Preparation and properties of anisotropic cellulose nanofiber/aramidnanofiber composite foam

-

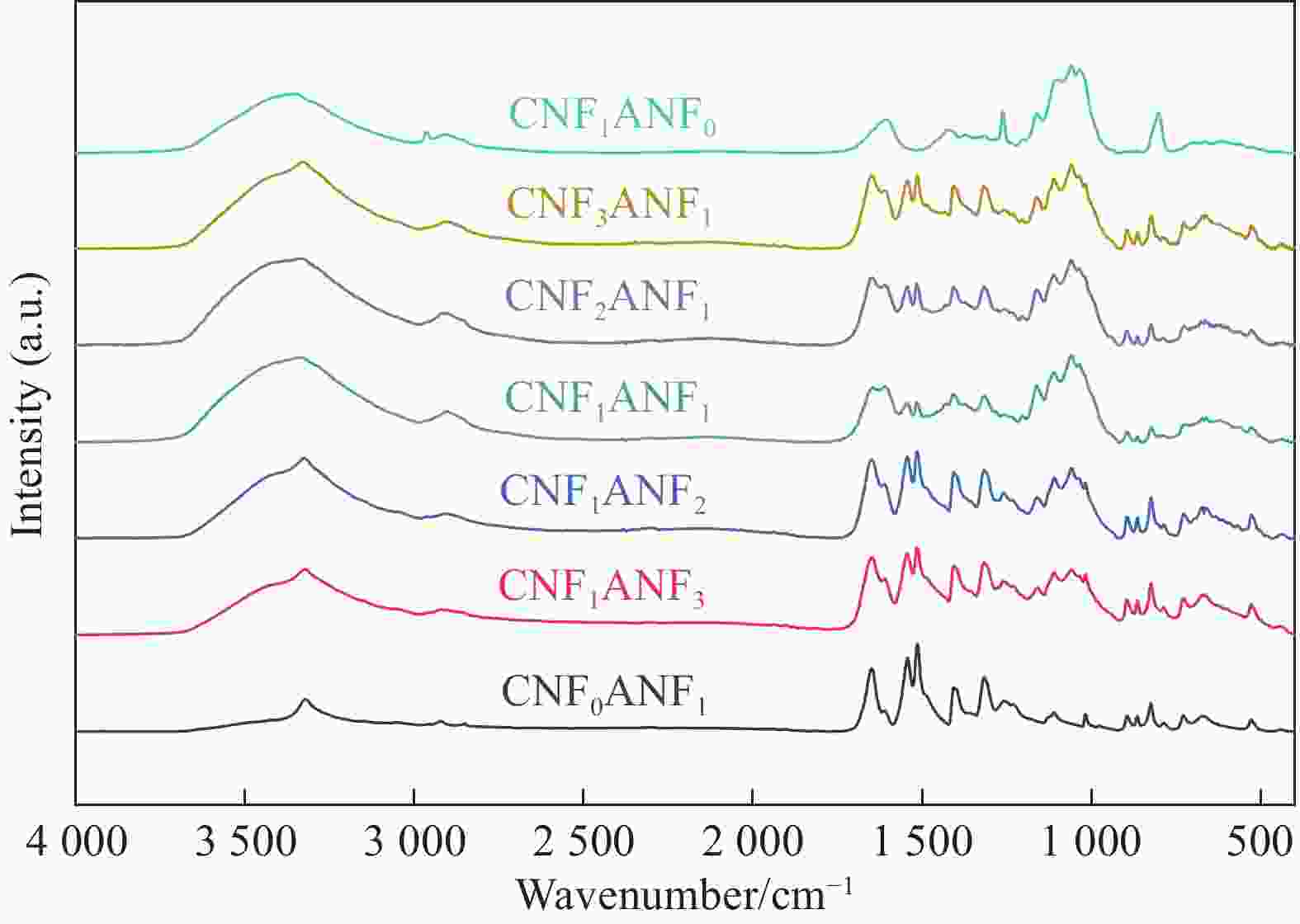

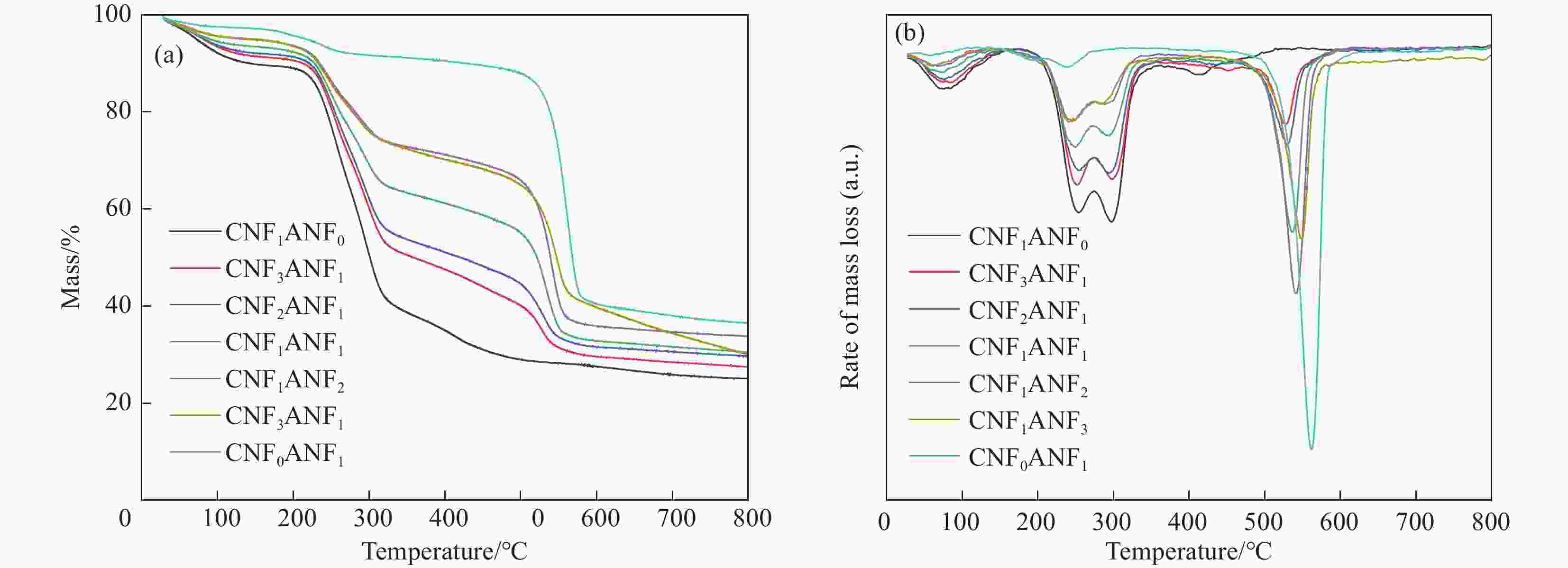

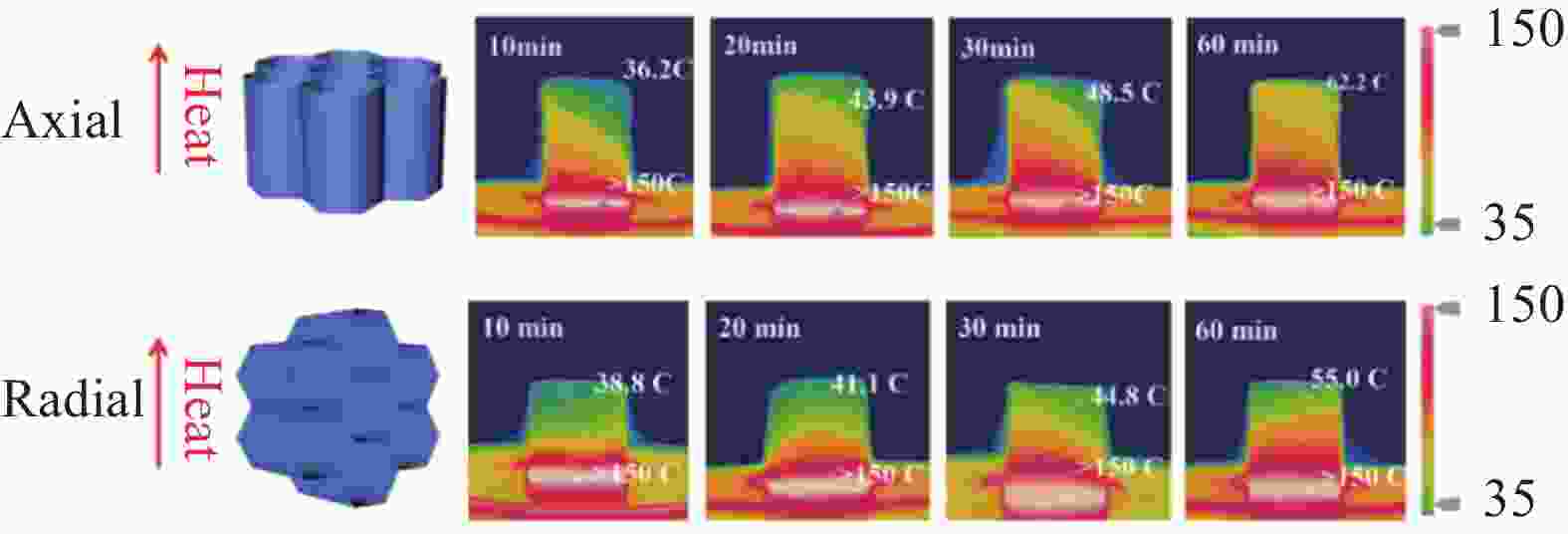

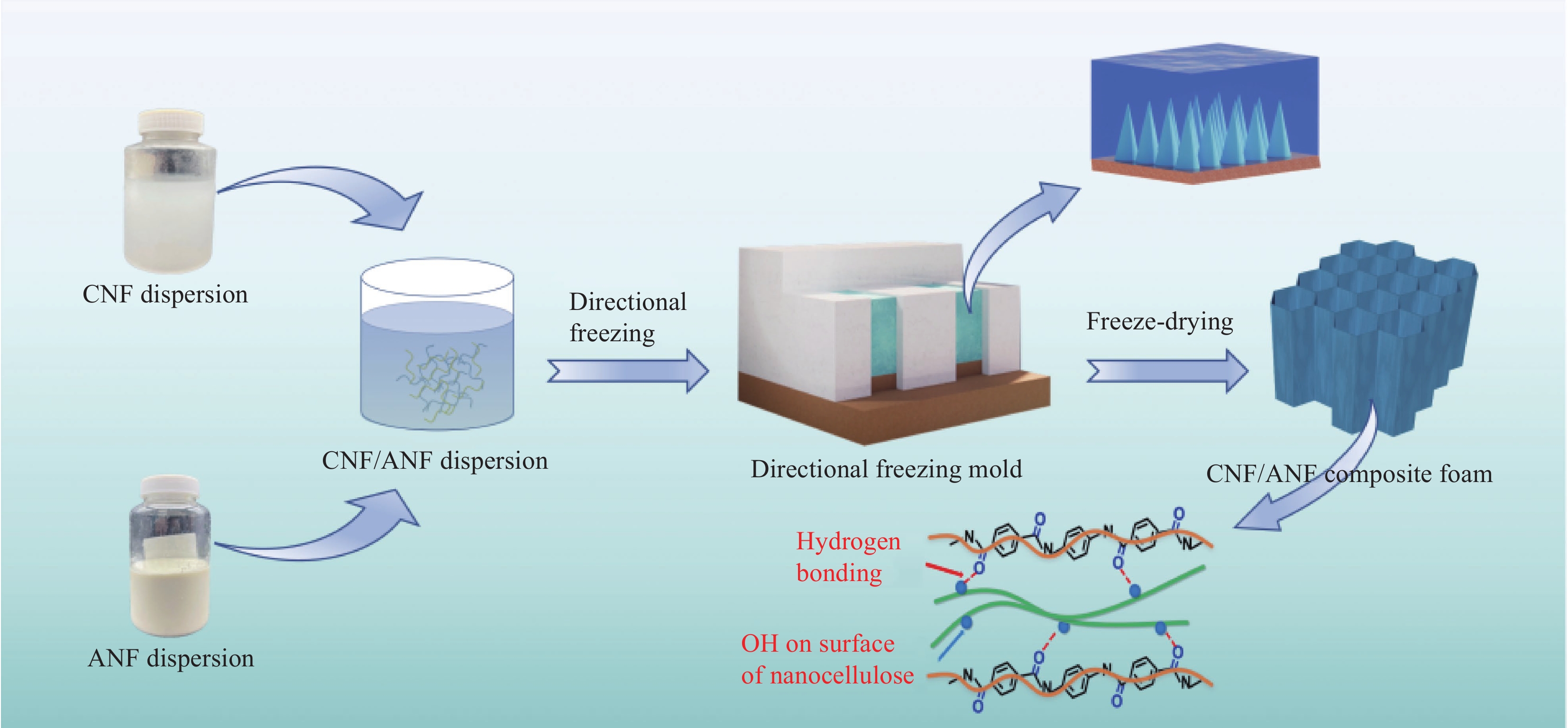

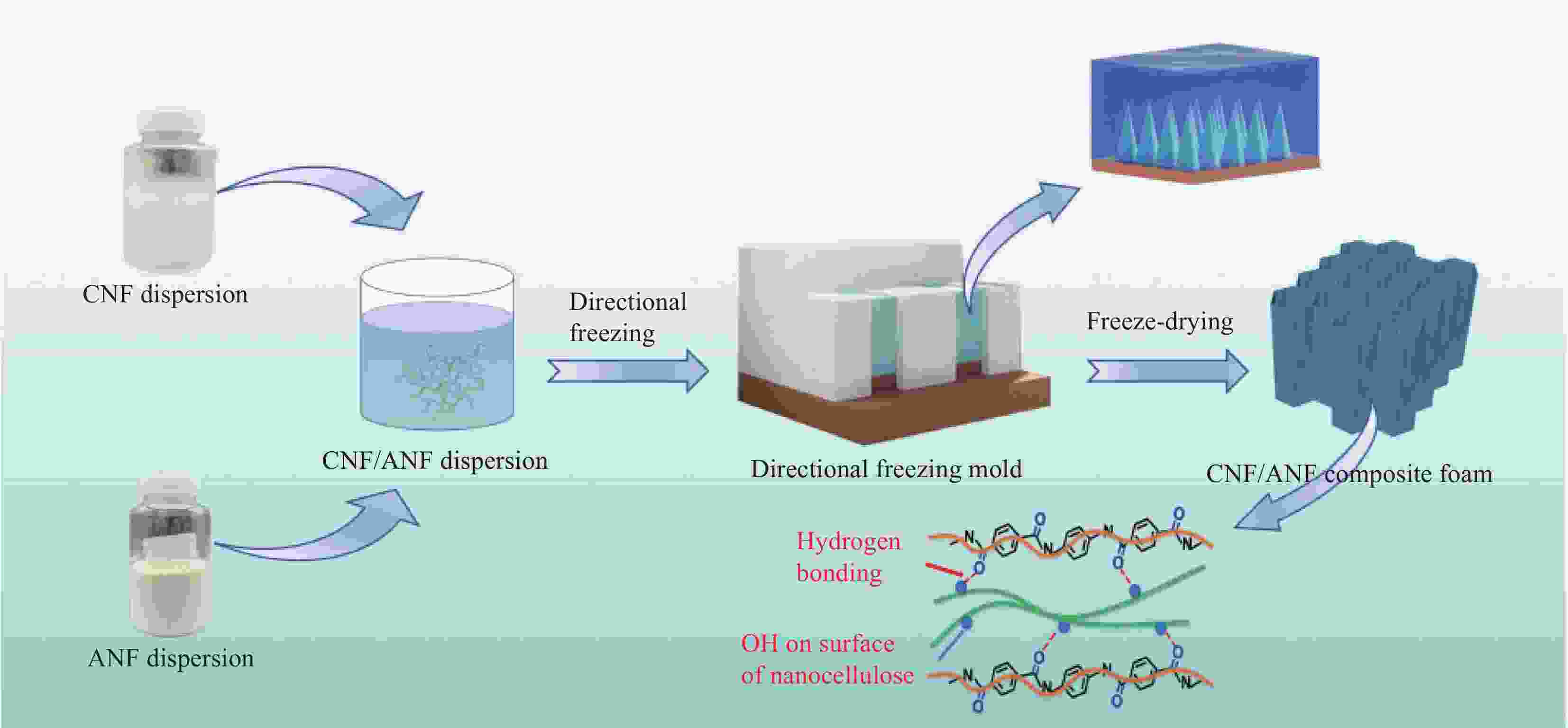

摘要: 纤维素纳米纤维(CNF)泡沫材料因其轻质、可生物降解、可再生性以及优良的隔热性能等特点,在保温隔热领域备受关注。但是CNF泡沫存在力学性能差、热稳定性差、易燃等缺点,在一定程度限制了其实际应用。本文通过将CNF与芳纶纳米纤维(ANF)进行复合,通过冰模板法和冷冻干燥技术制备了具有各向异性结构的CNF/ANF复合泡沫。探究了ANF添加量和各向异性结构的引入对复合泡沫微观结构、力学性能、热稳定性和隔热性能的影响。结果表明,当CNF和ANF的质量比为2∶1时,CNF/ANF复合泡沫具有超低的密度(12.25 mg/cm3)、良好的力学强度(纵向压缩强度为74.56 kPa)和优异的隔热性能(25.2 mW/(m·K)),此外,该复合泡沫还具有良好的热稳定性和自熄灭性能,这些特性赋予了其在保温隔热等领域更加广阔的应用前景。Abstract: Cellulose nanofibers (CNF) foam has gained attention in the field of thermal insulation due to its lightweight, biodegradable, renewable nature, and excellent insulation properties. However, CNF foam suffers from drawbacks such as poor mechanical properties, flammability, and limited thermal stability, which restrict their practical applications. This study prepared anisotropic CNF/ANF composite foam by introducing aramid nanofibers (ANF) into nanocellulose fibers, using ice templating method combined with freeze-drying technique. The effects of ANF content and the introduction of anisotropic structure on the microstructure, mechanical properties, thermal stability, and thermal insulation performance of the composite foam were investigated. The results showed that,when the mass ratio of CNF to ANF is 2∶1, the CNF/ANF composite foam exhibits an ultra-low density (12.25 mg/cm3), good mechanical strength (axial compressive strength of 74.56 kPa), and excellent thermal insulation performance (25.2 mW/(m·K)). Additionally, this composite foam also possesses good thermal stability and flame retardant properties, which endow it with broad prospects for applications in areas such as insulation and self-extinguishing property.

-

Key words:

- foam /

- aramid nanofiber /

- cellulose nanofiber /

- directional freeze-casting /

- thermal insulation /

- self-extinguishing

-

图 4 CNF/ANF复合泡沫纵切面和横切面上的SEM图像:(a1, a2) CNF1ANF0;(b1,b2) CNF3ANF1;(c1,c2) CNF2ANF1;(d1,d2) CNF1ANF1;(e1,e2) CNF1ANF2; (f1,f2) CNF1ANF3;(g1,g2) CNF0ANF1

Figure 4. SEM images of CNF/ANF composite foam at axial and radial section: (a1, a2) CNF1ANF0; (b1,b2) CNF3ANF1; (c1,c2) CNF2ANF1; (d1,d2) CNF1ANF1; (e1,e2) CNF1ANF2; (f1,f2) CNF1ANF3 ; (g1,g2) CNF0ANF1

图 7 (a)泡沫在纵向/横向上的导热系数;(b) CNF/ANF复合泡沫与其他研究导热系数对比图[21–27]

Figure 7. (a) Thermal conductivity of foam in the axial and radial directions; (b) Comparison graph of thermal conductivity between CNF/ANF composite foam in other researches[21–27]

ATM—Acid tempo methyltrimethoxysilane; PVA-co-PE—Polyvinyl alcohol-co-ethylene; PAN/BA-a/SiO2—Polyacrylonitrile/Bifunctional benzoxazine/SiO2; GA—Gelatin aerogel; PVA/CNF/GONS—Polyvinyl alcohol/Cellulose nanofibrils/Graphene

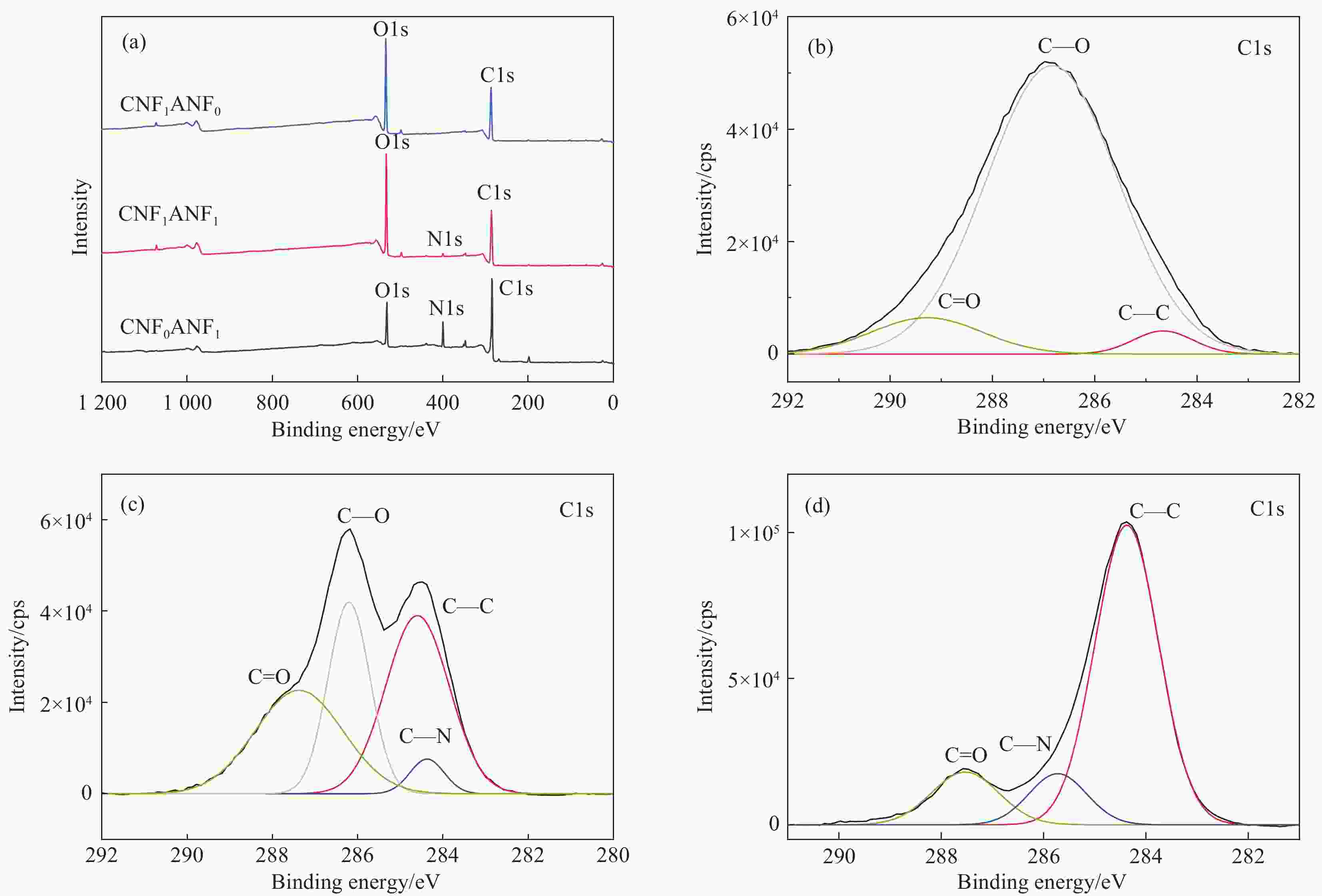

表 1 CNF1ANF0、CNF1ANF1、CNF0ANF1复合泡沫的元素含量分析(at%)

Table 1. Element content analysis of CNF1ANF0, CNF1ANF1, and CNF0ANF1 composite foam (at%)

Sample C N O CNF1ANF0 56.21 0.61 43.18 CNF1ANF1 53.72 2.79 43.49 CNF0ANF1 72.36 13.68 13.96 表 2 不同配比的CNF/ANF复合泡沫的密度、孔隙率以及收缩率

Table 2. Density, porosity and shrinkage of CNF/ANF composite foam with different ratios

Sample Density/

(mg·cm−3)Porosity/% Shrinkage

ratio/%CNF1ANF0 13.67±0.59 99.07±0.04 18.30±0.05 CNF3ANF1 12.57±0.88 99.15±0.06 17.02±0.14 CNF2ANF1 12.25±1.02 99.16±0.07 16.58±0.11 CNF1ANF1 12.63±1.41 99.13±0.10 16.40±0.07 CNF1ANF2 12.92±0.65 99.10±0.05 16.56±0.08 CNF1ANF3 11.11±0.86 99.26±0.09 16.25±0.012 CNF0ANF1 11.49±0.96 98.97±0.07 15.50±0.07 -

[1] YU Z, YANG N, APOSTOLOPOULOU V, et al. Fire-retardant and thermally insulating phenolic-silica aerogels[J]. Angewandte Chemie International Edition, 2018, 130(17): 4628-4632. doi: 10.1002/ange.201711717 [2] MOON R J, MARTIN A, NAIRN J, et al. Cellulose nanomaterials review: Structure, properties and nanocomposites[J]. Chemical Society Reviews, 2011, 40(7): 3941. doi: 10.1039/c0cs00108b [3] 陈一鸣. 各向异性纳米纤维素气凝胶的结构调控及其性能影响机制研究[D]. 南京:南京林业大学, 2021.CHEN Yiming. Structure control and mechanism investigation of anisotropic nanocellulose aerogels and their performance effects [D]. Nanjing: Nanjing Forestry University, 2021(in Chinese). [4] ZHENG R, HU J, LIN Z, et al. Anisotropic polyimide/cellulose nanofibril composite aerogels for thermal insulation and flame retardancy[J]. ACS Applied Polymer Materials, 2023, 5(6): 41804189. [5] 桓珊, 赵国栋, 李晓捷, 等. 芳纶复合纳米纤维气凝胶的制备及其性能研究[J]. 合成纤维, 2021, 50(6): 30-35.HUAN Shan, ZHAO Guodong, LI Xiaojie, et al. Preparation and performance study of aromatic polyamide composite nanofiber aerogels[J]. Synthetic Fiber, 2021, 50(6): 30-35(in Chinese). [6] XIE C, LIU S, ZHANG Q, et al. Macroscopic-scale preparation of aramid nanofiber aerogel by modified freezing-drying method[J]. ACS Nano, 2021, 15(6): 10000-10009. doi: 10.1021/acsnano.1c01551 [7] 黄连青. 芳纶纳米纤维高效制备及其有序结构凝胶构筑机制的研究[D]. 西安: 陕西科技大学, 2022.HUANG Lianqing. Efficient Preparation of Aromatic polyamide nanofibers and study on the mechanism of ordered structure gel construction[D]. Xi'an: Shaanxi University of Science and Technology(in Chinese). [8] 刘增伟. 芳纶气凝胶纤维的制备表征及应用[D]. 合肥: 中国科学技术大学, 2022.LIU Zengwei. Preparation, characterization, and application of aromatic polyamide aerogel fibers [D]. Hefei: University of Science and Technology of China, 2022(in Chinese). [9] ZHENG J, HANG T, Li Z, et al. High-performance and multifunctional conductive aerogel films for outstanding electromagnetic interference shielding, Joule heating and energy harvesting[J]. Chemical Engineering Journal, 2023, 471: 144548. [10] LIU Q, SGENG M, DUAN C, et al. 3D hierarchical porous carbon aerogel electrocatalysts based on cellulose/aramid nanofibers and application in high-performance Zn–Air batteries[J]. ACS Applied Energy Materials, 2022, 5(12): 15146-15154. doi: 10.1021/acsaem.2c02801 [11] 胡锦澜, 李嘉杰, 张彦飞, 等. 环氧树脂/多巴胺增强芳纶纤维界面性能[J]. 工程塑料应用, 2023, 51(4): 36-41.HU Jinlan, LI Jiajie, ZHANG Yanfei, et al. Interface performance of epoxy resin/dopamine reinforced aromatic aramid fiber[J]. Engineering Plastics Application, 2023, 51(4): 36-41(in Chinese). [12] YANG B, WANG L, ZHANG M, et al. Fabrication, applications, and prospects of aramid nanofiber[J]. Advanced Functional Materials, 2020, 30(22): 2000186. doi: 10.1002/adfm.202000186 [13] YANG B, WANG L, ZHANG M, et al. Timesaving, high-efficiency approaches to fabricate aramid nanofibers[J]. ACS Nano, 2019, 13(7): 7886-7897. doi: 10.1021/acsnano.9b02258 [14] MAITI S, JAYARAMUDU J, DAS K, et al. Preparation and characterization of nano-cellulose with new shape from different precursor[J]. Carbohydrate Polymers, 2013, 98(1): 562-567. doi: 10.1016/j.carbpol.2013.06.029 [15] WANG S, MENG W, LV H, et al. Thermal insulating, light-weight and conductive cellulose/aramid nanofibers composite aerogel for pressure sensing[J]. Carbohydrate Polymers, 2021, 270: 118414. [16] 张艳, 马忠雷, 李桢, 等. 轻质高强MXene/细菌纤维素复合气凝胶的制备及其电磁屏蔽性能[J]. 复合材料学报, 2023, 40(11): 6409-6417. doi: 10.13801/j.cnki.fhclxb.20230109.003ZHANG Yan, MA Zhonglei, LI Zhen, et al. Preparation and EMI shielding properties of lightweight and mechanically strong MXene/bacterial cellulose composite aerogels[J]. Acta Materiae Compo-sitae Sinica, 2023, 40(11): 6409-6417(in Chinese). doi: 10.13801/j.cnki.fhclxb.20230109.003 [17] YANG M, ZHAO N, CUI Y, et al. Biomimetic architectured graphene aerogel with exceptional strength and resilience[J]. ACS Nano, 2017, 11(7): 6817-6824. doi: 10.1021/acsnano.7b01815 [18] YANG X, CRANSTON E D. Chemically cross-linked cellulose nanocrystal aerogels with shape recovery and superabsorbent properties[J]. Chemistry of Materials, 2014, 26(20): 6016-6025. doi: 10.1021/cm502873c [19] ZHANG J, CHANG Y, TEBYETEKERWA M, et al. “Stiff–Soft” binary synergistic aerogels with superf-lexibility and high thermal insulation performance[J]. Advanced Functional Materials, 2019, 29(15): 1806407. doi: 10.1002/adfm.201806407 [20] APOSTOLOPOULOU V, MUNIER P, BERGSTROM L. Thermally insulating nanocellulose-based materials[J]. Advanced Materials, 2021, 33(28): 2001839. doi: 10.1002/adma.202001839 [21] WICKLEIN B, KOCJAN A, SALAZAR G, et al. Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide[J]. Nature Nanotechnology, 2015, 10(3): 277-283. doi: 10.1038/nnano.2014.248 [22] JIANG S, ZHANG M, JIANG W, et al. Multiscale nanocelluloses hybrid aerogels for thermal insulation: The study on mechanical and thermal properties[J]. Carbohydrate Polymers, 2020, 247: 116701. doi: 10.1016/j.carbpol.2020.116701 [23] ZUO X, CHANG K, ZHAO J, et al. Bubble-template-assisted synthesis of hollow fullerene-like MoS2 nanocages as a lithium ion battery anode materi-al[J]. Journal of Materials Chemistry A, 2016, 4(1): 51-58. doi: 10.1039/C5TA06869J [24] SI Y, YU J, TANG X, et al. Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality[J]. Nature Communications, 2014, 5(1): 5802. doi: 10.1038/ncomms6802 [25] JIANG S, ZHANG M, LI M, et al. Cellulose nanofiber (CNF) based aerogels prepared by a facile process and the investigation of thermal insulati-on performance[J]. Cellulose, 2020, 27(11): 6217-6233. doi: 10.1007/s10570-020-03224-4 [26] JAVADI A, ZHENG Q, PAYEN F, et al. Polyvinyl alcohol-cellulose nanofibrils-graphene oxide hybrid organic aerogels[J]. ACS Applied Materials & Interfaces, 2013, 5(13): 5969-5975. [27] DRUEL L, BARDL R, VORWERG W, et al. Starch aerogels: A member of the family of thermal super insulating materials[J]. Biomacromolecules, 2017, 18(12): 4232-4239. doi: 10.1021/acs.biomac.7b01272 [28] YANG M, CAO K, SUI L, et al. Dispersions of aramid nanofibers: A new nanoscale building block[J]. ACS Nano, 2011, 5(9): 6945-6954. doi: 10.1021/nn2014003 -

下载:

下载: