Load distribution law in multi-bolts connected composite structure

-

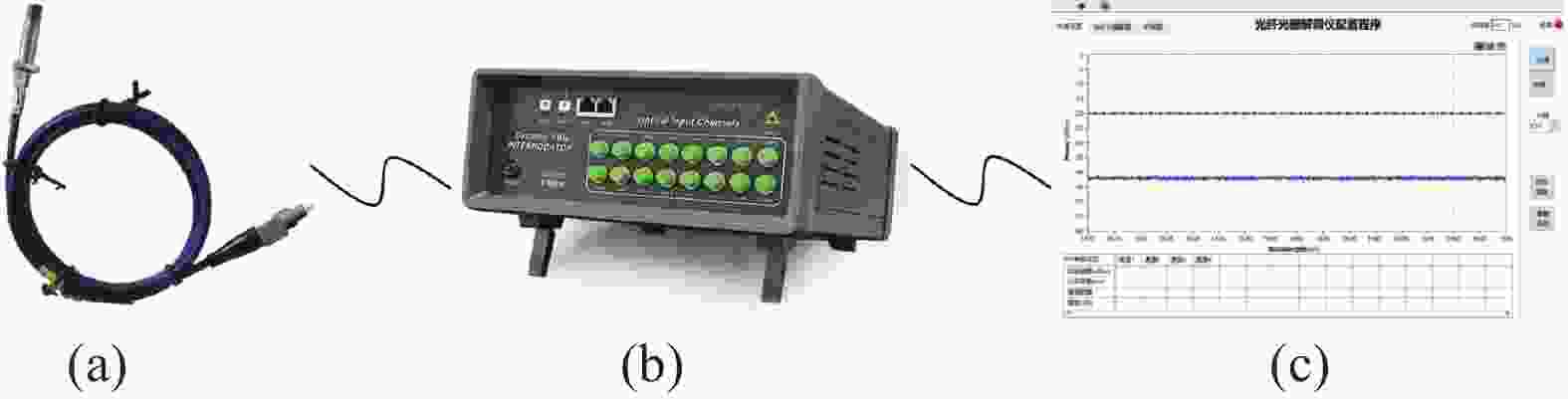

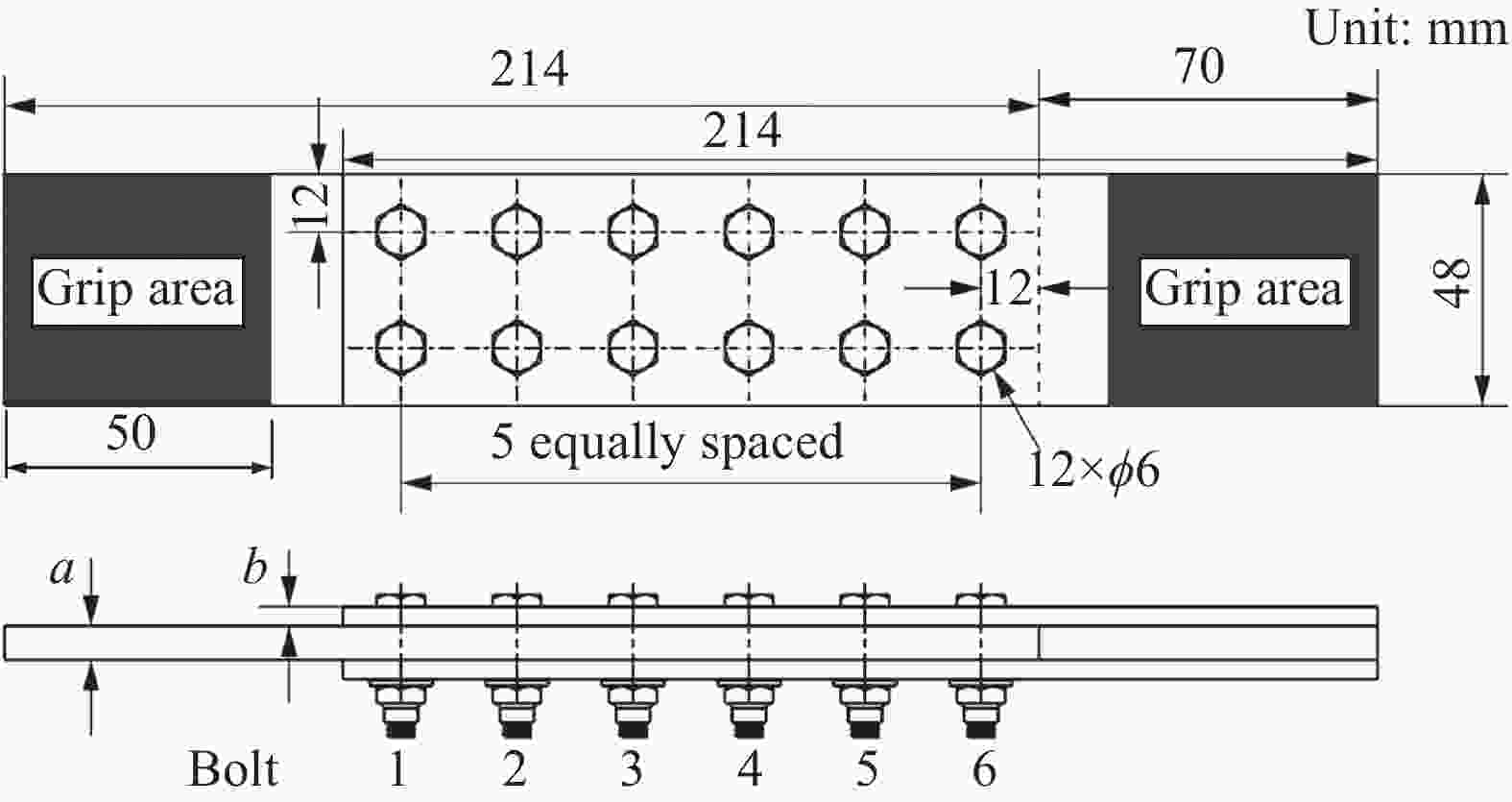

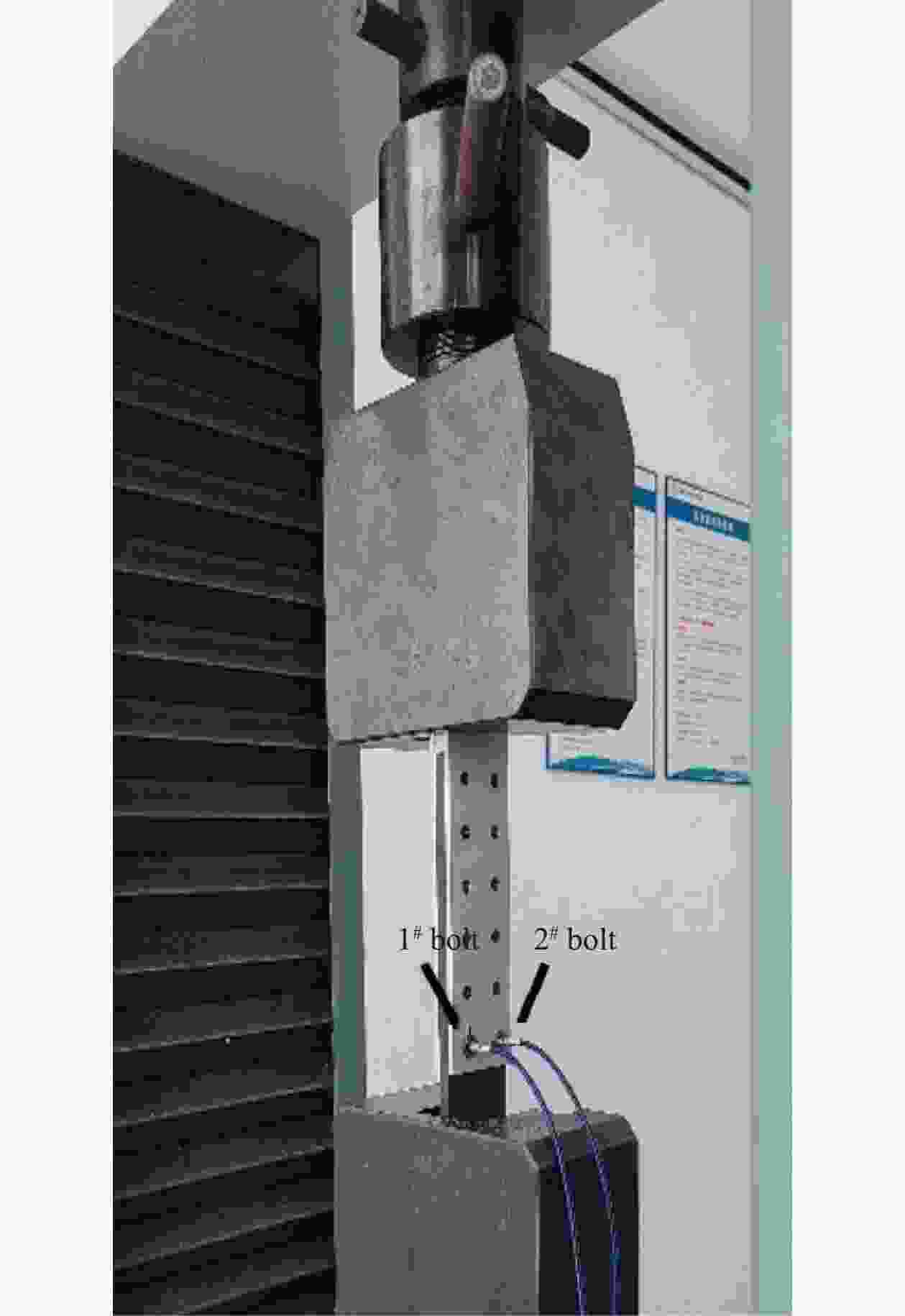

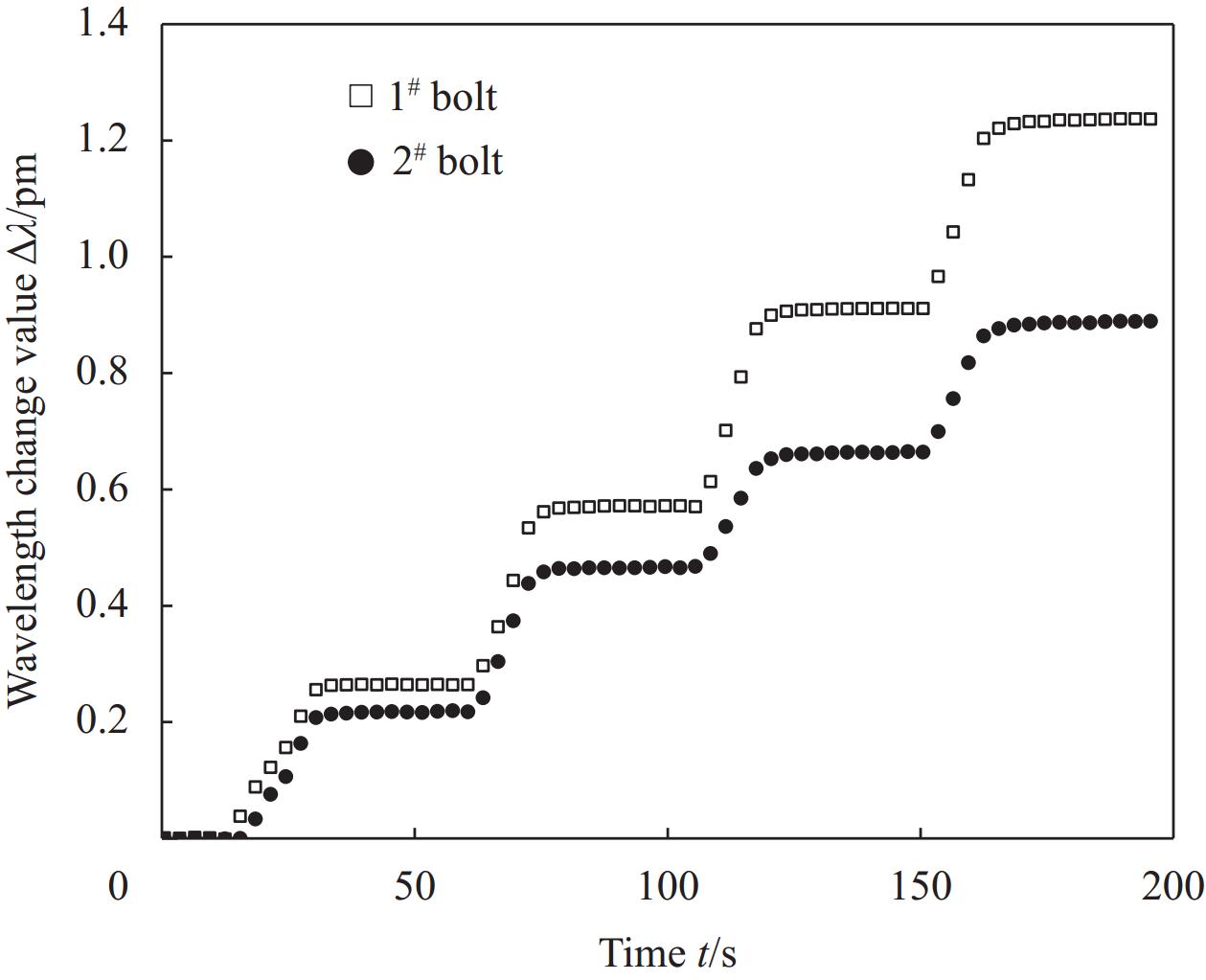

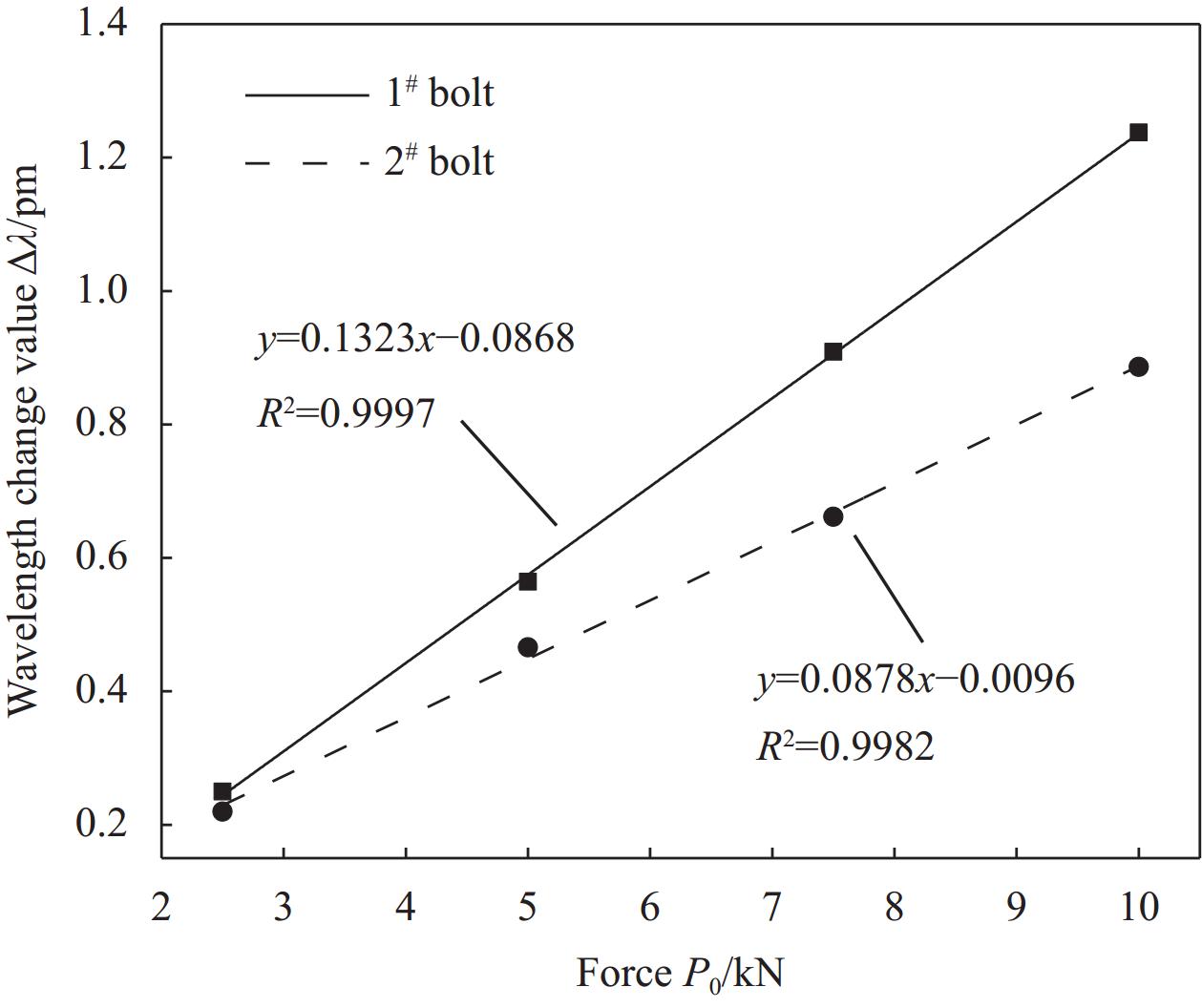

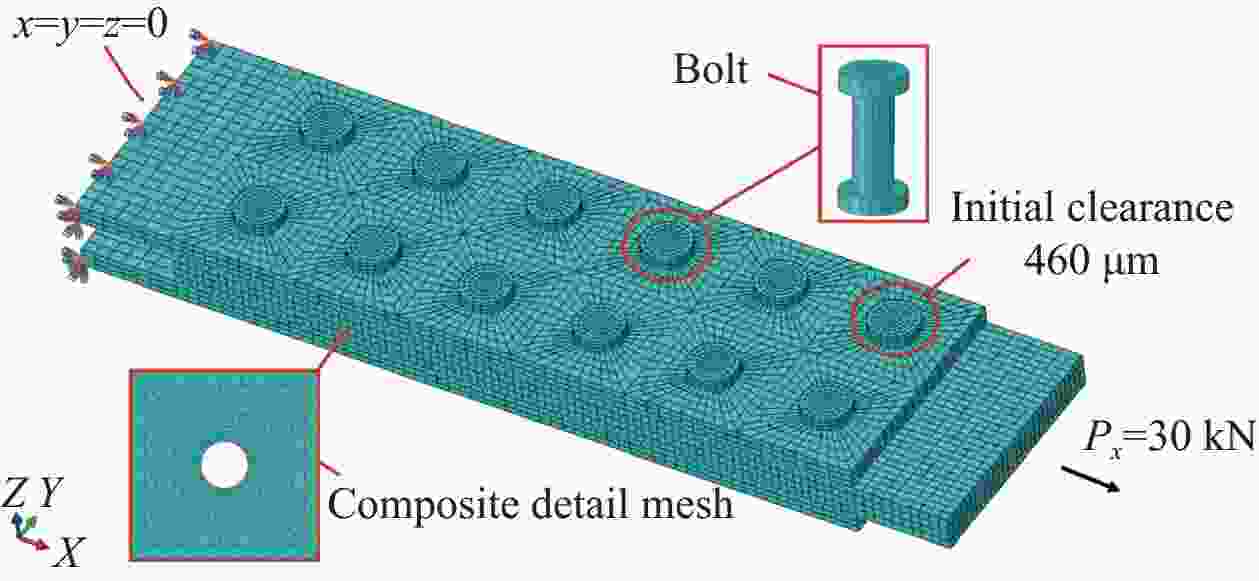

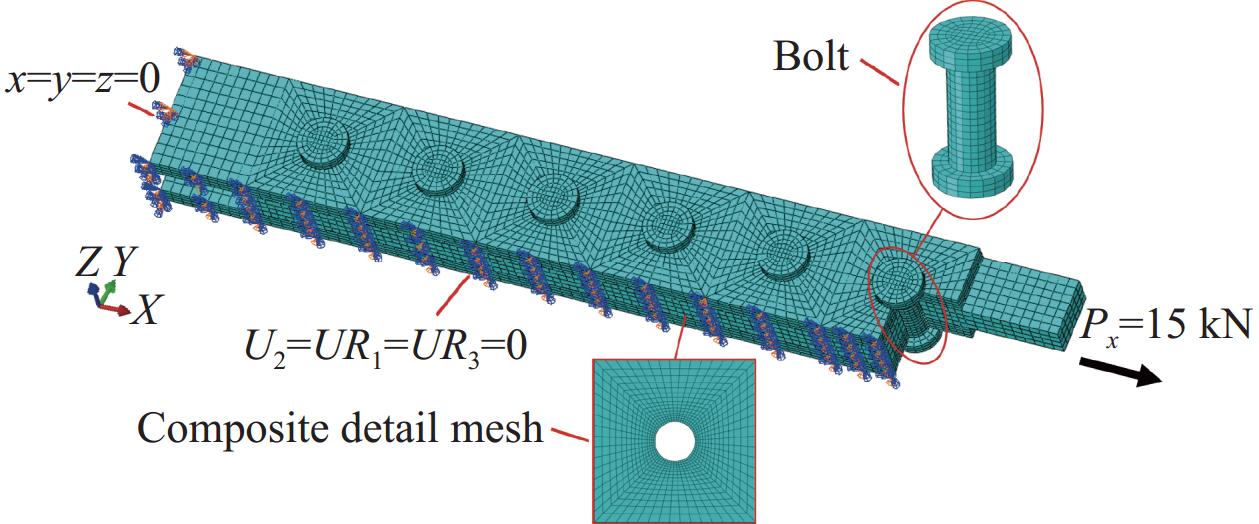

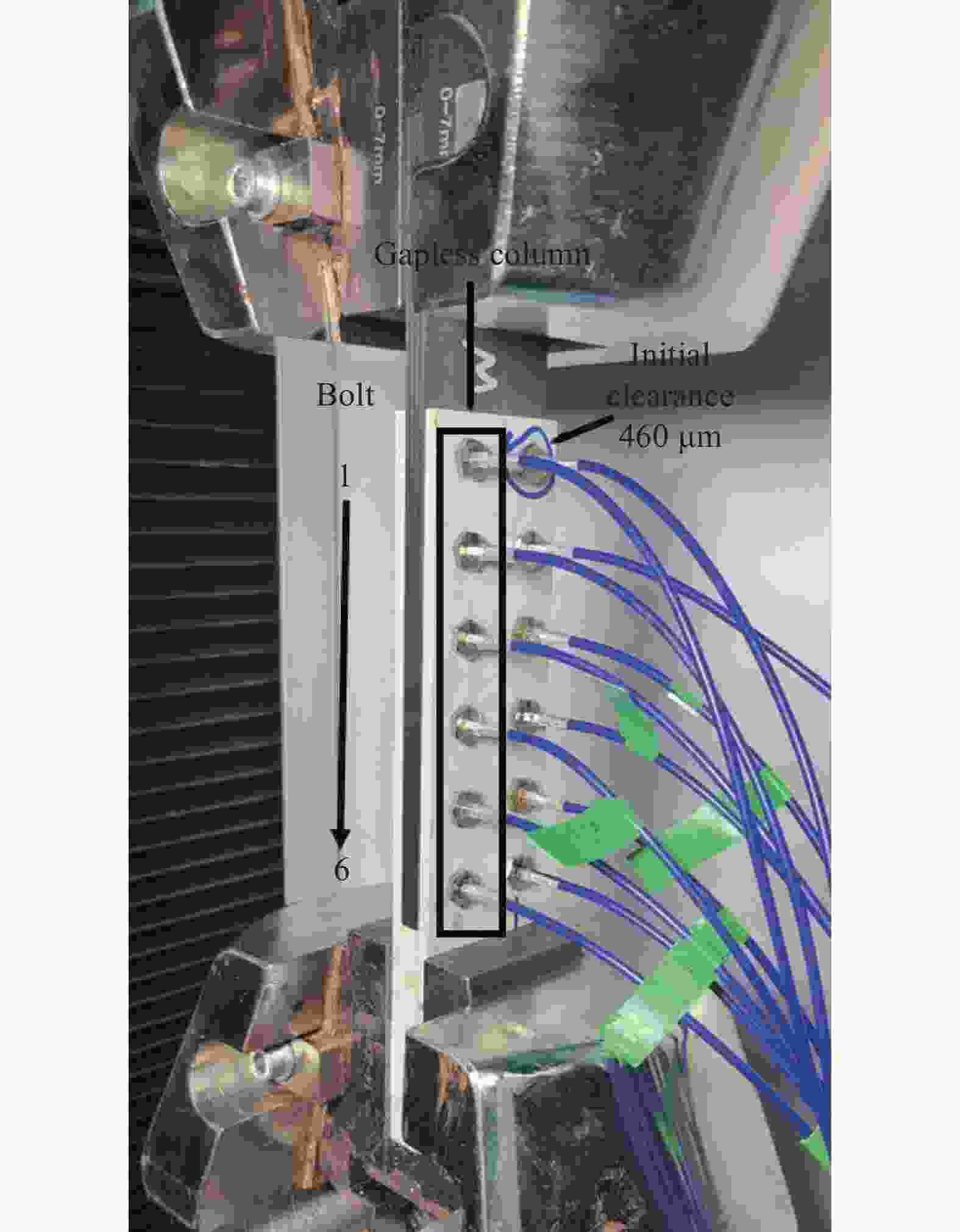

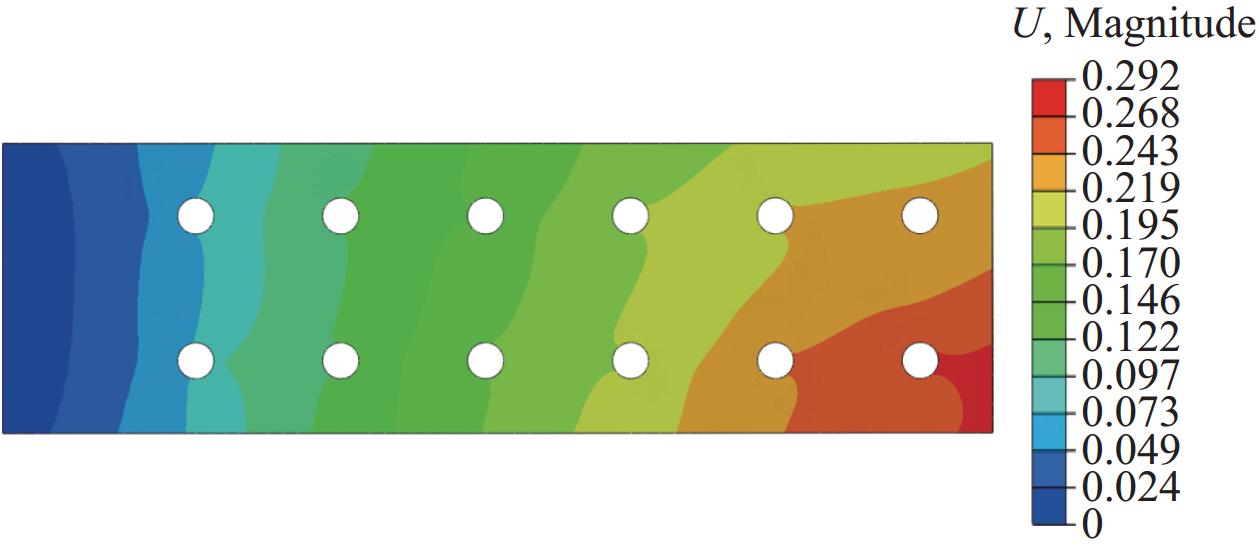

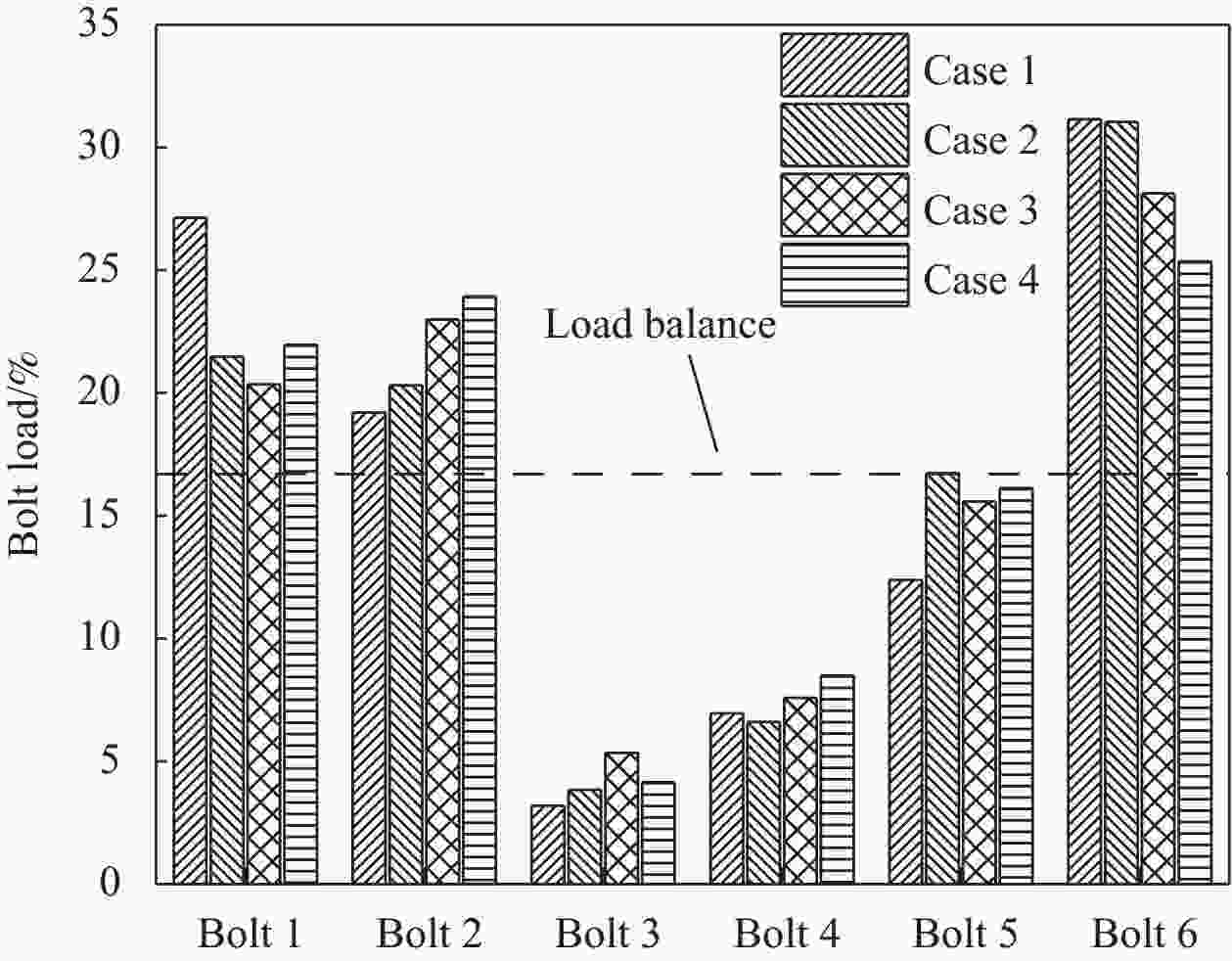

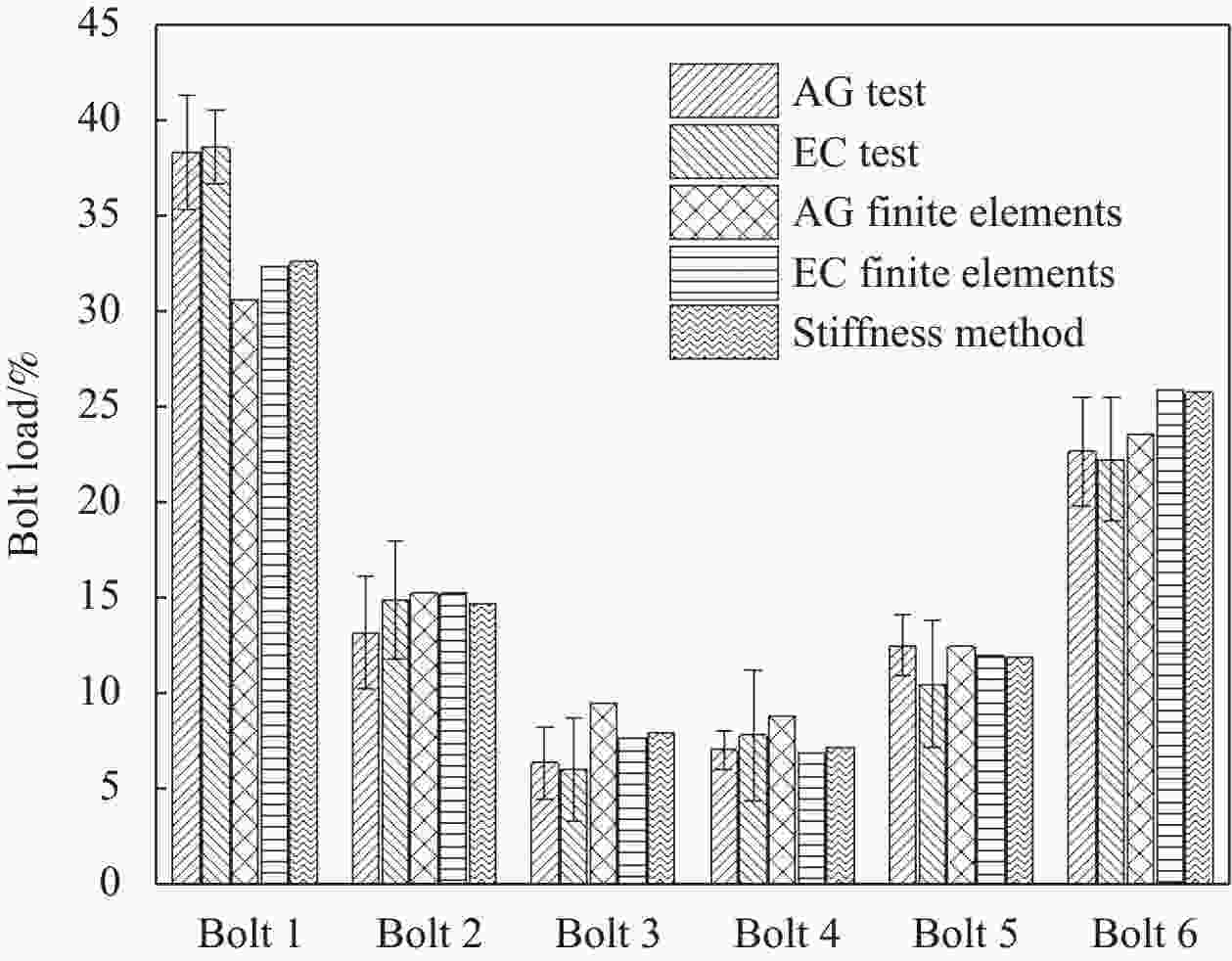

摘要: 针对复合材料多排钉连接结构实际强度破坏极限和破坏模式与传统工程算法不一致的问题,本文以光纤螺栓试验手段为基础,开展了复合材料连接结构钉载分配规律的研究。主要研究了钉载不对称、装配顺序、装配间隙等工艺特征对钉载分配的影响,同时建立了高精度有限元模型进行对比研究。研究结果表明:多排钉连接结构钉载不对称时会加剧钉载的不均匀分配;装配顺序对钉载分配存在影响,在装配螺栓时最后安装最外侧螺栓,可以有效降低钉载分布差异;连接结构存在一致装配间隙时的钉载分配与无间隙情况的载荷分配结果一致。同时,本文发现通过试验手段测得关键螺栓的钉载占比最大比有限元结果高出10%,因此工程算法需要根据装配间隙等制造和工艺特征进行修正。Abstract: To address the issue of inconsistencies between the actual strength and failure mode of composite multi-row nail connection structures and traditional engineering algorithms, this study investigated nail load distribution patterns in composite connection structures based on fibre optic bolt testing techniques. The study primarily examines the effect of process characteristics such as nail load asymmetry, assembly sequence and assembly clearance on nail load distribution, while also establishing a high-precision finite element model for comparative study. The results indicate that asymmetric nail loading in a multi-row nail connection structure exacerbates uneven nail load distribution. Assembly sequence affects nail load distribution, and installing the outermost bolt last during bolt assembly can effectively reduce differences in nail load distribution. Nail load distribution in structures with uniform assembly clearance is consistent with load distribution in structures with no clearance. Additionally, the study finds that the proportion of critical bolt nail loads measured through testing is over 10% higher than the finite element results, suggesting that engineering algorithms need to be modified based on manufacturing and process characteristics such as assembly clearance.

-

表 1 3种试验件尺寸参数

Table 1. Size parameters of three test pieces

Specimen Assembly tolerance/mm b/mm a/mm Ply method Number of pieces EC 0 4 7 1 5 AG 0.1 4 7 1 5 AS 0 3.5 3 2 1 Notes: EC test pieces are used for nail-loading asymmetry studies, and for comparison with AG test pieces to study the influence of assembly clearance on nail-loading distribution, and AS test pieces are used for assembly sequence studies. 表 2 复合材料铺层方式

Table 2. Composite material lay-up mode

Ply method Thickness/mm Ply angle 1 7 [45/−45/0/−45/45/90/0/0/

90/45/−45/0/−45/45]2S2 3 [45/−45/0/−45/0/45/0/−45/

90/45/90/0]SParameter Value Parameter Value $ {E}_{1}/\mathrm{G}\mathrm{P}\mathrm{a} $ 157 $ {X}_{\mathrm{T}}/\mathrm{M}\mathrm{P}\mathrm{a} $ 2630 $ {E}_{2}/\mathrm{G}\mathrm{P}\mathrm{a} $ 8.5 $ {X}_{\mathrm{C}}/\mathrm{M}\mathrm{P}\mathrm{a} $ 1480 $ {\mu }_{12} $ 0.35 $ {Y}_{\mathrm{T}}/\mathrm{M}\mathrm{P}\mathrm{a} $ 62 $ {G}_{12}/\mathrm{G}\mathrm{P}\mathrm{a} $ 4.2 $ {Y}_{\mathrm{C}}/\mathrm{M}\mathrm{P}\mathrm{a} $ 213 $ {G}_{13}/\mathrm{G}\mathrm{P}\mathrm{a} $ 4.2 $ {S}_{12}/\mathrm{M}\mathrm{P}\mathrm{a} $ 109 $ {G}_{23}/\mathrm{G}\mathrm{P}\mathrm{a} $ 2.7 $ {S}_{23}/\mathrm{M}\mathrm{P}\mathrm{a} $ 86 Notes: E1, E2—Elasticity modulus in X, Y directions; G12, G13, G23—Shear modulus in X, Y and Z directions; μ12—X-Y planar Poisson's ratio; XT, XC—X-direction tensile and compressive strength; YT, YC—Y-direction tensile and compressive strength; S12, S23—X-Y and Y-Z planar shear strengths. 表 4 EC试验件无间隙列试验与有限元钉载分配结果

Table 4. Nail load distribution results of EC test piece gapless column test and finite element

Gapless column Test Finite element Asymmetrical bolt load/% Symmetrical bolt loads/% Asymmetrical bolt load/% Symmetrical bolt loads/% Bolt 1 37.5 35.8 32.4 32.0 Bolt 2 16.6 16.8 16.3 15.2 Bolt 3 8.8 9.3 9.0 8.0 Bolt 4 4.3 5.3 7.3 7.2 Bolt 5 5.7 5.5 11.3 12.0 Bolt 6 27.1 27.3 23.7 25.6 Resultant force/kN 17.2 14.9 16.9 15.0 Notes: The EC test piece is loaded and unloaded three times, and the experimental data are the average of the three times data. The table provides information on the bolt load, which represents the coefficient for nail load. The coefficient for nail load is defined as the proportion of the load on a singular bolt to the total load on all bolts. 表 5 AS试验件4种装配顺序

Table 5. Four assembly sequences for AS test pieces

Case Step 1 Step 2 Step 3 Step 4 Step 5 Step 6 1 Bolt 1 Bolt 2 Bolt 3 Bolt 4 Bolt 5 Bolt 6 2 Bolt 1 Bolt 6 Bolt 2 Bolt 5 Bolt 3 Bolt 4 3 Bolt 3 Bolt 4 Bolt 2 Bolt 5 Bolt 1 Bolt 6 4 Bolt 6 Bolt 5 Bolt 4 Bolt 3 Bolt 2 Bolt 1 表 6 AS试验件4种装配顺序螺栓载荷标准差结果对比

Table 6. Comparison of standard deviation results of bolt loads for four assembly sequences of AS test pieces

Case Standard deviation/% 1 11.1 2 10.1 3 8.9 4 8.7 -

[1] THOPPULS D, FINEGAN J, GIBSONR F. Mechanics of mechanically fastened joints in polymer-matrix composite structures—A review[J]. Composites Science and Technology, 2009, 69(3-4): 301-329. doi: 10.1016/j.compscitech.2008.09.037 [2] GIRÃO COELHO A M, MOTTRAM J T. A review of the behaviour and analysis of bolted connections and joints in pultruded fibre reinforced polymers[J]. Materials & Design, 2015, 74: 86-107. [3] DU A, LIU Y Q, XIN H H, et al. Progressive damage analysis of PFRP double-lap bolted joints using explicit finite element method[J]. Composite Structures, 2016, 152: 860-869. doi: 10.1016/j.compstruct.2016.06.028 [4] LI H S, GU R J, ZHAO X. Global sensitivity analysis of load distribution and displacement in multi-bolt composite joints[J]. Composites Part B: Engineering, 2017, 116: 200-210. doi: 10.1016/j.compositesb.2017.01.058 [5] CAMANHO P P, MATTHEWS F L. Stress analysis and strength prediction of mechanically fastened joints in FRP: A review[J]. Composites Part A: Applied Science and Manufacturing, 1997, 28(6): 529-547. doi: 10.1016/S1359-835X(97)00004-3 [6] 刘兴科, 李亚智, 刘向东, 等. 金属和复合材料多钉连接钉载分配研究[J]. 航空工程进展, 2011, 2(2): 193-198.LIU Xingke, LI Yazhi, LIU Xiangdong, et al. Study on load distribution of multiple-bolted metal to composite joints[J]. Advances in Aeronautical Science and Engineering, 2011, 2(2): 193-198(in Chinese). [7] 刘向东, 李亚智, 舒怀, 等. 多钉连接钉载分配特性研究方法[J]. 复合材料学报, 2013, 30(1): 210-217.LIU Xiangdong, LI Yazhi, SHU Huai, et al. Experimental and numerical study on the pin-load distribution of multiple-bolted joints[J]. Acta Materiae Compositae Sinica, 2013, 30(1): 210-217(in Chinese). [8] LAWLOR V P, MCCARTHY M A, STANLEY W F. An experimental study of bolt–hole clearance effects in double-lap, multi-bolt composite joints[J]. Composite Structures, 2005, 71(2): 176-190. doi: 10.1016/j.compstruct.2004.09.025 [9] 陈龙, 陈普会. 复合材料-钛合金混合结构多钉连接钉载分布及有限元计算[J]. 航空工程进展, 2020, 11(5): 679-685.CHEN Long, CHEN Puhui. Load distribution and finite element analysis of composite-to-titanium hybrid structure with multiple-bolted joints[J]. Advances in Aeronautical Science and Engineering, 2020, 11(5): 679-685(in Chinese). [10] 张明俊. 复合材料多钉连接有限元分析[C]//第十八届中国科协年会. 北京: 中国科学技术协会, 2016: 114-118.ZHANG Mingjun. Research by finite element analysis on multi-fastened composite laminate[C]//The Eighteenth Annual Meeting of China Association for Science and Technology. Beijing: China Association for Science and Technology, 2016: 114-118(in Chinese). [11] STANLEY W F, MCCARTHY M A, LAWLOR V P. Measurement of load distribution in multibolt composite joints, in presence of varying clearance[J]. Plastics, Rubber and Composites, 2002, 31(9): 412-418. doi: 10.1179/146580102225006512 [12] LIU F R, LU X H, ZHAO L B, et al. An interpretation of the load distributions in highly torqued single-lap composite bolted joints with bolt-hole clearances[J]. Composites Part B: Engineering, 2018, 138: 194-205. doi: 10.1016/j.compositesb.2017.11.027 [13] 张建宇, 刘丰睿, 山美娟, 等. 复合材料多钉连接钉载矢量传感器[J]. 复合材料学报, 2015, 32(5): 1420-1427.ZHANG Jianyu, LIU Fengrui, SHAN Meijuan, et al. Instrumented bolt for load vector of composite multi-bolt joints[J]. Acta Materiae Compositae Sinica, 2015, 32(5): 1420-1427(in Chinese). [14] 谢鸣九. 复合材料多排机械连接钉载分配研究[C]//第十五届全国复合材料学术会议. 北京: 国防工业出版社, 2008: 472-475.XIE Mingjiu. Analysis research on load distribution for multirow fastened joint in fibrous composites[C]//2008 National Conference on Composite Materials. Beijing:National Defense Industry Press, 2008: 472-475(in Chinese). [15] 郑岩冰. 复合材料多钉连接结构钉载分配比例研究[D]. 大连: 大连理工大学, 2017.ZHENG Yanbing. Research on the bolt-load distribution of multi-bolt composite joints[D]. Dalian: Dalian University of Technology, 2017(in Chinese). [16] 龚潇. 碳纤维复合材料机械连接载荷分配均匀化研究[D]. 上海: 上海交通大学, 2015,GONG Xiao. Research on the equalization of load distribution of carbon fibre composite bolt joints[D]. Shanghai: Shanghai Jiao Tong University, 2015(in Chinese). [17] LI H N, LI D S, SONG G B. Recent applications of fiber optic sensors to health monitoring in civil engineering[J]. Engineering Structures, 2004, 26(11): 1647-1657. doi: 10.1016/j.engstruct.2004.05.018 [18] RAO Y J. Recent progress in applications of in-fibre Bragg grating sensors[J]. Optics and Lasers in Engineering, 1999, 31(4): 297-324. doi: 10.1016/S0143-8166(99)00025-1 [19] OKAGAWA S, BERNUS P, NORAN O. Realtime health monitoring of composite structures using FBG sensors[J]. IFAC-Papers On Line, 2022, 55(19): 157-162. doi: 10.1016/j.ifacol.2022.09.200 [20] MA J X, PEI H F, ZHU H H, et al. A review of previous studies on the applications of fiber optic sensing technologies in geotechnical monitoring[J]. Rock Mechanics Bulletin, 2023, 2(1): 100021. doi: 10.1016/j.rockmb.2022.100021 [21] ROVERI N, CARCATERRA A, SESTIERI A. Real-time monitoring of railway infrastructures using fibre Bragg grating sensors[J]. Mechanical Systems and Signal Processing, 2015, 60-61: 14-28. doi: 10.1016/j.ymssp.2015.01.003 [22] 戎小戈, 章献民. 光纤光栅传感器原理及应用[J]. 武汉科技学院学报, 2003, 16(3): 42-45.RONG Xiaoge, ZHANG Xianmin. Principles and applications of fiber grating sensors[J]. Journal of Wuhan University of Science and Engineering, 2003,16 (3): 42-45(in Chinese). [23] 谢鸣九. 复合材料连接技术[M]. 上海: 上海交通大学出版社, 2016: 202-203.XIE Mingjiu. Joint for composites materials[M]. Shanghai: Shanghai Jiao Tong University Press, 2016: 202-203(in Chinese). [24] MCCARTHY C T, GRAY P J. An analytical model for the prediction of load distribution in highly torqued multi-bolt composite joints[J]. Composite Structures, 2011, 93(2): 287-298. doi: 10.1016/j.compstruct.2010.09.017 [25] ILYAS M, ESPINOSA C, LACHAUD F, et al. Simulation of dynamic delamination and mode I energy dissipation[C]//7th European LS-DYNA Conference. Salzburg: DYNAmore GmbH, 2009: 1-7. [26] 许良, 涂宜鸣, 崔浩, 等. T800碳纤维复合材料低速冲击渐进损伤仿真与试验研究[J]. 大连理工大学学报, 2021, 61(6): 608-614.XU Liang, TU Yiming, CUI Hao, et al. Simulation and experimental research on progressive damage of T800 carbon fiber composites under low velocity impact[J]. Journal of Dalian University of Technology, 2021, 61(6): 608-614(in Chinese). [27] ASTM. Standard test method for bearing response of polymer matrix composite laminates: ASTM D5961/D5961M—13[S]. West Conshehoken: ASTM, 2013. [28] 中国航空研究院. 复合材料连接手册[M]. 北京: 航空工业出版社, 1994: 75-78.Chinese Aeronautical Establishment. Composite connection manual[M]. Beijing: Aviation Industry Press, 1994: 75-78(in Chinese). -

下载:

下载: