Optimization of response surface methodology and performance of oxidized wheat straw/polylactic acid composites

-

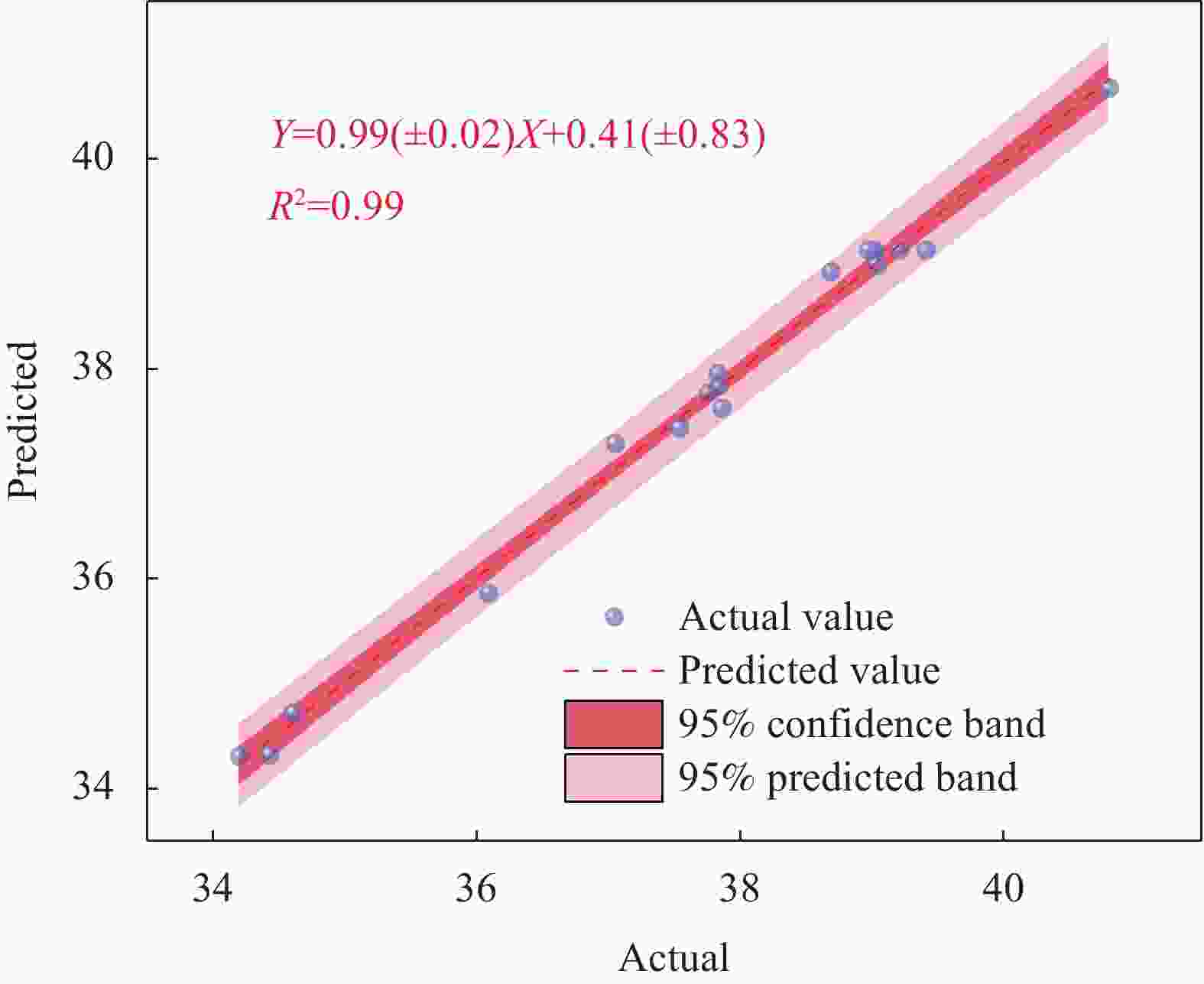

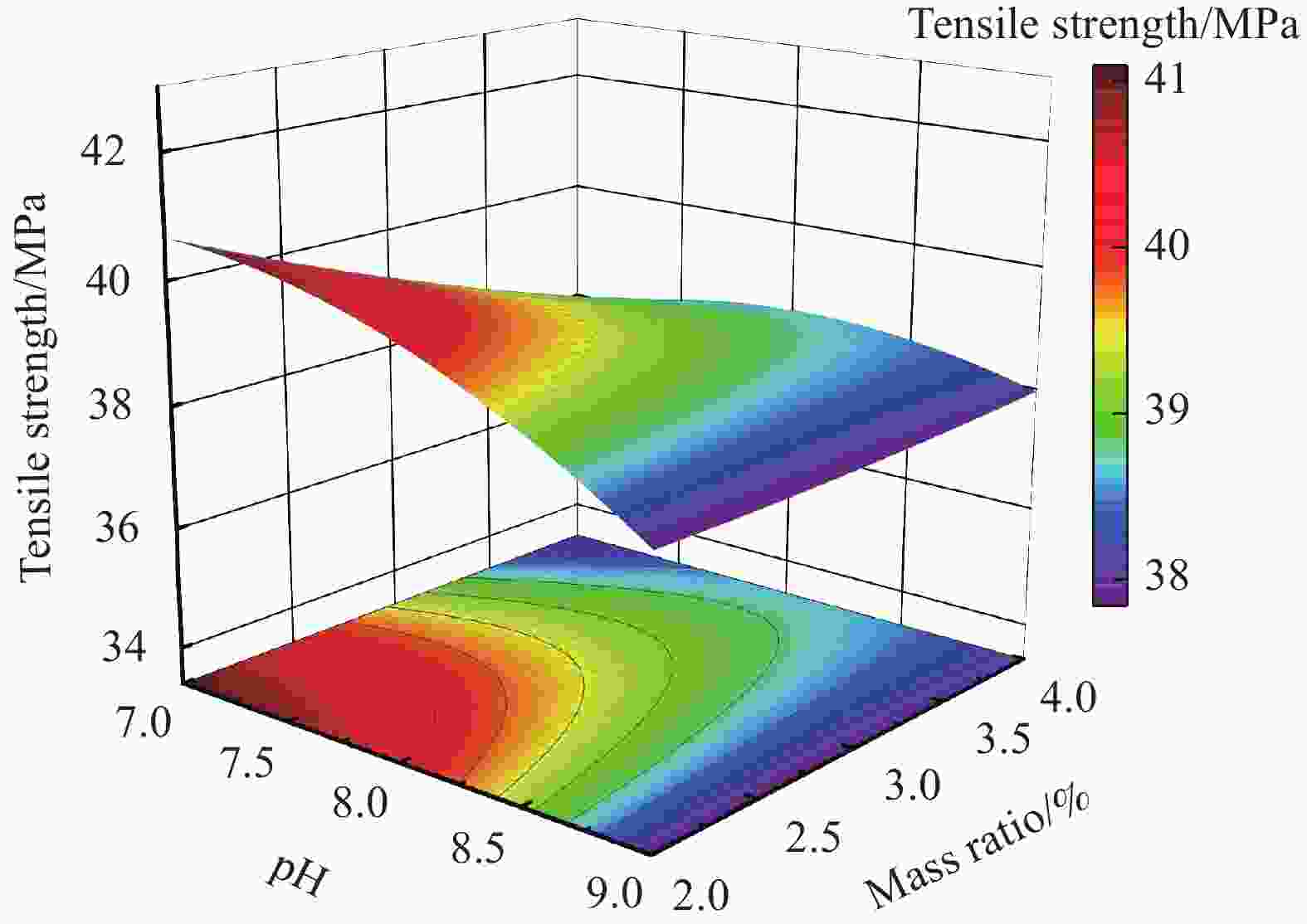

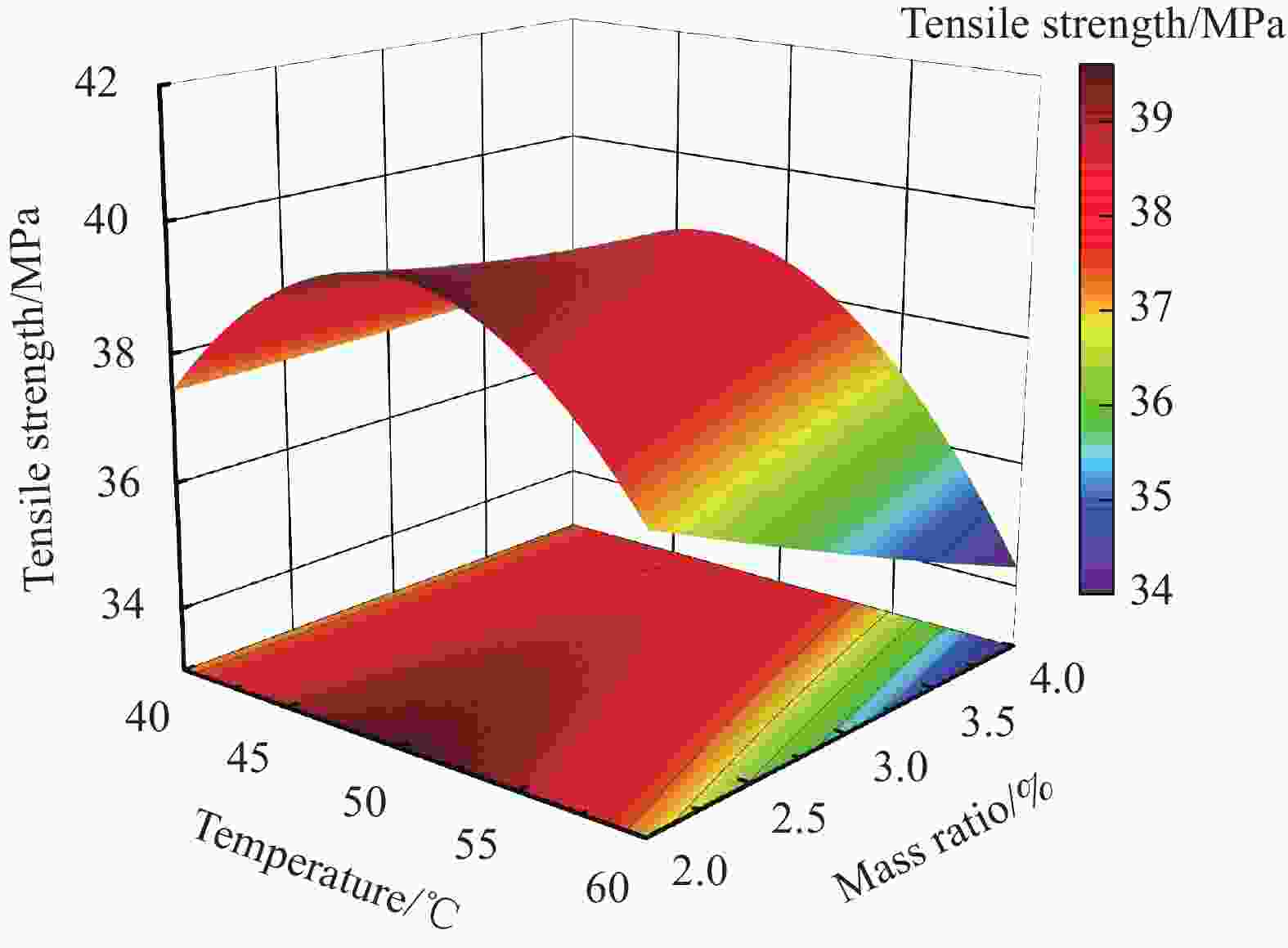

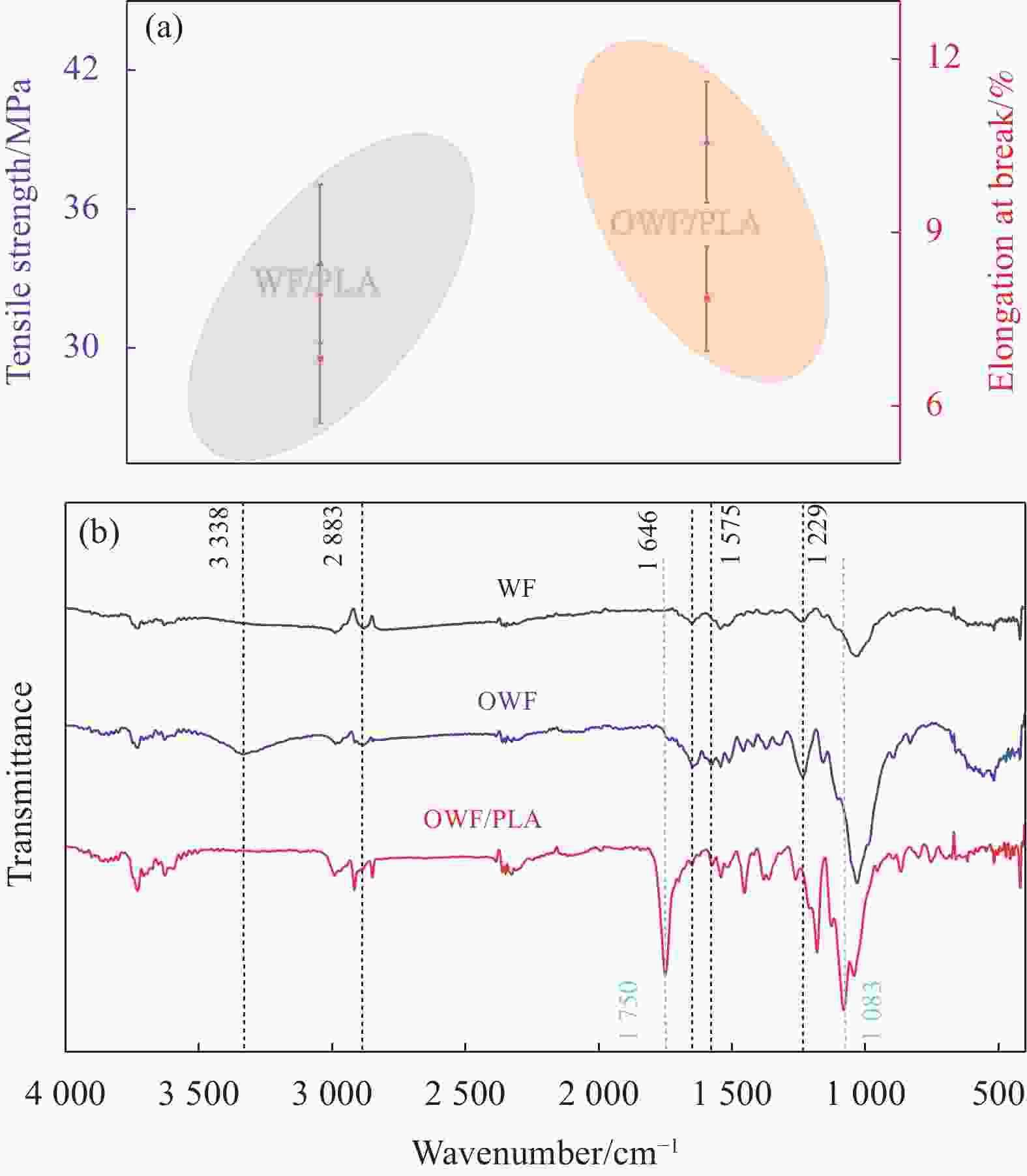

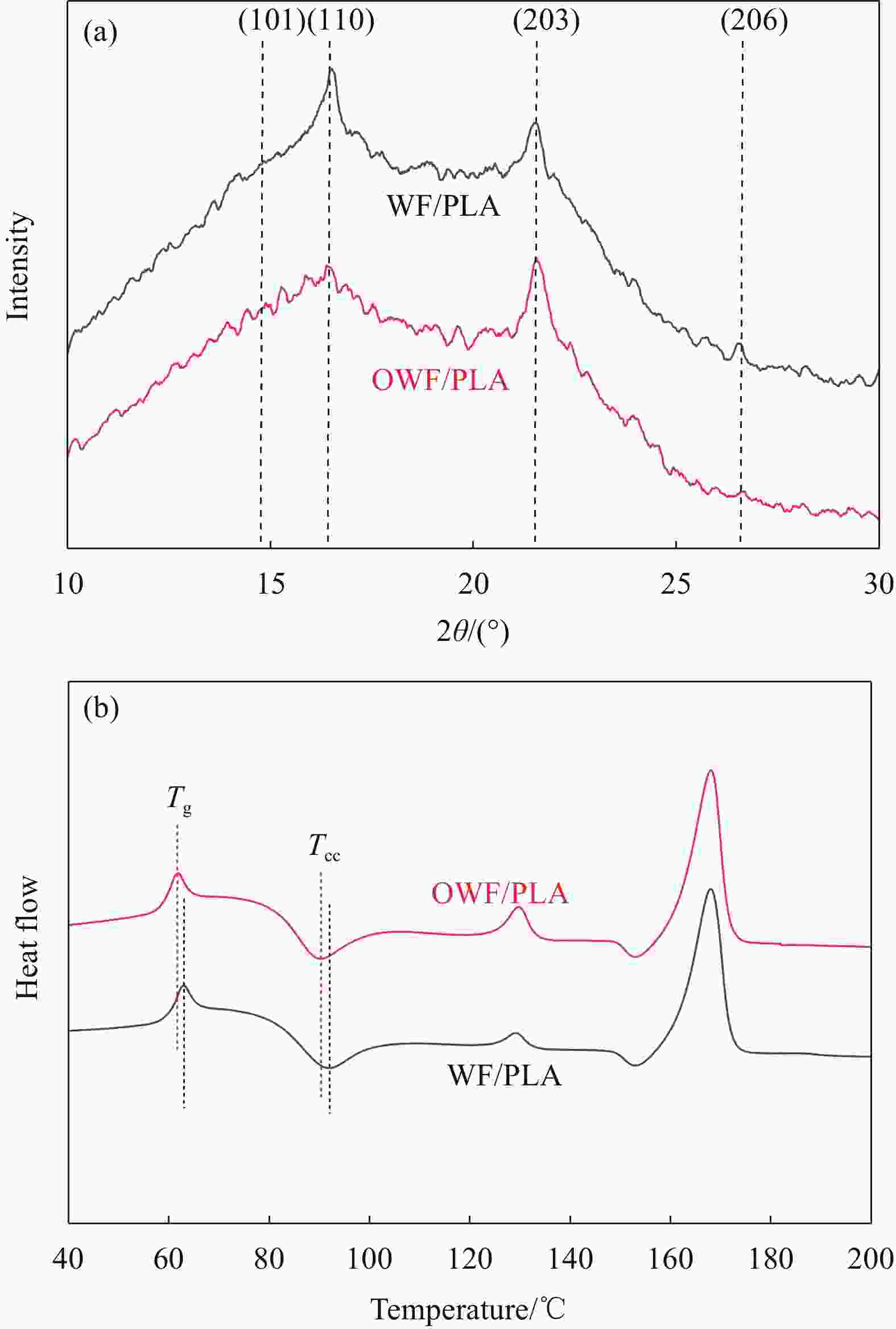

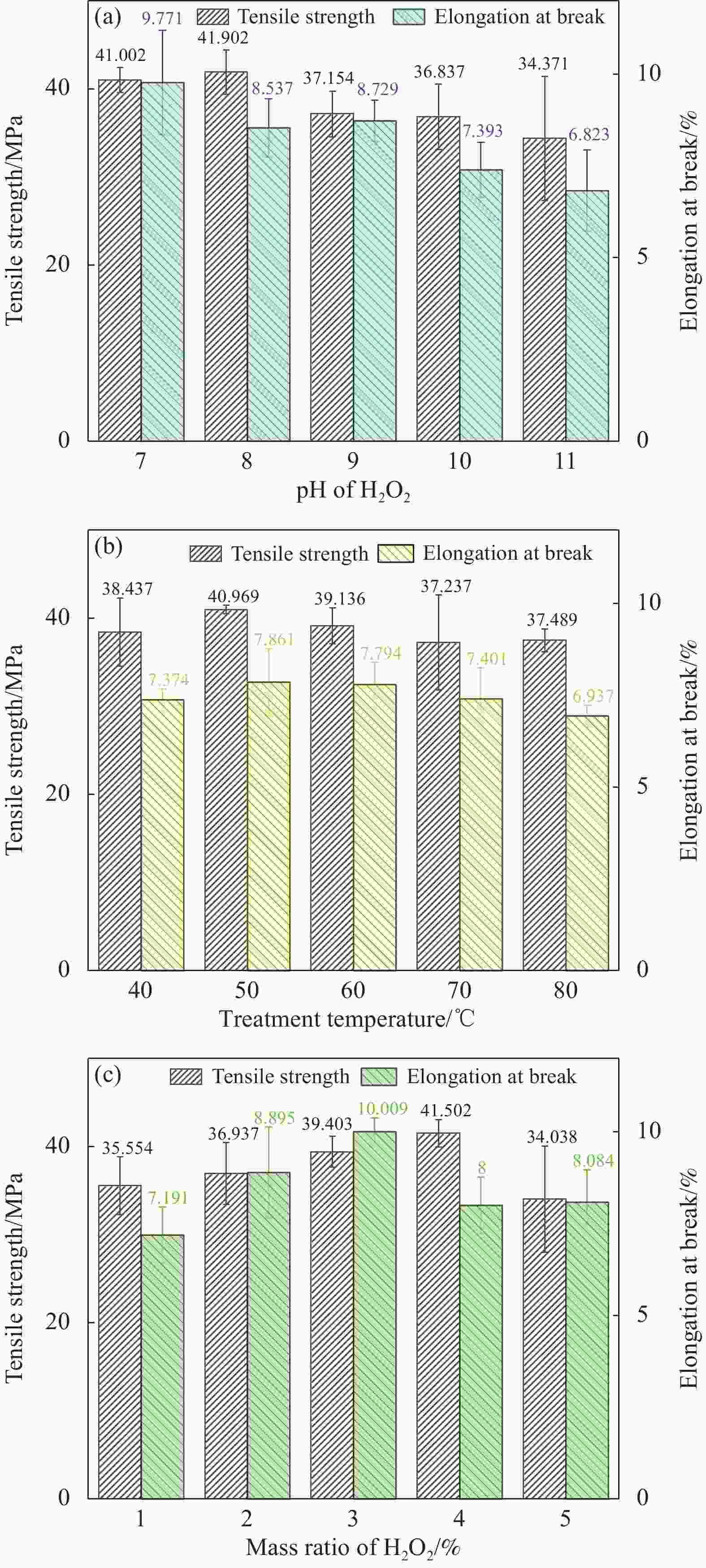

摘要: 为解决麦秸纤维/聚乳酸(WF/PLA)复合材料界面相容性较差的问题,以H2O2作为氧化剂处理麦秸,采用响应面试验法探究H2O2的pH、处理温度、质量比对氧化麦秸纤维(OWF)/PLA复合材料力学性能的影响,得到各因素对复合材料力学性能的影响规律。结果表明:pH和处理温度、pH和质量比、处理温度和质量比之间均表现出明显的交互作用。回归方程预测的最佳工艺参数如下:H2O2的pH为8.9,H2O2的处理温度为52.3℃,H2O2的质量比为2%。在此条件下,复合材料的拉伸强度和断裂伸长率分别为38.89 MPa和7.85%,较未改性前分别提高了15.64%和15.20%。FTIR结果表明,OWF中的部分羟基被H2O2氧化为羧基。SEM结果表明,OWF能够更好地与PLA进行结合,经过熔融共混后制备的复合材料之间具有更好的界面相容性。此外,XRD和DSC结果表明,H2O2的加入促进了聚合物的异相成核过程,使其结晶度有所提高。Abstract: To solve the problem of poor interfacial compatibility of wheat straw fiber/poly(lactic acid) (WF/PLA) composites, WF was treated with H2O2 as oxidant, and the effects of pH, treatment temperature, and mass ratio of H2O2 on the mechanical properties of oxidized wheat straw fiber (OWF)/PLA composites were investigated by response surface method. The results show that there is a significant interaction between pH and treatment temperature, pH and mass ratio, and treatment temperature and mass ratio. The optimal process parameters predicted by the regression equation are as follows: The pH of H2O2 is 8.9, the treatment temperature of H2O2 is 52.3℃, and the mass ratio of H2O2 is 2%. Under these conditions, the tensile strength and elongation at break of the composite material are 38.89 MPa and 7.85% respectively, which are 15.64% and 15.20% higher than before modification. FTIR results indicate that some hydroxyl groups in OWF are oxidized to carboxyl groups by H2O2. SEM results indicate that OWF can better bind with PLA, and the composite materials prepared after melt blending have better interfacial compatibility. In addition, XRD and DSC results indicate that the addition of H2O2 promotes the heterogeneous nucleation process of the polymer, resulting in an increase in its crystallinity.

-

表 1 Box-Behnken因素水平表

Table 1. Factors and levels table for Box-Behnken

Level Factor A: pH of H2O2 B: Treatment temperature/℃ C: Mass ratio of H2O2/% −1 7.0 40 2 0 8.0 50 3 1 9.0 60 4 Notes: Total mass of polylactic acid (PLA) blended with wheat straw fiber (WF) is 100%, the mass ratio of H2O2 refers to its proportion to the mass of WF. 表 2 响应面法优化OWF/PLA复合材料拉伸性能试验的设计与结果

Table 2. Design and results of tensile properties test of OWF/PLA composites optimized by response surface method

Run Factors Tensile strength/MPa A B/℃ C/% 1 7.0 40 3 38.69±0.57 2 9.0 40 3 34.61±2.75 3 7.0 60 3 34.43±0.98 4 9.0 60 3 36.09±1.38 5 7.0 50 2 40.80±0.81 6 9.0 50 2 37.84±1.67 7 7.0 50 4 37.76±0.72 8 9.0 50 4 37.83±1.07 9 8.0 40 2 37.54±1.80 10 8.0 60 2 37.05±1.63 11 8.0 40 4 37.86±1.32 12 8.0 60 4 34.20±1.17 13 8.0 50 3 39.02±0.65 14 8.0 50 3 39.41±1.78 15 8.0 50 3 39.21±2.75 16 8.0 50 3 38.97±2.03 17 8.0 50 3 39.04±1.21 表 3 响应面法优化OWF/PLA复合材料力学性能实验中回归方程的方差分析

Table 3. Variance analysis of response surface experimental regression equation of optimization of the mechanical properties of OWF/PLA composites

Source Tensile strength Significance F value P value Model 102.27 <0.0001 *** A 57.83 0.0001 ** B 98.50 <0.0001 *** C 63.86 <0.0001 *** AB 135.15 <0.0001 *** AC 37.66 0.0005 ** BC 41.22 0.0004 ** A2 28.30 0.0011 ** B2 443.96 <0.0001 *** C2 0.31 0.5923 Lack of fit 3.02 0.1566 R2 0.9925 RAdj 2 0.9827 CV 0.66 Notes: F—Ratio of the mean square to the residual term; P—Influence degree value of each factor; ***—Significant in [−∞, 0.0001]; **—Significant in [0.0001, 0.01]; *—Significant in [0.01, 0.05]; R2—Coefficient of determination; RAdj 2 —Adjusted R2; CV—Coefficient of variation. 表 4 复合材料的结晶过程参数

Table 4. Crystallization process parameters of composites

Sample Tg/℃ Tcc/℃ Tm/℃ ΔHcc/

(J·g−1)ΔHm/

(J·g−1)Xc/% WF/PLA 62.9 91.6 168.1 11.97 27.98 42.7 OWF/PLA 61.7 89.9 168.0 11.82 29.88 45.6 Notes: Tm—Melting temperature; ΔHcc—Cold crystallization enthalpy; ΔHm—Melting enthalpy; Xc—Crystallinity. -

[1] 高利伟, 马林, 张卫峰, 等. 中国作物秸秆养分资源数量估算及其利用状况[J]. 农业工程学报, 2009, 25(7): 173-179. doi: 10.3969/j.issn.1002-6819.2009.07.032GAO Liwei, MA Lin, ZHANG Weifeng, et al. Estimation of nutrient resource quantity of crop straw and its utilization situation in China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(7): 173-179(in Chinese). doi: 10.3969/j.issn.1002-6819.2009.07.032 [2] 石祖梁, 王飞, 王久臣, 等. 我国农作物秸秆资源利用特征、技术模式及发展建议[J]. 中国农业科技导报, 2019, 21(5): 8-16. doi: 10.13304/j.nykjdb.2018.0314SHI Zuliang, WANG Fei, WANG Jiuchen, et al. Utilization characteristics, technical model and development suggestion on crop straw in China[J]. Journal of Agricultural Science and Technology, 2019, 21(5): 8-16(in Chinese). doi: 10.13304/j.nykjdb.2018.0314 [3] XU J J, HAO X L, TANG W, et al. Mechanical properties, morphology, and creep resistance of ultra-highly filled bamboo fiber/polypropylene composites: Effects of filler content and melt flow index of polypropylene[J]. Construction and Building Materials, 2021, 310: 125289. doi: 10.1016/j.conbuildmat.2021.125289 [4] 张扬, 张静, 江雯钊, 等. PLA/植物纤维全生物降解复合材料的研究进展[J]. 中国塑料, 2015, 29(8): 25-31.ZHANG Yang, ZHANG Jing, JIANG Wenzhao, et al. Research development of fully biodegrade poly(lactic acid)/plant fiber composites[J]. China Plastics, 2015, 29(8): 25-31(in Chinese). [5] KOST B, BASKO M, BEDNAREK M, et al. The influence of the functional end groups on the properties of polylactide-based materials[J]. Progress in Polymer Science, 2022, 130: 101556. [6] WU H, WEI X H, LIU Y C, et al. Dynamic degradation patterns of porous polycaprolactone/β-tricalcium phosphate composites orchestrate macrophage responses and immunoregulatory bone regeneration[J]. Bioactive Materials, 2023, 21: 595-611. doi: 10.1016/j.bioactmat.2022.07.032 [7] BARLETTA M, AVERSA C, AYYOOB M, et al. Poly(butylene succinate) (PBS): Materials, processing, and industrial applications[J]. Progress in Polymer Science, 2022, 132: 101579. doi: 10.1016/j.progpolymsci.2022.101579 [8] ALI S S, ELSAMAHY T, ABDELKARIM E A, et al. Biowastes for biodegradable bioplastics production and end-of-life scenarios in circular bioeconomy and biorefinery concept[J]. Bioresource Technology, 2022, 363: 127869. doi: 10.1016/j.biortech.2022.127869 [9] 徐冲, 张效林, 丛龙康, 等. 天然纤维增强聚乳酸基可降解复合材料的研究进展[J]. 化工进展, 2017, 36(10): 3751-3756. doi: 10.16085/j.issn.1000-6613.2017-0123XU Chong, ZHANG Xiaolin, CONG Longkang, et al. Progress of natural fiber reinforced polylactic acid biodegradable composites[J]. Chemical Industry and Engineering Progress, 2017, 36(10): 3751-3756(in Chinese). doi: 10.16085/j.issn.1000-6613.2017-0123 [10] LYU S S, GU J Y, TAN H Y, et al. Modification of wood flour/PLA composites by reactive extrusion with maleic anhydride[J]. Journal of Applied Polymer Science, 2016, 133(15): 43295. [11] YANG Y X, HAURIE L, WEN J H, et al. Effect of oxidized wood flour as functional filler on the mechanical, thermal and flame-retardant properties of polylactide biocomposites[J]. Industrial Crops and Products, 2019, 130: 301-309. doi: 10.1016/j.indcrop.2018.12.090 [12] 中国石油和化学工业联合会. 塑料 拉伸性能的测定 第1部分总则: GB/T 1040.1—2018[S]. 北京: 中国标准出版社, 2018.China Petroleum and Chemical Industry Federation. Plastics—Determination of tensile properties—Part 1: General: GB/T 1040.1—2018[S]. Beijing: China Standards Press, 2018(in Chinese). [13] 刘俊劭, 胡家朋, 赵升云, 等. 白杨木粉碱性过氧化氢漂白条件的优化[J]. 生物质化学工程, 2011, 45(2): 25-28. doi: 10.3969/j.issn.1673-5854.2011.02.006LIU Junshao, HU Jiapeng, ZHAO Shengyun, et al. Condition optimization for bleaching poplar wood powder by alkaline peroxide[J]. Biomass Chemical Engineering, 2011, 45(2): 25-28(in Chinese). doi: 10.3969/j.issn.1673-5854.2011.02.006 [14] 余木火, 王昊, 余许多, 等. 干法缠绕用预浸纱制备工艺优化及其性能[J]. 复合材料学报, 2022, 39(12): 5688-5698.YU Muhuo, WANG Hao, YU Xuduo, et al. Preparation process optimization and performance of pre-impregnated yarn for dry winding[J]. Acta Materiae Compositae Sinica, 2022, 39(12): 5688-5698(in Chinese). [15] 赵冰冰, 方艳, 武康, 等. 蓝藻粉-青霉素菌渣/低密度聚乙烯复合材料配方的响应面法优化设计和验证[J]. 复合材料学报, 2020, 37(8): 1894-1903. doi: 10.13801/j.cnki.fhclxb.20191206.001ZHAO Bingbing, FANG Yan, WU Kang, et al. Optimization design and validation of algae powder-penicillin residue/low density polyethylene composites formulation by response surface methodology[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 1894-1903(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191206.001 [16] 孙晓东, 彭亮, 吴义强, 等. 基于响应面优化竹单板泡沫铝复合材料工艺研究[J]. 林产工业, 2021, 58(7): 1-5, 10. doi: 10.19531/j.issn1001-5299.202107001SUN Xiaodong, PENG Liang, WU Yiqiang, et al. Study on process of bamboo veneer foam aluminum composites based on response surface optimization[J]. China Forest Products Industry, 2021, 58(7): 1-5, 10(in Chinese). doi: 10.19531/j.issn1001-5299.202107001 [17] RAYUNG M, IBRAHIM N A, ZAINUDDIN N, et al. The effect of fiber bleaching treatment on the properties of poly(lactic acid)/oil palm empty fruit bunch fiber composites[J]. International Journal of Molecular Sciences, 2014, 15(8): 14728-14742. doi: 10.3390/ijms150814728 [18] RAZAK N I A, IBRAHIM N A, ZAINUDDIN N, et al. The influence of chemical surface modification of kenaf fiber using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly(lactic acid) composites[J]. Molecules, 2014, 19(3): 2957-2968. doi: 10.3390/molecules19032957 [19] THEN Y Y, IBRAHIM N A, ZAINUDDIN N, et al. Static mechanical, interfacial, and water absorption behaviors of alkali treated oil palm mesocarp fiber reinforced poly (butylene succinate) biocomposites[J]. BioResources, 2014: 10(1), 123-136. [20] 裴继诚. 植物纤维化学[M]. 北京: 中国轻工业出版社, 2012: 229-233.PEI Jicheng. Plant fiber chemistry[M]. Beijing: China Light Industry Press, 2012: 229-233(in Chinese). [21] JUBINVILLE D, TZOGANAKIS C, MEKONNEN T H. Recycled PLA-wood flour based biocomposites: Effect of wood flour surface modification, PLA recycling, and maleation[J]. Construction and Building Materials, 2022, 352: 129026. doi: 10.1016/j.conbuildmat.2022.129026 [22] ZHANG X Z, ZHANG Y. Reinforcement effect of poly(butylene succinate) (PBS)-grafted cellulose nanocrystal on toughened PBS/polylactic acid blends[J]. Carbohydrate Polymers, 2016, 140: 374-382. doi: 10.1016/j.carbpol.2015.12.073 -

下载:

下载: