In-plane compression properties of foam-filled anti-tetrachiral structure and re-entrant structure

-

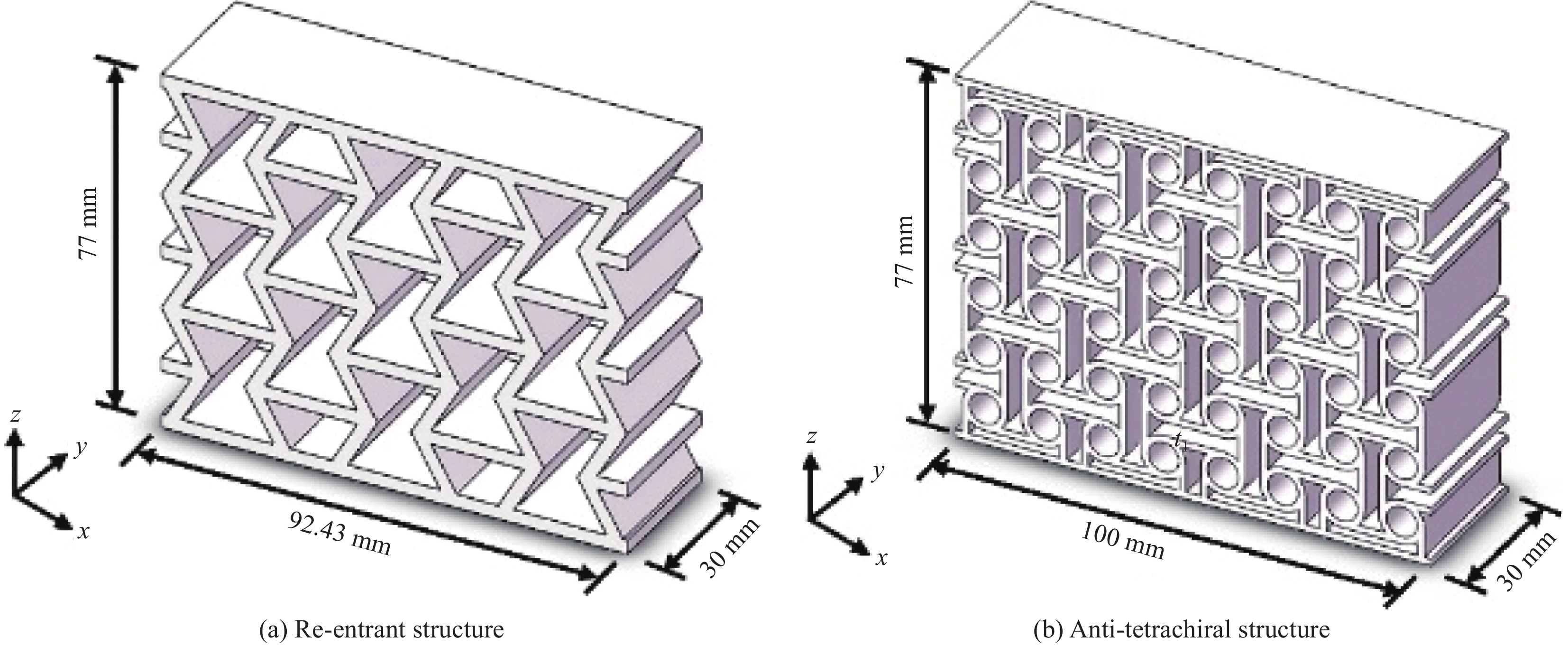

摘要: 负泊松比蜂窝结构具有优良的力学性能,包括抗压痕性、抗冲击性、吸能性。为了更好地研究负泊松比结构的力学性能,分别选取了内凹结构和四韧带反手性结构两种负泊松比结构进行对比分析。为了提高蜂窝结构的力学性能,在结构中填充聚氨酯泡沫材料。并对填充后的内凹结构和四韧带反手性结构的变形模式和力学性能进行了试验研究。此外通过对填充四韧带反手性结构进行参数研究,分析了壁厚t和节点半径r对结构吸能性和泊松比的影响。研究结果表明:四韧带反手性结构比内凹结构的吸能性好、承载能力强。对两种结构分别进行填充后,结构具有更高的的刚度和吸能性,但是“拉胀”效应减弱。随着壁厚t和节点半径r的增加,填充四韧带反手性结构的刚度和能量吸收能力增强,泊松比值增大,“拉胀”效应减弱。但是壁厚过大会使结构脆性破坏增强,其比吸能性降低。另外随着壁厚t增大、节点半径减小,填充四韧带反手性结构的压实应变减小。Abstract: Negative Poisson's ratio honeycomb structure has excellent mechanical properties including indentation resistance, impact resistance and energy absorption. In order to better study the mechanical properties of negative Poisson's ratio structure, this paper selects two kinds of negative Poisson's ratio structure: Anti-tetrachiral structure and re-entrant structure for comparative analysis. In order to improve the mechanical properties of honeycomb structure, polyurethane foam was filled in the structure. The deformation modes and mechanical properties of the foam-filled anti-tetrachiral structure and re-entrant structure were experimentally studied. In addition, through the parametric study of the foam-filled anti-tetrachiral structure, the effects of wall thickness ‘t’ and node radius ‘r’ on the energy absorption and Poisson's ratio of the structure were analyzed. The results show that the energy absorption and bearing capacity of anti-tetrachiral structure is better than that of the re-entrant structure. After filling the two kinds of structures respectively, the structure has higher stiffness and energy absorption, but the ‘auxetics’ effect is weakened. With the increase of wall thickness ‘t’ and node radius ‘r’, the stiffness and energy absorption capacity of the foam-filled anti-tetrachiral structure increase, the Poisson's ratio increases, and the ‘auxetics’ effect decreases. However, the brittle failure of the structure is enhanced and its specific energy absorption is weakened when the wall thickness is too thick. In addition, the compaction strain of the four-ligament backhand structure decreases with the increase of the wall thickness ‘t’ and the decrease of the node radius ‘r’.

-

图 2 不同负泊松比结构单胞示意图

Figure 2. Unit cell schematic of different negative Poisson's ratio structures

a—Horizontal rib length; t1—Wall thickness of RS; h—Height; θ—Angle of inclination of the ribs; L—Horizontal and vertical center-to-center distance between ATC cells; t2—Wall thickness of ATC; r—Radius of the circular node; ATC—Anti-tetrachiral structure; RS—Re-entrant structure

表 1 不同参数ATC结构的准静态压缩试验能量吸收指标

Sample class ATC1 ATC2 ATC3 ATC4 ATC5 ATC6 εD 0.63 0.56 0.61 0.62 0.60 0.56 SEA/(J·kg-1) 2566 2712 2810 3690 3260 2513 σmax/MPa 1.59 2.06 2.55 3.28 4.40 5.75 表 1 四韧带反手性结构(ATC)参数

Table 1. Anti-tetrachiral structure (ATC) parameters

Sample L/mm r/mm t/mm ATC1 12.50 4.00 0.75 ATC2 12.50 3.50 1.00 ATC3 12.50 4.00 1.00 ATC4 12.50 4.50 1.00 ATC5 12.50 4.00 1.25 ATC6 12.50 4.00 1.50 表 2 内凹结构(RS)参数

Table 2. Re-entrant structure (RS) parameters

Sample a/mm h/mm θ/(°) t/mm RS 25 25 55 2 表 3 C-UV9400 E的材料性能

Table 3. Material properties of C-UV9400 E

Materials Strength of extension/MPa Young's modulus/MPa Elongation at break/% Density/(g·cm−3) C-UV9400 E 56 2650 12 1.19 表 4 不同参数ATC结构的准静态压缩试验能量吸收指标

Table 4. Energy absorption indexes of quasi-static compression test of ATC structures with different parameters

Sample εD ESA/(J·kg−1) σmax/MPa ATC1 0.63 2566 1.59 ATC2 0.56 2712 2.06 ATC3 0.61 2810 2.55 ATC4 0.62 3690 3.28 ATC5 0.60 3260 4.40 ATC6 0.56 2513 5.75 -

[1] EVANS K E. Auxetic polymers: A new range of materials[J]. Endeavour, 1991, 15(4): 170-174 [2] LOVE A E H. A treatise on the mathematical theory of elasticity[M]. Cambridge: Cambridge University Press, 1927: 104-106 [3] SCARPA F. Auxetic materials for bioprostheses[J]. IEEE Signal Processing Magazine, 2008, 25(5): 126-128 [4] LIU Y, HU H. A review on auxetic structures and polymeric materials[J]. Scientific Research and Essays, 2010, 5(10): 1052-1063. [5] LIU Q. Literature review: Materials with negative Poisson's ratios and potential applications to aerospace and defence[M]. Victoria: DSTO, 2006: 31-37. [6] MA Z D, BIAN H, SUN C, et al. Functionally-graded NPR (negative Poisson's ratio) material for a blast-protective deflector[C]//Proceedings of the 2010 NDIA Ground Vehicle Systems Engineering and Technology Symposium Modeling & Simulation, Testing and Validation Mini-Symposium. Dearborn: 2010: 17-19. [7] MA Y, SCARPA F, ZHANG D, et al. A nonlinear auxetic structural vibration damper with metal rubber particles[J]. Smart Materials and Structures, 2013, 22(8): 084012. doi: 10.1088/0964-1726/22/8/084012 [8] 尤泽华, 肖俊华, 王美芬. 弧边内凹蜂窝负泊松比结构的力学性能[J]. 复合材料学报, 2022, 39(7): 3570-3580. doi: 10.13801/j.cnki.fhclxb.20210729.003YOU Zehua, XIAO Junhua, WANG Meifen. Mechanical properties of arc concave honeycomb structure with negative Poisson's ratio[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3570-3580(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210729.003 [9] 刘旭畅, 李爽, 杨金水. 一种新型手性负泊松比结构的减振性能[J]. 复合材料学报, 2024, 41(1): 477-484.LIU Xuchang, LI Shuang, YANG Jinshui. Damping performance of a new chiral negative Poisson's ratio structure [J]. Acta Materiae Compositae Sinica, 2024, 41(1): 477-484(in Chinese). [10] 刘浩, 周宏元, 王小娟, 等. 泡沫混凝土填充旋转薄壁多胞方管负泊松比结构面内压缩性能[J]. 复合材料学报, 2024, 41(2): 839-857.LIU Hao, ZHOU Hongyuan, WANG Xiaojuan, et al. In-plane compression properties of negative Poisson's ratio structure of rotating thin walled multi-cell square tubes with foam concrete filler[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 839-857(in Chinese). [11] 高飞宇. 四韧带反手性蜂窝的面外变形分析[D]. 哈尔滨: 哈尔滨工业大学, 2021.GAO Feiyu. Analysis of out-of-plane deformation of anti-tetra-chiral honeycomb[D]. Harbin: Harbin Institute of Technology, 2021 (in Chinese). [12] 吕亦乐. 负泊松比超材料的减振性能研究[D]. 成都: 电子科技大学, 2020.LYU Yile. Study on damping performance of negative Poisson's ratio metamaterials[D]. Chengdu: School of Mechanical and Electrical Engineering, 2020(in Chinese). [13] 王奕霖, 秦卫阳, 刘琦. 负泊松比超材料减振结构设计与实验验证[J]. 动力学与控制学报, 2023, 21(5): 53-59.WANG Yilin, QIN Weiyang, LIU Qi. A vibration attenuation structure based on negative Poisson' ratio metamaterial and its experimental validation[J]. Journal of Dynamics and Control, 2023, 21(5): 53-59(in Chinese). [14] 周宏元, 贾昆程, 王小娟, 等. 负泊松比三明治结构填充泡沫混凝土的面内压缩性能[J]. 复合材料学报, 2020, 37(8): 2005-2014. doi: 10.13801/j.cnki.fhclxb.20191207.001ZHOU Hongyuan, JIA Kuncheng, WANG Xiaojuan, et al. In-plane compression properties of negative Poisson's ratio sandwich structure filled with foam concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 2005-2014(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191207.001 [15] 赵飞, 朱鹏飞, 李梦瑶, 等. 钢筋混凝土的负泊松比设计与抗弯性能研究[J]. 硅酸盐通报, 2023, 42(5): 1640-1649. doi: 10.16552/j.cnki.issn1001-1625.2023.05.005ZHAO Fei, ZHU Pengfei, LI Mengyao, et al. Negative Poisson' ratio design and flexural performance of reinforced concrete[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(5): 1640-1649(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2023.05.005 [16] 王陶. 负泊松比结构力学特性研究及其在商用车耐撞性优化设计中的应用[D]. 南京: 南京理工大学, 2019.WANG Tao. Mechanical research of an auxetic cellular structure and its application in commercial vehicle crashworthiness optimization design[D]. Nanjing: Nanjing University of Science and Technology, 2019(in Chinese). [17] 马芳武, 梁鸿宇, 赵颖, 等. 倾斜荷载下内凹三角形负泊松比材料的面内冲击动力学性能[J]. 振动与冲击, 2020, 39(4): 81-87. doi: 10.13465/j.cnki.jvs.2020.04.010MA Fangwu, LIANG Hongyu, ZHAO Ying, et al. In-plane dynamic crushing of concave triangles materials with negative Poisson's ratio under inclined load[J]. Journal of Vibration and Shock, 2020, 39(4): 81-87(in Chinese). doi: 10.13465/j.cnki.jvs.2020.04.010 [18] PENG B, YANG Y, GU K, et al. Digital light processing 3D printing of triple shape memory polymer for sequential shape shifting[J]. ACS Materials Letters, 2019, 1(4): 410-417 doi: 10.1021/acsmaterialslett.9b00262 [19] 罗伟洪, 何婉青, 吴文军, 等. 不同速度下负泊松比弧形结构的变形行为[J]. 爆炸与冲击, 2023, 43(11): 75-87.LUO Weihong, HE Wanqing, WU Wenjun, et al. Deformation behavior of curved structures with negative Poisson's ratio at diverse velocities[J]. Explosion and Shock Waves, 2023, 43(11): 75-87(in Chinese). [20] LI T, CHEN Y, HU X, et al. Exploiting negative Poisson's ratio to design 3D-printed composites with enhanced mechanical properties[J]. Materials & Design, 2018, 142: 247-258. [21] SCARPA F, TOMLIN P J. On the transverse shear modulus of negative Poisson's ratio honeycomb structures[J]. Fatigue & Fracture of Engineering Materials & Structures, 2000, 23(8): 717-720. [22] LAKES R S, ELMS K. Indentability of conventional and negative Poisson's ratio foams[J]. Journal of Composite Materials, 1993, 27(12): 1193-1202. doi: 10.1177/002199839302701203 [23] LAKES R. Foam structures with a negative Poisson's ratio[J]. Science, 1987, 235(4792): 1038-1040. doi: 10.1126/science.235.4792.1038 [24] OH J H, KIM J S, OH I K. Auxetic graphene oxide-porous foam for acoustic wave and shock energy dissipation[J]. Composites Part B: Engineering, 2020, 186: 107817. doi: 10.1016/j.compositesb.2020.107817 [25] IMBALZANO G, TRAN P, NGO T D, et al. A numerical study of auxetic composite panels under blast loadings[J]. Composite Structures, 2016, 135: 339-352. doi: 10.1016/j.compstruct.2015.09.038 [26] ZHOU J, LIU H, JOHN P, et al. Comparison of different quasi-static loading conditions of additively manufactured composite hexagonal and auxetic cellular structures[J]. International Journal of Mechanical Sciences, 2023, 244: 108054. doi: 10.1016/j.ijmecsci.2022.108054 [27] LUO H C, REN X, ZHANG Y, et al. Mechanical properties of foam-filled hexagonal and re-entrant honeycombs under uniaxial compression[J]. Composite Structures, 2022, 280: 114922. doi: 10.1016/j.compstruct.2021.114922 [28] 韩会龙, 张新春, 王鹏. 负泊松比蜂窝材料的动力学响应及能量吸收特性[J]. 爆炸与冲击, 2019, 39(1): 47-57.HAN Huilong, ZHANG Xinchun, WANG Peng. Dynamic responses and energy absorption properties of honeycombs with negative Poisson's ratio[J]. Explosion and Shock Waves, 2019, 39(1): 47-57(in Chinese). [29] PIETRAS D, LINUL E, SADOESKI T, et al. Out-of-plane crushing response of aluminum honeycombs in-situ filled with graphene-reinforced polyurethane foam[J]. Composite Structures, 2020, 249: 112548. doi: 10.1016/j.compstruct.2020.112548 [30] ALOMARAH A, MASOOD S H, SBARSKI L, et al. Compressive properties of 3D printed auxetic structures: Experimental and numerical studies[J]. Virtual and Physical Prototyping, 2020, 15(1): 1-21. doi: 10.1080/17452759.2019.1644184 [31] SHEN J, LU G, RUAN D. Compressive behaviour of closed-cell aluminium foams at high strain rates[J]. Composites Part B: Engineering, 2010, 41: 678-685. [32] HABIB F N, IOVENITTI P. In-plane energy absorption evaluation of 3D printed polymeric honeycombs[J]. Virtual and Physical Prototyping, 2017, 12: 117-131. doi: 10.1080/17452759.2017.1291354 -

下载:

下载: