Research progress of glue-free fiberboard based on straw

-

摘要: 无胶秸秆基纤维板是生物质复合材料,具有无毒、可降解、可回收和可再生等特点。因其不消耗石油资源,有利于可持续发展,可替代部分木材应用于地板、建筑材料、家具、室内装修等领域。但对其制板机制及工艺的研究较欠缺,导致市场份额占比仍较低。本文综述了无胶秸秆基纤维板的自粘结机制和应用现状,分析了近年来无胶秸秆基纤维板的工艺进展,着重从纤维的预处理、纤维尺寸、工艺参数(压制时间、压力和温度)对无胶秸秆基纤维板性能的影响进行了系统综述,并对未来无胶秸秆纤维板的优化设计、大规模生产及推广应用进行了展望。Abstract: Glue-free straw-based fiberboard is a biomass composite material, which is nontoxic, degradable, recyclable and renewable. As it does not consume petroleum resources, it is conducive to sustainable development, and can replace some wood used in fields such as flooring, building materials, furniture and interior decoration. However, there is a lack of research on its board making mechanism and process, resulting in a still low market share. In this paper, the self-bonding mechanism and application status of glue-free straw-based fiberboard are summarized. The technological progress of glueless straw-based fiberboard in recent years is introduced. The effects of fiber pretreatment, fiber size and process parameters (such as pressing time, pressure and temperature) on the performances of glueless straw-based fiberboard are systematically discussed. The future prospect of glueless straw-based fiberboard in optimal design, industrial production and promotion on a large scale are put forward.

-

表 1 秸秆类型及预处理方法对无胶秸秆纤维板性能的影响

Table 1. Effects of different raw materials and different pretreatments on the properties of glue-free straw fiberboard

Raw materials Pretreatment classification Pre-processing methods Changes in board performance Ref. Corn straw Chemical pretreatment Alkaline treatment with 2% NaOH solution MOR increased by 75.6%, MOE increased by 101.4%, IB increased by 75%, and TS decreased by 22% compared to no pretreatment [16] Rice straw NaOH solution alkali treatment The highest IB value of hot pressed straw board was obtained when the mass fraction of 1wt%NaOH pretreated straw fiber, and the mechanical properties of the board were poor when the NaOH content was greater than 1wt% [28] Oxalic acid (OA) treatment Compared with steam treatment, MOE and MOR were reduced by 9.9% and 8.6% respectively, and the mechanical properties of the board met ANSI standards [31] Bis-(3-triethoxysilylpropyl) tetra sulphide (Si-69) pre-cured With the increase of Si-69 concentration, both MOR and MOE of fiberboard tended to increase, and TS and WA decreased sharply [32] Wheat

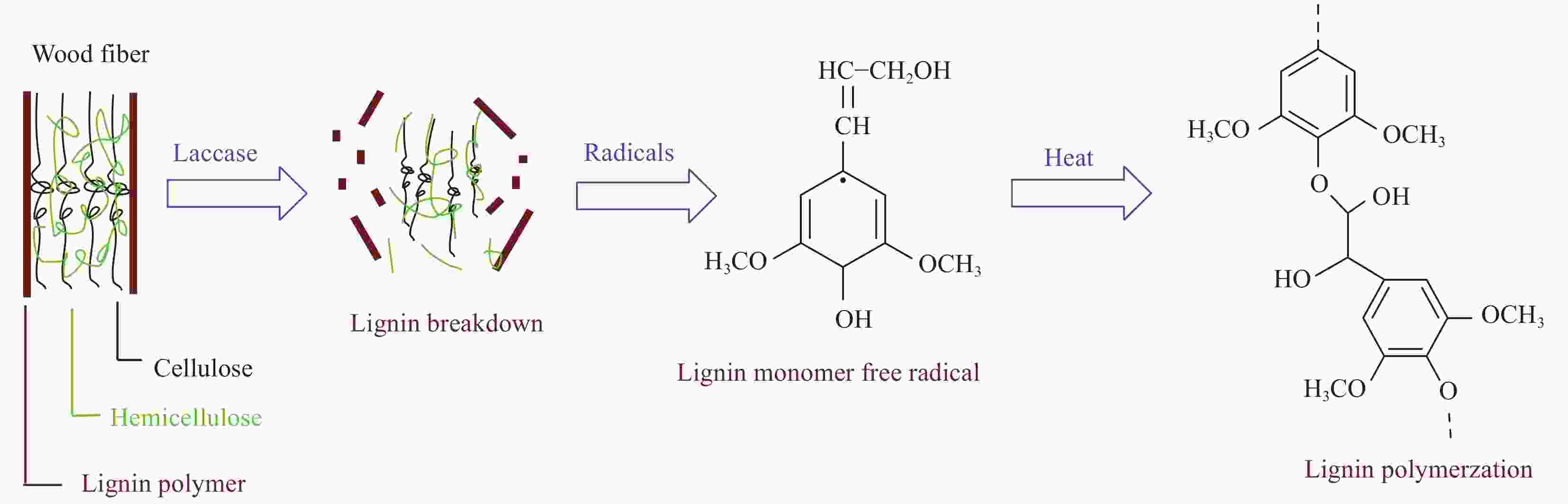

strawTreatment with 10% H2SO4 followed by 4% H2O2 H2SO4 loosened the physical structure of straw, H2O2 reacted with the fiber surface and activated the fiber surface to make it self-bonding, which improved the mechanical properties of fiberboard [33] Triticale straw Bleaching with sodium hypochlorite after treatment with sodium hydroxide pulping Significantly lower hemicellulose content and enhanced board mechanical properties [34] Winter wheat hulls 2% NaOH solution treatment The lignin content and equilibrium moisture content increased, the thickness expansion of the slab after pretreatment increased, and the mechanical properties of the board decreased [35] Jute straw Alkali (NaOH) and alkali, silane The crystallinity index of jute fibers treated with alkali silane was lower than that of alkali-treated jute fibers [36] Rice straw Physical pretreatment Steaming and hot grinding Compared with OA treatment, the MOE and MOR of the board increased by 6.0% and 13.9% respectively, and the mechanical properties of the board were better than untreated [37] Giant reed straw Steam blasting pretreatment The best IB, MOE, MOR, WA and TS were 1.28 MPa, 7439 MPa, 40.4 MPa, 17.6% and 13.3%, respectively, and the fiberboards exceeded the requirements of the relevant standard specifications [38] Sugarcane straw Compared to the NaOH pretreated material, the steam-exploded material had high tensile strength and high water resistance [39] Winter wheat hulls Heat treatment (boiling water) and plasma treatment Both can improve the surface energy of the shell, reduce the equilibrium moisture content of the shell, and improve the mechanical properties of the sheet [35] Coriander straw Steam treatment and mechanical refining of twin-screw extruders The material had good properties with a MOR of 29 MPa and a TS of 24%, and the water sensitivity of the plate had been reduced by 63% [40] Rape straw Steam treatment The tensile strength and modulus of elasticity of the fiberboard both increased significantly with the increase in cooking temperature, and at a cooking temperature of 200℃, the tensile strength was 0.014 MPa, the modulus of elasticity was 0.442 MPa, and the TS was 3.4% [41] Wheat straw Enzymatic pretreatment Enzyme treatment The mechanical properties of enzyme-treated fiberboard were significantly higher than those of non-enzyme-treated semi-chemical pulp fiberboard, and had excellent bond strength [3] Laccase pretreatment Activation of the fiber surface, increase in the number of chemical bonding points between the fibers, increase in the mechanical properties of the board with longer incubation time of laccase [24, 15] Notes: MOR—Modulus of rupture; MOE—Modulus of elasticity; IB—Internal bonding; TS—Thickness swelling; WA—Water absorption; ANSI—American National Standards Institute. 表 2 热压工艺对比

Table 2. Comparison of hot pressing process

Hot pressing process Advantages and disadvantages Application Ref. Continuous flat pressing method Small thickness error, no sanding, small trimming loss, advanced technology, but large equipment and high primary cost Preparation for reed straw fiber particle board [53] Roller press method Economical, with good mechanical properties and water resistance, but only boards up to 1 cm thick can be prepared High-performance wood scrimber prepared by a roller-pressing impregnation method [54] Multi-layer press flat pressing method Suitable for the preparation of medium-thick plates, but the thickness error is large and the sanding area is large Bonded bamboo panels [55] -

[1] 付敏, 陈效庆, 高泽飞, 等. 秸秆粉体利用技术及秸秆微粉碎研究现状与展望[J]. 中国农机化学报, 2023, 44(7): 91-100.FU Min, CHEN Xiaoqing, GAO Zefei, et al. Current status and prospect of straw powder utilization technology and straw microcrushing research[J]. Chinese Journal of Agricultural Mechanical Chemistry, 2023, 44(7): 91-100(in Chinese). [2] FERRÁNDEZ-GARCÍA A, FERRÁNDEZ-VILLENA M, FERRÁNDEZ-GARCÍA C E, et al. Potential use of Phoenix canariensis biomass in binderless particleboards at low temperature and pressure[J]. BioResources, 2017, 12(3): 6698-6712. [3] DOMÍNGUEZ-ROBLES J, TARRES Q, ALCALA M, et al. Development of high-performance binderless fiberboards from wheat straw residue[J]. Construction and Building Materials, 2020, 232: 117247. doi: 10.1016/j.conbuildmat.2019.117247 [4] DUKARSKA D, CZARNECKI R, DZIURKA D, et al. Construction particleboards made from rapeseed straw glued with hybrid pMDI/PF resin[J]. European Journal of Wood and Wood Products, 2017, 75: 175-184. doi: 10.1007/s00107-016-1143-x [5] European Committee for Standardization. Particleboards-speciications: EN 312[S]. Brussels: CEN, 2005.European Committee for Standardization. Particleboards-speciications: EN 312[S]. Brussels: CEN, 2005. [6] MOSLEMI A, KOOHI M Z, BEHZAD T, et al. Addition of cellulose nanofibers extracted from rice straw to urea formaldehyde resin: Effect on the adhesive characteristics and medium density fiberboard properties[J]. International Journal of Adhesion and Adhesives, 2020, 99: 102582. doi: 10.1016/j.ijadhadh.2020.102582 [7] 玄夕娟. 蓖麻秆制造中密度纤维板的研究[D]. 南京: 南京林业大学, 2012.XUAN Xijuan. Research on the manufacture of medium density fiberboard from castor straw[D]. Nanjing: Nanjing Forestry University, 2012(in Chinese). [8] 全国人造板标准化技术委员会. 中密度纤维板: GB/T 11718—2009[S]. 北京: 中国标准出版社, 2009.National Technical Committee for the Standardization of Manufactured Boards. Medium density fibreboard: GB/T 11718—2009[S]. Beijing: China Standard Press, 2009(in Chinese). [9] DUŠEK J, JERMAN M, PODLENA M, et al. Sustainable composite material based on surface-modified rape straw and environment-friendly adhesive[J]. Construction and Building Materials, 2021, 300: 124036. doi: 10.1016/j.conbuildmat.2021.124036 [10] JI X, LI B, YUAN B, et al. Preparation and characterizations of a chitosan-based medium-density fiberboard adhesive with high bonding strength and water resistance[J]. Carbohydrate Polymers, 2017, 176: 273-280. doi: 10.1016/j.carbpol.2017.08.100 [11] 温平威. 零甲醛大豆蛋白胶粘剂粘合的稻草纤维板研制[D]. 南昌: 南昌大学, 2012.WEN Pingwei. Development of rice straw fiberboard bonded with zero formaldehyde soy protein adhesive[D]. Nanchang: Nanchang University, 2012(in Chinese). [12] 全国人造板标准化技术委员会. 麦(稻)秸秆刨花板: GB/T 21723—2008[S]. 北京: 中国标准出版社, 2008.National Technical Committee for the Standardization of Artificial Boards. Wheat (rice) straw particleboard: GB/T 21723—2008[S]. Beijing: China Standard Press, 2008(in Chinese). [13] NASIR M, KHALI D P, JAWAID M, et al. Recent development in binderless fiber-board fabrication from agricultural residues: A review[J]. Construction and Building Materials, 2019, 211: 502-516. doi: 10.1016/j.conbuildmat.2019.03.279 [14] TUPCIAUSKAS R, RIZHIKOVS J, BRAZDAUSKS P, et al. Influence of steam explosion pre-treatment conditions on binder-less boards from hemp shives and wheat straw[J]. Industrial Crops and Products, 2021, 170: 113717. doi: 10.1016/j.indcrop.2021.113717 [15] YANG Z, SONG W, CAO Y, et al. The effect of laccase pretreatment conditions on the mechanical properties of binderless fiberboards with wheat straw[J]. BioResources, 2017, 12(2): 3707-3719. [16] 肖力光, 丁艳波. 秸秆碱活化预处理对秸秆板性能影响的研究[J]. 新型建筑材料, 2021, 48(6): 124-126, 135. doi: 10.3969/j.issn.1001-702X.2021.06.026XIAO Liguang, DING Yanbo. Research on the effect of alkaline activation pretreatment of straw on the performance of straw board[J]. New Building Materials, 2021, 48(6): 124-126, 135(in Chinese). doi: 10.3969/j.issn.1001-702X.2021.06.026 [17] WANG J, WANG B, LIU J, et al. Effect of hot-pressing temperature on characteristics of straw-based binderless fiberboards with pulping effluent[J]. Materials (Basel), 2019, 12(6): 922. doi: 10.3390/ma12060922 [18] PINTIAUX T, VIET D, VANDENBOSSCHE V, et al. Binderless materials obtained by thermo-compressive processing of lignocellulosic fibers: A comprehensive review[J]. BioResources, 2015, 10(1): 1915-1963. doi: 10.15376/biores.10.1.1915-1963 [19] WANG B, LI D L, CHEN T Y, et al. Understanding the mechanism of self-bonding of bamboo binderless boards: Investigating the structural changes of lignin macromolecule during the molding pressing process[J]. BioResources, 2017, 12(1): 514-532. [20] 黄莉莉. 农作物秸秆板材的制备及其自胶合机理的研究[D]. 合肥: 安徽农业大学, 2016.HUANG Lili. Preparation of crop straw panels and study of its self-gluing mechanism[D]. Hefei: Anhui Agricultural University, 2016(in Chinese). [21] JIANG B, CHEN C, LIANG Z, et al. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement[J]. Advanced Functional Materials, 2020, 30(4): 1906307. doi: 10.1002/adfm.201906307 [22] ARÉVALO R, PEIJS T. Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres[J]. Composites Part A: Applied Science and Manufacturing, 2016, 83: 38-46. doi: 10.1016/j.compositesa.2015.11.027 [23] GE S, MA N L, JIANG S, et al. Processed bamboo as a novel formaldehyde-free high-performance furniture biocomposite[J]. ACS Applied Materials & Interfaces, 2020, 12(27): 30824-30832. [24] ZHU X, HAN S, LIU Y, et al. Effects of laccase incubated from white rot fungi on the mechanical properties of fiberboard[J]. Journal of Forestry Research, 2017, 28(6): 1293-1300. doi: 10.1007/s11676-017-0398-3 [25] FERRANDEZ-VILLENA M, FERRANDEZ-GARCIA C E, GARCIA-ORTUNO T, et al. The influence of processing and particle size on binderless particleboards made from Arundodonax L. rhizome[J]. Polymers (Basel), 2020, 12(3): 696. doi: 10.3390/polym12030696 [26] MAHIEU A, ALIX S, LEBLANC N. Properties of particleboards made of agricultural by-products with a classical binder or self-bound[J]. Industrial Crops and Products, 2019, 130: 371-379. doi: 10.1016/j.indcrop.2018.12.094 [27] SALA C M, ROBLES E, KOWALUK G. Influence of adding offcuts and trims with a recycling approach on the properties of high-density fibrous composites[J]. Polymers (Basel), 2020, 12(6): 1327. doi: 10.3390/polym12061327 [28] ZHANG W, SUN H, ZHU C, et al. Mechanical and water-resistant properties of rice straw fiberboard bonded with chemically-modified soy protein adhesive[J]. RSC Advances, 2018, 8(27): 15188-15195. doi: 10.1039/C7RA12875D [29] DOMÍNGUEZ-ROBLES J, TARRES Q, DELGADO-AGUILAR M, et al. Approaching a new generation of fiberboards tang advantage of self lignin as green adhesive[J]. International Journal of Biological Macromolecules, 2018, 108: 927-935. doi: 10.1016/j.ijbiomac.2017.11.005 [30] ALHARBI M A H, HIRAI S, TUAN H A, et al. Effects of chemical composition, mild alkaline pretreatment and particle size on mechanical, thermal, and structural properties of binderlesslignocellulosic biopolymers prepared by hot-pressing raw microfibrillated Phoenix dactylifera and Cocosnucifera fibers and leaves[J]. Polymer Testing, 2020, 84: 106384. doi: 10.1016/j.polymertesting.2020.106384 [31] LI X, WU Y, CAI Z, et al. Primary properties of MDF using thermomechanical pulp made from oxalic acid pretreated rice straw particles[J]. Industrial Crops and Products, 2013, 41: 414-418. doi: 10.1016/j.indcrop.2012.04.039 [32] RADABUTRA S, KHEMTHONG P, SAENGSUWAN S. Effect of silane coupling agent pretreatment on the properties of rice straw particleboard bonded with prevulcanized natural rubber latex[J]. Journal of Rubber Research, 2021, 24: 157-163. doi: 10.1007/s42464-021-00081-z [33] HALVARSSON S, EDLUND H, NORGREN M. Manufacture of non-resin wheat straw fibreboards[J]. Industrial Crops and Products, 2009, 29(2-3): 437-445. [34] TARRES Q, EHMAN N V, VALLEJOS M E, et al. Lignocellulosic nanofibers from triticale straw: The influence of hemicelluloses and lignin in their production and properties[J]. Carbohydrate Polymers, 2017, 163: 20-27. doi: 10.1016/j.carbpol.2017.01.017 [35] HYSEK Š, PODLENA M, BARTSCH H, et al. Effect of wheat husk surface pre-treatment on the properties of husk-based composite materials[J]. Industrial Crops and Products, 2018, 125: 105-113. doi: 10.1016/j.indcrop.2018.08.035 [36] ZAFAR M T, MAITI S N, GHOSH A K. Effect of surface treatment of jute fibers on the interfacial adhesion in poly (lactic acid)/jute fiber biocomposites[J]. Fibers and Polymers, 2016, 17 (2): 266-274. doi: 10.1007/s12221-016-5781-8 [37] THENG D, ARBAT G, DELGADO-AGUILAR M, et al. Comparison between two different pretreatment technologies of rice straw fibers prior to fiberboard manufacturing: Twin-screw extrusion and digestion plus defibration[J]. Industrial Crops and Products, 2017, 107: 184-197. doi: 10.1016/j.indcrop.2017.05.049 [38] RAMOS D, El MANSOURI N E, FERRANDO F, et al. All-lignocellulosic fiberboard from steam exploded Arundo donax L[J]. Molecules, 2018, 23(9): 2088. doi: 10.3390/molecules23092088 [39] NGIWNGAM K, CHINVORARAT S, RACHTANAPUN P, et al. Effect of chemical and steam explosion pulping on the physical and mechanical properties of sugarcane straw pulp trays[J]. Polymers, 2023, 15(14): 3132. doi: 10.3390/polym15143132 [40] UITTERHAEGEN E, LABONNE L, MERAH O, et al. Impact of thermomechanical fiber pre-treatment using twin-screw extrusion on the production and properties of renewable binderless coriander fiberboards[J]. International Journal of Molecular Sciences, 2017, 18(7): 1539. [41] JERMAN M, BOHM M, DUSEK J, et al. Effect of steaming temperature on microstructure and mechanical, hygric, and thermal properties of binderless rape straw fiberboards[J]. Building and Environment, 2022, 223: 109474. doi: 10.1016/j.buildenv.2022.109474 [42] CHEN Y, DANG B, JIN C, et al. Processing lignocellulose-based composites into an ultrastrong structural material[J]. ACS Nano, 2019, 13 (1): 371-376. doi: 10.1021/acsnano.8b06409 [43] LI P, ZUO Y F, WU Y Q, et al. Research progress in the manufacture and application of straw-based wood-based panels[J]. Materials Guide, 2019, 33(15): 2624-2630. [44] HAN G, DENG J, ZHANG S, et al. Effect of steam explosion treatment on characteristics of wheat straw[J]. Industrial Crops and Products, 2010, 31(1): 28-33. doi: 10.1016/j.indcrop.2009.08.003 [45] ZHANG B, LI H, CHEN L, et al. Recent advances in the bioconversion of waste straw biomass with steam explosion technique: A comprehensive review[J]. Processes, 2022, 10(10): 1959. doi: 10.3390/pr10101959 [46] YANG Y, SHEN H, QIU J. Bio-inspired self-bonding nanofibrillated cellulose composite: A response surface methodology for optimization of processing variables in binderless biomass materials produced from wheat-straw-lignocelluloses[J]. Industrial Crops and Products, 2020, 149: 112335. doi: 10.1016/j.indcrop.2020.112335 [47] ALVAREZ C, ROJANO B, ALMAZA O, et al. Self-bonding boards from plantain fiber bundles after enzymatic treatment: Adhesion improvement of lignocellulosic products by enzymatic pre-treatment[J]. Journal of Polymers and the Environment, 2011, 19: 182-188. doi: 10.1007/s10924-010-0260-6 [48] 赵美云, 蒋婧. 纸质秸秆复合纤维板热压成型工艺研究[J]. 长春工程学院学报(自然科学版), 2020, 21(4): 23-26.ZHAO Meiyun, JIANG Jing. Research on hot pressing forming process of paper straw composite fiberboard[J]. Journal of Changchun College of Engineering (Natural Science Edition), 2020, 21(4): 23-26(in Chinese). [49] ESPINOSA E, TARRES Q, THENG D, et al. Effect of enzymatic treatment (endo-glucanases) of fiber and mechanical lignocellulose nanofibers addition on physical and mechanical properties of binderless high-density fiberboards made from wheat straw[J]. Journal of Building Engineering, 2021, 44: 103392. doi: 10.1016/j.jobe.2021.103392 [50] 张燕. 我国农作物秸秆板产业化发展的动因及模式研究[D]. 南京: 南京林业大学, 2011.ZHANG Yan. Research on the motivation and mode of industrialization of crop strawboard in China[D]. Nanjing: Nanjing Forestry University, 2011(in Chinese). [51] FAHMY T, MOBARAK F. Advanced binderless board-like green nanocomposites from undebarked cotton stalks and mechanism of self-bonding[J]. Cellulose, 2013, 20(3): 1453-1457. doi: 10.1007/s10570-013-9911-9 [52] EVON P, BARTHOD-MALAT B, GRÉGOIRE M, et al. Production of fiberboards from shives collected after continuous fiber mechanical extraction from oleaginous flax[J]. Journal of Natural Fibers, 2019, 16(3): 453-469. [53] NIU Q, JI L, LI Y J, et al. Preparation method for reed fiber particle board: CN, 104227819A[P]. 2014-12-24. [54] GAO Q, LIN Q, HUANG Y, et al. High-performance wood scrimber prepared by a roller-pressing impregnation method[J]. Construction and Building Materials, 2023, 368: 130404. doi: 10.1016/j.conbuildmat.2023.130404 [55] YU L H, LIU D, CHEN L H. Multi-layer hot-press device for gluing bamboo boards: CN, 201755859U[P]. 2010-08-05. [56] EL-KASSAS A M, ELSHEIKH A H. A new eco-friendly mechanical technique for production of rice straw fibers for medium density fiberboards manufacturing[J]. International Journal of Environmental Science and Technology, 2021, 18(4): 979-988. [57] Turkish Standards Institute Ankara. Fiberboards-specifications—Part 5: Requirements for dry process boards (MDF): EN 622[S]. Turkey: Turkish Standards Institute Ankara, 2008.Turkish Standards Institute Ankara. Fiberboards-specifications—Part 5: Requirements for dry process boards (MDF): EN 622[S]. Turkey: Turkish Standards Institute Ankara, 2008. [58] European Committee for Standardization. Particleboards and iberboards. Determination of swelling in thickness after immersion in water: EN 317[S]. Brussels: CEN, 1993.European Committee for Standardization. Particleboards and iberboards. Determination of swelling in thickness after immersion in water: EN 317[S]. Brussels: CEN, 1993. [59] European Committee for Standardization. Wood based panels. Determination of modulus of elasticity in bending and of bending strength: EN 310[S]. Brussels: CEN, 1993.European Committee for Standardization. Wood based panels. Determination of modulus of elasticity in bending and of bending strength: EN 310[S]. Brussels: CEN, 1993. [60] KUROKOCHI Y, SATO M. Properties of binderless board made from rice straw: The morphological effect of particles[J]. Industrial Crops & Products, 2015, 69: 55-59. [61] REBOLLEDO P, CLOUTIER A, YEMELEM C. Effect of density and fiber size on porosity and thermal conductivity of fiberboard mats[J]. Fibers, 2018, 6(4): 81. doi: 10.3390/fib6040081 [62] SONG X, WANG X, KITO K. Effects of heating temperature on the properties of bio-board manufactured by using soybean straw[J]. Materials (Basel), 2020, 13(3): 662. doi: 10.3390/ma13030662 [63] YUE X, HUANG L, HUANG L, et al. A sustainable strategy for medium-density fiberboards preparation from waste hybrid pennisetum straws[J]. Waste and Biomass Valorization, 2021, 12(6): 1-13. [64] SIHAG K, YADAV S M, LUBIS M A R, et al. Influence of needle-punching treatment and pressure on selected properties of medium density fiberboard made of bamboo (Dendrocalamus strictus Roxb. Nees)[J]. Wood Material Science & Engineering, 2022, 17(6): 712-719. [65] SAARI N, LAMAMING J, HASHIM R, et al. Optimization of binderless compressed veneer panel manufacturing process from oil palm trunk using response surface methodology[J]. Journal of Cleaner Production, 2020, 265: 121757. doi: 10.1016/j.jclepro.2020.121757 [66] 吴婷婷, 王秀仑, 姚天曙. 玉米秸秆生物质板材加工工艺研究[J]. 信息系统工程, 2011(2): 98-100. doi: 10.3969/j.issn.1001-2362.2011.02.036WU Tingting, WANG Xiulun, YAO Tianshu. Research on processing process of corn straw biomass panels[J]. Information Systems Engineering, 2011(2): 98-100(in Chinese). doi: 10.3969/j.issn.1001-2362.2011.02.036 [67] ZHOU X, ZHENG F, LI H, et al. An environment-friendly thermal insulation material from cotton stalk fibers[J]. Energy and Buildings, 2010, 42(7): 1070-1074. doi: 10.1016/j.enbuild.2010.01.020 [68] THENG D, ARBAT G, DELGADO-AGUILAR M, et al. Production of fiberboard from rice straw thermomechanical extrudates by thermopressing: influence of fiber morphology, water and lignin content[J]. European Journal of Wood and Wood Products, 2019, 77: 15-32. doi: 10.1007/s00107-018-1358-0 [69] ZHANG K, LIU Y, GUO Z, et al. Co-modification of corn straw lignin and its enhancement on glue-free fiberboard based on freezing activated wood fibers[J]. Industrial Crops and Products, 2022, 177: 114452. doi: 10.1016/j.indcrop.2021.114452 [70] KUROKOCHI Y, SATO M. Effect of surface structure, wax and silica on the properties of binderless board made from rice straw[J]. Industrial Crops and Products, 2015, 77: 949-953. doi: 10.1016/j.indcrop.2015.10.007 [71] Japanese Standard Association. Particleboards: JIS A5908—2003[S]. Tokyo: Japanese Standards Association, 2003.Japanese Standard Association. Particleboards: JIS A5908—2003[S]. Tokyo: Japanese Standards Association, 2003. [72] Japanese Standard Association. Fiberboards: JIS A5905—2014[S]. Tokyo: Japanese Standards Association, 2014.Japanese Standard Association. Fiberboards: JIS A5905—2014[S]. Tokyo: Japanese Standards Association, 2014. [73] ALI M, ALABDULKAREM A, NUHAIT A, et al. Characteristics of agro waste fibers as new thermal insulation and sound absorbing materials: Hybrid of date palm tree leaves and wheat straw fibers[J]. Journal of Natural Fibers, 2022, 19(13): 6576-6594. doi: 10.1080/15440478.2021.1929647 [74] ZHANG S. Study on the preparation process of rice straw fiberboard for packaging[J]. IOP Conference Series Earth and Environmental Science, 2019, 233: 052031. doi: 10.1088/1755-1315/233/5/052031 [75] LUTHFI N, WANG X, KITO K, et al. Effect of drying temperature on the mechanical properties of binderless fiberboard from bagasse: Study of flexural and tensile strength[J]. JIIF (Jurnal Ilmu dan Inovasi Fisika), 2020, 4(2): 86-94. doi: 10.24198/jiif.v4i2.28412 [76] VITRONE F, RAMOS D, VITAGLIANO V, et al. All-lignocellulosic fiberboards from giant reed (Arundo donax L): Effect of steam explosion pre-treatment on physical and mechanical properties[J]. Construction and Building Materials, 2022, 319: 126064. doi: 10.1016/j.conbuildmat.2021.126064 -

下载:

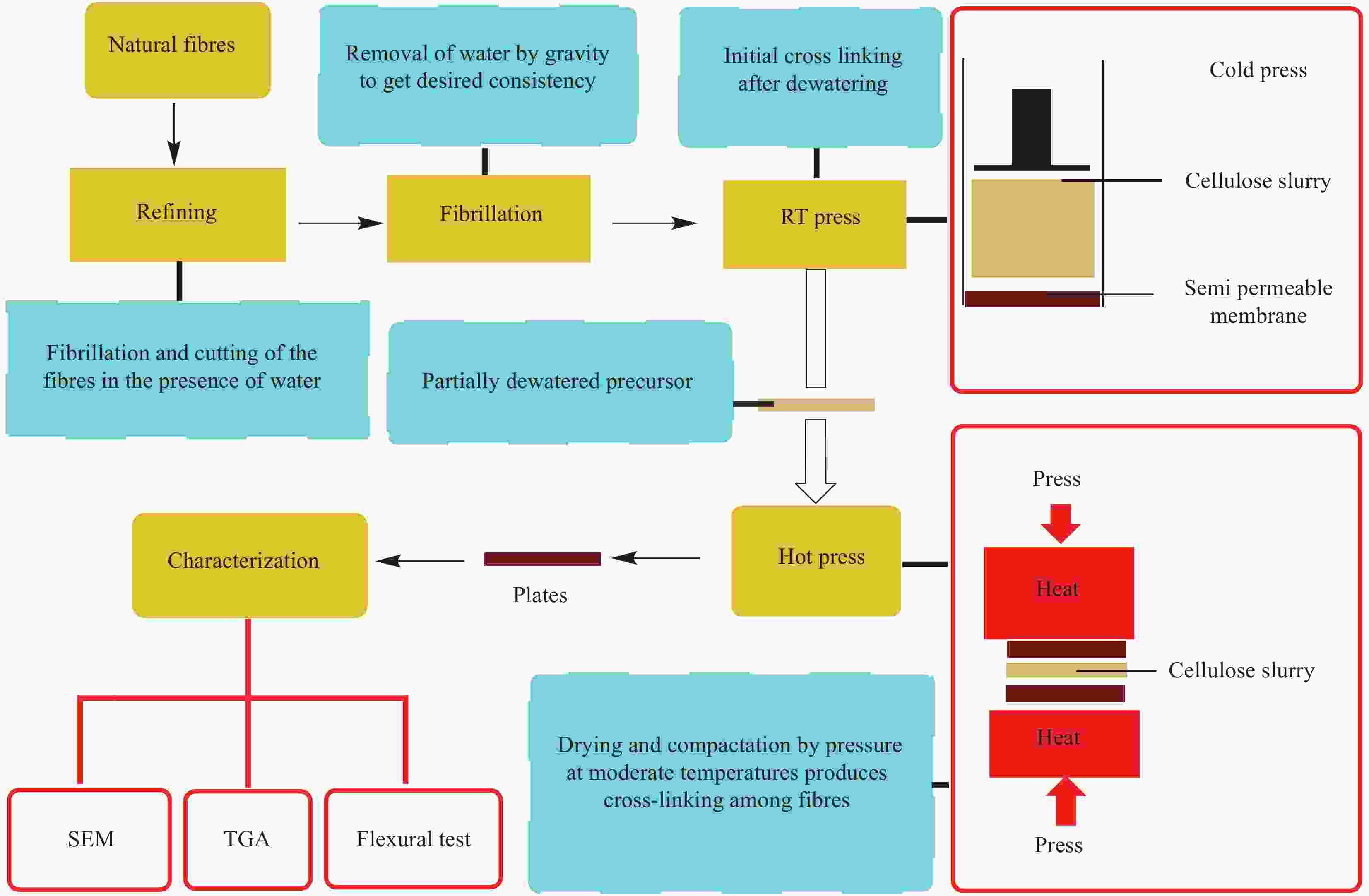

下载: