| [1] |

YANG Y F, WANG W K, MENG G L, et al. Function-directed design of battery separators based on microporous polyolefin membranes[J]. Journal of Materials Chemistry A, 2022, 10(27): 14137-14170.

|

| [2] |

YU L Y, GU J Y, PAN C, et al. Recent developments of composite separators based on high-performance fibers for lithium batteries[J]. Composites Part A: Applied Science and Manufacturing, 2022, 162: 107132.

|

| [3] |

CHOI J, KIM P J. A roadmap of battery separator development: Past and future[J]. Current Opinion in Electrochemistry, 2022, 31: 100858.

|

| [4] |

DAI X K, ZHANG X M, WEN J W, et al. Research progress on high-temperature resistant polymer separators for lithium-ion batteries[J]. Energy Storage Materials, 2022, 51: 638-659.

|

| [5] |

邓玉睿. 聚酰亚胺气凝胶安全电池隔膜设计及综合性能研究[D]. 合肥: 中国科学技术大学, 2022.DENG Yurui. Design and comprehensive performance research of polyimide aerogel safety battery separator[D]. Hefei: University of Science and Technology of China, 2022(in Chinese).

|

| [6] |

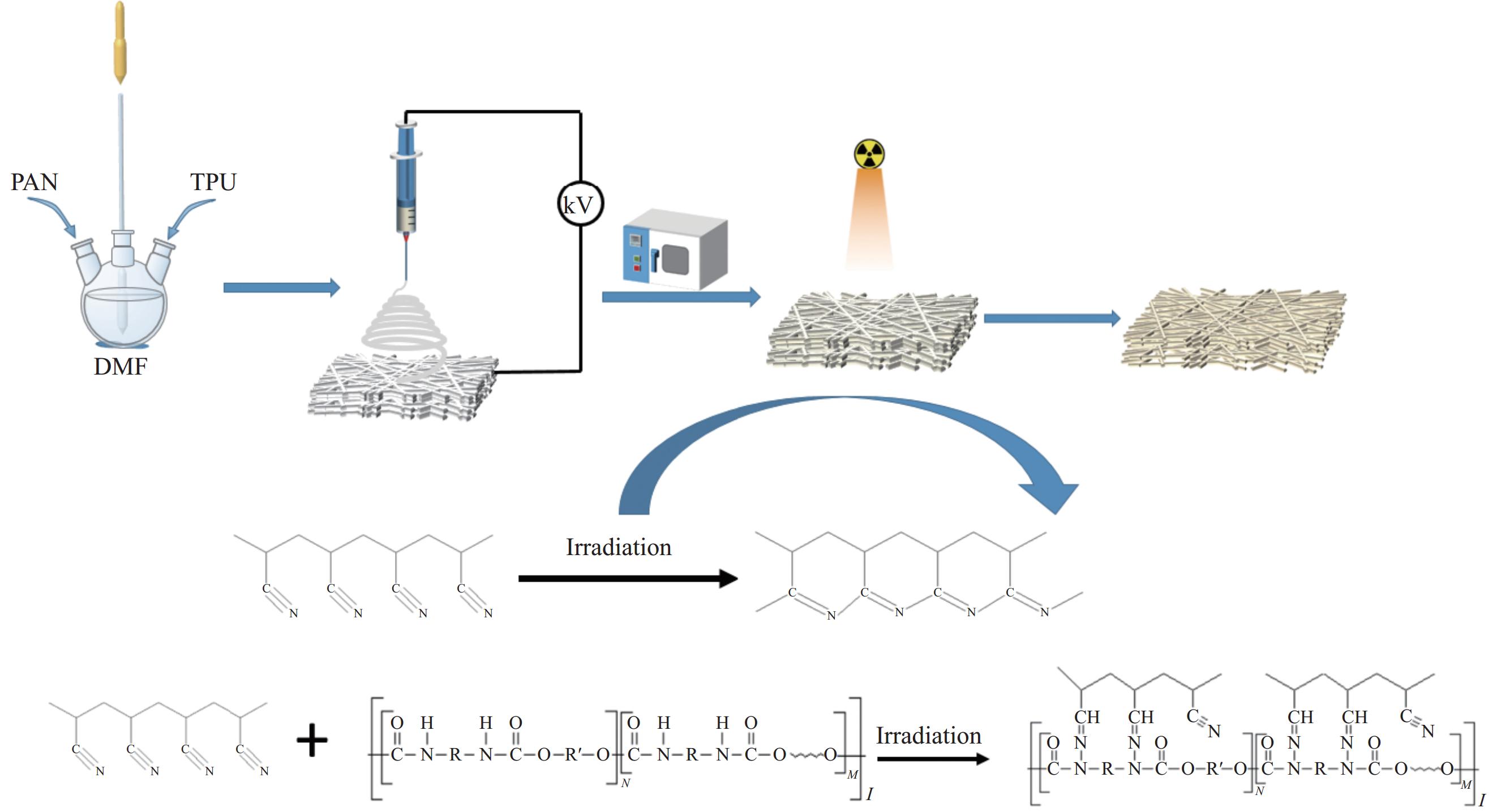

赵卫哲. γ射线辐照对聚丙烯腈纤维环化交联及碳纤维结构与性能的影响[D]. 上海: 东华大学, 2016.ZHAO Weizhe. The effects of gamma ray on cyclization and crosslinking of polyacrylontrile fibers and structure and properties of carbon fibers[D]. Shanghai: Donghua University, 2016(in Chinese).

|

| [7] |

ALVES P, COELHO J F J, HAACK J, et al. Surface modification and characterization of thermoplastic polyurethane[J]. European Polymer Journal, 2009, 45(5): 1412-1419.

|

| [8] |

PILLAI S D, PILLAI E T. Agriculture: Electron beam irradiation technology applications in the food industry[J]. Reference Module in Earth Systems and Environmental Sciences, 2021: 313-329.

|

| [9] |

GASTON F, DUPUY N, GIRARD-PERIER N, et al. Investigations at the product, macromolecular, and molecular level of the physical and chemical properties of a γ-irradiated multilayer EVA/EVOH/EVA film: Comprehensive analysis and mechanistic insights[J]. Polymers, 2021, 13(16): 2671.

|

| [10] |

CHAND P, JOSHI A, SINGH V. High performance of facile microwave-assisted BiPO4 nanostructures as electrode material for energy storage applications[J]. Materials Science in Semiconductor Processing, 2021, 122(1): 105472.

|

| [11] |

DA Z, RUO Z, HONG L. Application of microwave irradiation in extracting of gold, uranium and environmental protection [J]. Hydrometallurgy of China, 2002, 21(2): 62.

|

| [12] |

WU Z T, QIAO D L, ZHAO S M, et al. Nonthermal physical modification of starch: An overview of recent research into structure and property alterations[J]. International Journal of Biological Macromolecules, 2022, 203: 153-175.

|

| [13] |

KUMAR R, SAHOO S, JOANNI E, et al. A review on the current research on microwave processing techniques applied to graphene-based supercapacitor electrodes: An emerging approach beyond conventional heating[J]. Journal of Energy Chemistry, 2022, 74: 252-282.

|

| [14] |

WANG S S, HAN C Y, HAN L J, et al. Gamma radiation on poly(ε-caprolactone) in the presence of vinyltrimethoxysilane[J]. Polymer Engineering & Science, 2011, 51(2): 369-376.

|

| [15] |

SINGH A K, ADHIKARI R, SUSAN M A B H. Editorial: Modification of polymers with gamma radiation for various high-performance applications[J]. Frontiers in Chemistry, 2022, 10: 1042056.

|

| [16] |

徐翔宇. 电纺聚丙烯腈纳米纤维的辐照效应及对预氧化的影响[D]. 上海: 中国科学院研究生院(上海应用物理研究所), 2017.XU Xiangyu. Radiation effect of electrospun polyacrylonitrile nanofibers and the subsequent effect on stabilization process[D]. Shanghai: Graduate School of Chinese Academy of Sciences (Shanghai Institute of Applied Physics), 2017(in Chinese).

|

| [17] |

GAMZE KARSLI N, AYTAC A, AKBULUT M, et al. Effects of irradiated polypropylene compatibilizer on the properties of short carbon fiber reinforced polypropylene composites[J]. Radiation Physics & Chemistry, 2013, 84: 74-78.

|

| [18] |

钱群, 吴明红, 包伯荣. 丙烯酰胺在预辐照聚丙烯纤维上接枝反应的研究[J]. 辐射研究与辐射工艺学报, 2001, 19(4): 259-262.QIAN Qun, WU Hongming, BAO Borong. Study on grafting reaction of acrylamide onto pre-irradiated polypropylene fibers[J]. Journal of Radiation Research and Radiation Processing, 2001, 19(4): 259-262.

|

| [19] |

王鑫. 聚丙烯腈纳米纤维增强聚氨酯基复合膜的力学性能研究[D]. 杭州: 浙江理工大学, 2018.WANG XIN. Preparation and mechanical properties of polyacrylonitrile nanofiber reinforced thermoplastic polyurethane film [D]. Hangzhou: Zhejiang University of Technology, 2018(in Chinese).

|

| [20] |

张艳华, 黄玉东, 赵峰, 等. γ-射线辐照对聚丙烯腈纤维结构和强度的影响[J]. 化学与粘合, 2009, 31(1): 1-3, 27.ZHANG Yanhua, HUANG Yudong, ZHAO Feng, et al. Influence of γ-ray radiation on the structure and strength of PAN fibers[J]. Chemistry and Adhesion, 2009, 31(1): 1-3, 27(in Chinese).

|

| [21] |

SUI H L, LIU X Y, ZHONG F C, et al. Relationship between free volume and mechanical properties of polyurethane irradiated by Gamma rays[J]. Journal of Radioanalytical & Nuclear Chemistry, 2014, 300(2): 701-706.

|

| [22] |

JIA S J, HUANG K L, LONG J T, et al. Electron beam irradiation modified electrospun polyvinylidene fluoride/polyacrylonitrile fibrous separators for safe lithium-ion batteries[J]. Journal of Applied Polymer Science, 2021, 138(18): 50359.

|

| [23] |

ZOU M G, LUO Y M, MA X, et al. High-performance electrospun membrane for lithium-ion batteries[J]. Journal of Membrane Science, 2021, 637: 119597.

|

| [24] |

CHEN W Y, LIU Y B, MA Y, et al. Improved performance of PVDF-HFP/PI nanofiber membrane for lithium ion battery separator prepared by a bicomponent cross-electrospinning method[J]. Materials Letters, 2014, 133(10): 67-70.

|

| [25] |

TANG L P, WU Y K, HE D, et al. Electrospun PAN membranes toughened and strengthened by TPU/SHNT for high-performance lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2023, 931: 117181.

|

| [26] |

DENG J H, CAO D Q, YANG X Q, et al. Cross-linked cellulose/carboxylated polyimide nanofiber separator for lithium-ion battery application[J]. Chemical Engineering Journal, 2022, 433(3): 133934.

|

下载:

下载: