Curing behavior of epoxy resin with acetal structure and preparation and properties ofits carbon fiber composites

-

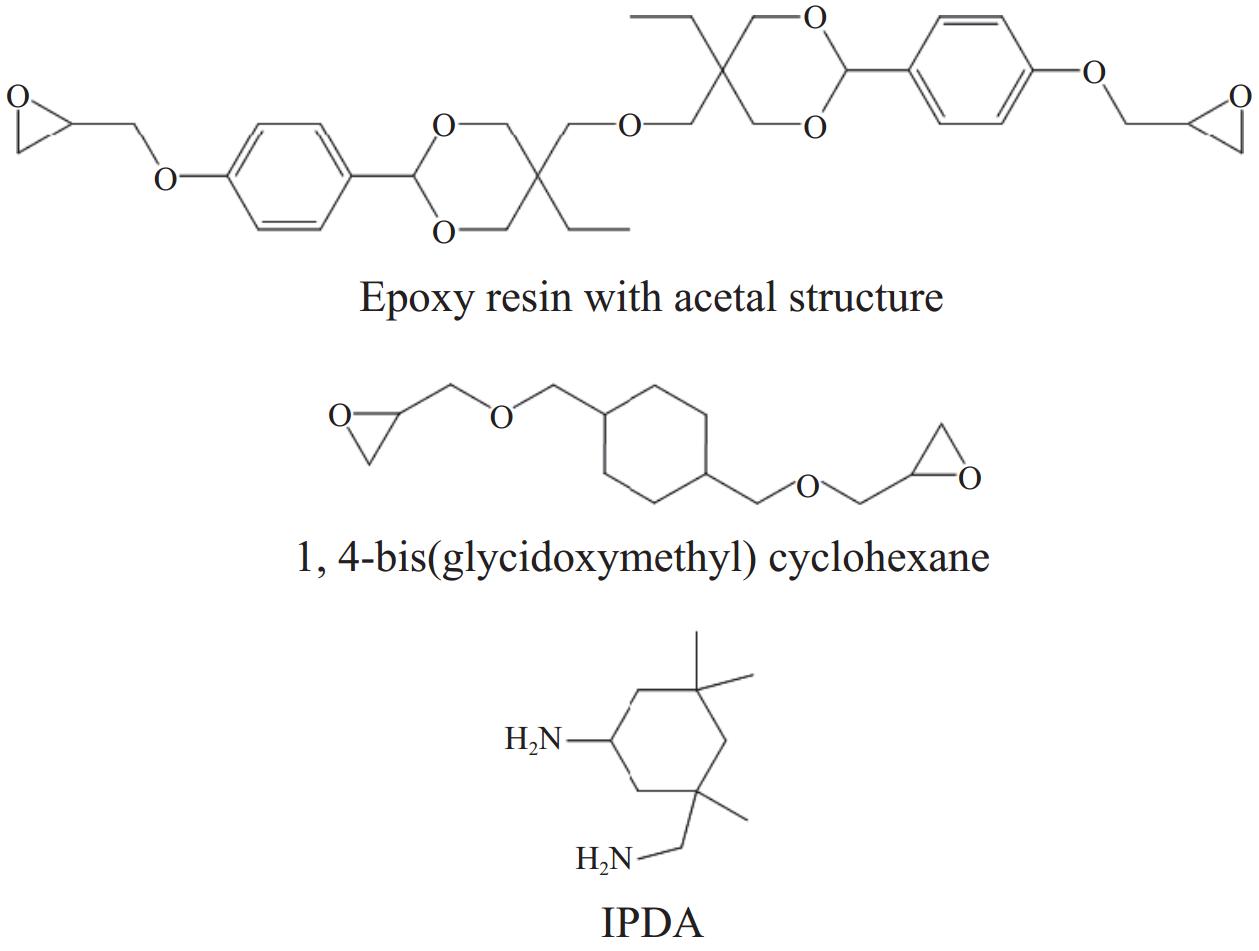

摘要: 针对含缩醛结构生物基环氧树脂体系的工艺性能开展研究,采用旋转流变仪和非等温DSC对缩醛环氧树脂体系的流变性能和固化行为进行了分析,确定了其注胶温度约为40℃。采用自催化模型结合n级模型的分段模型获得其固化动力学参数,分段模型拟合得到的曲线与实验曲线吻合较好,表明该模型在2.5~20 K/min的升温速率下能较好地描述含缩醛结构环氧树脂体系的固化反应过程。通过外推法确定了树脂体系的优化固化工艺条件,制备出的含缩醛结构环氧树脂的拉伸强度和弯曲强度分别为79 MPa和130 MPa。进一步研究了碳纤维与环氧树脂之间的界面粘结性能和力学性能,发现碳纤维/缩醛环氧树脂复合材料的界面剪切强度和力学性能与碳纤维/商用环氧树脂复合材料的基本相当,表明可降解的缩醛环氧树脂可以替代商用环氧树脂,具有广泛的应用前景。另外,碳纤维/缩醛环氧树脂复合材料具有较好的降解性能,回收碳纤维的单丝拉伸强度与原始碳纤维的相当,可以有效回收高质量的碳纤维。Abstract: To investigate the forming process of bio-based epoxy resin system with acetal structure, the rheological properties and curing behavior of the epoxy resin system with acetal structure were studied by rotating rheometer and non-isothermal DSC. The glue injecting temperature is determined to be about 40℃. The curing kinetic parameters were obtained by the piecewise model combining the autocatalytic model and the n-order model. The fitting curves from the piecewise model are in good agreement with the experimental curves, indicating that the model can accurately describe the curing reaction process of epoxy resin system with acetal structure at the heating rates of 2.5-20 K/min. The curing procedure of the resin system was determined by an extrapolation method. The tensile strength and bending strength of the epoxy resin with acetal structure are 79 MPa and 130 MPa, respectively. It is found that the interfacial shear strength (IFSS) and interlaminar shear strength (ILSS) of carbon fiber/acetal epoxy resin composites are similar to those of carbon fiber/commercial epoxy resin composites, indicating that the interfacial bonding property between acetal epoxy resin and carbon fiber is similar to that of commercial epoxy resin. In addition, the tensile and flexural properties of the two composites are similar, indicating that the degradable acetal epoxy resin may replace the commercial epoxy resin and give potential competitive advantages over the applications. In addition, the carbon fiber/acetal epoxy resin composites have good degradation performance, and the single fiber tensile strength of the recovered carbon fiber is comparable to that of the original carbon fiber, indicating that high-quality carbon fiber can be effectively recycled.

-

Key words:

- epoxy resin /

- rheological properties /

- curing kinetics /

- curing model /

- carbon fiber composites /

- mechanical properties

-

表 1 由DSC分析得到的αp、αM和$\alpha_{\mathrm{p}}^{\infty} $值

Table 1. Values of αp, αM and $\alpha_{\mathrm{p}}^{\infty} $ obtained by DSC

Heating rate/(K·min−1) αp αM $\alpha_{\mathrm{p}}^{\infty} $ 2.5 0.43 0.036 0.92 5 0.46 0.041 0.92 10 0.47 0.042 0.93 15 0.49 0.031 0.92 20 0.51 0.047 0.89 Notes: αp―Curing degree at the maximum values of heat flow; αM―Curing degree at the maximum values of y(α); $\alpha_{\mathrm{p}}^{\infty} $―Curing degree at the maximum values of z(α). 表 2 缩醛环氧树脂体系自催化模型固化动力学参数

Table 2. Curing kinetic parameters of autocatalytic model of acetal epoxy resin system

Heating rate/(K·min−1) Ea/(kJ·mol−1) lnA m n 2.5 66.19 16.31 0.049 1.33 5 16.34 0.057 1.34 10 16.30 0.059 1.36 15 16.26 0.044 1.36 20 16.19 0.064 1.28 Notes: Ea―Activation energy; A―Pre-exponential factor; m, n―Reaction orders. 表 3 缩醛环氧树脂体系分段模型固化动力学参数

Table 3. Curing kinetic parameters for piecewise model of acetal epoxy resin system

Heating rate/(K·min−1) Ea/(kJ·mol−1) Autocatalytic model

(α<0.825)n-order model (α≥0.825) Correlation index R2 lnA m n lnA n 2.5 66.19 16.63 0.071 1.83 15.71 1.26 0.9925 5 16.62 0.071 1.83 15.95 1.42 0.9976 10 16.53 0.066 1.70 15.89 1.33 0.9995 15 16.48 0.087 1.65 15.91 1.34 0.9992 20 16.35 0.061 1.58 15.96 1.37 0.9997 表 4 环氧树脂(EP)的力学性能

Table 4. Mechanical properties of epoxy resins (EP)

Sample Tensile

strength/

MPaTensile

modulus/

GPaFlexural

strength/

MPaFlexural

modulus/

GPaAcetal EP 79 2.5 130 2.8 Commercial EP 76 2.2 115 2.4 -

[1] ZHANG J, LIN G, VAIDYA U, et al. Past, present and future prospective of global carbon fibre composite developments and applications[J]. Composites Part B: Engineering, 2023, 250: 110463. doi: 10.1016/j.compositesb.2022.110463 [2] 张洋, 张隽爽, 马崇攀, 等. 碳纤维增强含酯键环氧树脂基复合材料的化学降解与回收[J]. 复合材料学报, 2023, 40(9): 5026-5034.ZHANG Yang, ZHANG Junshuang, MA Chongpan, et al. Chemical degradation and recovery of carbon fiber reinforced epoxy resin matrix composites containing ester bond[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5026-5034(in Chinese). [3] LIU Y L, WANG B B, MA S Q, et al. Catalyst-free malleable, degradable, bio-based epoxy thermosets and its application in recyclable carbon fiber composites[J]. Composites Part B: Engineering, 2021, 211: 108654. doi: 10.1016/j.compositesb.2021.108654 [4] LI J H, WENG Z H, CAO Q, et al. Synthesis of an aromatic amine derived from biomass and its use as a feedstock for versatile epoxy thermoset[J]. Chemical Engineering Journal, 2022, 433: 134512. [5] LI P Y, MA S Q, WANG B B, et al. Degradable benzyl cyclic acetal epoxy monomers with low viscosity: Synthesis, structure-property relationships, application in recyclable carbon fiber composite[J]. Composites Science and Technology, 2022, 219: 109243. doi: 10.1016/j.compscitech.2021.109243 [6] TRATNIK N, TANGUY N R, YAN N. Recyclable, self-strengthening starch-based epoxy vitrimer facilitated by exchangeable disulfide bonds[J]. Chemical Engineering Journal, 2023, 451: 138610. [7] PATIL A S, MOHEIMANI R, DALIR H. Thermomechanical analysis of composite plates curing process using ANSYS composite cure simulation[J]. Thermal Science and Engineering Progress, 2019, 14: 100419. doi: 10.1016/j.tsep.2019.100419 [8] 杨旭静, 张良胜, 李茂君, 等. 超声振动对快速固化环氧树脂体系固化动力学特性的影响[J]. 复合材料学报, 2022, 39(5): 2470-2481.YANG Xujing, ZHANG Liangsheng, LI Maojun, et al. Influence of ultrasonic vibration on curing kinetics of rapid curing epoxy resin system[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2470-2481(in Chinese). [9] MA Z H, WANG X, LI J R, et al. Isoconversional models toward the curing kinetics of self-healable epoxy resin TGDDM and acid anhydride[J]. Journal of Applied Polymer Science, 2022, 139(31): e52718. doi: 10.1002/app.52718 [10] 韦君, 颜春, 祝颖丹, 等. 生物基可降解环氧树脂体系固化反应动力学研究[J]. 热固性树脂, 2021, 36(5): 25-30. doi: 10.13650/j.cnki.rgxsz.2021.05.005WEI Jun, YAN Chun, ZHU Yingdan, et al. Curing kinetics of bio-based degradable epoxy resin system[J]. Thermosetting Resin, 2021, 36(5): 25-30(in Chinese). doi: 10.13650/j.cnki.rgxsz.2021.05.005 [11] 张雨晴, 张锋锋, 王锦艳, 等. 非等温DSC法研究TSPZ-EP环氧树脂的固化动力学[J]. 高分子材料科学与工程, 2021, 37(11): 77-85. doi: 10.16865/j.cnki.1000-7555.2021.0274ZHANG Yuqing, ZHANG Fengfeng, WANG Jinyan, et al. Curing kinetics of TSPZ-EP epoxy resin characterized by non-isothermal DSC[J]. Polymer Materials Science and Engineering, 2021, 37(11): 77-85(in Chinese). doi: 10.16865/j.cnki.1000-7555.2021.0274 [12] MA Z L, QI L, HE W, et al. A novel approach on the study of cure kinetics for rheological isothermal and non-isothermal methods[J]. Composites Part B: Engineering, 2019, 162: 242-249. [13] MOHAJERI S, VAFAYAN M, GHANBARALIZADEH R, et al. Advanced isoconversional cure kinetic analysis of epoxy/poly(furfuryl alcohol) bio-resin system[J]. Journal of Applied Polymer Science, 2017, 134(42): 45432. doi: 10.1002/app.45432 [14] CHEN Y H, XI Z H, ZHAO L. Curing kinetics of bio-based epoxy resin based on epoxidized soybean oil and green curing agent[J]. AIChE Journal, 2017, 63(1): 147-153. doi: 10.1002/aic.15486 [15] FACHE M, BOUTEVIN B, CAILLOL S. Epoxy thermosets from model mixtures of the lignin-to-vanillin process[J]. Green Chemistry, 2016, 18(3): 712-725. doi: 10.1039/C5GC01070E [16] ASTM. Standard test method for tensile properties of plastics: ASTM D638[S]. West Conshohocken: ASTM International, 2014. [17] ASTM. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: ASTM D790[S]. West Conshohocken: ASTM International, 2017. [18] ASTM. Standard test method for tensile properties of polymer matrix composites: ASTM D3039[S]. West Conshohocken: ASTM International, 2014. [19] ASTM. Standard test method for flexural properties of polymer matrix composite materials: ASTM D7264[S]. West Conshohocken: ASTM International, 2015. [20] ASTM. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344[S]. West Conshohocken: ASTM International, 2016. [21] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 碳纤维单丝拉伸性能的测定: GB/T 31290—2014[S]. 北京: 中国标准出版社, 2014.General Administration of Quality Supervision Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Carbon fibre—Determination of the tensile properties of single-filament specimens: GB/T 31290—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [22] MÁLEK J. Kinetic analysis of crystallization processes in amorphous materials[J]. Thermochimica Acta, 2000, 355(1-2): 239-253. [23] 陈刚, 徐海兵, 刘东, 等. 快速RTM成型工艺用环氧树脂化学流变及固化行为研究[J]. 高科技纤维与应用, 2016, 41(1): 45-50. doi: 10.3969/j.issn.1007-9815.2016.01.008CHEN Gang, XU Haibing, LIU Dong, et al. Studies on the chemical rheological behavior and curing of epoxy resin in rapid RTM process[J]. Hi-Tech Fiber and Application, 2016, 41(1): 45-50(in Chinese). doi: 10.3969/j.issn.1007-9815.2016.01.008 [24] MÁLEK J. The kinetic analysis of non-isothermal data[J]. Thermochimica Acta, 1992, 200: 257-269. doi: 10.1016/0040-6031(92)85118-F [25] SENUM G I, YANG R T. Rational approximations of the integral of the Arrhenius function[J]. Journal of Thermal Analysis, 1977, 11(3): 445-447. doi: 10.1007/BF01903696 [26] ZHANG Y C, FANG R, XUE H Y, et al. Investigation of DSC curing kinetic model fitting and rheological behavior of urushiol/IPDI system[J]. Thermochimica Acta, 2022, 711: 179210. doi: 10.1016/j.tca.2022.179210 [27] JIA H L, ZHU Y D, YAN C, et al. Reliability evaluation of a new method developed for DSC curing kinetic model of epoxy resin[J]. Journal of Applied Polymer Science, 2023, 140(26): e53986. doi: 10.1002/app.53986 [28] PASTARNOKIENĖ L, JONIKAITĖ-ŠVĖGŽDIENĖ J, LAPINSKAITĖ N, et al. The effect of reactive diluents on curing of epoxy resins and properties of the cured epoxy coatings[J]. Journal of Coatings Technology and Research, 2023, 20(4): 1207-1221. [29] 姚红伟, 钟盛根, 李显华, 等. CNTs强化碳纤维/环氧复合材料界面过渡层及其对界面性能的影响[J]. 材料工程, 2016, 44(12): 13-21. doi: 10.11868/j.issn.1001-4381.2016.12.003YAO Hongwei, ZHONG Shenggen, LI Xianhua, et al. Strengthening interface transition layer of carbon fiber/epoxy composites with CNTs and its effect on interfacial performance[J]. Journal of Materials Engineering, 2016, 44(12): 13-21(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.12.003 [30] YUAN W C, MA S Q, WANG S, et al. Synthesis of fully bio-based diepoxy monomer with dicyclo diacetal for high-performance, readily degradable thermosets[J]. European Polymer Journal, 2019, 117: 200-207. doi: 10.1016/j.eurpolymj.2019.05.028 [31] 张策, 徐志伟, 郭兴峰. 基于微波等离子体方法生长的纳米碳对碳纤维/环氧树脂复合材料界面性能的影响[J]. 复合材料学报, 2018, 35(11): 2994-3000. doi: 10.13801/j.cnki.fhclxb.20180409.003ZHANG Ce, XU Zhiwei, GUO Xingfeng. Effect of nanocarbon on interfacial properties of carbon fiber/epoxy composites based on microwave plasma enhanced chemical vapor deposition[J]. Acta Materiae Compositae Sinica, 2018, 35(11): 2994-3000(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180409.003 [32] 闫民杰, 刘梁森, 陈莉, 等. 基于碳纳米管界面改性的碳纤维复合材料抗γ辐射性能研究[J]. 材料导报, 2019, 33(24): 4174-4180. doi: 10.11896/cldb.18120140YAN Minjie, LIU Liangsen, CHEN Li, et al. Anti-gamma radiation properties of carbon fiber composites modified by carbon nanotubes in interface[J]. Materials Reports, 2019, 33(24): 4174-4180(in Chinese). doi: 10.11896/cldb.18120140 [33] MA S Q, WEI J J, JIA Z, et al. Readily recyclable, high-performance thermosetting materials based on a lignin-derived spiro diacetal trigger[J]. Journal of Materials Chemistry A, 2019, 7(3): 1233-1243. doi: 10.1039/C8TA07140C [34] YAN C, WEI J, ZHU Y D, et al. Preparation and properties of carbon fiber reinforced bio-based degradable acetal-linkage-containing epoxy resin composites by RTM process[J]. Polymer Composites, 2023, 44(7):4081-4094. [35] 冯浩洋, 胡靖媛, 陈青, 等. 生物基胺固化的可降解、可再加工环氧树脂的合成及性能[J]. 精细化工, 2022, 39(12): 2577-2584.FENG Haoyang, HU Jingyuan, CHEN Qing, et al. Synthesis and properties of degradable and recycled bio-based amine cured epoxy resin[J]. Fine Chemicals, 2022, 39(12): 2577-2584(in Chinese). -

下载:

下载: