders of magnitude, the corrosion charge transfer is suppressed, the corrosion rate is greatly reduced, the self-power supply of CP for reinforcement in offshore structures is realized, and its mechanical properties and durability are guaranteed when simultaneously serving as concrete cover. -

图 10 两组钢筋的腐蚀电位变化曲线(a)和在腐蚀模拟孔隙液(CSF)中浸泡21天后的动电位极化曲线图(b)

Ecorr—Corrosion potential

Figure 10. Corrosion potential change curves for two groups of steel rebars (a) and dynamic potential polarization plots for two groups of steel rebars after 21 d immersion in corrosion simulation of pore fluid (CSF) (b)

图 12 不同腐蚀龄期下的EIS模拟等效电路图

Rs—Resistance of the electrolyte solution; Rf—Film resistance of the conversion film on the surface of the steel rebars; Rct—Resistance of the charge transfer during the corrosion of the steel rebars; CPEf—Membrane capacitor; CPEdl—Double layer capacitor

Figure 12. Equivalent circuit diagrams for EIS simulations at different corrosion ages

表 1 碳纳米管(CNTs)的主要物理性能指标

Table 1. Main physical property indexes of carbon nanotubes (CNTs)

Diameter/nm Length/μm Purity/% Amorphous

carbon/%Specific surface

area/(m2·g−1)Thermal

conductivity/(W·(m·K)−1)Resistivity/

(Ω·cm)20-40 5-15 ≥90% ≤3% 40-300 1.60 <5 表 2 两组钢筋的极化曲线拟合数据

Table 2. Fitting data of polarization curves for two groups of steel rebars

Group Ecorr/V Icorr/(μA·cm−2) Corrosion rate/(mm·a−1) CSF-NP −0.762 1.56×10 1.83×10−1 CSF-CP −0.336 7.58×10−2 8.91×10−4 Note: Icorr—Corrosion current density. 表 3 不同腐蚀龄期下钢筋的EIS拟合数据

Table 3. EIS fitting data for steel rebars at differentcorrosion ages

Group Corrosion

ages/dRs/(Ω·cm2) Rf/(kΩ·cm2) Rct/(kΩ·cm2) CSF-NP 0 3.24 101.38 – 3 2.85 126.42 236.51 7 2.88 154.36 180.04 14 2.84 7.20 62.92 21 3.07 1.07 29.26 CSF-CP 0 2.97 123.77 – 3 2.95 253.70 302.64 7 2.80 501.48 447.21 14 2.83 245.73 3125.21 21 2.95 102.31 3232.93 -

[1] QU F, LI W, DONG W, et al. Durability deterioration of concrete under marine environment from material to structure: A critical review[J]. Journal of Building Engineering, 2021, 35: 102074. doi: 10.1016/j.jobe.2020.102074 [2] JIN Z, CHANG H, DU F, et al. Influence of SAP on the chloride penetration and corrosion behavior of steel bar in concrete[J]. Corrosion Science, 2020, 171: 108714. doi: 10.1016/j.corsci.2020.108714 [3] WANG Z, YU J, LI G, et al. Corrosion behavior of steel rebar embedded in hybrid CNTs-OH/polyvinyl alcohol modified concrete under accelerated chloride attack[J]. Cement and Concrete Composites, 2019, 100: 120-129. doi: 10.1016/j.cemconcomp.2019.02.013 [4] MONTEMOR M F, SIMOES A M P, FERREIRA M G S. Chloride-induced corrosion on reinforcing steel: From the fundamentals to the monitoring techniques[J]. Cement and Concrete Composites, 2003, 25: 491-502. doi: 10.1016/S0958-9465(02)00089-6 [5] ZAKI A, CHAI H K, AGGELIS D G, et al. Non-destructive evaluation for corrosion monitoring in concrete: A review and capability of acoustic emission technique[J]. Sensors, 2015, 15(8): 19069-19101. doi: 10.3390/s150819069 [6] CAIRNS J, DU Y, LAW D. Structural performance of corrosion-damaged concrete beams[J]. Magazine of Concrete Research, 2008, 60(5): 359-370. doi: 10.1680/macr.2007.00102 [7] HU J Y, ZHANG S S, CHEN E, et al. A review on corrosion detection and protection of existing reinforced concrete (RC) structures[J]. Construction and Building Materials, 2022, 325: 126718. doi: 10.1016/j.conbuildmat.2022.126718 [8] KOLEVA D A, GUO Z, VAN BREUGEL K, et al. Conventional and pulse cathodic protection of reinforced concrete: Electrochemical behavior of the steel reinforcement after corrosion and protection[J]. Materials and Corrosion, 2009, 60(5): 344-354. doi: 10.1002/maco.200805150 [9] 邱玉婷, 鲁翰宸, 金阳, 等. 热电复合材料的研究进展[J]. 复合材料学报, 2022, 39(9): 4213-4226.QIU Yuting, LU Hanchen, JIN Yang, et al. Research progress in thermoelectric composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4213-4226(in Chinese). [10] WEI J, FAN Y, ZHAO L, et al. Thermoelectric properties of carbon nanotube reinforced cement-based composites fabricated by compression shear[J]. Ceramics International, 2018, 44(6): 5829-5833. doi: 10.1016/j.ceramint.2018.01.074 [11] JI T, ZHANG X Y, ZHANG X, et al. Effect of manganese dioxide nanorods on the thermoelectric properties of cement composites[J]. Journal of Materials in Civil Engineering, 2018, 30(9): 04018224. doi: 10.1061/(ASCE)MT.1943-5533.0002401 [12] 崔一纬, 魏亚. 水泥基复合材料热电效应综述: 机制、材料、影响因素及应用[J]. 复合材料学报, 2020, 37(9): 2077-2093.CUI Yiwei, WEI Ya. A review of thermoelectric effect of cement-based composites: Mechanism, material, factor and application[J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2077-2093(in Chinese). [13] WEN S, CHUNG D D L. Enhancing the Seebeck effect in carbon fiber-reinforced cement by using intercalated carbon fibers[J]. Cement and Concrete Research, 2000, 30(8): 1295-1298. doi: 10.1016/S0008-8846(00)00341-0 [14] MIAO T, SHI S, YAN S, et al. Integrative characterization of the thermoelectric performance of an individual multiwalled carbon nanotube[J]. Journal of Applied Physics, 2016, 120(12): 124302. doi: 10.1063/1.4962942 [15] JI T, ZHANG X, LI W. Enhanced thermoelectric effect of cement composite by addition of metallic oxide nanopowders for energy harvesting in buildings[J]. Construction and Building Materials, 2016, 115: 576-581. doi: 10.1016/j.conbuildmat.2016.04.035 [16] WALIA S, BALENDHRAN S, NILI H, et al. Transition metal oxides-Thermoelectric properties[J]. Progress in Materials Science, 2013, 58(8): 1443-1489. doi: 10.1016/j.pmatsci.2013.06.003 [17] CHIRITESCU C, CAHILL D, NGUYENI N, et al. Ultralow thermal conductivity in disordered, layered WSe2 crystals[J]. Science, 2007, 315(5810): 351-353. doi: 10.1126/science.1136494 [18] LI W, LIAO X, JI T, et al. Thermoelectric property of cement composites with MnO2 added[J]. Journal of Building Materials, 2017, 20(5): 770-773. [19] HOU X, ZHOU Y, WANG L, et al. Growth and thermoelectric properties of Ba8Ga16Ge30 clathrate crystals[J]. Journal of Alloys and Compounds, 2009, 482(1): 544-547. [20] SONG F, WU L, LIANG S. Giant Seebeck coefficient thermoelectric device of MnO2 powder[J]. Nanotechnology, 2012, 23(8): 085401. doi: 10.1088/0957-4484/23/8/085401 [21] ISLAM A K M, ISLAM R, KHAN K A. Studies on the thermoelectric effect in semiconducting MnO2 thin films[J]. Journal of Materials Science: Materials in Electronics, 2005, 16(4): 203-207. doi: 10.1007/s10854-005-0766-1 [22] HEDDEN M, FRANCIS N, HARALDSEN J T, et al. Thermoelectric properties of nano- meso- micro β-MnO2 powders as a function of electrical resistance[J]. Nanoscale Research Letters, 2015, 10(1): 292-300. doi: 10.1186/s11671-015-1000-6 [23] 中国建筑材料联合会. 水泥胶砂强度检验方法(ISO法). GB/T 17671—2021[S]. 1—2021[S]. 北京: 中国标准出版社, 2021.China Building Materials Federation. Test method of cement mortar strength (ISO method). GB/T 17671—2021[S]. Beijing: China Standards Press, 2021(in Chinese).andards Press, 2021(in Chinese). [24] HAN B, GUAN X, OU J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors[J]. Sensors and Actuators A: Physical, 2007, 135(2): 360-369. doi: 10.1016/j.sna.2006.08.003 [25] 中国建筑科学研究院. 普通混凝土长期性能和耐久性能试验方法标准. GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009.d-citation>China Academy of Building Research. Standard for test methods of long-term performance and durability of ordinary concrete. GB/T 50082—2009[S]. Beijing: China Architecture & Building Press, 2009(in Chinese).ilding Press, 2009(in Chinese). [26] CAO G, SU L, ZHANG X, et al. Hydrothermal synthesis and catalytic properties of α-and β-MnO2 nanorods[J]. Materials Research Bulletin, 2010, 45(4): 425-428. doi: 10.1016/j.materresbull.2009.12.016 [27] MAKAR J M, CHAN G W. Growth of cement hydration products on single walled carbon nanotubes[J]. Journal of the American Ceramic Society, 2010, 92(6): 1303-1310. [28] CARRICO A, BOGAS J A, HAWREEN A, et al. Durability of multi-walled carbon nanotube reinforced concrete[J]. Construction and Building Materials, 2018, 164: 121-133. doi: 10.1016/j.conbuildmat.2017.12.221 [29] TYSON B M, ABU AI-RUB R K, YAZDANBAKHSH A, et al. Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials[J]. Journal of Materials in Civil Engineering, 2011, 23(7): 1028-1035. doi: 10.1061/(ASCE)MT.1943-5533.0000266 [30] ASTM International. Standard test method for corrosion potentials of uncoated reinforcing steel in concrete: ASTM C876—2009[S]. West Conshohocken: ASTM International, 2009. [31] ZENG Y. Passive film properties and their influence on hydrogen absorption into titanium[D]. London: University of Western Ontario, 2009. [32] ANDRADE C, ALONSO C. Corrosion rate monitoring in the laboratory and on-site[J]. Construction Building Materials, 1996, 10(5): 315-328. doi: 10.1016/0950-0618(95)00044-5 [33] 刘昂. 水滑石基功能化缓蚀-涂层防护体系构建和机制研究[D]. 青岛: 中国科学院大学, 2020.LIU Ang. The protection system construction and mechanism research of functional corrosion inhibition-coating based on layered double hydroxides[D]. Qingdao: University of Chinese Academy of Sciences, 2020(in Chinese). [34] SUN Z W, KONG G, CHE C S, et al. Growth behaviour of cerium-based conversion coating on ZnAl alloy[J]. Surface and Interface Analysis, 2018, 51(4): 465-474. [35] 中国钢铁工业协会. 金属和合金的腐蚀 混凝土用钢筋的阴极保护. GB/T 39154—2020[S]. 北京: 中国标准出版社, 2020.-citation>China Iron and Steel Association. Corrosion of metals and alloys-cathodic protection of and alloys-cathodic protection of steel in concrete: GB/T 39154—2020[S]. Beijing: China Standards Press, 2020(in Chinese). -

下载:

下载: