Research progress of decommissioned wind power blade resource utilization technology

-

摘要: 风力发电因其清洁、高效、可再生等优点,成为我国能源发展战略行动计划的重要一环,我国已成为全球风电装机规模最大的国家。随着风电机组退役潮的到来,退役风电叶片(Retired wind turbine blades,RWTB)成为我国急需解决的大型固体废弃材料。风电叶片主要由玻璃纤维/碳纤维/植物纤维增强复合材料制备而成,传统处理方式主要为填埋和焚烧,不仅造成大量资源浪费,而且导致环境污染。对RWTB的资源化和高值化利用已成为国家高度关注的研究热点。本文简述了国内外风电装机规模及RWTB的发展规模,综述了风电叶片的现有回收技术(机械回收、热解回收、化学回收)及RWTB的回收应用现状,总结分析了各类回收技术及应用领域的优缺点。对RWTB的回收技术及应用前景进行了分析展望,提出“多措并举”的梯级利用及尽可能避免出现二次废弃物的“高效规范全利用”是RWTB回收利用技术重要的研究方向。Abstract: Wind power, because of its clean, efficient, renewable and other advantages, has become an important part of China's strategic action plan for energy development, and China has become the world's largest installed wind power capacity. With the arrival of the wind turbine retirement tide, the retired wind turbine blade (RWTB) has become a large solid waste material that China urgently needs to solve. Wind turbine blades are mainly prepared from glass fibre/carbon fibre/plant fibre reinforced composites, and the traditional treatment menthods are

mainly landfill and incineration, which not only results in a large amount of wasted resources, but also leads to environmental pollution. The resourceful and high-value utilisation of decommissioned wind turbine blades has become a research hotspot of great concern to the country. This paper briefly describes the scale of installed wind power and the development scale of RWTB at home and abroad, overviews the existing recycling technologies (mechanical recycling, pyrolytic recycling, chemical recycling) of wind turbine blades, overviews the current status of recycling application of RWTB, summarises and analyses the strengths and weaknesses of various types of recycling technologies and the current status of their application. Analysed the prospect of RWTB recycling technology and application, put forward the "multi-method" gradient use and the "high efficiency and standardised full use" without secondary pollution are important research direction of RWTB recycling technology. -

Key words:

- wind power /

- retired wind turbine blades /

- glass fiber /

- machinery recycling /

- pyrolysis recycling /

- chemical recycling

-

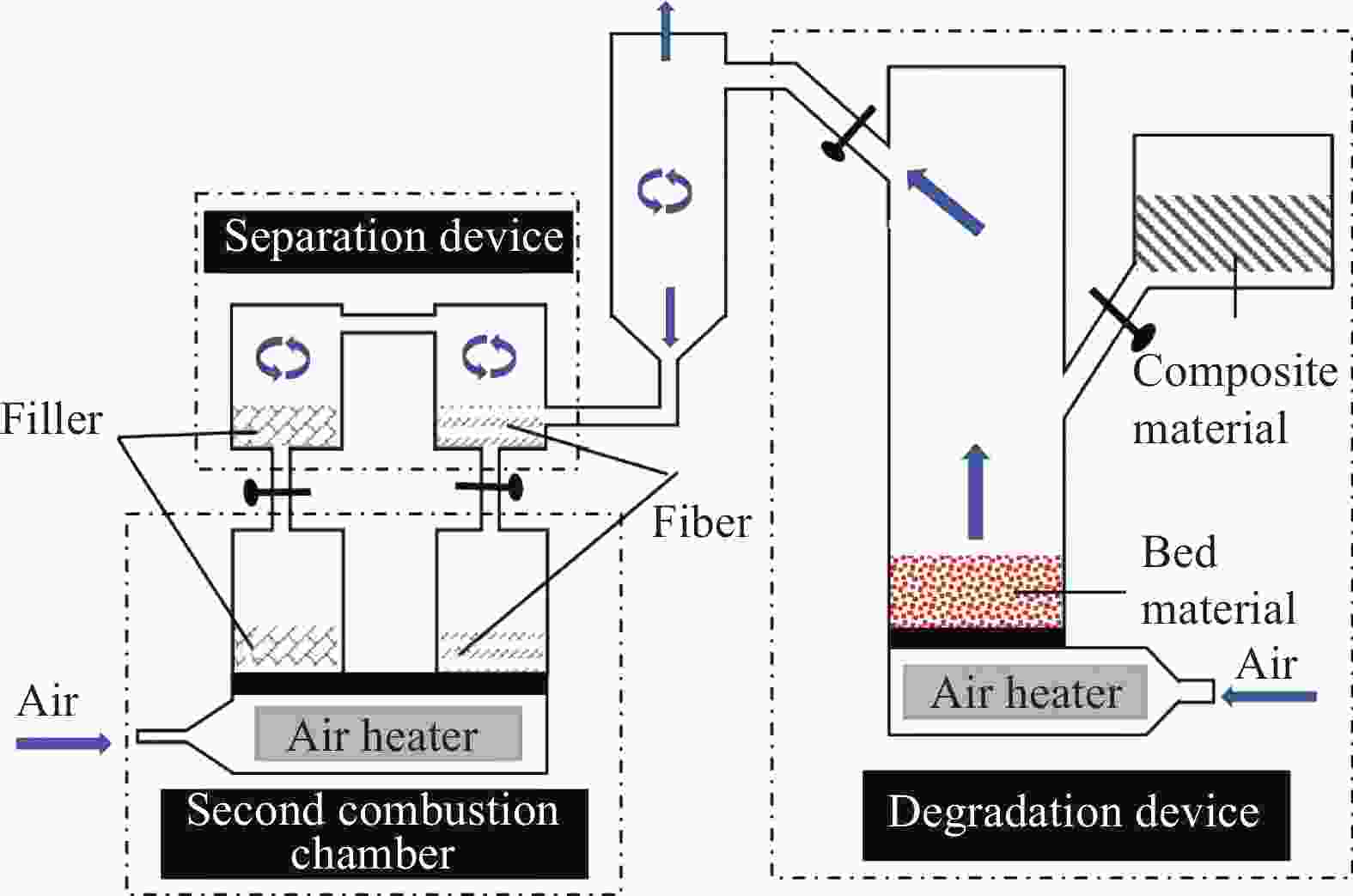

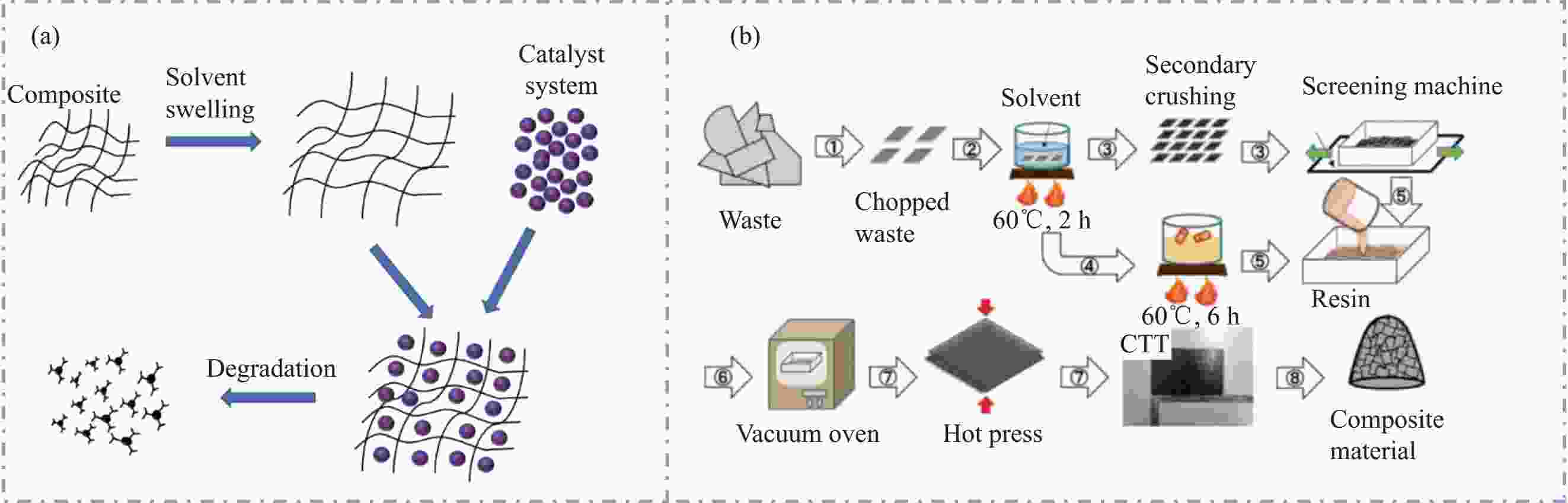

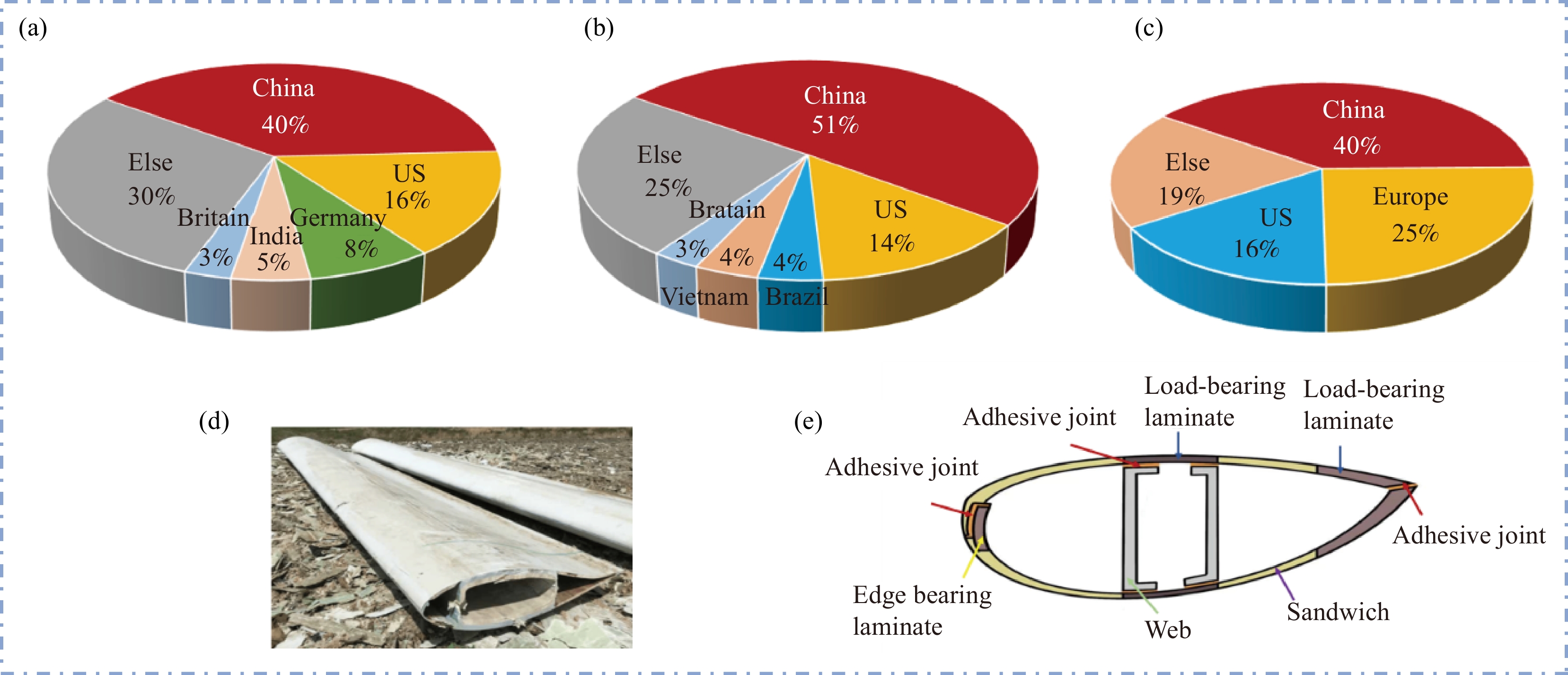

图 1 (a) 累计风电装机容量;(b) 新增风电装机容量;(c) 预计截至2050年累计退役风电叶片(RWTB);(d) RWTB实物图;(e) 风电叶片截面图[9]

Figure 1. (a) Cumulative installed wind power capacity; (b) New installed wind power capacity; (c) Projected cumulative retired wind turbine blades (RWTB) up to 2050 year; (d) RWTB; (e) Wind turbine blade cross section[9]

Recovery process Retained tensile strength of

recycled fibre compared

to virgin fibre/%GF CF Traditional mechanical 78 50 High voltage fragmentation 88 83 Pyrolysis 52 78 Fluidised bed 50 75 Microwave assisted pyrolysis 52 80 Chemical 58 95 Notes: GF—Glass fiber; CF—Carbon fiber. Recovery process Power consumption/(MJ·kg−1) GF GF/CF CF Traditional mechanical 0.26 0.26 0.26 High voltage fragmentation 16.20 16.20 16.20 Pyrolysis 21.21 21.21 21.21 Fluidised bed 22.22 22.22 9.00 Microwave assisted pyrolysis 10.00 10.00 10.00 Chemical 19.20 19.20 19.20 -

[1] RAHMAN A, FARROK O, HAQUE M M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic[J]. Renewable and Sustainable Energy Reviews, 2022, 161: 112279. doi: 10.1016/j.rser.2022.112279 [2] LIU P, BARLOW C Y. Wind turbine blade waste in 2050[J]. Waste Management, 2017, 62: 229-240. doi: 10.1016/j.wasman.2017.02.007 [3] REDDY S S P, SURESH R, MB H, et al. Use of composite materials and hybrid composites in wind turbine blades[J]. Materials Today: Proceedings, 2021, 46: 2827-2830. doi: 10.1016/j.matpr.2021.02.745 [4] 王昊康. 玻璃纤维增强复合材料力学性能研究进展[J]. 合成纤维, 2022, 51(11): 40-43, 68. doi: 10.16090/j.cnki.hcxw.2022.11.005WANG Haokang. Study on the influence of different fiber types on the splitting tensile strength of recycled concrete[J]. Synthetic Fiber in China, 2022, 51(11): 40-43, 68(in Chinese). doi: 10.16090/j.cnki.hcxw.2022.11.005 [5] RAJAK D K, PAGAR D D, MENEZES P L, et al. Fiber-reinforced polymer composites: Manufacturing, properties, and applications[J]. Polymers, 2019, 11(10): 1667. doi: 10.3390/polym11101667 [6] KIM D H, KIM H G, KIM H S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle[J]. Composite Structures, 2015, 131: 742-752. doi: 10.1016/j.compstruct.2015.06.028 [7] JUSTO J, TAVARA L, GARCIA-GUZMAN L, et al. Characterization of 3D printed long fibre reinforced composites[J]. Composite Structures, 2018, 185: 537-548. [8] EGBO M K. A fundamental review on composite materials and some of their applications in biomedical engineering[J]. Journal of King Saud University—Engineering Sciences, 2021, 33(8): 557-568. doi: 10.1016/j.jksues.2020.07.007 [9] MISHNAEVSKY L, BRANNER K, PETERSEN H N, et al. Materials for wind turbine blades: An overview[J]. Materials, 2017, 10(11): 1285. doi: 10.3390/ma10111285 [10] SHUAIB N A, MATIVENGA P T, KAZIE J, et al. Resource efficiency and composite waste in UK supply chain[J]. Procedia CIRP, 2015, 29: 662-667. doi: 10.1016/j.procir.2015.02.042 [11] 陈瑞哲, 程磊磊, 顾菁, 等. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. doi: 10.11949/0438-1157.20221489CHEN Ruizhe, CHENG Leilei, GU Jing, et al. Research progress in chemical recovery technology of fiber-reinforced polymer composites[J]. CIESC Journal, 2023, 74(3): 981-994(in Chinese). doi: 10.11949/0438-1157.20221489 [12] 刘雪辉, 徐世美, 王玉忠. 热固性树脂及其复合材料的升级回收新方法[J]. 中国材料进展, 2022, 41(1): 7-13, 66.LIU Xuehui, XU Shimei, WANG Yuzhong. Upcycling of thermosetting resin and its composites[J]. Materials China, 2022, 41(1): 7-13, 66(in Chinese). [13] DORIGATO A. Recycling of thermosetting composites for wind blade application[J]. Advanced Industrial and Engineering Polymer Research, 2021, 4(2): 116-132. doi: 10.1016/j.aiepr.2021.02.002 [14] MAMANPUSH S H, LI H, ENGLUND K, et al. Recycled wind turbine blades as a feedstock for second generation composites[J]. Waste Management, 2018, 76: 708-714. doi: 10.1016/j.wasman.2018.02.050 [15] LI X, BAI R, MCKECHNIE J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes[J]. Journal of Cleaner Production, 2016, 127: 451-460. doi: 10.1016/j.jclepro.2016.03.139 [16] HOWARTH J, MAREDDY S S R, MATIVENGA P T. Energy intensity and environmental analysis of mechanical recycling of carbon fibre composite[J]. Journal of Cleaner Production, 2014, 81: 46-50. doi: 10.1016/j.jclepro.2014.06.023 [17] SHUAIB N A, MATIVENGA P T. Effect of process parameters on mechanical recycling of glass fibre thermoset composites[J]. Procedia Cirp, 2016, 48: 134-139. doi: 10.1016/j.procir.2016.03.206 [18] 丁江浩, 龚裕, 杨飞华, 等. 热固性树脂复合材料回收方法研究进展[J]. 现代化工, 2020, 40(3): 22-25. doi: 10.16606/j.cnki.issn0253-4320.2020.03.005DING Jianghao, GONG Yu, YANG Feihua, et al. Research progress on recovery methods of thermosetting resin composites[J]. Modern Chemical Industry, 2020, 40(3): 22-25(in Chinese). doi: 10.16606/j.cnki.issn0253-4320.2020.03.005 [19] ABDALLAH R, JUAIDI A, SAVAS M A, et al. A critical review on recycling composite waste using pyrolysis for sustainable development[J]. Energies, 2021, 14(18): 5748. doi: 10.3390/en14185748 [20] RANI M, CHOUDHARY P, KRISHNAN V, et al. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades[J]. Composites Part B: Engineering, 2021, 215: 108768. doi: 10.1016/j.compositesb.2021.108768 [21] WU Y, GE Z, HUANG C, et al. In-situ pyrolysis kinetic analysis and fixed-bed pyrolysis behavior of ex-service wind turbine blades[J]. Waste Management, 2023, 168: 54-62. doi: 10.1016/j.wasman.2023.05.049 [22] TERMINE S, NAXAKI V, SEMITEKOLOS D, et al. Investigation of carbon fibres reclamation by pyrolysis process for their reuse potential[J]. Polymers, 2023, 15(3): 768. doi: 10.3390/polym15030768 [23] YOUSEF S, EIMONTAS J, ZAKARAUSKAS K, et al. Recovery of styrene-rich oil and glass fibres from fibres-reinforced unsaturated polyester resin end-of-life wind turbine blades using pyrolysis technology[J]. Journal of Analytical and Applied Pyrolysis, 2023, 173: 106100. [24] CHEN W, YE M, LI M, et al. Characteristics, kinetics and product distribution on pyrolysis process for waste wind turbine blades[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105859. [25] MA C, SANCHEZ-RODRIGUEZ D, KAMO T. A comprehensive study on the oxidative pyrolysis of epoxy resin from fiber/epoxy composites: Product characteristics and kinetics[J]. Journal of Hazardous Materials, 2021, 412: 125329. doi: 10.1016/j.jhazmat.2021.125329 [26] XU M, JI H, WU Y, et al. The pyrolysis of end-of-life wind turbine blades under different atmospheres and their effects on the recovered glass fibers[J]. Composites Part B:Engineering, 2023, 251: 110493. doi: 10.1016/j.compositesb.2022.110493 [27] SOGANCIOGLU M, YEL E, AHMETLI G. Pyrolysis of waste high density polyethylene (HDPE) and low density polyethylene (LDPE) plastics and production of epoxy composites with their pyrolysis chars[J]. Journal of Cleaner Production, 2017, 165: 369-381. doi: 10.1016/j.jclepro.2017.07.157 [28] GE L, LI X, FENG H, et al. Analysis of the pyrolysis process, kinetics and products of the base components of waste wind turbine blades (epoxy resin and carbon fiber)[J]. Journal of Analytical and Applied Pyrolysis, 2023, 170: 105919. [29] CHENG G, YANG S, WANG X, et al. Study on the recycling of waste wind turbine blades[J]. Journal of Engineering Research, 2023, 11(3): 13-17. [30] GHARDE S, KANDASUBRAMANIAN B. Mechanothermal and chemical recycling methodologies for the fibre reinforced plastic (FRP)[J]. Environmental Technology & Innovation, 2019, 14: 100311. [31] KENNERLEY J R, KELLY R M, FENWICK N J, et al. The characterisation and reuse of glass fibres recycled from scrap composites by the action of a fluidised bed process[J]. Composites Part A: Applied Science and Manufacturing, 1998, 29(7): 839-845. doi: 10.1016/S1359-835X(98)00008-6 [32] HAN S W, LEE J L, TOKAMURZIN D, et al. Gasification characteristics of waste plastics (SRF) in a bubbling fluidized bed: Effects of temperature and equivalence ratio[J]. Energy, 2022, 238: 121944. doi: 10.1016/j.energy.2021.121944 [33] PENDER K, YANG L. Regenerating performance of glass fibre recycled from wind turbine blade[J]. Composites Part B: Engineering, 2020, 198: 108230. doi: 10.1016/j.compositesb.2020.108230 [34] ŻUKOWSKI W, JANKOWSKI D, BARON J, et al. Combustion dynamics of polymer wastes in a bubbling fluidized bed[J]. Journal of Cleaner Production, 2021, 320: 128807. doi: 10.1016/j.jclepro.2021.128807 [35] MENG F, MCKECHNIE J, TURNER T A, et al. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres[J]. Composites Part A: Applied Science and Manufacturing, 2017, 100: 206-214. doi: 10.1016/j.compositesa.2017.05.008 [36] OLIVEUX G, DANDY L O, LEEKE G A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties[J]. Progress in Materials Science, 2015, 72: 61-99. doi: 10.1016/j.pmatsci.2015.01.004 [37] HUANG Y F, CHIUEH P T, LO S L. A review on microwave pyrolysis of lignocellulosic biomass[J]. Sustainable Environment Research, 2016, 26(3): 103-109. doi: 10.1016/j.serj.2016.04.012 [38] DENG J, XU L, LIU J, et al. Efficient method of recycling carbon fiber from the waste of carbon fiber reinforced polymer composites[J]. Polymer Degradation and Stability, 2020, 182: 109419. doi: 10.1016/j.polymdegradstab.2020.109419 [39] DENG J, XU L, ZHANG L, et al. Recycling of carbon fibers from CFRP waste by microwave thermolysis[J]. Processes, 2019, 7(4): 207. doi: 10.3390/pr7040207 [40] MORAES V T, JERMOLOVICIUS L A, TENORIO J A S, et al. Microwave-assisted recycling process to recover fiber from fiberglass polyester composites[J]. Materials Research, 2020, 22: 0389. [41] SHEN M, GUO Z, FENG W. A study on the characteristics and thermal properties of modified regenerated carbon fiber reinforced thermoplastic composite recycled from waste wind turbine blade spar[J]. Composites Part B: Engineering, 2023, 264: 110878. doi: 10.1016/j.compositesb.2023.110878 [42] CHEN C H, CHIANG C L, WANG J X, et al. A circular economy study on the characterization and thermal properties of thermoplastic composite created using regenerated carbon fiber recycled from waste thermoset CFRP bicycle part as reinforcement[J]. Composites Science and Technology, 2022, 230: 109761. doi: 10.1016/j.compscitech.2022.109761 [43] PENDER K, YANG L. Investigation of catalyzed thermal recycling for glass fiber-reinforced epoxy using fluidized bed process[J]. Polymer Composites, 2019, 40(9): 3510-3519. doi: 10.1002/pc.25213 [44] LIU B, ZHU P, XU A, et al. Investigation of the recycling of continuous fiber-reinforced thermoplastics[J]. Journal of Thermoplastic Composite Materials, 2019, 32(3): 342-356. doi: 10.1177/0892705718759388 [45] RIJO B, DIAS A P S, CARVLHO J P S. Recovery of carbon fibers from aviation epoxy composites by acid solvolysis[J]. Sustainable Materials and Technologies, 2023, 35: e00545. doi: 10.1016/j.susmat.2022.e00545 [46] COUSINS D S, SUZUKI Y, MURRAY R E, et al. Recycling glass fiber thermoplastic composites from wind turbine blades[J]. Journal of Cleaner Production, 2019, 209: 1252-1263. doi: 10.1016/j.jclepro.2018.10.286 [47] ČEŠAREK U, PAHOVNIK D, ŽAGAR E. Chemical recycling of aliphatic polyamides by microwave-assisted hydrolysis for efficient monomer recovery[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(43): 16274-16282. [48] RANI M, CHOUDHARY P, KRISHNAN V, et al. Development of sustainable microwave-based approach to recover glass fibers for wind turbine blades composite waste[J]. Resources, Conservation and Recycling, 2022, 179: 106107. doi: 10.1016/j.resconrec.2021.106107 [49] ZHAO Q, AN L, LI C, et al. Environment-friendly recycling of CFRP composites via gentle solvent system at atmospheric pressure[J]. Composites Science and Technology, 2022, 224: 109461. doi: 10.1016/j.compscitech.2022.109461 [50] KIM Y N, KIM Y O, KIM S Y, et al. Application of supercritical water for green recycling of epoxy-based carbon fiber reinforced plastic[J]. Composites Science and Technology, 2019, 173: 66-72. doi: 10.1016/j.compscitech.2019.01.026 [51] JIANG G, PICKERING S J, LESTER E H, et al. Characterisation of carbon fibres recycled from carbon fibre/epoxy resin composites using supercritical n-propanol[J]. Composites Science and Technology, 2009, 69(2): 192-198. doi: 10.1016/j.compscitech.2008.10.007 [52] KEITH M J, ROMAN-RAMIREZ L A, LEEKE G, et al. Recycling a carbon fibre reinforced polymer with a supercritical acetone/water solvent mixture: Comprehensive analysis of reaction kinetics[J]. Polymer Degradation and Stability, 2019, 161: 225-234. doi: 10.1016/j.polymdegradstab.2019.01.015 [53] MATTSON C, ANDRE A, JUNTIKKA M, et al. Chemical recycling of end-of-life wind turbine blades by solvolysis/HTL[C]//IOP Conference Series: Materials Science and Engineering. Britain: IOP Publishing, 2020, 942(1): 012013. [54] MUMTAZ H, SOBEK S, SAJDAK M, et al. An experimental investigation and process optimization of the oxidative liquefaction process as the recycling method of the end-of-life wind turbine blades[J]. Renewable Energy, 2023, 211: 269-278. doi: 10.1016/j.renene.2023.04.120 [55] LEIßNER T, HAMANN D, WUSCHKE L, et al. High voltage fragmentation of composites from secondary raw materials—Potential and limitations[J]. Waste Management, 2018, 74: 123-134. [56] MATIVENGA P T, SHUAIB N A, HOWARTH J, et al. High voltage fragmentation and mechanical recycling of glass fibre thermoset composite[J]. CIRP Annals, 2016, 65(1): 45-48. doi: 10.1016/j.cirp.2016.04.107 [57] LIU P, MENG F, BARLOW C Y. Wind turbine blade end-of-life options: An eco-audit comparison[J]. Journal of Cleaner Production, 2019, 212: 1268-1281. doi: 10.1016/j.jclepro.2018.12.043 [58] CINAR S. Sustainable reverse logistic network design for end-of-life use-case study[J]. RAIRO-Operations Research, 2021, 55: S503-S521. [59] RUANE K, ZHANG Z, NAGLE A, et al. Construction and cost analysis of bladebridges made from decommissioned FRP wind turbine blades[J]. Sustainability, 2023, 15(4): 3366. doi: 10.3390/su15043366 [60] RUANE K, SOUTSOS M, AN H, et al. Material and structural characterization of a wind turbine blade for use as a bridge girder[J]. Transportation Research Record, 2022, 2676(8): 354-362. doi: 10.1177/03611981221083619 [61] ALSHANNAQ A A, BANK L C, SCOTT D W, et al. A decommissioned wind blade as a second-life construction material for a transmission pole[J]. Construction Materials, 2021, 1(2): 95-104. doi: 10.3390/constrmater1020007 [62] ALSHANNAQ A A, ASCE S M, BANK L C, et al. Structural analysis of a wind turbine blade repurposed as an electrical transmission pole[J]. Journal of Composites for Construction, 2021, 25(4): 04021023. doi: 10.1061/(ASCE)CC.1943-5614.0001136 [63] BANK L C, ARIAS F R, YAZDANBAKHSH A, et al. Concepts for reusing composite materials from decommissioned wind turbine blades in affordable housing[J]. Recycling, 2018, 3(1): 3. doi: 10.3390/recycling3010003 [64] DELANEY E L, LEAHY P G, MCKINLEY J M, et al. Sustainability implications of current approaches to end-of-life of wind turbine blades—A review[J]. Sustainability, 2023, 15(16): 12557. doi: 10.3390/su151612557 [65] JO B W, PARK S K, PARK J C. Mechanical properties of polymer concrete made with recycled PET and recycled concrete aggregates[J]. Construction and Building Materials, 2008, 22(12): 2281-2291. doi: 10.1016/j.conbuildmat.2007.10.009 [66] BATURKIN D, HISSEINE O A, MASMOUDI R, et al. Valorization of recycled FRP materials from wind turbine blades in concrete[J]. Resources, Conservation and Recycling, 2021, 174: 105807. doi: 10.1016/j.resconrec.2021.105807 [67] OLIVEIRA P S, ANTUNES M L P, DA CRUZ N C, et al. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction[J]. Journal of Cleaner Production, 2020, 274: 122948. doi: 10.1016/j.jclepro.2020.122948 [68] YAZDANBAKHSH A, BANK L C, RIEDER K A, et al. Concrete with discrete slender elements from mechanically recycled wind turbine blades[J]. Resources, Conservation and Recycling, 2018, 128: 11-21. doi: 10.1016/j.resconrec.2017.08.005 [69] 杨立琳. 废弃风电叶片再生纤维对石膏性能影响的研究[D]. 济南: 济南大学, 2022.YANG Lilin. Research on the effect of recycled fiber from waste wind turbine blades on the properties of gypsum[D]. Jinan: University of Jinan, 2022(in Chinese). [70] LAN T, WANG B, ZHANG J, et al. Utilization of waste wind turbine blades in performance improvement of asphalt mixture[J]. Frontiers in Materials, 2023, 10: 1164693. doi: 10.3389/fmats.2023.1164693 [71] PLAWECKA K, PRZYBYLA J, KORNIEJENKO K, et al. Recycling of mechanically ground wind turbine blades as filler in geopolymer composite[J]. Materials, 2021, 14(21): 6539. doi: 10.3390/ma14216539 [72] MOSLEHI A, AJJI A, HEUZEY M C, et al. Polylactic acid/recycled wind turbine glass fiber composites with enhanced mechanical properties and toughness[J]. Journal of Applied Polymer Science, 2022, 139(15): 51934. doi: 10.1002/app.51934 [73] BEAUSON J, MADSEN B, TONCELLI C, et al. Recycling of shredded composites from wind turbine blades in new thermoset polymer composites[J]. Composites Part A: Applied Science and Manufacturing, 2016, 90: 390-399. doi: 10.1016/j.compositesa.2016.07.009 [74] RAHIMIZADEH A, KALMAN J, FAYAZBAKHSH K, et al. Recycling of fiberglass wind turbine blades into reinforced filaments for use in additive manufacturing[J]. Composites Part B: Engineering, 2019, 175: 107101. doi: 10.1016/j.compositesb.2019.107101 -

下载:

下载: