Establishment of fiber tow spreading model on mechanical rollers

-

摘要: 制备预浸带需要将纤维束铺展变宽以便于树脂浸润,而牵引张力是纤维束展宽的动力来源,当前纤维束的展宽模型少有涉及牵引张力的影响效果。针对纤维束在机械棍子上的牵引展宽过程,结合受力分析得出纤维束运动系统的输入功及沿轴向、横向上的摩擦消耗功,依据能量守恒原理建立纤维束展宽模型。利用实验室自行搭建的机械棍子预分散装置,对展宽模型进行对比验证与分析。结果表明:牵引张力是纤维束展宽的重要原因,机械辊子个数、半径、光滑程度及纤维束与辊子间的包角都会影响纤维束的展宽,相较于Wilson展宽模型,能量平衡展宽模型能够更好地预测纤维的展开宽度,可用于指导纤维束的预分散过程。Abstract: The preparation of prepreg tape required spreading the fiber tow to facilitate resin impregnation. Traction tension is the driving force for fiber bundle spreading, but current fiber tow-spreading models rarely involve the effect of traction tension. Aiming at the spreading process of fiber tow on mechanical rollers, combining force analysis, the input work, and the friction work along the axial and lateral directions can be computed. Then the fiber tow spreading model can be established by energy conservation law. Utilizing the pre-dispersion device with mechanical rollers which was built by laboratory, contrastively validate and analyze the spreading model. The results indicate that traction tension is an important reason for fiber tow spreading. And the numbers, radius, smoothness of mechanical rollers, and the wrap angle between the fiber tow and the roller all affect the fiber tow spreading. Compared to the Wilson spreading model, the energy-balance spreading model can better predict the spreading width of fiber tow, and it can be used to guide the pre-dispersion process of fiber tow.

-

Key words:

- fiber tow spreading /

- energy conservation /

- mechanical rollers /

- prepreg tape /

- pre-dispersion device

-

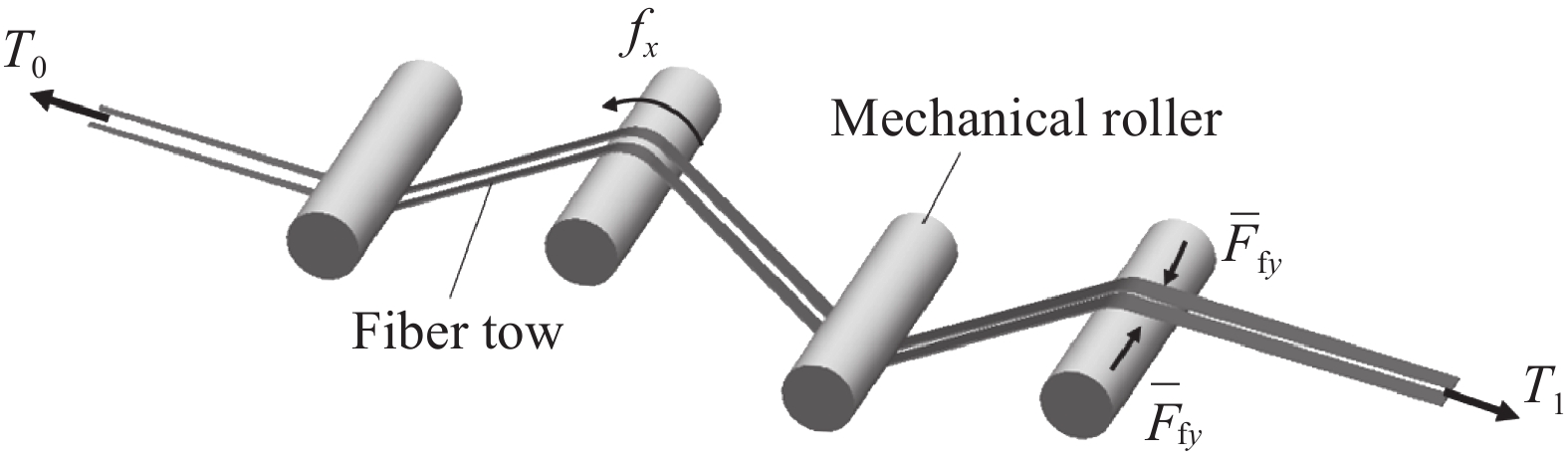

图 1 纤维束展宽过程示意图

Figure 1. Schematic diagram of fiber tow spreading process

$ {T}_{0} $—Unwinding tension of fiber tow; $ {T}_{1} $—Traction tension of fiber tow; $ f_{\mathrm{\mathit{x}}} $—Axial friction force of fiber tow; $ \overline{F}_{\mathrm{f}\mathrm{\mathit{y}}} $—Transverse friction force of fiber tow

图 6 辊子顶部纤维束的受力分析

Figure 6. Stress analysis of fiber bundle at the top of dispersion roller

$ {\alpha }_{\mathrm{f}} $—Angle between the fiber tows on both sides of the roller; $ \phi $—Wrap angle of the fiber tow on the roller; $ {N}_{\mathrm{f}} $—Number of fiber monofilament; $ T_{\mathrm{\mathrm{g}}} $—Force exerted on each fiber monofilament at the vertex of the roller

表 1 SE4849玻璃纤维展宽比例系数测试结果

Table 1. Test results of spreading scale coefficient of glass fiber SE4849

$ {T}_{0} $/N $ {w}_{1} $/mm $ {k}_{1} $ 8 13.8 4.7177 9 12.6 4.6826 10 11.6 4.5526 11 10.6 4.4310 12 9.5 4.4042 13 8.7 4.1135 Note: $ {k}_{1} $—Scale coefficient of spreading width. 表 2 HF30 F碳纤维展宽比例系数测试结果

Table 2. Test results of spreading scale coefficient of carbon fiber HF30 F

$ {T}_{0} $/N $ {w}_{1} $/mm $ {k}_{2} $ 8 12.3 8.5298 9 11.5 8.4465 10 10.8 8.2479 11 9.6 9.1960 12 9.0 8.9906 13 8.5 8.4642 -

[1] ALTIN KARATAŞ M, GÖKKAYA H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials[J]. Defence Technology, 2018, 14(4): 318-326 doi: 10.1016/j.dt.2018.02.001 [2] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review[J]. Advanced Composites and Hybrid Materials, 2019, 2(2): 214-233. doi: 10.1007/s42114-018-0072-z [3] 胡侨乐, 端玉芳, 刘志, 等. 碳纤维增强聚合物基复合材料回收再利用现状[J]. 复合材料学报, 2022, 39(1): 64-76. doi: 10.13801/j.cnki.fhclxb.20210615.003HU Qiaole, DUAN Yufang, LIU Zhi, et al. Current status of carbon fiber reinforced polymer composites recycling and re-manufacturing[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 64-76(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210615.003 [4] SHIRVANIMOGHADDAM K, HAMIM S U, KARBALAEI AKBARI M, et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties[J]. Composites Part A: Applied Science and Manufacturing, 2017, 92: 70-96. doi: 10.1016/j.compositesa.2016.10.032 [5] LIU X, YAN B R, REN F, et al. Isothermal crystallisation ATP process for thermoplastic composites with semi-crystalline matrices using automated tape placement machine[J]. Composites Part B: Engineering, 2021, 227: 109381. doi: 10.1016/j.compositesb.2021.109381 [6] 罗云烽, 孙永春, 段跃新, 等. 薄层化大丝束碳纤维复合材料性能研究[J]. 航空制造技术, 2010, 53(20): 75-78. doi: 10.3969/j.issn.1671-833X.2010.20.015LUO Yunfeng, SUN Yongchun, DUAN Yuexin, et al. Study on property of spreaded large tow carbon fiber composites[J]. Aeronautical Manufacturing Technology, 2010, 53(20): 75-78(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.20.015 [7] 袁满, 何亚东, 李锐, 等. 连续纤维增强热塑性复合材料熔融浸渍模型[J]. 塑料科技, 2019, 47(7): 12-17. doi: 10.15925/j.cnki.issn1005-3360.2019.07.003YUAN Man, HE Yadong, LI Rui, et al. Melt impregnation model of continuous fiber reinforced thermoplastic composites[J]. Plastics Science and Technology, 2019, 47(7): 12-17(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2019.07.003 [8] 李杰, 徐然, 任峰, 等. 连续玻纤增强聚丙烯预浸带熔融浸渍过程纤维断裂研究[J]. 中国塑料, 2022, 36(6): 69-76.LI Jie, XU Ran, REN Feng, et al. Fiber fracture of continuous glass fiber-reinforced polypropylene prepreg tapes during melt impregnation[J]. China Plastics, 2022, 36(6): 69-76(in Chinese). [9] 王勇, 于伟东, 王府梅. 在线展丝环锭复合纺纱技术及设备[J]. 纺织学报, 2016, 37(12): 160-166. doi: 10.13475/j.fzxb.20151200507WANG Yong, YU Weidong, WANG Fumei. Composite spinning technology and equipment based on multifilament online-spreading method using ring spinning system[J]. Journal of Textile Research, 2016, 37(12): 160-166(in Chinese). doi: 10.13475/j.fzxb.20151200507 [10] EL-DESSOUKY H M, LAWRENCE C A. Ultra-lightweight carbon fibre/thermoplastic composite material using spread tow technology[J]. Composites Part B: Engineering, 2013, 50: 91-97. doi: 10.1016/j.compositesb.2013.01.026 [11] SIHN S, KIM R Y, KAWABE K, et al. Experimental studies of thin-ply laminated composites[J]. Composites Science and Technology, 2007, 67(6): 996-1008. doi: 10.1016/j.compscitech.2006.06.008 [12] 马丕波, 蒋高明, 高哲, 等. 一种碳纤维的超声波展纤方法: 中国, ZL 201310187189.5[P]. 2023-09-03.MA Pibo, JIANG Gaoming, GAO Zhe, et al. A method of ultrasonic fiber expansion for carbon fibers: Chinese patent, ZL 201310187189.5[P]. 2023-09-03(in Chinese). [13] 陈金良. 大丝束碳纤维展纤机理及实验研究 [D]. 天津: 天津工业大学, 2020.CHEN Jinliang. Mechanism and experimental study on fiber spreading of large bundle carbon fibers[D]. Tianjin: Tianjin Polytechnic University, 2020(in Chinese). [14] 郝傲松. 碳纤维展纤纱及展纤织物复合材料制备与性能研究 [D]. 上海: 东华大学, 2018.HAO Aosong. Study on preparation and properties of spread tow and spread tow fbric composites[D]. Shanghai: Donghua University, 2018(in Chinese). [15] ZHOU Q H, WU G Z, WANG Z X, et al. Analysis and prediction of the width of spreading carbon fiber tow based on gray system theory[J]. Journal of Applied Polymer Science, 2021, 138(12): e50069. [16] WILSON S D R. Lateral spreading of fibre tows[J]. Journal of Engineering Mathematics, 1997, 32(1): 19-26. doi: 10.1023/A:1004253531061 [17] WEUSTINK A P D. Development of a rapid thermoplastic impregnation device[M]. Delft: Technische Universiteit Delft, 2007: 55-58. [18] IRFAN M S, MACHAVARAM V R, MAHENDRAN R S, et al. Lateral spreading of a fiber bundle via mechanical means[J]. Journal of Composite Materials, 2012, 46(3): 311-330. [19] 冯一川, 傅增祥, 曹兵妥, 等. 纤维束展开宽度的理论计算[J]. 科学技术与工程, 2012, 12(7): 1489-1491, 507. doi: 10.3969/j.issn.1671-1815.2012.07.005FENG Yichuan, FU Zengxiang, CAO Bingtuo, et al. Theoretical calculation of fibre bundle spreading width[J]. Science Technology and Engineering, 2012, 12(7): 1489-1491, 507(in Chinese). doi: 10.3969/j.issn.1671-1815.2012.07.005 [20] 陈剑昭. 连续纤维增强聚丙烯预浸带设备与工艺研究 [D]. 北京: 北京化工大学, 2021.CHEN Jianzhao. Research on equipment and process of continuous glass fiber reinforced polypropylene prepreg tape[D]. Beijing: Beijing University of Chemical Technology, 2021(in Chinese). [21] 王伟民. 绳绕圆柱体的摩擦力分析[J]. 物理教师, 2014, 35(10): 65-66. doi: 10.3969/j.issn.1002-042X.2014.10.030WANG Weimin. Analysis of friction force of rope wrapped cylinder[J]. Physics Teacher, 2014, 35(10): 65-66(in Chinese). doi: 10.3969/j.issn.1002-042X.2014.10.030 [22] VENKATARAMAN M, MILITKÝ J, SAMKOVÁ A, et al. Hybrid prepreg tapes for composite manufacturing: A case study[J]. Materials, 2022, 15(2): 619. [23] VENKATARAMAN M, MILITKÝ J, SAMKOVÁ A, et al. Hybrid prepreg tapes for composite manufacturing: A case study[J]. Materials, 2022, 15: 619. [24] 李元帅, 贺磊, 薛德波, 等. 干式碳纤维编织套管磨损特性试验研究[J]. 现代制造工程, 2023(4): 81-86.LI Yuanshuai, HE Lei, XUE Debo, et al. Experimental investigation on wear characteristics of dry carbon fibre braided sleeves[J]. Modern Manufacturing Engineering, 2023(4): 81-86(in Chinese). [25] XUE D B, HE L, CHENG X, et al. Study on wear characteristics of carbon fiber at needle end in prefabricated composite weaving[J]. Journal of Materials Research and Technology, 2021, 13: 1045-1055. doi: 10.1016/j.jmrt.2021.05.023 [26] PETERS S T. Composite filament winding [M]. Ohio: ASM International, 2011: 65-80. [27] 李潭, 顾轶卓, 王绍凯, 等. 碳纤维丝束起毛量测试方法[J]. 材料工程, 2017, 45(7): 84-90. doi: 10.11868/j.issn.1001-4381.2015.001362LI Tan, GU Yizhuo, WANG Shaokai, et al. Measuring method for fuzz mass of carbon fiber tow[J]. Journal of Materials Engineering, 2017, 45(7): 84-90(in Chinese). doi: 10.11868/j.issn.1001-4381.2015.001362 -

下载:

下载: