Interface shear resistance of precast keyway UHPC and post-cast normal concrete

-

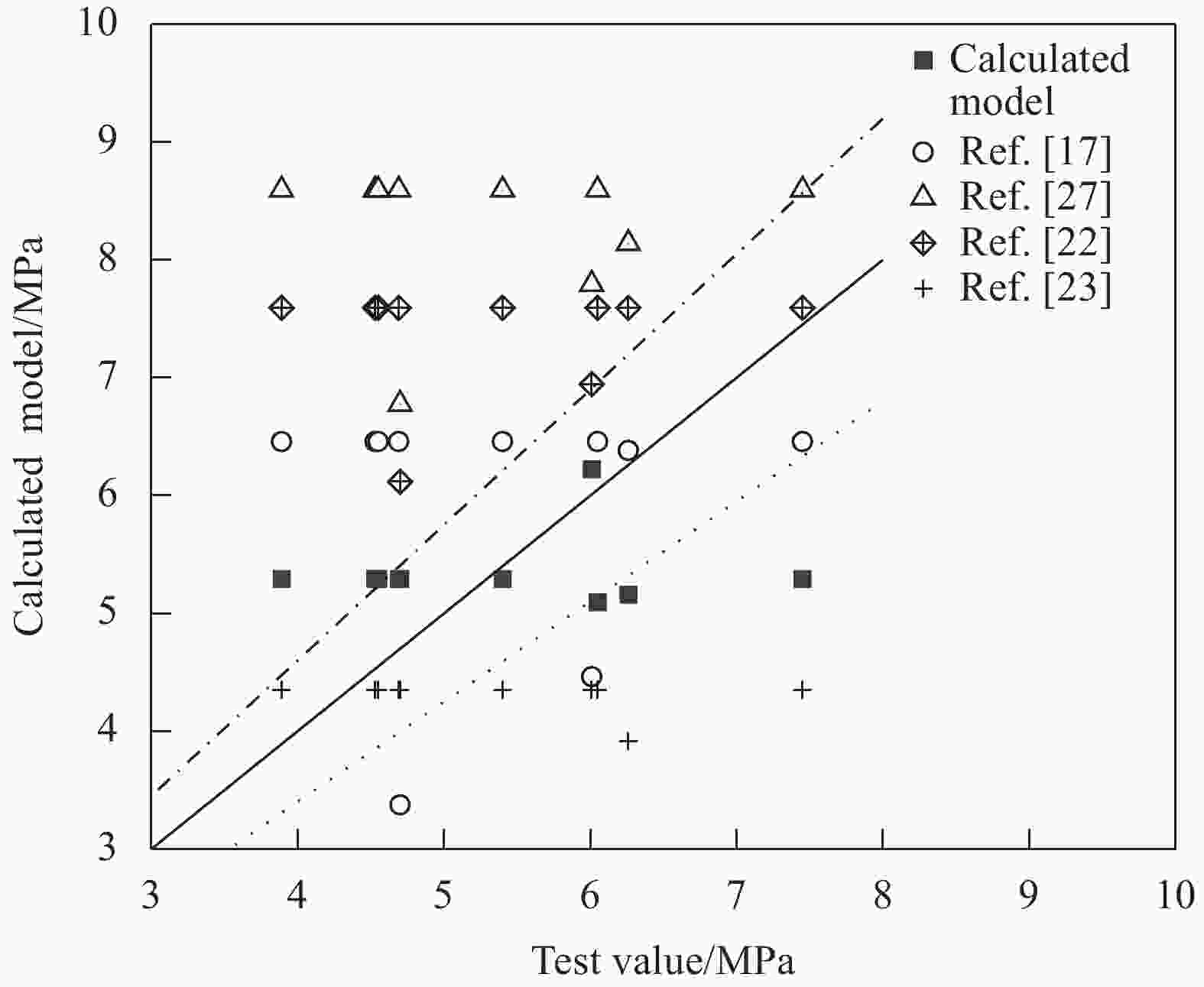

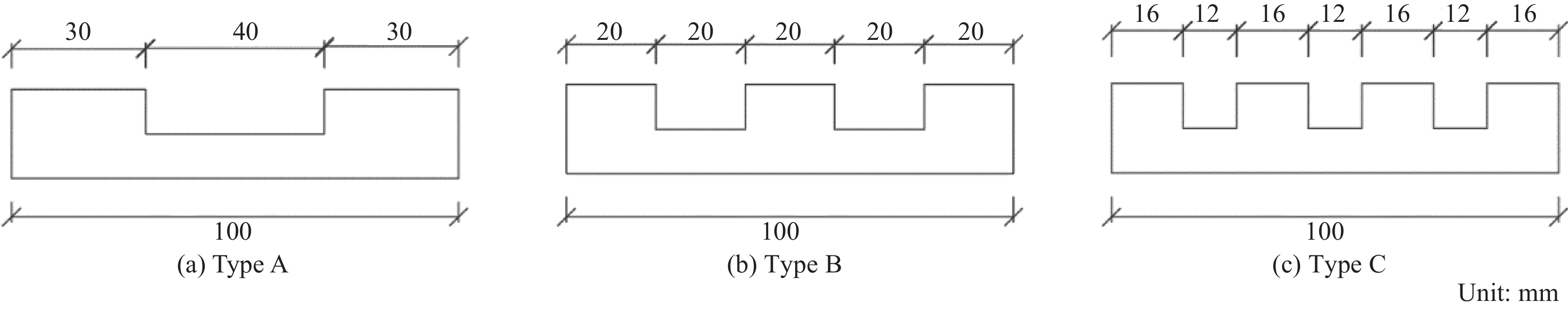

摘要: 永久性模板的使用可实现混凝土结构的快速施工,缩短工期,提高整体结构的承载能力和耐久性能。其界面粘结抗剪性能是确保永久性模板与混凝土协同工作的关键。本文设计并制作了3组不同强度混凝土试件和10组键槽式超高性能混凝土(UHPC)-普通混凝土(NC)复合试件,通过单面剪切试验和理论分析,系统研究了键槽密度、键槽间距、混凝土强度、养护条件等对键槽式UHPC-NC结合面抗剪性能的影响。结果表明:整体试件的裂缝与加载中心轴线呈一定角度,UHPC-NC结合面破坏发生于普通混凝土一侧。UHPC-NC荷载-滑移曲线细分为4个近似线性阶段,其极限滑移量均在0.9 mm以内。复合试件UHPC-NC的粘结面总剪切强度由粘结面接触摩擦力、水泥石-骨料相互作用、键槽-骨料互锁机制、剪切膨胀提供。合理的UHPC-NC键槽界面在提高界面粘结抗剪强度的同时,可有效提高界面相对位移。在60℃蒸汽养护条件下,水泥石-骨料界面及UHPC-混凝土界面作用减弱。建立了键槽式UHPC-后浇NC界面抗剪承载力修正公式,其计算值与试验值具有较高的吻合度,大多数结果落在90%置信区间,置信区间之外的点,受试件养护龄期的影响。因此,要准确计算键槽式UHPC-NC复合试件抗剪强度还需要考虑养护龄期的影响,引入养护龄期修正参数。Abstract: Use of permanent formwork can achieve rapid construction, shorten the construction period, and improve the bearing capacity and durability of concrete structure. Interfacial bond shear performance is the key to ensure the collaborative work of permanent formwork and concrete. Three groups of concrete specimens with different compressive strengths and ten groups of keyway ultra-high performance concrete (UHPC)-normal concrete (NC) composite specimens were prepared. The effects of keyway density, spacing, concrete strength, and curing condition on the shear property of keyway UHPC-NC were systematically studied through single-side shear tests and theoretical analysis. Results show that the crack of the concrete specimen is at a certain angle to the loading center axis. And the failure of the UHPC-NC joint surface occurs on the side of concrete. The load-displacement curve of UHPC-NC specimens can be subdivided into four approximately linear stages. And all of the displacements are within 0.9 mm. The total shear strength of the UHPC-NC composite specimen was provided by the contact friction of the bonding surface, matrix-aggregate interaction, keyway-aggregate interlocking mechanism and shear expansion. A reasonable interface of the UHPC-NC keyway can improve both the shear strength and the interface relative displacement of UHPC-NC specimens. After steam curing at 60℃, the interface of matrix-aggregate and the interface UHPC-NC are weakened. According to the results, a modified equation for the shear strength of the keyway UHPC-NC composite specimen was proposed. The calculated values agree well with the experimental results. Most of the calculated values fall within the 90% confidence interval. The values outside the confidence interval are affected by the curing time of the specimens. Therefore, to accurately calculate the shear strength of the keyway UHPC-NC composite specimen, the influence of curing time should also be considered by the curing time factor.

-

表 1 超高性能混凝土(UHPC)配合比 (kg/m3)

Table 1. Mix proportion of ultra-high performance concrete (UHPC) (kg/m3)

Cement Silica fume Fly ash Quartz sand Steel fiber Superplasticizer Water 680 144 200 1060 156 30 180 表 2 普通混凝土(NC)配合比和材料性能(kg/m3)

Table 2. Mix proportion and mechanical property of normal concrete (NC) (kg/m3)

Cement Sand Aggregate

(10-20 mm)Aggregate

(5-10 mm)Fly ash Slag Water Super-

plasticizer28 d compressive

strength/MPa28 d elastic

modulus/GPaC30 214 704 879 211 71 71 178 5.7 34.6 30.96 C40 279 645 878 207 79 79 175 7.0 44.6 33.69 C50 325 522 922 221 50 125 170 8.0 53.3 35.76 表 3 剪切试验试件编号

Table 3. Number of specimen for shear test

Specimen type Strength of post-cast concrete Type of the interface Curing time/d Influence parameter N3 C30 Monolithic 7 — N4 C40 Monolithic 7 — N5 C50 Monolithic 7 — UN5-B-7 C50 B 7 Curing time UN5-B-Z7 C50 B 1+6 Curing regime UN5-B-14 C50 B 14 Curing time UN5-B-Z14 C50 B 1+13 Curing regime UN5-A-28 C50 A 28 Type of keyway UN5-B-28 C50 B 28 Type of keyway UN5-C-28 C50 C 28 Type of keyway UN3-B-28 C30 B 28 Strength of concrete UN4-B-28 C40 B 28 Strength of concrete UN5-B-Z28 C50 B 1+27 Curing regime 表 4 NC试件与UHPC-NC试件的剪切性能参数

Table 4. Shear parameters of NC specimen and UHPC-NC specimen

Specimen type Ultimate

load Pu/kNNominal shear

strength τ/MPaVertical limit

displacement S/mmShear stiffness

K/(kN·mm−1)N3 27.36 2.74 0.185 136.80 N4 32.02 3.20 0.370 68.96 N5 43.08 4.31 0.354 147.10 UN5-B-7 45.51 4.55 0.545 113.98 UN5-BZ-7 45.20 4.53 0.290 211.26 UN5-B-14 60.48 6.05 0.410 134.40 UN5-BZ-14 38.96 3.89 0.400 97.40 UN5-A-28 46.94 4.69 0.684 66.78 UN5-B-28 74.50 7.45 0.985 127.36 UN5-C-28 62.59 6.26 0.800 58.42 UN3-B-28 47.00 4.70 0.540 86.58 UN4-B-28 60.15 6.01 0.650 113.80 UN5-BZ-28 53.99 5.40 0.660 85.90 表 5 UHPC-NC试件粘结面抗剪强度计算值与试验值(MPa)

Table 5. Calculated values and experimental values for shear strength of UHPC-NC specimen (MPa)

Test value Mohr Coulomb theory[15-16] Eurocode 2[31] AASHTO LRFD[32] ACI 318[33] Fib model code[34] N3 2.74 3.84 1.025 0.3 0.866 0.4 N4 3.20 4.96 1.325 0.3 0.983 0.4 N5 4.31 5.93 1.583 0.3 1.075 0.4 UN5-B-7 4.55 5.93 1.583 0.3 2.150 0.4 UN5-BZ-7 4.53 5.93 1.583 0.3 2.150 0.4 UN5-B-14 6.05 5.93 1.583 0.3 2.150 0.4 UN5-BZ-14 3.89 5.93 1.583 0.3 2.150 0.4 UN5-A-28 4.69 5.93 1.583 0.3 2.150 0.4 UN5-B-28 7.45 5.93 1.583 0.3 2.150 0.4 UN5-C-28 6.26 5.93 1.583 0.3 2.040 0.4 UN3-B-28 4.70 3.84 1.025 0.3 1.732 0.4 UN4-B-28 6.01 4.96 1.325 0.3 1.966 0.4 UN5-BZ-28 5.40 5.93 1.583 0.3 2.150 0.4 表 6 UHPC-NC试件粘结面抗剪强度(τs)修正模型计算值与试验值(MPa)

Table 6. Calculated values of corrected model and experimental values for shear strength (τs) of UHPC-NC specimens (MPa)

Test

valueRef. [17] Ref. [22] Ref. [23] Ref. [29] Calculated model τs (Test value (Calculated value) ) UN5-B-7 4.55 6.457 (0.705) 7.593 (0.599) 4.351 (1.046) 8.594 (0.529) 5.293 (0.860) UN5-BZ-7 4.53 6.457 (0.702) 7.593 (0.597) 4.351 (1.041) 8.594 (0.527) 5.293 (0.856) UN5-B-14 6.05 6.457 (0.937) 7.593 (0.797) 4.351 (1.390) 8.594 (0.704) 5.293 (1.143) UN5-BZ-14 3.89 6.457 (0.602) 7.593 (0.512) 4.351 (0.894) 8.594 (0.453) 5.293 (0.735) UN5-A-28 4.69 6.457 (0.726) 7.593 (0.618) 4.351 (1.078) 8.594 (0.546) 5.293 (0.886) UN5-B-28 7.45 6.457 (1.154) 7.593 (0.981) 4.351 (1.712) 8.594 (0.867) 5.293 (1.407) UN5-C-28 6.26 6.383 (0.981) 7.593 (0.824) 3.916 (1.599) 8.140 (0.769) 6.223 (1.006) UN3-B-28 4.70 3.374 (1.394) 6.117 (0.768) 4.351 (1.080) 6.777 (0.694) 5.094 (0.923) UN4-B-28 6.01 4.462 (1.347) 6.945 (0.868) 4.351 (1.381) 7.792 (0.771) 5.160 (1.165) UN5-BZ-28 5.40 6.457 (0.836) 7.593 (0.711) 4.351 (1.241) 8.594 (0.628) 5.293 (1.020) -

[1] SHI C J, WU Z M, XIAO J F, et al. A review on ultra high performance concrete: Part I. Raw materials and mixture design[J]. Construction and Building Materials, 2015, 101: 741-751. doi: 10.1016/j.conbuildmat.2015.10.088 [2] SAFDAR M, MATSUMOTO T, KAKUMA K. Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC)[J]. Composite Structures, 2016, 157: 448-460. doi: 10.1016/j.compstruct.2016.09.010 [3] ZHANG Y, ZHANG C Y, ZHU Y P, et al. An experimental study: Various influence factors affecting interfacial shear performance of UHPC-NSC[J]. Construction and Building Materials, 2020, 236: 117480. doi: 10.1016/j.conbuildmat.2019.117480 [4] 张雷顺, 闫国新, 张晓磊. 新老混凝土切槽法结合面抗剪性能试验研究分析[J]. 工业建筑, 2007, 37(6): 101-103, 115. doi: 10.3321/j.issn:1000-8993.2007.06.026ZHANG Leishun, YAN Guoxin, ZHANG Xiaolei. Experimental study and analysis on shearing property of interficial bonding of new to old concrete by cutting groove[J]. Industrial Construction, 2007, 37(6): 101-103, 115(in Chinese). doi: 10.3321/j.issn:1000-8993.2007.06.026 [5] DE LA VARGA I, HABER Z B, GRAYBEAL B A. Enhancing shrinkage properties and bond performance of prefabricated bridge deck connection grouts: Material and component testing[J]. Journal of Materials in Civil Engineering, 2018, 30(4): 04018053. doi: 10.1061/(ASCE)MT.1943-5533.0002235 [6] MOMAYEZ A, EHSANI M R, RAMEZANIANPOUR A A, et al. Comparison of methods for evaluating bond strength between concrete substrate and repair materials[J]. Cement and Concrete Research, 2005, 35(4): 748-757. doi: 10.1016/j.cemconres.2004.05.027 [7] TAYEH B A, ABU BAKAR B H, MEGAT JOHARI M A, et al. Evaluation of bond strength between normal concrete substrate and ultra high performance fiber concrete as a repair material[J]. Procedia Engineering, 2013, 54: 554-563. doi: 10.1016/j.proeng.2013.03.050 [8] 张雷顺, 闫国新, 张晓磊, 等. 沟槽式新老混凝土粘结面抗剪强度试验研究[J]. 郑州大学学报(工学版), 2006, 27(2): 24-28.ZHANG Leishun, YAN Guoxin, ZHANG Xiaolei, et al. Experimental research on shear strength of interfacial bonding of new and old concrete by cutting groove[J]. Journal of Zhengzhou University (Engineering Science), 2006, 27(2): 24-28(in Chinese). [9] YANG J, XIA J R, CHENG C S, et al. Research on the bonding performance of UHPC-NC interfaces with different sizes of grooves[J]. Frontiers in Materials, 2022, 9: 859717. doi: 10.3389/fmats.2022.859717 [10] WANG Z, NIE X, FAN J S, et al. Experimental and numerical investigation of the interfacial properties of non-steam-cured UHPC-steel composite beams[J]. Construction and Building Materials, 2019, 195: 323-339. doi: 10.1016/j.conbuildmat.2018.11.057 [11] BIRKELANDD P W, BIRKELAND H W. Connections in precast concrete construction[J]. ACI Structural Journal, 1966, 63(3): 345-368. [12] JANG H O, LEE H S, CHO K H, et al. Experimental study on shear performance of plain construction joints integrated with ultra-high performance concrete (UHPC)[J]. Construction and Building Materials, 2017, 152: 16-23. doi: 10.1016/j.conbuildmat.2017.06.156 [13] JIANG H B, DONG X T, FANG Z C, et al. Experimental study on shear behavior of a UHPC connection between adjacent precast prestressed concrete voided beams[J]. Journal of Bridge Engineering, 2020, 25(12): 04020106. doi: 10.1061/(ASCE)BE.1943-5592.0001644 [14] JIANG H B, SHAO T F, FANG Z C, et al. Shear-friction behavior of grooved construction joints between a precast UHPC girder and a cast-in-place concrete slab[J]. Engineering Structures, 2021, 228: 111610. doi: 10.1016/j.engstruct.2020.111610 [15] 张阳, 王兴旺. UHPC加固RC结构交界面抗剪性能试验研究[J]. 中外公路, 2017, 37(2): 105-111. doi: 10.14048/j.issn.1671-2579.2017.02.024ZHANG Yang, WANG Xingwang. Experimental study on shear performance of RC structures reinforced by UHPC[J]. Journal of China & Foreign Highway, 2017, 37(2): 105-111(in Chinese). doi: 10.14048/j.issn.1671-2579.2017.02.024 [16] SANTOS P M D, JÚLIO E N B S. Development of a laser roughness analyser to predict in situ the bond strength of concrete-to-concrete interfaces[J]. Magazine of Concrete Research, 2008, 60(5): 329-337. doi: 10.1680/macr.2007.00024 [17] DU C Q, LIU X F, LIU Y Y, et al. Prediction of the interface shear strength between ultra-high-performance concrete and normal concrete using artificial neural networks[J]. Materials (Basel), 2021, 14(19): 5707. doi: 10.3390/ma14195707 [18] MATTOCK A H, HAWKINS N M. Shear transfer in reinforced concrete—Recent research[J]. PCI Journal, 1972, 17(2): 55-75. doi: 10.15554/pcij.03011972.55.75 [19] MOHAMAD M E, IBRAHIM I S, ABDULLAH R, et al. Friction and cohesion coefficients of composite concrete-to-concrete bond[J]. Cement and Concrete Composites, 2015, 56: 1-14. doi: 10.1016/j.cemconcomp.2014.10.003 [20] HARRIS D K, SARKAR J, AHLBORN T T M. Characterization of interface bond of ultra-high-performance concrete bridge deck overlays[J]. Transportation Research Record, 2011, 2240: 40-49. doi: 10.3141/2240-07 [21] HUSSEIN H H, WALSH K K, SARGAND S M, et al. Interfacial properties of ultrahigh-performance concrete and high-strength concrete bridge connections[J]. Journal of Materials in Civil Engineering, 2016, 28(5): 04015208. doi: 10.1061/(ASCE)MT.1943-5533.0001456 [22] 王景全, 胡玉庆, 刘桐旭, 等. 超高性能混凝土大键齿干接缝受剪性能与承载力计算方法[J]. 建筑结构学报, 2021, 42(10): 177-185. doi: 10.14006/j.jzjgxb.2020.C318WANG Jingquan, HU Yuqing, LIU Tongxu, et al. Shear performance and bearing capacity calculation method for UHPC dry joints with large-keys[J]. Journal of Building Structures, 2021, 42(10): 177-185(in Chinese). doi: 10.14006/j.jzjgxb.2020.C318 [23] ZHANG Y, ZHU P, WANG X W, et al. Shear properties of the interface between ultra-high performance concrete and normal strength concrete[J]. Construction and Building Materials, 2020, 248: 118455. doi: 10.1016/j.conbuildmat.2020.118455 [24] ZHU Y P, ZHANG Y, HUSSEIN H H, et al. Numerical modeling for damaged reinforced concrete slab strengthened by ultra-high performance concrete (UHPC) layer[J]. Engineering Structures, 2020, 209: 110031. doi: 10.1016/j.engstruct.2019.110031 [25] ZHU Y P, ZHANG Y, LI X L, et al. Finite element model to predict structural response of predamaged RC beams reinforced by toughness-improved UHPC under unloading status[J]. Engineering Structures, 2021, 235: 112019. doi: 10.1016/j.engstruct.2021.112019 [26] SANTOS P M D, JÚLIO E N B S. A state-of-the-art review on shear-friction[J]. Engineering Structures, 2012, 45: 435-448. doi: 10.1016/j.engstruct.2012.06.036 [27] 中国工程建设标准化协会. 超高性能混凝土(UHPC)技术要求: T/CECS 10107—2020[S]. 北京: 中国标准出版社, 2020.China Engineering Construction Standardization Association. Technical requirements for ultra high performance concrete: T/CECS 10107—2020[S]. Beijing: China Standards Press, 2020(in Chinese). [28] 中华人民共和国住房与城乡建设部. 普通混凝土配合比设计规程: JGJ 55—2011[S]. 北京: 中国建筑工业出版社, 2011.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Specification for mix proportion design of ordinary concrete: JGJ 55—2011[S]. Beijing: China State Engineering and Construction Press, 2011(in Chinese). [29] 王德弘, 沈彤, 鞠彦忠, 等. 后浇普通混凝土与预制UHPC的粘结受剪性能研究[J]. 建筑结构学报, 2020, 41(S2): 411-419. doi: 10.14006/j.jzjgxb.2020.S2.0046WANG Dehong, SHEN Tong, JU Yanzhong, et al. Study on shear bond behavior of post-cast normal concrete and precast UHPC[J]. Journal of Building Structures, 2020, 41(S2): 411-419(in Chinese). doi: 10.14006/j.jzjgxb.2020.S2.0046 [30] 王鹏刚, 付华, 郭腾飞, 等. 蒸汽养护混凝土变形行为及开裂风险评估[J]. 材料导报, 2022, 36(24): 86-93.WANG Penggang, FU Hua, GUO Tengfei, et al. Deformation behavior and cracking risk assessment of steam-cured concrete[J]. Materials Reports, 2022, 36(24): 86-93(in Chinese). [31] JOHNSON R P, ANDERSON D. Eurocode 2. General rules and rules for buildings[C]//The European Union Per Regulation. Brussels: European Committee for Standardization, 2004: 1-99 . [32] SWARTZ B D, SCANLON A, SCHOKKER A J. AASHTO LRFD bridge design specifications provisions for loss of prestress[J]. PCI Journal, 2012, 57(4): 108-132. doi: 10.15554/pcij.09012012.108.132 [33] JACK P M, SANTANA G. Commentary on building code requirements for structural concrete (ACI 318r-14): An ACI report [R]. Washington: American Concrete Institute, 2014. [34] TAERWE L, MATTHYS S. Fib model code for concrete structures 2010[C]//Joost Walraven. The International Federation for Structural Concrete. Switzerland: Wiley-VCH Verlag CmbH & Co., KCaA, 2013: 48-73. [35] TABATABAEI M, DAHI TALEGHANI A, ALEM N. Measurement of mixed mode interfacial strengths with cementitious materials[J]. Engineering Fracture Mechanics, 2020, 223: 106739. doi: 10.1016/j.engfracmech.2019.106739 -

下载:

下载: