Theoretical models and meso-scale mechanism of in-layer failure mechanicalbehaviours of 3D printing GFRP

-

摘要: 为实现3D打印纤维增强树脂基复合材料(Fiber reinforced polymer,FRP)桥梁工程构件力学性能的精确分析,推进3D打印FRP技术在桥梁工程中的应用,本文分别从理论及试验角度对3D打印FRP的关键力学性能进行了探索。首先,结合打印FRP的细观结构空间几何特征,提出了打印丝连续假设。进而,基于该假设及面内应力转轴模型,构建了层内应力下3D打印FRP的杨氏模量分析预测模型。同时,考虑材料的多种失效模式,基于Tsai-Wu理论建立了层内应力下该材料的抗拉强度分析预测模型,且该模型考虑了4种不同的剪切强度计算模式。其次,考虑材料的打印角度、线宽及层厚,设计了系统性的杨氏模量及抗拉强度测试分析试验,对上述两类理论模型的精确性进行了验证。研究结果表明:打印角度与杨氏模量及抗拉强度之间呈明显的负相关关系,当打印角度从0°增加至90°时,杨氏模量的减小幅度范围为65.48%~79.62%,抗拉强度的减小幅度范围为50.99%~71.55%。打印线宽对杨氏模量及抗拉强度的影响较明显,0.6 mm及0.8 mm线宽下材料的两类关键力学性能相近,且均明显强于0.4 mm线宽下的力学性能,其中杨氏模量的变化幅度范围为20.18%~49.27%,抗拉强度的变化幅度范围为27.53%~54.55%。宏观尺度失效结果表明,存在两类失效模式,分别为打印丝断裂失效及打印丝分离失效。同时,本文从细观尺度揭示了两类失效模式产生的机制及打印参数对关键力学性能的影响机制。综上,本次构建的两类模型为量化评价3D打印FRP桥梁工程构件的关键力学性能提供了理论支撑。

-

关键词:

- 桥梁工程 /

- 3D打印纤维增强树脂基复合材料 /

- 细观结构 /

- 失效模式 /

- 打印参数

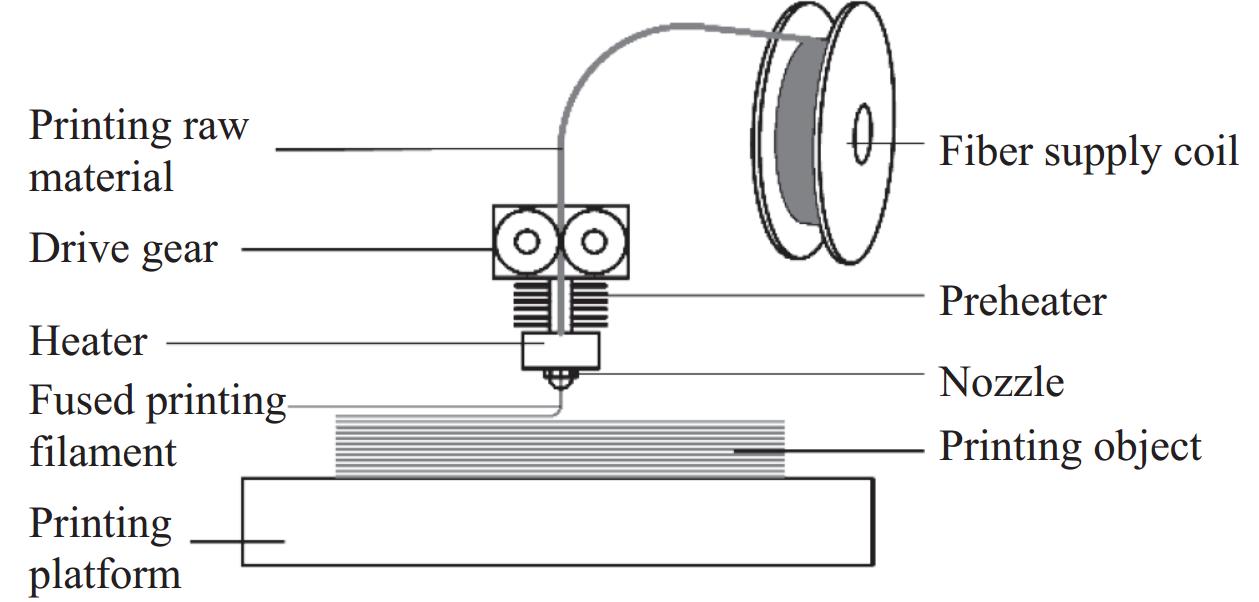

Abstract: In order to realize the accurate analysis of mechanical properties of 3D printing fiber reinforced polymer (FRP) bridge components and promote the application of 3D printing FRP technology in bridge engineering, the key mechanical properties of 3D printing FRP were explored based on theoretical and experimental methods. Firstly, the hypothesis of printing filament continuity was proposed based on the spatial geometry characteristics of the meso-structure of printing FRP. Based on the hypothesis and the in-plane stress rotation axis model, the Young's modulus analysis and prediction model of 3D printing FRP under in-layer stress was constructed. At the same time, considering multiple failure modes of the material, a tensile strength prediction model under in-plane stress was established based on Tsai-Wu theory, and four different shear strength calculation modes were considered in this model. Secondly, considering the printing angle, filament width, and layer thickness, systematic testing and analysis of Young's modulus and tensile strength were designed to verify the accuracy of the above two theoretical models. The results show that there is an obvious negative correlation between printing angle and the two kinds of key mechanical properties. When the printing angle increases from 0° to 90°, the decrease range of Young's modulus is 65.48%-79.62%, and the decrease range of tensile strength is 50.99%-71.55%. The filament width has obvious influence on Young's modulus and tensile strength. These two kinds of key mechanical properties with 0.6 mm and 0.8 mm filament width are similar to each other, and both are significantly bigger than those with 0.4 mm filament width. The variation range of Young's modulus is 20.18%-49.27%, and the variation range of tensile strength is 27.53%-54.55%. The macro-scale failure results show that there are two types of failure modes, namely, printing filament fracture and printing filament separation. Additionally, the mechanism of the two types of failure modes and the influence mechanism of printing parameters on the key mechanical properties are revealed from the meso-scale. In conclusion, these two models established in this study provide theoretical support for the quantitative evaluation of the key mechanical properties of 3D printing FRP bridge engineering components. -

图 9 0.4 mm线宽下3D打印GFRP杨氏模量理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 9. Comparative analysis between theoretical results and test data of Young's modulus of 3D printing GFRP with 0.4 mm filament width: (a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

图 10 0.6 mm线宽下3D打印GFRP杨氏模量理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 10. Comparative analysis between theoretical results and test data of Young's modulus of 3D printing GFRP with 0.6 mm filament width:(a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

图 11 0.8 mm线宽下3D打印GFRP杨氏模量理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 11. Comparative analysis between theoretical results and test data of Young's modulus of 3D printing GFRP with 0.8 mm filament width: (a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

图 13 0.4 mm线宽下3D打印GFRP抗拉强度理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 13. Comparative analysis between theoretical results and test data of tensile strength of 3D printing GFRP with 0.4 mm filament width: (a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

图 14 0.6 mm线宽下3D打印GFRP抗拉强度理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 14. Comparative analysis between theoretical results and test data of tensile strength of 3D printing GFRP with 0.6 mm filament width: (a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

图 15 0.8 mm线宽下3D打印GFRP抗拉强度理论结果与试验测试数据的对比分析:(a) 0.1 mm层厚;(b) 0.2 mm层厚;(c) 0.3 mm层厚

Figure 15. Comparative analysis between theoretical results and test data of tensile strength of 3D printing GFRP with 0.8 mm filament width: (a) 0.1 mm layer thickness; (b) 0.2 mm layer thickness; (c) 0.3 mm layer thickness

表 1 3D打印玻璃纤维增强树脂基复合材料(GFRP)组分材料的关键力学特性

Table 1. Key mechanical properties of component materials of 3D printing glass fiber reinforced polymer (GFRP)

Parameter Glass fiber (GF) Polyamide 6 (PA6) Young's modulus/MPa 74000 2621.0 Tensile strength/MPa 3500 53.2 表 2 3D打印GFRP原材料的物理特性及推荐打印参数

Table 2. Physical properties and recommended printing parameters of 3D printing GFRP raw material

Parameter Value Density/(g·cm−3, 21.5℃) 1.2 Filament diameter/mm 1.75 Crystallization temperature/℃ 174 Melting temperature/℃ 215 Printing temperature/℃ 260-290 Ambient temperature/℃ 50 Heated build platform temperature/℃ 90 表 3 3D打印GFRP的杨氏模量试验测试数据

Table 3. Young's modulus test data of 3D printing GFRP

Filament width/mm Printing angles/(°) Young's modulus (STDEV)/MPa Layer thickness/mm 0.1 0.2 0.3 0.4 E(0°) (E1) 4102 (95) 3689 (116) 3704 (87) E(45°) 1075 (49) 812 (34) 1028 (13) E(90°) (E2) 923 (51) 752 (56) 774 (59) 0.6 E(0°) (E1) 5178 (227) 4984 (18) 4241 (43) E(45°) 1942 (13) 1826 (52) 1656 (18) E(90°) (E2) 1679 (81) 1452 (89) 1439 (25) 0.8 E(0°) (E1) 5088 (145) 5206 (76) 4956 (65) E(45°) 1636 (142) 1833 (65) 1948 (127) E(90°) (E2) 1164 (52) 1657 (140) 1711 (27) Notes: E(0°) (E1)—Elastic modulus of 0° printing angle; E(45°)—Elastic modulus of 45° printing angle; E(90°) (E2)—Elastic modulus of 90° printing angle; STDEV—Standard deviation. 表 4 3D打印GFRP理论结果与试验测试数据之间的相对误差 (%)

Table 4. Relative errors of 3D printing GFRP between theoretical results and test data (%)

Filament

width/mmLayer

thickness/mmRelative errors/% Printing angle/(°) 15 30 60 75 0.4 0.1 1.23 6.83 5.99 1.81 0.2 11.00 2.65 1.59 2.34 0.3 15.33 4.12 5.97 11.43 0.6 0.1 3.77 5.26 0.74 1.64 0.2 1.64 1.56 8.43 8.26 0.3 2.06 4.20 8.11 7.44 0.8 0.1 11.33 8.44 17.12 4.03 0.2 2.32 4.18 9.04 7.82 0.3 2.72 2.61 0.27 0.98 表 5 打印线宽对3D打印GFRP杨氏模量的影响规律

Table 5. Influence of filament width on Young's modulus of 3D printing GFRP

Printing angle/(°) The average data of different layer thickness under each filament width/MPa The change range of the average value/% 0.4 mm 0.6 mm 0.8 mm 0.4_0.6 mm 0.4_0.8 mm 0.6_0.8 mm 0 3832 4801 5083 20.18 24.63 5.55 15 2314 3722 3674 37.83 37.02 1.31 30 1334 2437 2464 45.26 45.86 1.10 45 972 1808 1806 46.24 46.18 0.11 60 867 1669 1709 48.05 49.27 2.28 75 834 1614 1577 48.39 47.18 2.35 90 816 1523 1511 46.42 45.93 0.86 表 6 3D打印GFRP的抗拉强度试验测试数据

Table 6. Tensile strength test data of 3D printing GFRP

Filament width/mm Printing angles/(°) Tensile strength (STDEV)/MPa Layer thickness/mm 0.1 0.2 0.3 0.4 σ(0°) (T1) 42.78 (0.67) 40.91 (0.95) 43.06 (0.62) σ(45°) 14.78 (0.22) 13.30 (0.23) 18.47 (0.38) σ(90°) (T2) 12.17 (0.37) 11.81 (0.06) 14.56 (0.10) 0.6 σ(0°) (T1) 59.91 (2.08) 63.23 (0.99) 51.72 (0.38) σ(45°) 28.18 (0.48) 35.28 (0.70) 29.53 (0.07) σ(90°) (T2) 24.22 (0.62) 22.23 (0.47) 25.35 (0.24) 0.8 σ(0°) (T1) 58.82 (1.55) 63.85 (0.72) 60.52 (0.66) σ(45°) 23.37 (0.41) 31.46 (0.24) 32.79 (1.06) σ(90°) (T2) 21.77 (0.54) 30.33 (0.14) 26.95 (0.69) Notes: σ(0°) (T1)—Tensile strength of 0° printing angle; σ(45°)—Tensile strength of 45° printing angle; σ(90°) (T2)—Tensile strength of 90° printing angle. 表 7 打印线宽对3D打印GFRP抗拉强度的影响

Table 7. Influence of filament width on tensile strength of 3D printing GFRP

Printing angle/(°) Average data of different layer thickness under each filament width/MPa Change range of the average value/% 0.4 mm 0.6 mm 0.8 mm 0.4_0.6 mm 0.4_0.8 mm 0.6_0.8 mm 0 42.25 58.30 61.06 27.53 30.81 4.52 15 30.66 49.17 48.33 37.64 36.56 1.74 30 20.30 37.57 36.38 45.97 44.20 3.27 45 15.52 31.00 29.21 49.94 46.87 6.13 60 13.34 28.03 27.91 52.41 52.20 0.43 75 12.53 25.97 27.57 51.75 54.55 5.80 90 12.85 23.93 26.35 46.34 51.23 9.18 表 8 3D打印GFRP两类失效模式的分布区间

Table 8. Distribution interval of two types failure modes of 3D printing GFRP

Filament width/mm Layer thickness/mm Filament fracture Filament separation 0.4 0.1 0°, 15° 30°- 90° 0.2 0° 15°- 90° 0.3 0°, 15° 30°- 90° 0.6 0.1 0°- 30° 45°- 90° 0.2 0°- 45° 60°- 90° 0.3 0°- 45° 60°- 90° 0.8 0.1 0°- 30° 45°- 90° 0.2 0°- 45° 60°- 90° 0.3 0°- 45° 60°-90° -

[1] 冯鹏. 复合材料在土木工程中的发展与应用[J]. 玻璃钢/复合材料, 2014, 241(9): 99-104.FENG Peng. Development and application of composite in civil engineering[J]. Fiber Reinforced Plastics/Composites, 2014, 241(9): 99-104(in Chinese). [2] 梅葵花, 李雪, 李宇, 等. 大吨位CFRP拉索锚固系统静力性能研究[J]. 中国公路学报, 2022, 35(2): 76-87.MEI Kuihua, LI Xue, LI Yu, et al. Study on static performance of large-tonnage anchorage system with CFRP cable[J]. China Journal of Highway and Transport, 2022, 35(2): 76-87(in Chinese). [3] 梅葵花, 孙亚民, 孙晨然, 等. CFRP筋新型机械夹持-黏结型复合式锚具短期静力性能试验[J]. 中国公路学报, 2021, 34(1): 66-78.MEI Kuihua, SUN Yamin, SUN Chenran, et al. Short-term performance of a novel mechanical-bond composite anchorage with CFRP tendons[J]. China Journal of Highway and Transport, 2021, 34(1): 66-78(in Chinese). [4] 周竞洋, 汪昕, 吴智深, 等. FRP拉索锚固体系优化及其静力性能评价[J]. 中国公路学报, 2022, 35(2): 88-97. doi: 10.3969/j.issn.1001-7372.2022.02.007ZHOU Jingyang, WANG Xin, WU Zhishen, et al. Optimization and static behavior evaluation of fiber-reinforced polymer cable anchor system[J]. China Journal of Highway and Transport, 2022, 35(2): 88-97(in Chinese). doi: 10.3969/j.issn.1001-7372.2022.02.007 [5] WANG L C, ZHANG J Y, XU J, et al. Anchorage systems of CFRP cables in cable structures—A review[J]. Construction and Building Materials, 2018, 160: 82-99. doi: 10.1016/j.conbuildmat.2017.10.134 [6] 侯苏伟, 张昊, 张艳霞, 等. CFRP丝股新型锚固系统受力分析及试验研究[J]. 中国公路学报, 2023, 36(4): 135-145. doi: 10.3969/j.issn.1001-7372.2023.04.012HOU Suwei, ZHANG Hao, ZHANG Yanxia, et al. Stress analysis and experimental research on a new CFRP wire strand anchorage system[J]. China Journal of Highway and Transport, 2023, 36(4): 135-145(in Chinese). doi: 10.3969/j.issn.1001-7372.2023.04.012 [7] 冯鹏, 张汉青, 冯鑫淼, 等. 3D打印技术在工程建设中的应用及前景[J]. 工业建筑, 2019, 49(12): 154-165, 194. doi: 10.13204/j.gyjz201912027FENG Peng, ZHANG Hanqing, FENG Xinmiao, et al. The prospects and applications of 3D printing for construction[J]. Industrial Construction, 2019, 49(12): 154-165, 194(in Chinese). doi: 10.13204/j.gyjz201912027 [8] TOFAIL S A M, KOUMOULOS E P, BANDYOPADHYAY A, et al. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities[J]. Materials Today, 2018, 21(1): 22-37. doi: 10.1016/j.mattod.2017.07.001 [9] LU B H, LI D C, TIAN X Y. Development trends in additive manufacturing and 3D printing[J]. Engineering, 2015, 1(1): 85-89. doi: 10.15302/J-ENG-2015012 [10] 胡艺伟, 李亚智, 李彪, 等. 纤维增强聚合物基复合材料熔融堆积成型技术的研究进展及产品的力学性能[J]. 复合材料学报, 2021, 38(4): 979-996.HU Yiwei, LI Yazhi, LI Biao, et al. 3D printed fibre-reinforced polymer composites-review of the fused deposition modeling process and mechanical performance of products[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 979-996(in Chinese). [11] 田小永, 刘腾飞, 杨春成, 等. 高性能纤维增强树脂基复合材料3D打印及其应用探索[J]. 航空制造技术, 2016, 59(15): 26-31. doi: 10.16080/j.issn1671-833x.2016.15.026TIAN Xiaoyong, LIU Tengfei, YANG Chuncheng, et al. 3D printing for high performance fiber reinforced polymer composites and exploration on its applications[J]. Aeronautical Manufacturing Technology, 2016, 59(15): 26-31(in Chinese). doi: 10.16080/j.issn1671-833x.2016.15.026 [12] HAO W F, LIU Y, ZHOU H, et al. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites[J]. Polymer Testing, 2018, 65: 29-34. doi: 10.1016/j.polymertesting.2017.11.004 [13] LI H M, LIU B S, GE L, et al. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum[J]. Composites Part B: Engineering, 2021, 225: 109277. doi: 10.1016/j.compositesb.2021.109277 [14] SHANG J F, TIAN X Y, LUO M, et al. Controllable inter-line bonding performance and fracture patterns of continuous fiber reinforced composites by sinusoidal-path 3D printing[J]. Composites Science and Technology, 2020, 192: 108096. doi: 10.1016/j.compscitech.2020.108096 [15] LIU T F, TIAN X Y, ZHANG M Y, et al. Interfacial performance and fracture patterns of 3D printed continuous carbon fiber with sizing reinforced PA6 composites[J]. Composites Part A: Applied Science and Manufacturing, 2018, 114: 368-376. doi: 10.1016/j.compositesa.2018.09.001 [16] 张曼玉, 刘腾飞, 田小永, 等. 面向3D打印的连续碳纤维上浆工艺及其对复合材料性能的影响[J]. 中国材料进展, 2020, 39(5): 349-355, 363. doi: 10.7502/j.issn.1674-3962.201910003ZHANG Manyu, LIU Tengfei, TIAN Xiaoyong, et al. Sizing process of continuous carbon fiber for 3D printing and its influence on the properties of composites[J]. Materials China, 2020, 39(5): 349-355, 363(in Chinese). doi: 10.7502/j.issn.1674-3962.201910003 [17] 张帆, 尚雯, 谭跃刚. 连续碳纤维复合材料3D打印的切片方向调控[J]. 机械设计与制造, 2019, 344(10): 170-173.ZHANG Fan, SHANG Wen, TAN Yuegang. Slicing direction control algorithm for continuous carbon fiber composite 3D printing[J]. Machinery Design & Manufacture, 2019, 344(10): 170-173(in Chinese). [18] 董嫣然, 谭跃刚, 张帆, 等. 连续碳纤维3D打印的压力轨迹实时跟踪算法研究[J]. 数字制造科学, 2020, 18(1): 111-117.DONG Yanran, TAN Yuegang, ZHANG Fan, et al. Real-time tracking algorithm of pressure trajectory for the continuous carbon fiber 3D printing[J]. Digital Manufacture Science, 2020, 18(1): 111-117(in Chinese). [19] LI N Y, LI Y G, LIU S T. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing[J]. Journal of Materials Processing Technology, 2016, 238: 218-225. doi: 10.1016/j.jmatprotec.2016.07.025 [20] LIU S T, LI Y G, LI N Y. A novel free-hanging 3D printing method for continuous carbon fiber reinforced thermoplastic lattice truss core structures[J]. Materials and Design, 2018, 137: 235-244. doi: 10.1016/j.matdes.2017.10.007 [21] CAMINERO M A, CHACÓN J M, GARCÍA-MORENO I, et al. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Composites Part B: Engineering, 2018, 148: 93-103. doi: 10.1016/j.compositesb.2018.04.054 [22] CAMINERO M A, CHACÓN J M, GARCÍA-MORENO I, et al. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Polymer Testing, 2018, 68: 415-423. doi: 10.1016/j.polymertesting.2018.04.038 [23] MOHAMMADIZADEH M, IMERI A, FIDAN I, et al. 3D printed fiber reinforced polymer composites-structural analysis[J]. Composites Part B: Engineering, 2019, 175: 107112. doi: 10.1016/j.compositesb.2019.107112 [24] HE Q H, WANG H J, FU K K, et al. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance[J]. Composites Science and Technology, 2020, 191: 108077. doi: 10.1016/j.compscitech.2020.108077 [25] KASMI S, GINOUX G, ALLAOUI S, et al. Investigation of 3D printing strategy on the mechanical performance of coextruded continuous carbon fiber reinforced PETG[J]. Journal of Applied Polymer Science, 2021, 138(37): 50955. doi: 10.1002/app.50955 [26] German Institute for Standardization. Plastics-determination of tensile properties-Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites: DIN EN ISO 527-4—1997[S]. Berlin: German Institute for Standardization, 1997. [27] SOMIREDDY M, SINGH C V, CZEKANSKI A. Mechanical behaviour of 3D printed composite parts with short carbon fiber reinforcements[J]. Engineering Failure Analysis, 2020, 107: 104232. doi: 10.1016/j.engfailanal.2019.104232 [28] YAO T Y, OUYANG H J, DAI S, et al. Effects of manufacturing micro-structure on vibration of FFF 3D printing plates: Material characterisation, numerical analysis and experimental study[J]. Composite Structures, 2021, 268: 113970. doi: 10.1016/j.compstruct.2021.113970 [29] YAO T Y, ZHANG K, DENG Z C, et al. A novel generalized stress invariant-based strength model for inter-layer failure of FFF 3D printing PLA material[J]. Materials and Design, 2020, 193: 108799. doi: 10.1016/j.matdes.2020.108799 -

下载:

下载: