Effect of fluorine-containing groups on the corona resistance and dielectricproperties of polyimide

-

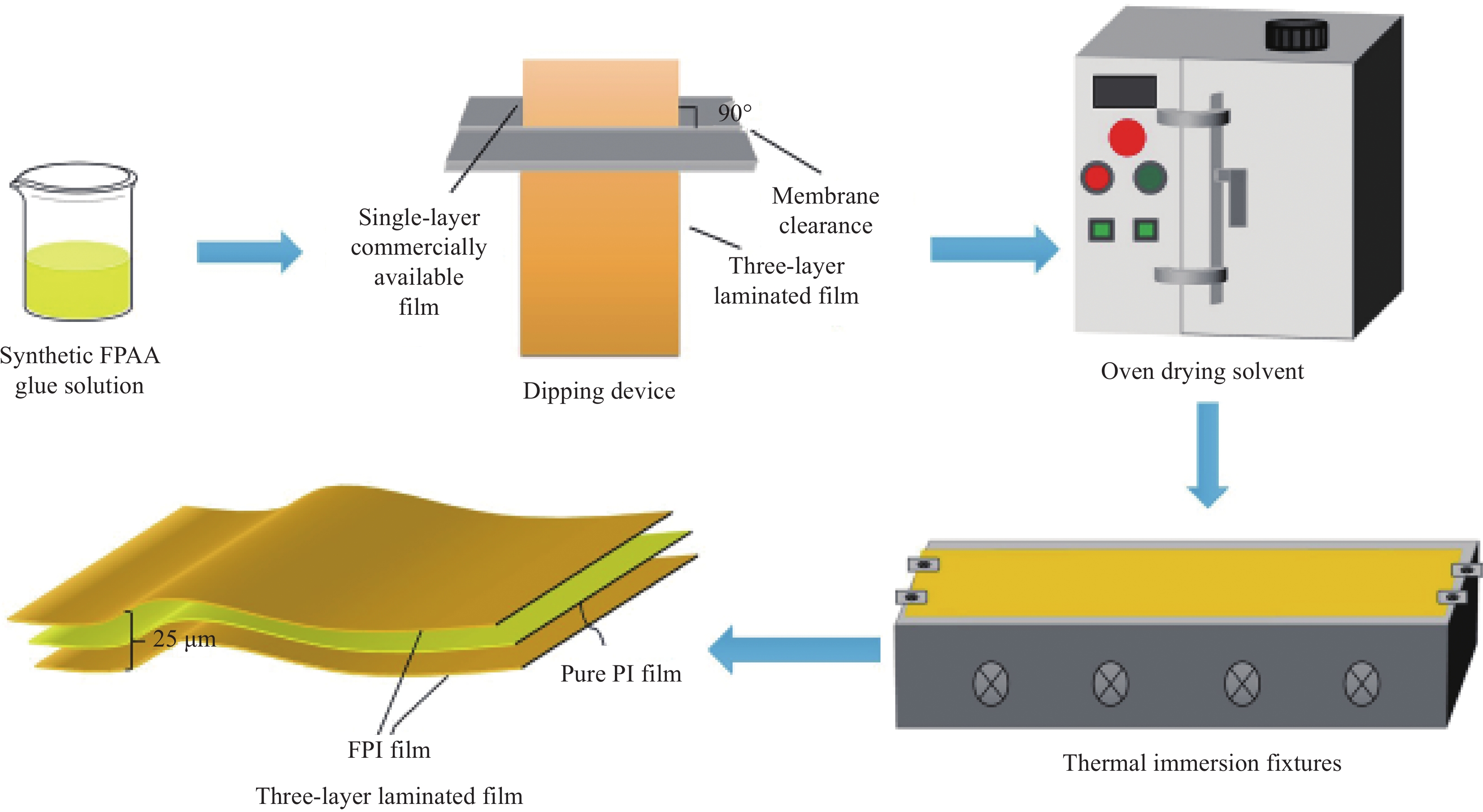

摘要: 电气设备的高频化趋势对绝缘材料的耐电晕老化性能及介电性能提出了更高的要求。因此,提高绝缘材料的绝缘性能对高频电力系统的发展至关重要。本文以2, 2'-双(三氟甲基)-4, 4'- 二氨基苯基醚(6FODA)、4, 4'-二氨基二苯醚(ODA)、均苯四甲酸二酐(PMDA)为反应单体,设计制备了嵌段共聚型含氟聚酰亚胺(FPI)三层薄膜,并重点研究了材料的耐电晕性能和介电性能。结果表明:不同含氟量嵌段共聚型FPI三层薄膜的耐电晕寿命均高于纯聚酰亚胺(PI)三层薄膜,且随着含氟量的增加,薄膜耐电晕寿命相应增大。当ODA与6FODA摩尔比为1∶9时三层薄膜的耐电晕寿命在常温(20℃)、80 kV/mm下最高可达4.0 h,是纯PI三层薄膜(1.4 h)的2.86倍。随着含氟量的增加,FPI三层薄膜的介电常数呈现先减后增趋势,ODA与6FODA摩尔比为1∶1时三层薄膜的介电常数在1 MHz时最低可降至2.26,介电损耗与电导率呈现先增后减趋势。介电强度随着含氟量的增加有所下降,但均高于纯PI三层薄膜,ODA与6FODA摩尔比为9∶1时,三层薄膜的介电强度高达434 kV/mm。Abstract: The increasing use of electrical equipment at high frequencies poses greater demands on the corona aging resistance and dielectric properties of insulating materials. Therefore, it is crucial to enhance the insulation properties of insulating materials for the development of high-frequency power systems. In this study, we utilized 2, 2'-bis(trifluoromethyl)-4, 4'-diaminodiphenyl ether (6FODA), 4, 4'-diaminodiphenyl ether (ODA), and 1, 2, 4, 5-benzenetetracarboxylic anhydride (PMDA) as reactive monomers to design and synthesize block copolymerized fluoro-polyimide (FPI) three-layer films. The focus was primarily on assessing the corona-resistant and dielectric properties of these materials. Results reveal that the corona-resistant life of the block copolymerized FPI three-layer films, with varying amounts of fluorine, is higher when compared to the pure polyimide (PI) three-layer films. Furthermore, the corona-resistant life of the films increase with an increase in fluorine content. When the molar ratio of ODA to 6FODA is 1∶9, the corona resistance life of the three-layer film can reach up to 4.0 h at room temperature (20℃) and 80 kV/mm, which is 2.86 times higher than that of the pure PI three-layer film (1.4 h). Moreover, with the increase of fluorine content, the dielectric constant of FPI three-layer film shows a trend of decreasing and then increasing, and the dielectric constant of the three-layer film when the molar ratio of ODA and 6FODA is 1∶1 can be reduced to as low as 2.26 at 1 MHz, and the dielectric loss and conductivity show a trend of increasing and then decreasing. The dielectric strength decreases with the increase of fluorine content, but they are all higher than that of the pure PI three-layer film, and the dielectric strength of the three-layer film is as high as 434 kV/mm when the molar ratio of ODA to 6FODA is 9∶1.

-

表 1 9种不同含氟量FPI三层薄膜编号

Table 1. Nine different fluorine content FPI three-layer film numbers

Specimen number n(ODA)∶n(6FODA) FPI-1 9∶1 FPI-2 8∶2 FPI-3 7∶3 FPI-4 6∶4 FPI-5 5∶5 FPI-6 4∶6 FPI-7 3∶7 FPI-8 2∶8 FPI-9 1∶9 Notes: n∶n—Molar ratio; ODA—4, 4'-diaminodiphenyl ether; 6FODA—2, 2'-bis (trifluoromethyl)-4, 4'-diaminophenyl ether. 表 2 常温、80 kV/mm场强下纯PI及FPI三层薄膜耐电晕寿命威布尔数据表

Table 2. Corona resistance life Weibull data sheet for pure PI and FPI three-layer films at room temperature and80 kV/mm field strength

Specimen number T0/h β Pure PI 1.4 12.04 FPI-1 2.1 4.51 FPI-2 2.3 4.22 FPI-3 2.5 4.11 FPI-4 3.0 4.90 FPI-5 3.0 4.26 FPI-6 3.1 7.18 FPI-7 3.2 7.42 FPI-8 3.7 9.08 FPI-9 4.0 10.16 Notes: β—Shape parameter; T0—Corona resistance life characteristics. 表 3 FPI三层薄膜受陷载流子密度数据

Table 3. Trapped carrier density data for FPI three-layer films

Specimen number ε/50 Hz VΩ/(kV·mm−1) nt/m−3 FPI-1 2.93 36.61 1.43×1030 FPI-3 2.73 38.83 1.19×1030 FPI-5 2.54 40.26 1.06×1030 FPI-7 2.62 33.57 9.89×1029 FPI-9 2.60 34.17 7.74×1029 Notes: ε—Dielectric constant at working frequency; VΩ—Electrical aging threshold; nt—Trapped carrier density. 表 4 纯PI及不同含氟量FPI三层薄膜击穿强度数据

Table 4. Breakdown strength data of pure PI and FPI three-layer films with different fluorine contents

Specimen number β E0/(kV·mm−1) PI 9.95 352 FPI-1 10.92 434 FPI-3 25.20 396 FPI-5 13.42 404 FPI-7 25.00 400 FPI-9 13.23 353 Notes: E0—Breakdown field strength eigenvalue. -

[1] WAN B Q, DONG X D, YANG X, et al. High strength, stable and self-healing copolyimide for defects induced by mechanical and electrical damages[J]. Journal of Materials Chemistry C, 2022, 10(31): 11307-11315. doi: 10.1039/D2TC01605B [2] 万宝全, 郑明胜, 查俊伟. 聚酰亚胺复合储能电介质材料研究进展[J]. 绝缘材料, 2021, 54(11): 23-33.WAN Baoquan, ZHENG Mingsheng, ZHA Junwei. Progress of polyimide-based composite dielectrics for energy storage applications[J]. Insulating Materials, 2021, 54(11): 23-33(in Chinese). [3] 王相文, 范勇, 陈昊, 等. 纳米Mg(OH)2-ZnO/聚酰亚胺复合薄膜的介电和热性能[J]. 复合材料学报, 2018, 35(1): 30-34.WANG Xiangwen, FAN Yong, CHEN Hao, et al. Dielectric and thermal properties of nano Mg(OH)2-ZnO/polyimide composite film[J]. Acta Materiae Compositae Sinica, 2018, 35(1): 30-34(in Chinese). [4] ZHAO W, FAN Y, CHEN H. Dielectric properties and corona resistance of Si-B/epoxy nano-composites[J]. Journal of Materials Science: Materials in Electronics, 2019, 30(17): 16298-16307. doi: 10.1007/s10854-019-02000-w [5] 杨瑞宵, 陈昊, 王相文, 等. 五层纳米SiO2-Al2O3/聚酰亚胺复合薄膜的制备及性能[J]. 复合材料学报, 2018, 35(5): 1050-1058.YANG Ruixiao, CHEN Hao, WANG Xiangwen, et al. Preparation and properties of five layer nano SiO2-Al2O3/polyimide composite film[J]. Acta Materiae Compositae Sinica, 2018, 35(5): 1050-1058(in Chinese). [6] ANGALANE S K, KASINATHAN E. A review on polymeric insulation for high-voltage application under various stress conditions[J]. Polymer Composites, 2022, 43(8): 4803-4834. doi: 10.1002/pc.26793 [7] WU X, CAI J, CHENG Y. Synthesis and characterization of high fluorine-containing polyimides with low-dielectric constant[J]. Journal of Applied Polymer Science, 2022, 139(16): 51972. doi: 10.1002/APP.51972 [8] PENG W, LEI H, QIU L, et al. Perfiuorocyclobutyl-containing transparent polyimides with low dielectric constant and low dielectric loss[J]. Polymer Chemistry, 2022, 13(26): 3949-3955. doi: 10.1039/d2py00550f [9] XIAO P, HE X, ZHENG F, et al. Superheat resistant, transparent and low dielectric polyimides based on spirocyclic bisbenzoxazole diamines with Tg>450℃[J]. Polymer Chemistry, 2022, 13(24): 3660-3669 . [10] 中国国家标准化管理委员会. 测定固体绝缘材料相对耐表面放电击穿能力的推荐试验方法: GB/T 22689—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Recommended test methods for determining the relative resistance of insulating materials to breakdown by surface discharges: GB/T 22689—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [11] ZHAO N, NIE Y J, LI S T. Space charge characteristics of fluorinated polyethylene: Different effects of fluorine and oxygen[J]. AIP Advances, 2018, 8(4): 045103. doi: 10.1063/1.5020063 [12] TIAN F Q, HOU C Y. A trap regulated space charge suppression model for LDPE based nanocomposites by simulation and experiment[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, 25(6): 2169-2177. doi: 10.1109/TDEI.2018.007282 [13] SERRA S, TOSATTI E, IARLORI S, et al. Interchain electron states in polyethylene[J]. Physical Review B, 2000, 62(7): 4389-4393. [14] LI S T, MIN D M, WANG W W, et al. Linking traps to dielectric breakdown through charge dynamics for polymer nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 2016, 23(5): 2777-2785. doi: 10.1109/TDEI.2016.7736837 [15] BLAISE G, SARJEANT W J. Space charge in dielectrics energy storage and transfer dynamics from atomistic to macroscopic scale[J]. IEEE Transactions on Dielectrics and Electrical Insulation, 1998, 5(5): 779-808. doi: 10.1109/94.729703 [16] LI X, HE T J, YIN Q, et al. Fluorinated Al2O3/siloxane modified PI films towards vastly enhanced corona resistance performance[J]. Composites Part A: Applied Science and Manufacturing, 2023, 172: 107613. doi: 10.1016/j.compositesa.2023.107613 [17] XING Y Q, YUAN R Y, LI A, et al. Trap distribution and breakdown characteristics of direct-fluorinated PI film for DC-HTSFCL[J]. IEEE Transactions on Applied Superconductivity, 2019, 29(2): 7701204. [18] YIN X D, FENG Y Y, ZHAO Q, et al. Highly transparent, strong, and flexible fluorographene/fluorinated polyimide nanocomposite films with low dielectric constant[J]. Journal of Materials Chemistry C, 2018, 6(24): 6378-6384. doi: 10.1039/C8TC00998H [19] ALBU R M, NICA S L, BARZIC A I. Refraction and polarization properties of some fluorinated imidic polymers[J]. Polymer Bulletin, 2018, 75(4): 1535-1546. doi: 10.1007/s00289-017-2108-x [20] QIU G R, MA W S, JIAO Y Q, et al. Low-dielectric-constant aromatic homopolyimide and copolyimide derived from pyromellitic dianhydride, 4, 4′-oxydianiline, 2, 2-bis[4-(4-aminephenoxy) phenyl] propane, 1, 4-bis (4-aminophenoxy) benzene, or 1, 3-bis (4-aminophenoxy) benzene[J]. Journal of Applied Polymer Science, 2019, 136(18): 47405. doi: 10.1002/app.47405 [21] DONG X D, WAN B Q, FENG Y, et al. Ultra-low-permittivity, high hydrophobic, and excellent thermally stable fluoroelastomer/polyimide composite films employing dielectric reduction[J]. European Polymer Journal, 2022, 181: 111667. doi: 10.1016/j.eurpolymj.2022.111667 [22] KUO C C, LIN Y C, CHEN Y C, et al. Correlating the molecular structure of polyimides with the dielectric constant and dissipation factor at a high frequency of 10 GHz[J]. ACS Applied Polymer Materials, 2021, 3(1): 362-371. doi: 10.1021/acsapm.0c01141 [23] 范振国, 刘四委, 池振国, 等. 本征型聚酰亚胺介电常数的定量构效关系模型构建与研究[J]. 高分子学报, 2021, 52(7): 750-761.FAN Zhenguo, LIU Siwei, CHI Zhenguo, et al. Construction and study of quantitative structure-property relationship model for intrinsic polyimide dielectric constant[J]. Acta Polymerica Sinica, 2021, 52(7): 750-761(in Chinese). [24] YU Y Y, CHIEN W C, TSAI T W. High transparent soluble polyimide/silica hybrid optical thin films[J]. Polymer Testing, 2010, 29(1): 33-40. doi: 10.1016/j.polymertesting.2009.09.002 [25] ZHA J W, JIA H J, WANG H Y, et al. Tailored ultralow dielectric permittivity in high-performance fluorinated polyimide films by adjusting nanoporous characterisitics[J]. Journal of Physical Chemistry C, 2012, 116(44): 23676-23681. doi: 10.1021/jp305286r [26] PARK S J, CHO K S, KIM S H. A study on dielectric characteristics of fluorinated polyimide thin film[J]. Journal of Colloid & Interface Science, 2004, 272(2): 384-390. [27] LI Y H, SUN G H, ZHOU Y, et al. Progress in low dielectric polyimide film—A review[J]. Progress in Organic Coatings, 2022, 172: 107103. doi: 10.1016/j.porgcoat.2022.107103 [28] XIAO Y, XU L Q, HONG T, et al. Ultrahigh carrier mobility contributes to remarkably enhanced thermoelectric performance in n-type PbSe[J]. Energy & Environmental Science, 2022, 15(1): 346-355. [29] DU B X, XING Y Q, JIN J X, et al. Effects of direct fluorination on space charge and trap distribution of PI film in LN2[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(7): 0607405. -

下载:

下载: