Effect and mechanism study of woven density on mechanical behavior of a 2D-SiCf/SiC

-

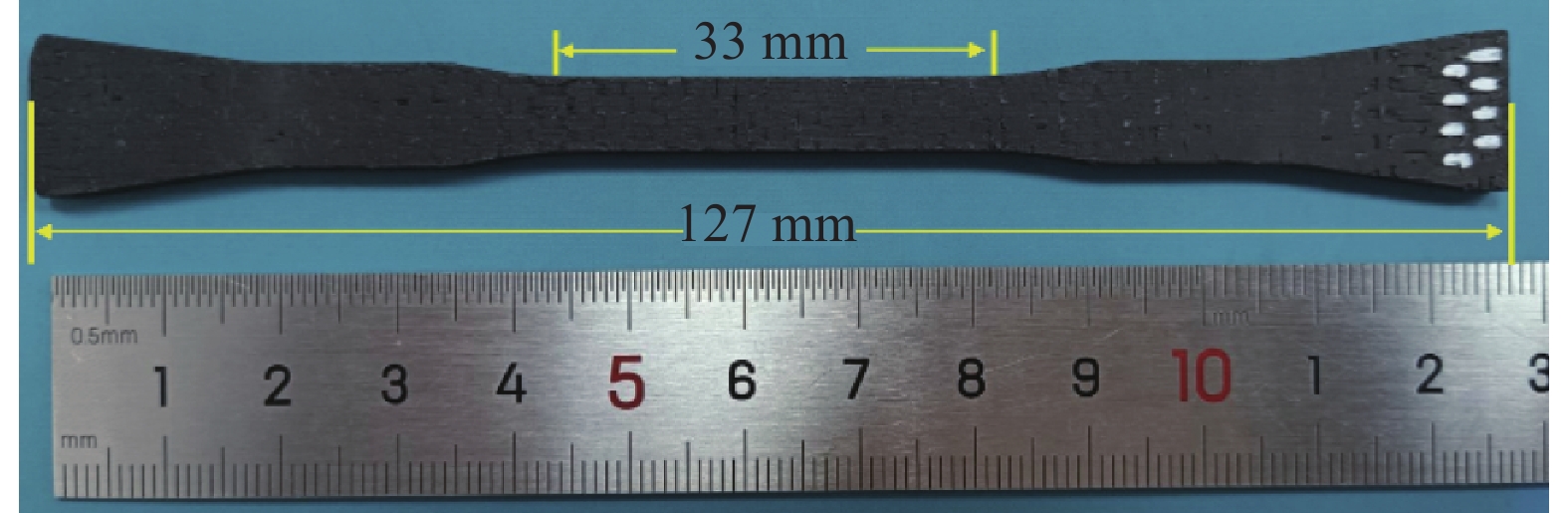

摘要: 编织陶瓷基复合材料逐渐成为提升航空发动机综合性能的热门材料。材料的失效机制分析为材料/结构的性能设计与优化提供着重要的理论与方法支持。本文针对不同编织密度的2D-SiCf/SiC复合材料开展室温拉伸试验,通过对力学行为、损伤演化进行对比分析,研究编织复合材料的力学行为及内在的损伤机制。结果表明:比例极限应力随着横向纤维束编织密度的增加逐渐降低,纵向纤维束编织密度对比例极限应力影响较小;纵向纤维编织密度较小时,拉伸强度较低,随着纵向编织密度的增加,拉伸强度增大并趋于稳定,横向纤维编织密度的增加,对拉伸强度有一定的弱化作用;根据拉伸应力/应变的演化过程,编织SiCf/SiC复合材料的拉伸过程可以划分为4个典型阶段;缝合孔对材料的拉伸强度有一定弱化作用,需要在材料制备、后处理过程中消除缝合孔的不利影响。Abstract: Woven ceramic matrix composites have gradually become a popular material for improving the comprehensive performance of aero-engines. Failure mechanism analysis of materials provides important theoretical and methodological support for material/structure performance design and optimization. In this paper, the tensile tests of 2D-SiCf/SiC composites with different woven densities were carried out at room temperature, and the mechanical behavior and damage mechanism of the woven composites were studied. The results show that: The proportional limit stress decreases gradually with the increase of the transverse fiber bundle woven density, and the longitudinal fiber bundle woven density has little effect on the proportional limit stress. When the density of longitudinal fiber is small, the tensile strength is low. With the increase of longitudinal fiber density, the tensile strength increases and tends to be stable, while the increase of transverse fiber density has a certain weakening effect on the tensile strength. According to the evolution of tensile stress/strain, the tensile process of the woven SiCf/SiC composites can be divided into four typical stages. The stitching hole has a certain weakening effect on the tensile strength of the material, so it is necessary to eliminate the adverse effect of the stitching hole in the material preparation and post-treatment process.

-

表 1 不同编织密度2D-SiC平纹布面密度及SiCf/SiC试样纤维体积分数

Table 1. 2D-SiC plain fabric surface density and fiber volume fraction of SiCf/SiC specimen with different woven densities

0° 90° 4 bundles/cm 6 bundles/cm 8 bundles/cm 4 bundles/cm 114 g/m2 180 g/m2 216 g/m2 6 bundles/cm 180 g/m2 216 g/m2 252 g/m2 8 bundles/cm 216 g/m2 252 g/m2 288 g/m2 4 bundles/cm 17.8vol% 28.1vol% 33.7vol% 6 bundles/cm 28.1vol% 33.7vol% 39.3vol% 8 bundles/cm 33.7vol% 39.3vol% 45.0vol% 表 2 SiCf/SiC室温拉伸力学性能汇总

Table 2. Summary of tensile mechanical properties of SiCf/SiC at room temperature

Specimen type Modulus/GPa PLS/MPa Strength/MPa 4×4 249.0 149.4 232.6 4×6 258.4 123.0 228.3 4×8 237.2 97.9 170.4 6×4 273.2 144.9 309.0 6×6 258.6 128.6 307.6 6×8 237.7 111.6 311.4 8×4 249.8 153.3 376.4 8×6 244.2 127.3 302.2 8×8 245.7 112.6 271.5 Notes: a×b, a and b represent the number of fiber bundles per unit length (Unit: bundles/cm); a for longitudinal direction; b for transverse direction; PLS—Proportional limit stress. 表 3 试样拉伸各阶段应变速率特征及内在机制

Table 3. Strain rate characteristics and internal mechanism of specimens at different tensile stages

Stage Strain-time curve slope Mechanism Stage I Low slope, low deformation rate Under the same tensile displacement increment, the matrix and fiber bundle deform together, the matrix and fiber bundle accumulate strain energy, and the macroscopic strain increment of the specimen is small. Stage II and stage III High slope, high deformation rate Under the same tensile displacement increment, the matrix is damaged, and the matrix gradually releases strain energy (the matrix gradually releases the strain energy generated in stage I and the deformation constraint of the matrix on the fiber bundle), and the deformation of the fiber bundle superimposes the deformation release of the matrix, resulting in a large macroscopic strain increment of the specimen. Stage IV Medium slope, medium deformation rate Under the same tensile displacement increment, the fiber bundle deforms independently, no matrix releases strain energy, and the macroscopic strain increment of the specimen is moderate. -

[1] 刘大响. 一代新材料, 一代新型发动机: 航空发动机的发展趋势及其对材料的需求[J]. 材料工程, 2017, 45(10): 1-5. doi: 10.11868/j.issn.1001-4381.2017.100001LIU Daxiang. One generation of new material, one generation of new type engine: Development trend of aero-engine and its requirements for materials[J]. Journal of Materials Engineering, 2017, 45(10): 1-5(in Chinese). doi: 10.11868/j.issn.1001-4381.2017.100001 [2] ZOK F W. Ceramic-matrix composites enable revolutionary gains in turbine engine efficiency[J]. American Ceramic Society Bulletin, 2016, 95(5): 22-28. [3] 焦健, 陈明伟. 新一代发动机高温材料—陶瓷基复合材料的制备、性能及应用[J]. 航空制造技术, 2014, 57(7): 62-69. doi: 10.3969/j.issn.1671-833X.2014.07.007JIAO Jian, CHEN Mingwei. New generation of high-temperature material for engine—Preparation, property and application of ceramic matrix composites[J]. Aeronautical Manufacturing Technology, 2014, 57(7): 62-69(in Chinese). doi: 10.3969/j.issn.1671-833X.2014.07.007 [4] 焦健, 孙世杰, 焦春荣, 等. SiCf/SiC复合材料涡轮导向叶片研究进展[J]. 复合材料学报, 2023, 40(8): 4342-4354.JIAO Jian, SUN Shijie, JIAO Chunrong, et al. Research progress of SiCf/SiC turbine guide vanes: A review[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4342-4354(in Chinese). [5] 杜昆, 陈麒好, 孟宪龙, 等. 陶瓷基复合材料在航空发动机热端部件应用及热分析研究进展[J]. 推进技术, 2022, 43(2): 113-131.DU Kun, CHEN Qihao, MENG Xianlong, et al. Advancement in application and thermal analysis of ceramic matrix composites in aeroengine hot components[J]. Journal of Propulsion Technology, 2022, 43(2): 113-131(in Chinese). [6] 刘小冲, 徐友良, 李坚, 等. 陶瓷基复合材料涡轮叶盘设计、制备与考核验证[J]. 复合材料学报, 2023, 40(3): 1696-1706.LIU Xiaochong, XU Youliang, LI Jian, et al. Design, fabrication and testing of ceramic-matrix composite turbine blisk[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1696-1706(in Chinese). [7] 罗潇, 李坚, 李敏, 等. 蛛网式骨架增强陶瓷基复合材料涡轮叶盘设计及验证[J]. 航空动力, 2021(1): 54-56.LUO Xiao, LI Jian, LI Min, et al. Design and test of the CMC blisk reinforced by spider-web-like framework[J]. Aerospace Power, 2021(1): 54-56(in Chinese). [8] CAI H X, QIAN Z, LI L, et al. Tensile behaviors of nanoporous phenolic composites reinforced by 3D needle-punched preforms with different weave patterns[J]. Composites Communications, 2023, 43: 101700. [9] KIASAT M S, SANGTABI M R. Effects of fiber bundle size and weave density on stiffness degradation and final failure of fabric laminates[J]. Composites Science and Technology, 2015, 111: 23-31. doi: 10.1016/j.compscitech.2015.02.016 [10] DIXIT A, MALI H S. Modeling techniques for predicting the mechanical properties of woven fabric textile composites—A review[J]. Mechanics of Composite Materials, 2013, 49(1): 1-20. doi: 10.1007/s11029-013-9316-8 [11] 惠新育, 许英杰, 张卫红, 等. 平纹编织SiC/SiC复合材料多尺度建模及强度预测[J]. 复合材料学报, 2019, 36(10): 2380-2388. doi: 10.13801/j.cnki.fhclxb.20181112.001HUI Xinyu, XU Yingjie, ZHANG Weihong, et al. Multi-scale modeling and strength prediction of plain woven SiC/SiC composites[J]. Acta Materiae Compositae Sinica, 2019, 36(10): 2380-2388(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181112.001 [12] ZHANG S, GAO X G, SONG Y D, et al. Fatigue behavior and damage evolution of SiC/SiC composites under high-temperature anaerobic cyclic loading[J]. Ceramics International, 2021, 47(21): 29646-29652. [13] LIU B, ZHOU Y F. Damage failure mechanism of unidirectional fiber reinforced SiCf/SiC composites under uniaxial tension[J]. Composite Structures, 2023, 307(1): 116610. [14] NAIR S V, JAKUS K. High temperature mechanical behavior of ceramic composites[M]. Boston: Butterworth-Heinemann, 1995: 39-40. [15] ASTM. Standard test method for monotonic tensile strength testing of continuous fiber-reinforced advanced ceramics with solid rectangular cross-section test specimens at elevated temperatures: ASTM C1359—13[S]. West Conshohocken: ASTM, 1996. [16] WANG F, TENG X F, HU X A, et al. Damage and failure analysis of a SiCf/SiC ceramic matrix composite using digital image correlation and acoustic emission[J]. Ceramics International, 2022, 48(4): 4699-4709. [17] 孙轩, 王雅萍, 王博怀. 数字图像相关法变形测量系统的研究与应用[J]. 机械设计与制造, 2019(3): 149-152, 157. doi: 10.19356/j.cnki.1001-3997.2019.03.037SUN Xuan, WANG Yaping, WANG Bohuai. Research and application on digital image correlation deformation measurement system[J]. Machinery Design & Manufacture, 2019(3): 149-152, 157(in Chinese). doi: 10.19356/j.cnki.1001-3997.2019.03.037 [18] HE W T, WANG C Z, WANG S Q, et al. Characterizing and predicting the tensile mechanical behavior and failure mechanisms of notched FMLs-combined with DIC and numerical techniques[J]. Composite Structures, 2020, 254(11): 112893. [19] YU G Q, GAO X G, XIE C Y, et al. In-plane shear damage behaviours of 2D needled C/SiC composites[J]. Fatigue & Fracture of Engineering Materials & Structures, 2019, 42(2): 454-465. [20] TABRIZI I E, KHAN R M A, MASSARWA E, et al. Determining tab material for tensile test of CFRP laminates with combined usage of digital image correlation and acoustic emission techniques[J]. Composites Part A: Applied Science and Manufacturing, 2019, 127: 105623. doi: 10.1016/j.compositesa.2019.105623 [21] 潘兵, 吴大方, 夏勇. 数字图像相关方法中散斑图的质量评价研究[J]. 实验力学, 2010, 25(2): 120-129.PAN Bing, WU Dafang, XIA Yong. Study of speckle pattern quality assessment used in digital image correlation[J]. Journal of Experimental Mechanics, 2010, 25(2): 120-129(in Chinese). [22] 孟利波, 金观昌, 姚学锋. DSCM中摄像机光轴与物面不垂直引起的误差分析[J]. 清华大学学报(自然科学版), 2006, 46 (11): 1930-1932, 1936. doi: 10.3321/j.issn:1000-0054.2006.11.035MENG Libo, JIN Guanchang, YAO Xuefeng. Errors caused by misalignment of the optical camera axis and the object surface in the DSCM[J]. Journal of Tsinghua University(Science and Technology), 2006, 46(11): 1930-1932, 1936(in Chinese). doi: 10.3321/j.issn:1000-0054.2006.11.035 [23] CORMAN G, UPADHYAY R, SINHA S, et al. General electric company: Selected applications of ceramics and composite materials[M]//Materials Research for Manufacturing. Cham Switzerland: Springer International Publishing, 2016: 66. [24] LIU S H, ZHANG L T, YIN X W, et al. Proportional limit stress and residual thermal stress of 3D SiC/SiC composite[J]. Journal of Materials Science & Technology, 2014, 30 (10): 959-964. -

下载:

下载: