Effect of multifunctional flame retardant tougheners on the flame retardant and mechanical properties of polycarbonates

-

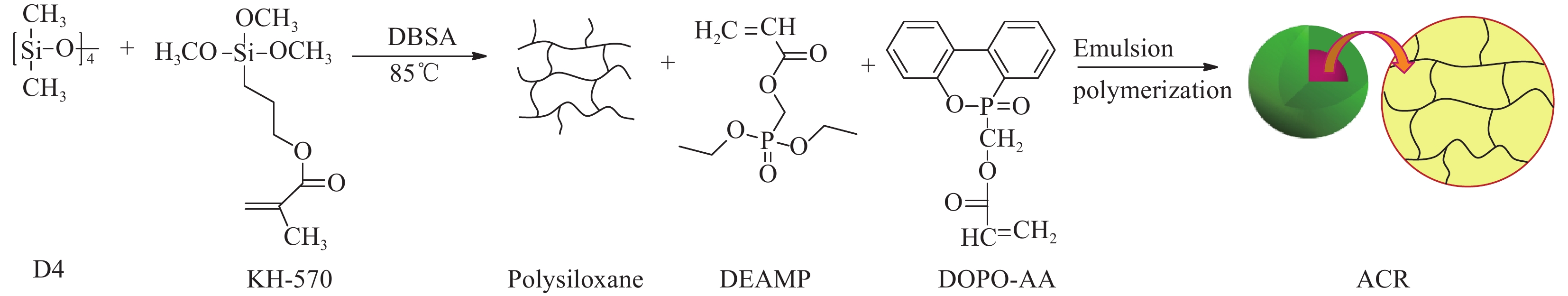

摘要: 为了平衡聚碳酸酯(PC)的阻燃改性和力学改性效果,本文采用由种子乳液聚合自制的有机硅-含磷丙烯酸酯核壳结构的阻燃增韧剂(ACR)共混改性PC材料。当在PC中添加质量分数为4wt%的ACR时,4%ACR/PC的极限氧指数(LOI)可达31.7%,垂直燃烧测试达到UL-94 V-0级,锥形量热测试表明燃烧释热和烟释放总量分别降低了43.2%和20.5%;同时,4%ACR/PC保持了与纯PC相近的拉伸强度,且冲击强度提高了9.4%。热重-红外联用、拉曼光谱和燃烧后残余物扫描电镜分析表明,阻燃作用主要来自于磷-硅协同效应及磷元素对PC的催化成炭作用。冲击断面SEM图像显示,增韧作用体现在ACR核层有机硅橡胶可以吸收冲击能量,抑制或终止裂纹的产生。Abstract: In order to balance the effect of flame retardant modification and mechanical modification of polycarbonate (PC), the flame retardant toughening agent with silicone-phosphorus-containing acrylate core-shell structure (ACR) prepared by seed emulsion polymerization was used to modify PC materials in this paper. When 4wt%ACR was added to PC, the limiting oxygen index (LOI) of 4%ACR/PC could reach 31.7%, the vertical combustion test reached UL-94 V-0 level, and the cone calorimeter test showed that the combustion heat release and smoke density were reduced by 43.2% and 20.5%, respectively. At the same time, the tensile strength of 4%ACR/PC was similar to that of pure PC, and the impact strength was increased by 9.4%. Thermogravimetric-infrared spectroscopy, Raman spectroscopy and post-combustion residue scanning electron microscopy analysis showed that the flame retardant effect was mainly due to the synergistic effect of phosphorus-silicon and the catalytic charring effect of phosphorus on PC. The impact cross-section SEM images showed that the toughening effect is reflected in the fact that the ACR core layer silicone rubber can absorb impact energy and inhibit or terminate the generation of cracks.

-

Key words:

- flame retardancy /

- toughening /

- mechanical properties /

- ACR /

- polycarbonate /

- phosphorus-silicon synergy

-

表 1 ACR/聚碳酸酯(PC)复合材料的配方表

Table 1. Formulation sheet for ACR/polycarbonate (PC) composites

Sample PC/wt% ACR/wt% PC 100 — 1%ACR/PC 99 1 2%ACR/PC 98 2 4%ACR/PC 96 4 表 2 PC、ACR/PC的UL-94和极限氧指数(LOI)

Table 2. UL-94 and limiting oxygen index (LOI) for PC, ACR/PC

Sample UL-94 LOI/% t1/t2 Dripping Ignition Rating PC 17/9 Yes Yes V-2 25.8 1%ACR/PC 13/4 Yes No V-1 26.3 2%ACR/PC 6/3 No No V-0 27.6 4%ACR/PC 1/1 No No V-0 31.7 Notes: t1—First afterflame time; t2—Second afterflame time. 表 3 ACR、PC、ACR/PC的TGA和DTG数据

Table 3. TGA and DTG data for ACR, PC, ACR/PC

Sample Td5%/℃ Td10%/℃ Td50%/℃ TMax/℃ Char

residue/wt%ACR 375 418 482 476 36.4 PC 496 506 528 526 26.2 1%ACR/PC 495 505 530 525 25.6 2%ACR/PC 485 495 515 513 26.1 4%ACR/PC 492 497 517 512 28.8 Notes: Td5%—5wt% mass loss temperature; Td10%—10wt% mass loss temperature; Td50%—50wt% mass loss temperature; TMax—Maximum mass loss temperature. 表 4 PC、ACR/PC的锥形量热数据

Table 4. Cone calorimetry data for PC, ACR/PC

Sample TTI/s tp/s pHRR/(kW·m−2) THR/(MJ·m−2) Av-EHC/(MJ·kg−1) Char residue/wt% TSP/m2 PC 165 280 165 15.5 6.2 17.5 7.3 1%ACR/PC 116 271 145 13.6 6.4 18.6 6.3 2%ACR/PC 112 258 125 12.1 5.0 20.2 6.1 4%ACR/PC 102 275 73 8.8 4.3 26.1 5.8 Notes: TTI—Ignition time, ±1 s; pHRR—Peak heat release rate, ±2 kW·m–2; tp—Peak time corresponding to the heat release rate, ±1 s; THR—Total heat release, ±0.5 MJ·m–2; Av-EHC—Average effective heat of combustion, ±0.1 MJ·kg–1; TSP—Total smoke production, ±0.1 m2. 表 5 PC、ACR/PC的力学性能测试结果

Table 5. Mechanical property test results of PC, ACR/PC

Sample Tensile strength/MPa Impact strength/(J·m−1) PC 69.7±1.5 6.4±0.1 1%ACR/PC 69.8±1.4 8.5±0.1 2%ACR/PC 69.1±1.7 7.6±0.2 4%ACR/PC 68.4±1.3 7.0±0.1 -

[1] 刘俊威, 高山俊, 沈春晖, 等. 硅-磷复配阻燃剂对聚碳酸酯/ASA复合材料阻燃性能及动态力学性能的影响[J]. 复合材料学报, 2018, 35(11): 3062-3072.LIU Junwei, GAO Shanjun, SHEN Chunhui, et al. Flame-retardation synergism and dynamic mechanical properties of polycarbonate/ASA composites modified by silicon and organo-phosphate containing flame retardants[J]. Acta Materiae Compositae Sinica, 2018, 35(11): 3062-3072(in Chinese). [2] NI P, FANG Y Y, QIAN L J, et al. Flame-retardant behavior of a phosphorus/silicon compound on polycarbonate[J]. Journal of Applied Polymer Science, 2018, 135(6): e45815. [3] YANG Y Y, LIU J, CAI X F. Antagonistic flame retardancy between hexakis(4-nitrophenoxy) cyclotriphosphazene and potassium diphenylsulfone sulfonate in the PC system[J]. Journal of Thermal Analysis and Calorimetry, 2016, 126(2): 571-583. doi: 10.1007/s10973-016-5519-2 [4] HOU S J, ZHANG Y J, JIANG P K. Phosphonium sulfonates as flame retardants for polycarbonate[J]. Polymer Degradation and Stability, 2016, 130: 165-172. doi: 10.1016/j.polymdegradstab.2016.06.004 [5] ZHANG X Y, ZHANG D L, ZHANG W C, et al. Flame retardant polycarbonate with ultralow loading 1, 3-benzenedisulfonate[J]. Polymer Degradation and Stability, 2023, 214: 110389. [6] WAWRZYN E, SCHARTEL B, KARRASCH A, et al. Flame-retarded bisphenol A polycarbonate/silicon rubber/bisphenol A bis(diphenyl phosphate): Adding inorganic additives[J]. Polymer Degradation and Stability, 2014, 106: 74-87. doi: 10.1016/j.polymdegradstab.2013.08.006 [7] WU X, QIN Z, ZHANG W, et al. KCl nanoparticles-loaded octaphenylsilsesquioxane as an efficient flame retardant for polycarbonate[J]. Reactive and Functional Polymers, 2022, 177: 105284. doi: 10.1016/j.reactfunctpolym.2022.105284 [8] STATLER D, STAJDUHAR E, GUPTA R K. Flame retardancy of polycarbonate upon repeated recycling[J]. Journal of Fire Sciences, 2008, 26(4): 331-350. [9] SUN C C, ZHANG W, CUI Y H, et al. Synthesis of phosphazene-triazine bi-base sulfonate and its applications in flame-retardant modified polycarbonate[J]. Journal of Applied Polymer Science, 2022, 139(21): e52224. [10] WANG X X, ZHANG W C, QIN Z L, et al. Optically transparent and flame-retarded polycarbonate nanocomposite based on diphenylphosphine oxide-containing polyhedral oligomeric silsesquioxanes[J]. Composites Part A: Applied Science and Manufacturing, 2019, 117: 92-102. doi: 10.1016/j.compositesa.2018.11.013 [11] QIAN Z Y, ZOU B, XIAO Y L, et al. Targeted modification of black phosphorus by MIL-53(Al) inspired by "Cannikin's Law" to achieve high thermal stability of flame retardant polycarbonate at ultra-low additions[J]. Composites Part B: Engineering, 2022, 238: 109943. doi: 10.1016/j.compositesb.2022.109943 [12] GAO X Y, YAN L, SANG X M. Preparation of multifunctional silicon-phosphorus acrylate particles for the simultaneous improvement of the flame retardancy and mechanical performance of polylactic acid[J]. Journal of Applied Polymer Science, 2023, 140(4): e53380. [13] JIANG Y, HAO Z F, LUO H S, et al. Synergistic effects of boron-doped silicone resin and a layered double hydroxide modified with sodium dodecyl benzenesulfonate for enhancing the flame retardancy of polycarbonate[J]. RSC Advances, 2018, 8(20): 11078-11086. [14] SAI T, RAN S Y, GUO Z H, et al. Transparent, highly thermostable and flame retardant polycarbonate enabled by rod-like phosphorous-containing metal complex aggregates[J]. Chemical Engineering Journal, 2021, 409(20): 128223. [15] WANG Z P, QIU Y, LIU A Q, et al. Micro-crosslinking of phosphaphenanthrene/siloxane molecule initiate aggregation flame retardant and toughening enhancement effects on its polycarbonate composite[J]. Chemical Engineering Journal, 2023, 466: 143169. [16] 中国石油和化学工业协会. 塑料用氧指数法测定 燃烧行为 第2部分: 室温试验: GB/T 2406.2—2008[S]. 北京: 中国标准出版社, 2009.China Petroleum and Chemical Industry Association. Plastics—Determination of burning behavior by oxygen index—Part 2: Ambient-temperature test: GB/T 2406.2—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [17] 中国石油和化学工业协会. 塑料燃烧性能的测定水平法和垂直法: GB/T 2408—2008[S]. 北京: 中国标准出版社, 2008.China Petroleum and Chemical Industry Association. Plastics—Determination of burning characteristics—Horizontal and vertical test: GB/T 2408—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [18] ISO/TC 92. Reaction-to-fire tests—Heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement): ISO 5660—1[S]. International Organization for Standardization, 2015. [19] 中国国家标准化管理委员会. 塑料 拉伸性能的测定: GB/T 1040—2006[S]. 北京: 中国标准出版社, 2007.Standardization Administration of the People's Republic of China. Plastics—Determination of tensile properties: GB/T 1040—2006[S]. Beijing: China Standards Press, 2007(in Chinese). [20] 中国国家标准化管理委员会. 塑料 悬臂梁冲击强度的测定: GB/T 1843—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Plastics—Determination of izod inpact sterngth: GB/T 1843—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [21] WANG Y C, YU K, ZHAO J P, et al. NaOH hydrothermally treated gibbsite modified silicone acrylic emulsion-based intumescent flame-retardant coatings for plywood[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 646: 129001. doi: 10.1016/j.colsurfa.2022.129001 [22] CHEN L M, ZENG S H, XU Y, et al. Epoxy-modified silicone resin based N/P/Si synergistic flame-retardant coating for wood surface[J]. Progress in Organic Coatings, 2022, 170: 106953. doi: 10.1016/j.porgcoat.2022.106953 [23] GAO D D, WEN X, GUAN Y Y, et al. Flame retardant effect and mechanism of nanosized NiO as synergist in PLA/APP/CSi-MCA composites[J]. Composites Communications, 2020, 17: 170-176. doi: 10.1016/j.coco.2019.12.007 [24] SCHARTEL B, HULL T R. Development of fire-retarded materials-interpretation of cone calorimeter data[J]. Fire and Materials, 2007, 31(5): 327-354. [25] YU M, ZHANG T T, LI J, et al. Enhancing toughness, flame retardant, hydrophobic and dielectric properties of epoxy resin by incorporating multifunctional additive containing phosphorus/silicon[J]. Materials & Design, 2023, 225: 111529. [26] LEE J Y, CHIN I J, CHOI H J. Effect of particle size and crosslinking on the toughening of core-shell-type rubber-modified poly(lactic acid) composites[J]. Polymer Testing, 2018, 65: 440-449. -

下载:

下载: