Construction of highly hydrophobic nanocellulose-chitosan/bentonite aerogel and its application of efficient oil-water separation

-

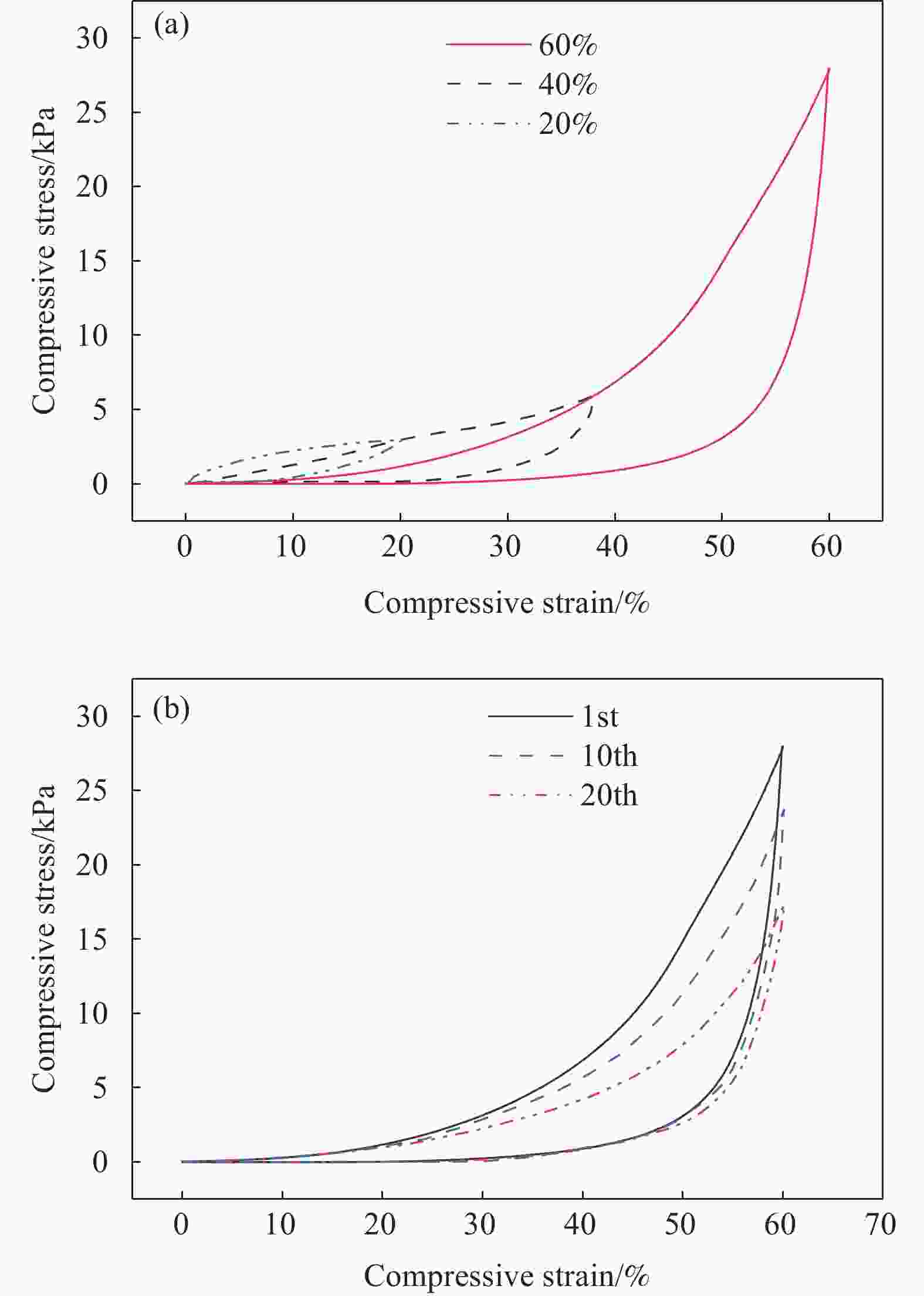

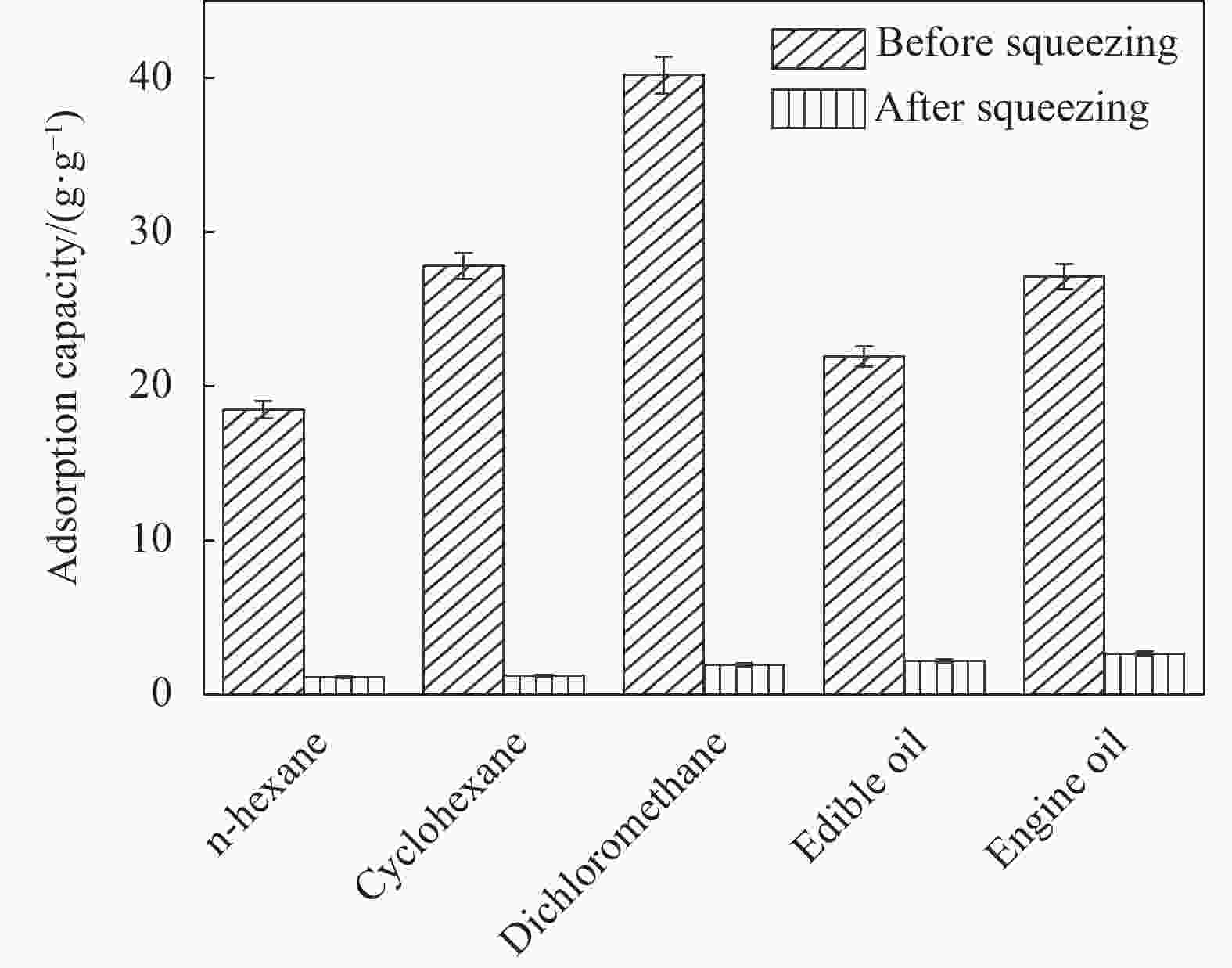

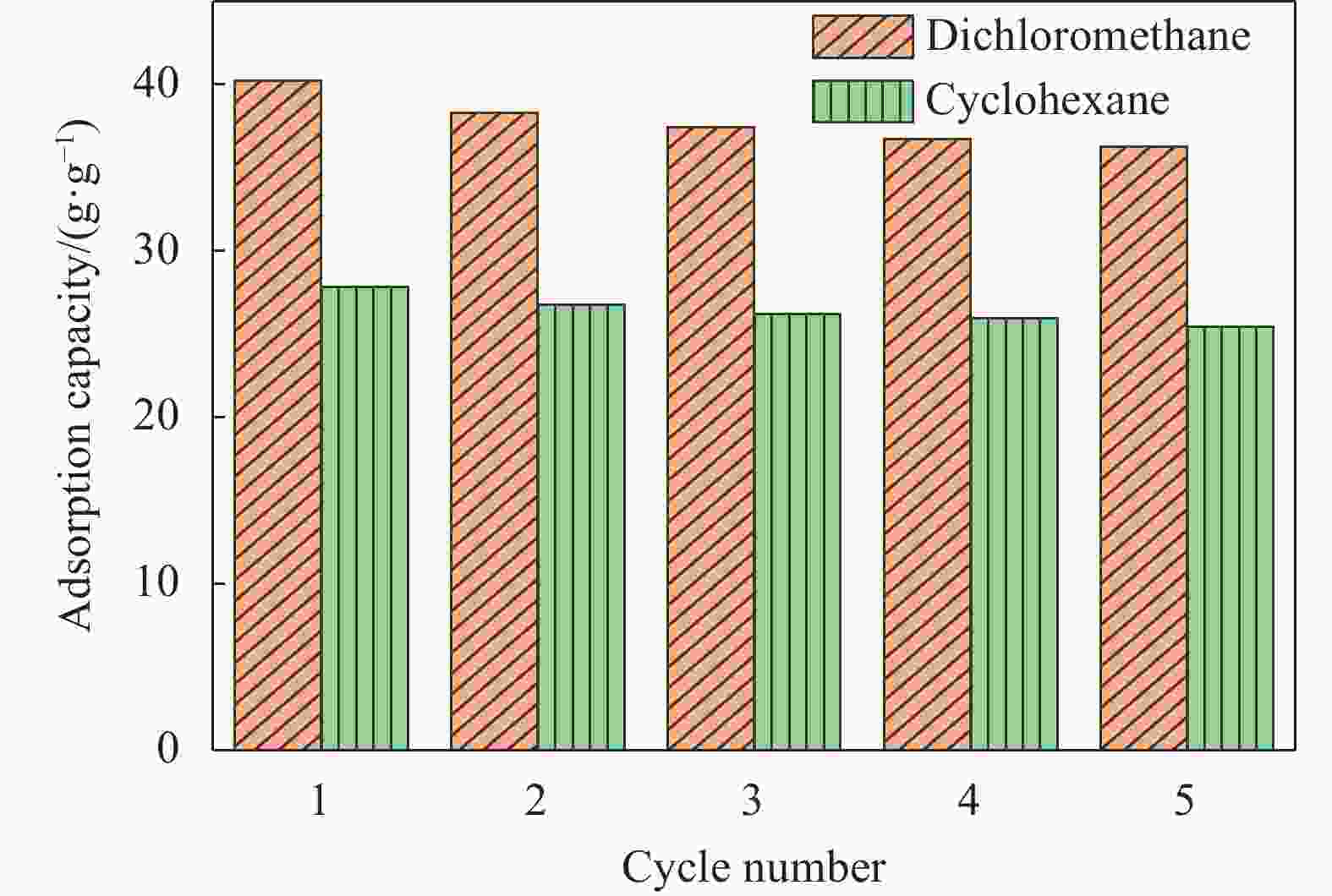

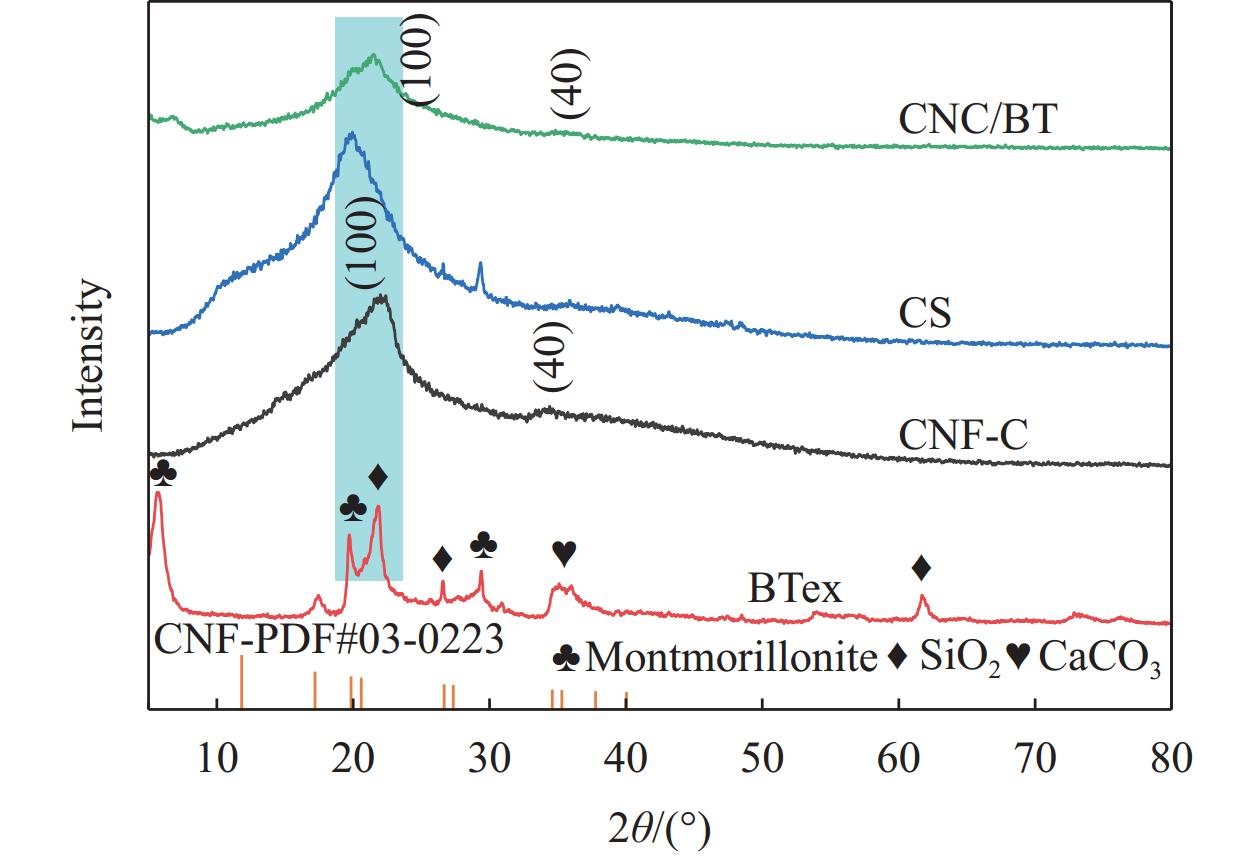

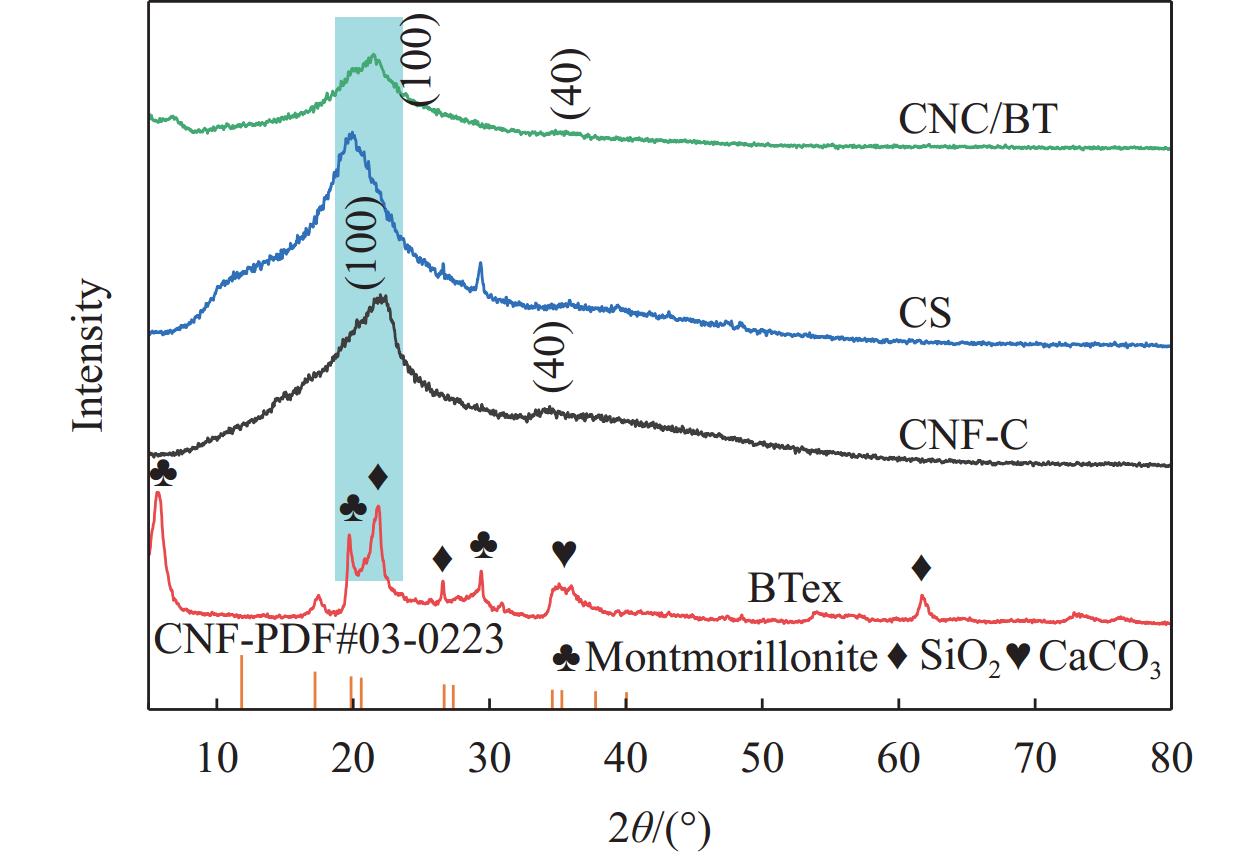

摘要: 气凝胶具有高孔隙率和高吸附性的特点,因此在含油废水处理领域是一种具有前景的候选材料。目前,所报道的气凝胶仍存在机械强度不足、制作工艺复杂、制备成本高等问题,限制了气凝胶在油水分离领域的应用。膨润土(Bentonite,BT)具有价格低、来源丰富、机械性能优良等特点,能够有效地改善气凝胶的机械性能。本文通过简单的冷冻干燥-常温浸渍法,在羧基纤维素纳米纤维(Carboxycellulose nanofibres,CNF-C)与壳聚糖(Chitosan,CS)的交联网络上引入剥离膨润土(Exfoliated bentonite,BTex),合成了疏水的纳米纤维素-壳聚糖/剥离膨润土气凝胶(CNC/BTex)。制备出的CNC/BTex气凝胶表现出优异的疏水性能(水接触角高达133°);经过挤压后在5 s内可恢复形变,具有良好的力学性能;对不同油品(正己烷、环己烷、二氯甲烷、食用油和发动机油)的吸附容量为18.48~40.20 g·g−1不等。以二氯甲烷和环己烷为主要研究对象,经过5次循环使用后依然保持稳定的吸油性能(维持在原始吸附量的90%)。本文的工作为制备低成本、高性能的油水分离吸附材料提供了参考。Abstract: Due to the high porosity and high absorption characteristics, aerogel has been a promising candidate material in the field of oily wastewater treatment. However, the reported aerogels were still suffering from insufficient mechanical strength, complicated fabrication process and high preparation cost, which limited the application of aerogels in the field of oil-water separation. Bentonite (BT) has the characteristics of low price, abundant source and excellent mechanical properties, which can effectively improve the mechanical properties of aerogels. In this paper, hydrophobic nanocellulose-chitosan/exfoliated bentonite aerogels (CNC/BTex) were synthesized by introducing exfoliated bentonite (BTex) onto a cross-linked network of carboxycellulose nanofibres (CNF-C) and chitosan (CS) by a simple freeze-drying and ambient temperature impregnation method. The prepared CNC/BTex aerogel exhibited excellent hydrophobic properties (water contact angle 133°), recovered deformation within 5 s after extrusion and showed good mechanical properties. The adsorption capacities for different oils (hexane, cyclohexane, dichloromethane, cooking oil and engine oil) ranged from 18.48-40.20 g·g−1. Using dichloromethane and cyclohexane as the main research objects, the oil adsorption performance remained stable (90% of the original adsorption capacity) after five cycles of use. In summary, the present work provides a reference for the preparation of low-cost and high-performance adsorbent materials for oil-water separation.

-

Key words:

- oil-water separation /

- aerogel /

- cellulose /

- chitosan /

- exfoliated bentonite

-

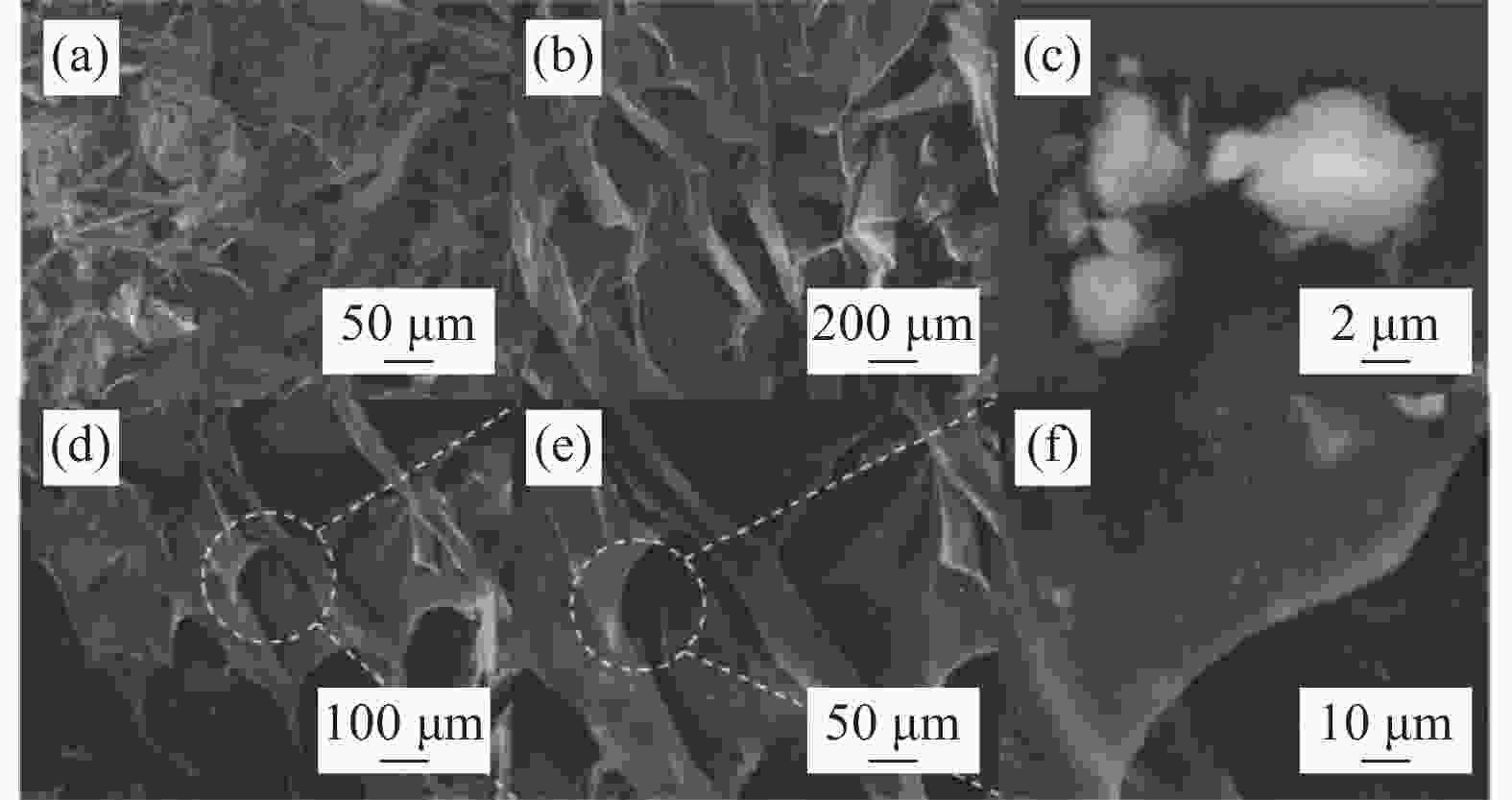

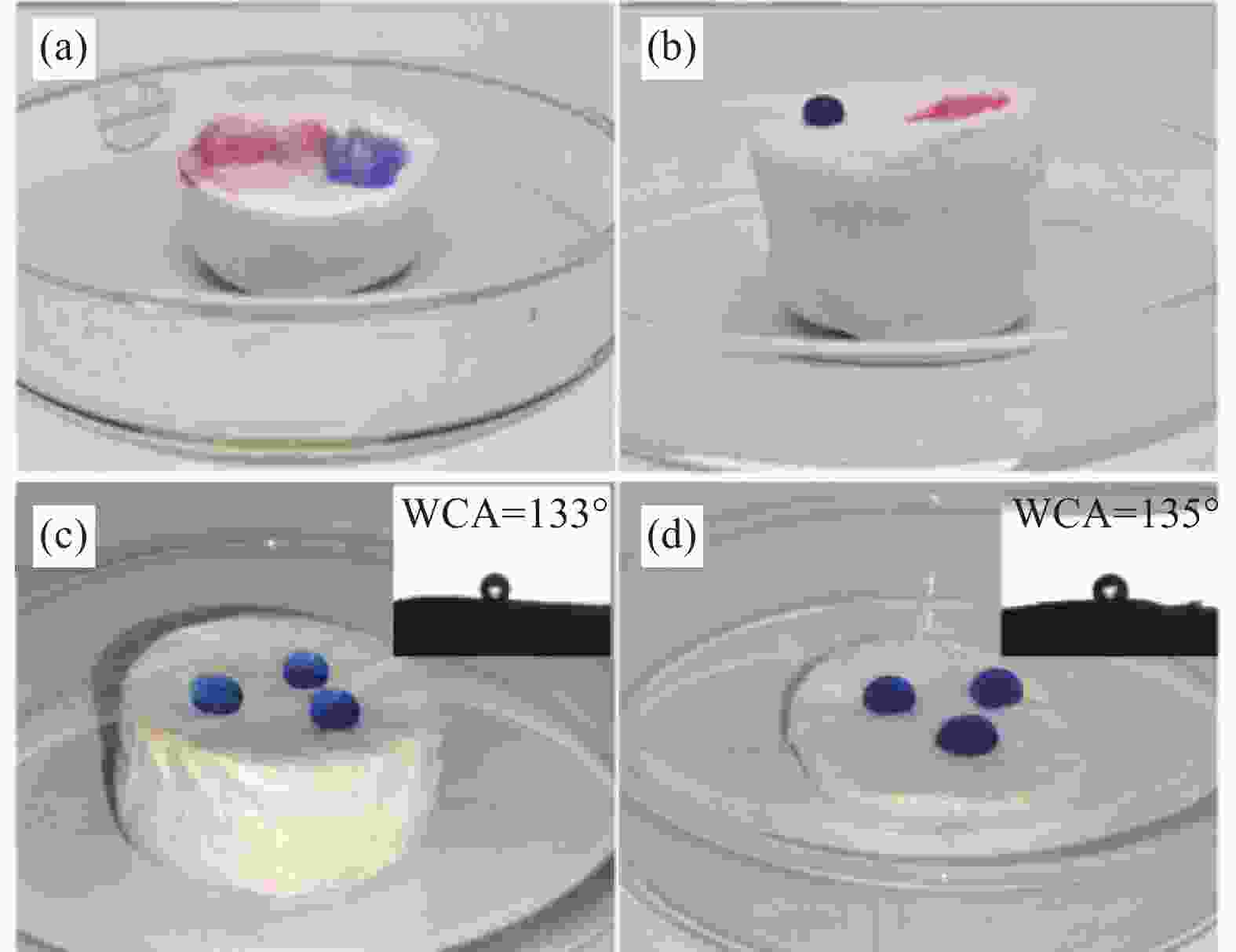

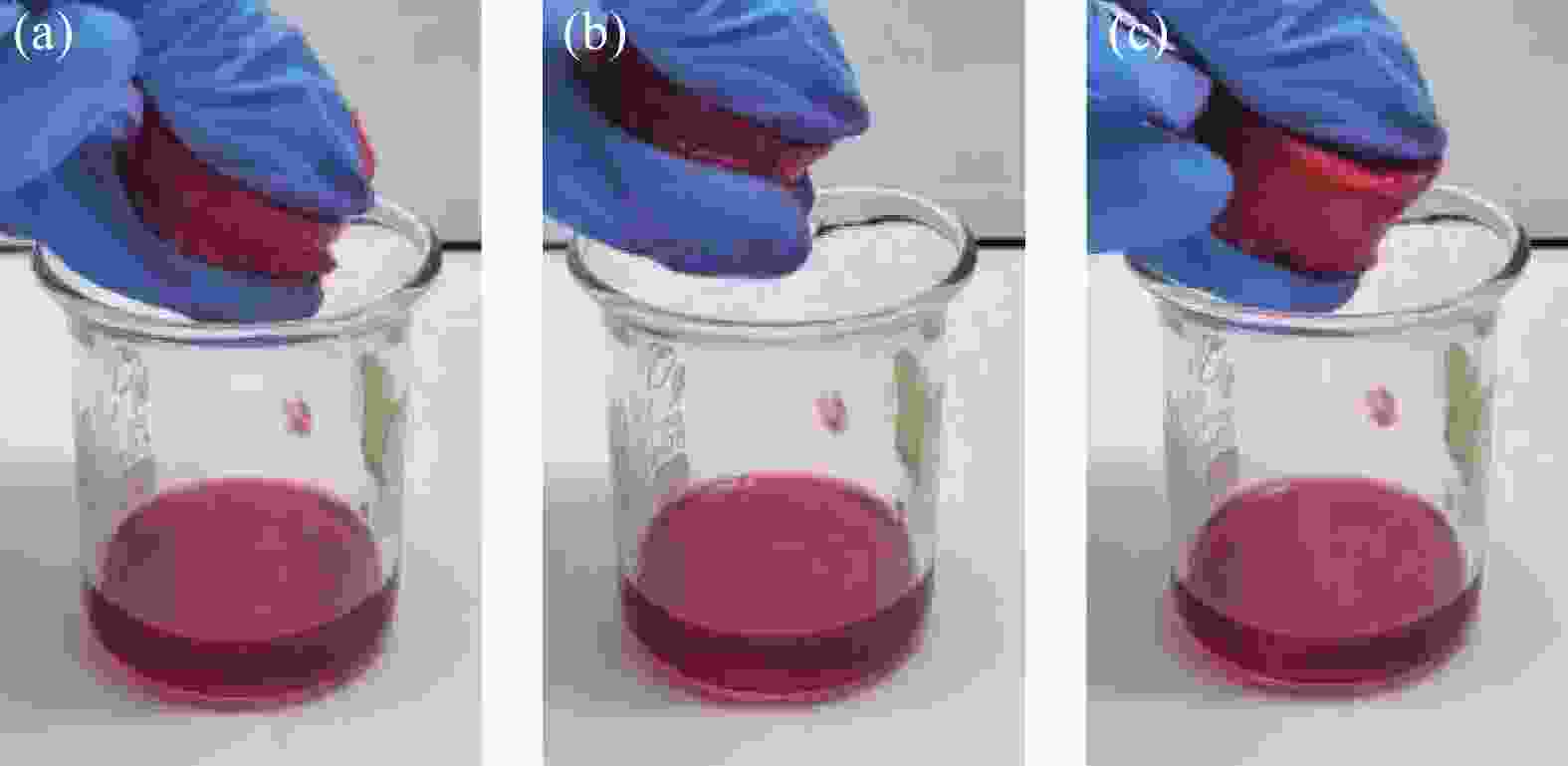

图 5 油(用油红O染成红色)和水(用亚甲基染成蓝色)液滴在原始CNC/BTex (a)和CNC/BTex (b)气凝胶表面上的照片及CNC/BTex气凝胶的表面(c)和内部(d)的水接触角(WCA)

Figure 5. Photographs of oil (dyed red with Oil Red O) and water (dyed blue with methylene) droplets on the surface of original CNC/BTex (a) and CNC/BTex aerogel (b); Water contact angle (WCA) on the surface (c) and the interior (d) of CNC/BTex aerogel

表 1 CNC/BTex与文献报道的多孔材料的比较

Table 1. Comparison of CNC/BTex with porous materials reported in the literature

Material Preparation method Adsorption capacity/(g·g–1) Ref. Kapok/cellulose aerogel Freeze-drying 141.9 [12] Graphene oxide decorated polyacrylonitrile nanofiber/

carbon nanotubes (PANF/CNTs) composite aerogelFreeze-drying and heat crosslinking 36.07-65.09 [35] Cellulose nanofiber-polydimethylsiloxane aerogel Directional freeze-drying, solution

immersion and heat treatment24-48 [36] Graphene/chitosan composite aerogel Directional freeze-drying 18-45 [37] Stem fiber/chitosan composite aerogel Freeze-drying 12.34-21.85 [38] Chitosan-enhanced hydrophobic silica aerogel Sol-gel method and atmospheric

drying method5-9 [39] Polydimethylsiloxane/SiO2 superhydrophobic rock wool Dipping 8-13 [40] CNC/BTex aerogel Freeze-drying 18.48-40.20 This study -

[1] 杨霄, 邵帅. 海岸带石油污染物自然衰减研究综述[J]. 应用海洋学学报, 2023, 42(2): 359-370. doi: 10.3969/J.ISSN.2095-4972.2023.02.018YANG Xiao, SHAO Shuai. Natural attenuation of petroleum pollutants in coastal zones: A review[J]. Journal of Applied Oceanographya, 2023, 42(2): 359-370(in Chinese). doi: 10.3969/J.ISSN.2095-4972.2023.02.018 [2] KALISZ S, KIBORT K, MIODUSKA J, et al. Waste management in the mining industry of metals ores, coal, oil and natural gas-A review[J]. Journal of Environmental Management, 2022, 304: 114239. doi: 10.1016/j.jenvman.2021.114239 [3] YU L, HAN M, HE F. A review of treating oily wastewater[J]. Arabian Journal of Chemistry, 2017, 10: S1913-S1922. doi: 10.1016/j.arabjc.2013.07.020 [4] WANG Q Z, LI Y. Facile and green fabrication of porous chitosan aerogels for highly efficient oil/water separation and metal ions removal from water[J]. Journal of Environmental Chemical Engineering, 2023, 11(3): 109689. doi: 10.1016/j.jece.2023.109689 [5] WU W Q, DU M, SHI H K, et al. Application of graphene aerogels in oil spill recovery: A review[J]. Science of the Total Environment, 2023, 856: 159107. doi: 10.1016/j.scitotenv.2022.159107 [6] MA X, ZHOU S, LI J T, et al. Natural microfibrils/regenerated cellulose-based carbon aerogel for highly efficient oil/water separation[J]. Journal of Hazardous Materials, 2023, 454: 131397. doi: 10.1016/j.jhazmat.2023.131397 [7] GAO J K, WANG J Q, CAI M M, et al. Advanced superhydrophobic and multifunctional nanocellulose aerogels for oil/water separation: A review[J]. Carbohydrate Polymers, 2023, 300: 120242. doi: 10.1016/j.carbpol.2022.120242 [8] LIU C, LI Z Z, LI B, et al. Montmorillonite-based aerogels assisted environmental remediation[J]. Applied Clay Science, 2023, 236: 106887. doi: 10.1016/j.clay.2023.106887 [9] XUE N, CUI H Z, DONG W C, et al. Multifunctional hydrophilic MXene/gelatin composite aerogel with vertically aligned channels for efficient sustainable solar water evaporation and oil/water separation[J]. Chemical Engineering Journal, 2023, 455: 140614. doi: 10.1016/j.cej.2022.140614 [10] BARHOUM A, RASTOGI V K, MAHUR B K, et al. Nanocelluloses as new generation materials: Natural resources, structure-related properties, engineering nanostructures, and technical challenges[J]. Materials Today Chemistry, 2022, 26: 101247. doi: 10.1016/j.mtchem.2022.101247 [11] 周红娟, 师文钊, 陆少锋, 等. 油水分离用纤维素基多孔复合材料研究现状[J]. 中国材料进展, 2023, 42(5): 391-397.ZHOU Hongjuan, SHI Wenzhao, LU Shaofeng, et al. Review on cellulose-based porous composite materials for oil-water separation[J]. Materials China, 2023, 42(5): 391-397(in Chinese). [12] ZHANG H M, ZHANG G R, ZHU H Q, et al. Multiscale kapok/cellulose aerogels for oil absorption: The study on structure and oil absorption properties[J]. Industrial Crops and Products, 2021, 171: 113902. doi: 10.1016/j.indcrop.2021.113902 [13] 汤琦龙, 傅晶依, 窦信, 等. 改性壳聚糖磁性纳米材料的研究进展[J]. 复合材料学报, 2022, 39(3): 1017-1025.TANG Qilong, FU Jingyi, DOU Xin, et al. Research progress of modified chitosan magnetic nanomaterials[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1017-1025(in Chinese). [14] DENG W F, TANG Y J, MAO J C, et al. Cellulose nanofibril as a crosslinker to reinforce the sodium alginate/chitosan hydrogels[J]. International Journal of Biological Macromolecules, 2021, 189: 890-899. doi: 10.1016/j.ijbiomac.2021.08.172 [15] 张益硕, 周仲魁, 李龙祥, 等. 羟基磷灰石改性膨润土对铀的吸附效果及其机制[J]. 复合材料学报, 2023, 40(12): 6740-6755.ZHANG Yishuo, ZHOU Zhongkui, LI Longxiang, et al. Study on adsorption effect and mechanism of uranium by hydroxyapatite modified bentonite [J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6740-6755(in Chinese). [16] ORTIZ-RAMOS U, LEYVA-RAMOS R, MENDOZA-MENDOZA E, et al. Removal of tetracycline from aqueous solutions by adsorption on raw Ca-bentonite: Effect of operating conditions and adsorption mechanism[J]. Chemical Engineering Journal, 2022, 432: 134428. doi: 10.1016/j.cej.2021.134428 [17] TANG R, XU S Q, HU Y, et al. Multifunctional nano-cellulose aerogel with anti-mold ability for efficient oil-water separation: Vital roles of magnetic exfoliated bentonite and polyethyleneimine[J]. Separation and Purification Technology, 2023, 314: 123557. doi: 10.1016/j.seppur.2023.123557 [18] YANG X D, SHAO X Q, TONG J, et al. Removal of aqueous eriochrome blue-black R by novel Na-bentonite/hickory biochar composites[J]. Separation and Purification Technology, 2023, 311: 123209. doi: 10.1016/j.seppur.2023.123209 [19] CHARTIER C, BUWALDA S, BERGHE H V D, et al. Tuning the properties of porous chitosan: Aerogels and cryogels[J]. International Journal of Biological Macromolecules, 2022, 202: 215-223. doi: 10.1016/j.ijbiomac.2022.01.042 [20] PAK S, AHN J B, KIM H. High performance and sustainable CNF membrane via facile in-situ envelopment of hydrochar for water treatment[J]. Carbohydrate Polymers, 2022, 296: 119948. doi: 10.1016/j.carbpol.2022.119948 [21] SALEH S, MOHAMMADNEJAD S, KHORGOOEI H, et al. Photooxidation/adsorption of arsenic (III) in aqueous solution over bentonite/chitosan/TiO2 heterostructured catalyst[J]. Chemosphere, 2021, 280: 130583. doi: 10.1016/j.chemosphere.2021.130583 [22] TANG J Y, XIONG Y S, LI M X, et al. Hyperbranched polyethyleneimine-functionalised chitosan aerogel for highly efficient removal of melanoidins from wastewater[J]. Journal of Hazardous Materials, 2023, 447: 130731. doi: 10.1016/j.jhazmat.2023.130731 [23] ZHANG Q, LU W, WU M Y, et al. Preparation and properties of cellulosenanofiber (CNF)/polyvinyl alcohol (PVA)/graphene oxide (GO): Application of CO2 absorption capacity and molecular dynamics simulation[J]. Journal of Environmental Management, 2022, 302: 114044. doi: 10.1016/j.jenvman.2021.114044 [24] HONG H J, BAN G, KIM H S, et al. Fabrication of cylindrical 3D cellulose nanofibril (CNF) aerogel for continuous removal of copper (Cu2+) from wastewater[J]. Chemosphere, 2021, 278: 130288. doi: 10.1016/j.chemosphere.2021.130288 [25] HUANG G F, LIU K, MUHAMMAD Y, et al. Integrating magnetized bentonite and pinecone-like BiOBr/BiOI step-scheme heterojunctions as novel recyclable photocatalyst for efficient antibiotic degradation[J]. Journal of Industrial and Engineering Chemistry, 2023, 122: 482-499. doi: 10.1016/j.jiec.2023.03.010 [26] ZHAI X S, GAO S, XIANG Y M, et al. Cationized high amylose maize starch films reinforced with borax cross-linked nanocellulose[J]. International Journal of Biological Macromolecules, 2021, 193: 1421-1429. doi: 10.1016/j.ijbiomac.2021.10.206 [27] WANG M Z, LI Y H, CUI M F, et al. Barium alginate as a skeleton coating graphene oxide and bentonite-derived composites: Excellent adsorbent based on predictive design for the enhanced adsorption of methylene blue[J]. Journal of Colloid and Interface Science, 2022, 611: 629-643. doi: 10.1016/j.jcis.2021.12.115 [28] CHENG Y R, CHEN J, WANG T, et al. Magnetically-separable acid-resistant CoFe2O4@polymer@MIL-100 core-shell catalysts for the acetalization of benzaldehyde and methanol[J]. Journal of Colloid and Interface Science, 2023, 629: 571-581. doi: 10.1016/j.jcis.2022.09.004 [29] 朱薇, 江坤, 游峰, 等. 三维立体介孔结构的海藻酸钠/氧化石墨烯复合气凝胶的制备及其对亚甲基蓝的吸附[J]. 复合材料学报, 2022, 39(5): 2215-2225.ZHU Wei, JIANG Kun, YOU Feng, et al. Preparation of 3-dimensional mesoporous sodium alginate/graphene oxide composite aerogel for adsorption of methylene blue[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2215-2225(in Chinese). [30] 翟俊俊, 赵思, 肖秦箭, 等. 生物质气凝胶的疏水改性及应用研究进展[J]. 材料导报, 2022, 36(23): 174-188.ZHAI Junjun, ZHAO Si, XIAO Qinjian, et al. Research progress on hydrophobic modification and application of biomass aerogels[J]. Materials Reports, 2022, 36(23): 174-188(in Chinese). [31] 范廷玉, 赵杰, 彭丹, 等. 植物纤维素基气凝胶吸油材料的制备及应用[J]. 材料导报, 2023, 37(16): 260-275.FAN Tingyu, ZHAO Jie, PENG Dan, et al. Preparation and application of plant cellulose-based aerogel for oil adsorption[J]. Materials Reports, 2023, 37(16): 260-275(in Chinese). [32] DONG X D, WAN B Q, ZHENG M S, et al. Versatile spider-web-like cross-linked polyimide aerogel with tunable dielectric permittivity for highly sensitive flexible sensors[J]. Chemical Engineering Journal, 2023, 465: 143034. doi: 10.1016/j.cej.2023.143034 [33] 张林琳, 顾学林, 向笑笑, 等. 石墨烯-羧甲基纤维素复合气凝胶的制备及吸油性能评价[J]. 材料工程, 2022, 50(9): 43-51.ZHANG Linlin, GU Xuelin, XIANG Xiaoxiao, et al. Preparation of graphene-carboxymethyl cellulose composite aerogel and evaluation of oil absorption performance[J]. Journal of Materials Engineering, 2022, 50(9): 43-51(in Chinese). [34] 柳泽鑫, 顾学林, 陈爽, 等. 弹性石墨烯气凝胶的制备及对含油污水的吸附[J]. 精细化工, 2021, 38(10): 1996-2003. doi: 10.13550/j.jxhg.20210302LIU Zexin, GU Xuelin, CHEN Shuang, et al. Preparation of elastic graphene aerogel and its adsorption on oily waste water[J]. Fine Chemicals, 2021, 38(10): 1996-2003(in Chinese). doi: 10.13550/j.jxhg.20210302 [35] MA W J, JIANG Z C, LU T, et al. Lightweight, elastic and superhydrophobic multifunctional nanofibrous aerogel for self-cleaning, oil/water separation and pressure sensing[J]. Chemical Engineering Journal, 2022, 430(3): 132989. [36] QIAO A H, HUANG R L, PENKOVA A, et al. Superhydrophobic, elastic and anisotropic cellulose nanofiber aerogels for highly effective oil/water separation[J]. Separation and Purification Technology, 2022, 295: 121266. doi: 10.1016/j.seppur.2022.121266 [37] HU J, ZHU J D, GE S Z, et al. Biocompatible, hydrophobic and resilience graphene/chitosan composite aerogel for efficient oil-water separation[J]. Surface and Coatings Technology, 2020, 385: 125361. doi: 10.1016/j.surfcoat.2020.125361 [38] 祝金亮, 王雪枫, 何龙, 等. 超疏水型生物质复合气凝胶的制备及吸油性能评价[J]. 油田化学, 2023, 40(1): 143-148, 174.ZHU Jinliang, WANG Xuefeng, HE Long, et al. Preparation and oil absorption performance evaluation of superhydrophobic biomass composite[J]. Aerogels Oilfield Chemistry, 2023, 40(1): 143-148, 174(in Chinese). [39] 刘泽泓, 卞兆勇. 壳聚糖增强疏水性硅气凝胶的制备及其吸油性能研究[J]. 环境科学研究, 2023, 36(2): 354-362.LIU Zehong, BIAN Zhaoyong. Preparation and oil absorption properties of chitosan-enhanced hydrophobic silica aerogel[J]. Research of Environmental Sciences, 2023, 36(2): 354-362(in Chinese). [40] HAO W T, XU J, LI R, et al. Developing superhydrophobic rock wool for high-viscosity oil/water separation[J]. Chemical Engineering Journal, 2019, 368: 837-846. doi: 10.1016/j.cej.2019.02.161 [41] 纪浩楠, 易昌凤, 徐祖顺, 等. 二氧化钛/ZIF-8复合超疏水海绵的制备及其油水分离性能[J]. 复合材料学报, 2022, 39(12): 5758-5767.JI Haonan, YI Changfeng, XU Zushun, et al. Preparation of titanium dioxide/ZIF-8 composite superhydrophobic sponge and its oil-water separation performance[J]. Acta Materiae Compositae Sinica, 2022, 39(12): 5758-5767(in Chinese). -

下载:

下载: