Process effects of long glass fiber reinforced polypropylene fluid assisted injection molding pipes

-

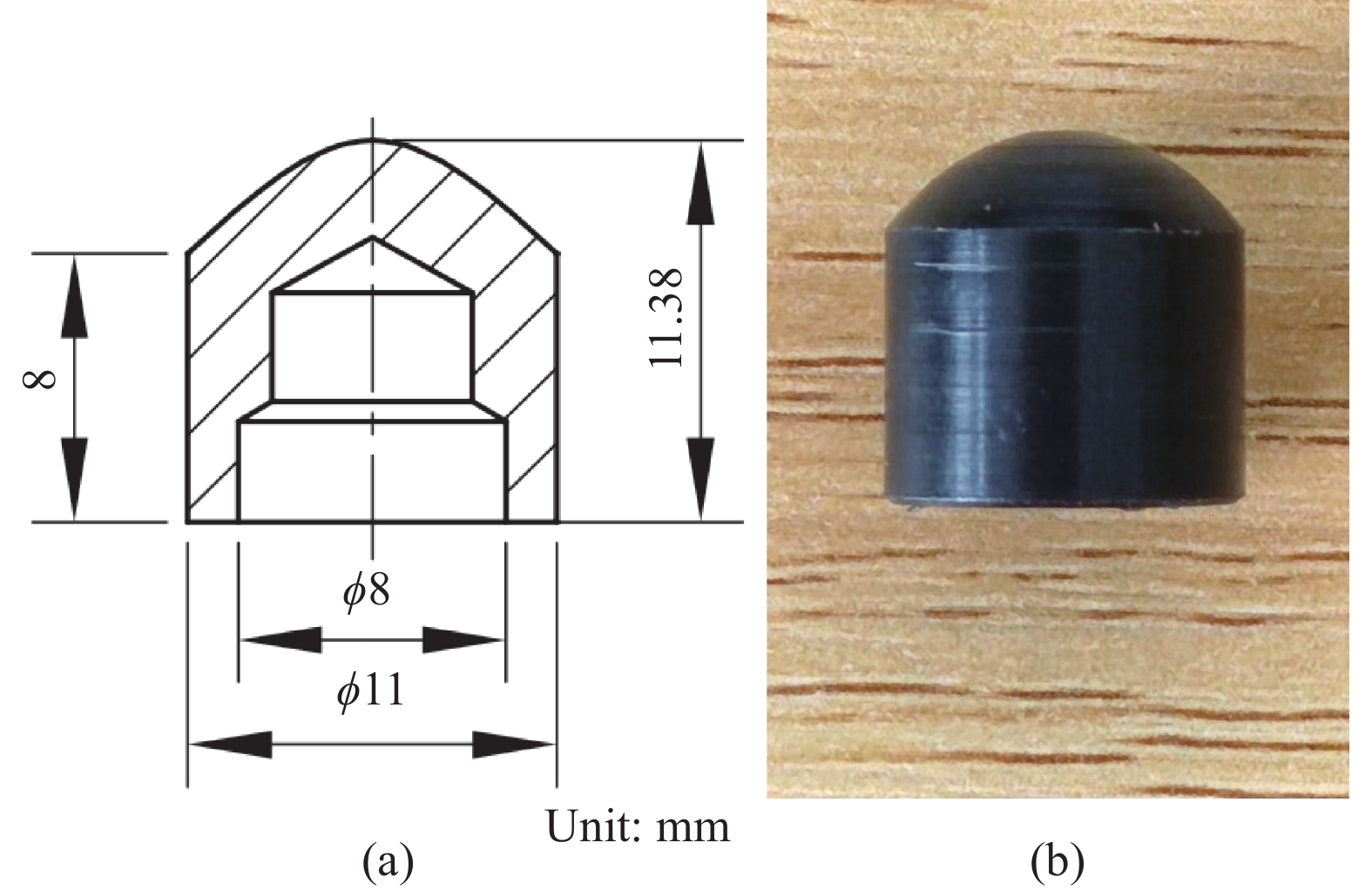

摘要: 采用气体辅助注塑工艺(GAIM)、气体驱动弹头辅助注塑工艺(G-PAIM)、水辅助注塑工艺(WAIM)和水驱动弹头辅助注塑工艺(W-PAIM)这4种工艺方法成型长玻纤增强聚丙烯(LGFR-PP)流体辅助注塑管件,对比研究各工艺方法对管件壁厚、玻纤断裂长度及玻纤取向的影响。结果表明:W-PAIM工艺管件壁厚最薄且壁厚均匀性最好,GAIM工艺管件壁厚最厚且壁厚均匀性最差;G-PAIM比WAIM管件壁厚均匀性更好,但WAIM管件壁厚更薄;4种工艺方法中玻纤断裂长度呈不均匀分布,平均玻纤断裂长度WAIM>GAIM>W-PAIM>G-PAIM,弹头的引入使玻纤断裂作用加剧,玻纤断裂长度更短;G-PAIM、WAIM和W-PAIM工艺中玻纤沿流动方向取向度由近模壁层到中间层再到近流道层呈现逐渐升高的趋势,GAIM玻纤取向杂乱无章;各工艺管件玻纤取向程度W-PAIM>WAIM>G-PAIM>GAIM。Abstract: The long glass fiber reinforced polypropylene fluid-assisted injection molding pipes were molded by four processes: Gas-assisted injection molding process (GAIM), gas-projectile-assisted injection molding process (G-PAIM), water-assisted injection molding process (WAIM) and water-projectile-assisted injection molding process (W-PAIM). The effects of each process on the wall thickness, glass fiber fracture length and glass fiber orientation of the pipes were compared and studied. The results show that the wall thickness of the W-PAIM process pipes is the thinnest and most uniform, and the wall thickness of the GAIM process pipes is the thickest and most non-uniform. G-PAIM had better wall thickness uniformity than WAIM pipes, but WAIM pipes has thinner wall thicknesses. The glass fiber fracture lengths are unevenly distributed among the four process methods. The average glass fiber fracture length is ranked as WAIM>GAIM>W-PAIM>G-PAIM. The introduction of the projectile intensifies the glass fiber fracture effect, so that the glass fiber fracture length is shorter. In G-PAIM, WAIM and W-PAIM processes, the orientation of glass fibers along the flow direction tends to increase gradually from near the mold wall layer to the middle layer to near the runner layer, and the orientation of GAIM glass fibers is disorganized. The degree of glass fiber orientation of each process pipes is ranked as W-PAIM>WAIM>G-PAIM>GAIM.

-

Key words:

- LGFR-PP /

- FAIM /

- process method /

- glass fiber orientation /

- glass fiber breakage length

-

图 6 4种工艺成型的管件不同位置的壁厚

GAIM—Gas-assisted injection molding process; G-PAIM—Gas-projectile-assisted injection molding process; WAIM—Water-assisted injection molding process; W-PAIM—Water-projectile-assisted injection molding process

Figure 6. Wall thickness at different positions of pipes molded by four processes

表 1 4种工艺方法成型的工艺参数

Table 1. Process parameters of the four process methods of molding

Process parameter Value Melt temperature/℃ 240 Fluid injection delay time/s 4 Melt injection pressure/MPa 7 Fluid injection pressure/MPa 6 Mold temperature/℃ 60 Pressure-holding time/s 10 -

[1] 仇永宏. 长玻纤增强聚丙烯复合材料结构与性能[J]. 石化技术, 2022, 29(6): 1-3. doi: 10.3969/j.issn.1006-0235.2022.06.001QIU Yonghong. Structure and properties of long glass fiber reinforced polypropylene composites[J]. Petrochemical Industry Technology, 2022, 29(6): 1-3(in Chinese). doi: 10.3969/j.issn.1006-0235.2022.06.001 [2] 刘国刚, 马伊, 梁文斌, 等. 长玻纤增强聚丙烯复合材料性能研究[J]. 塑料科技, 2017, 45(10): 25-29. doi: 10.15925/j.cnki.issn1005-3360.2017.10.001LIU Guogang, MA Yi, LIANG Wenbin, et al. Study on properties of long glass fiber reinforced polypropylene composites[J]. Plastics Science and Technology, 2017, 45(10): 25-29(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2017.10.001 [3] 张杨, 张海生, 陈剑锐. 基体树脂与短玻纤对聚丙烯复合材料性能影响研究[J]. 塑料科技, 2022, 50(3): 43-48.ZHANG Yang, ZHANG Haisheng, CHEN Jianrui. Effect of matrix resin and glass fiber on properties of polypropylene composites[J]. Plastics Science and Technology, 2022, 50(3): 43-48(in Chinese). [4] 侯旭秦, 李桂丽, 陈兴元, 等. 长玻纤增强塑料注射成型纤维断裂概述[J]. 高分子材料科学与工程, 2019, 35(5): 179-183.HOU Xuqin, LI Guili, CHEN Xingyuan, et al. Overview of the fracture of long glass fiber reinforced thermoplastics during injection molding[J]. Polymer Materials Science & Engineering, 2019, 35(5): 179-183(in Chinese). [5] TSENG H C, CHANG R Y, HSU C H. Numerical prediction of fiber orientation and mechanical performance for short/long glass and carbon fiber-reinforced composites[J]. Composites Science and Technology, 2017, 144: 51-56. doi: 10.1016/j.compscitech.2017.02.020 [6] ZHANG D H, HE M, LUO H, et al. Performance of long glass fiber-reinforced polypropylene composites at different injection temperature[J]. Journal of Vinyl and Additive Technology, 2018, 24(3): 233-238. doi: 10.1002/vnl.21563 [7] YANG X J, CHANG J Y, FANG W J, et al. Improved impact property of long glass fiber-reinforced polypropylene random copolymer composites toughened with beta-nucleating agent via tunning the crystallization and phase[J]. Polymer Composites, 2021, 42(7): 3169-3183. doi: 10.1002/pc.26047 [8] TSENG H C, CHANG R Y, HSU C H. Numerical predictions of fiber orientation and mechanical properties for injection-molded long-glass-fiber thermoplastic composites[J]. Composites Science and Technology, 2017, 150: 181-186. doi: 10.1016/j.compscitech.2017.07.026 [9] 王波, 黄捷, 杨金明, 等. 长玻纤增强聚丙烯复合材料力学性能的研究[J]. 塑料科技, 2017, 45(10): 35-38. doi: 10.15925/j.cnki.issn1005-3360.2017.10.003WANG Bo, HUANG Jie, YANG Jinming, et al. Study on mechanical properties of long glass fiber reinforced PP composite[J]. Plastics Science and Technology, 2017, 45(10): 35-38(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2017.10.003 [10] 孔小寅. 长玻纤增强聚丙烯复合材料的研究进展[J]. 造纸装备及材料, 2020, 49(3): 52, 72. doi: 10.3969/j.issn.1672-3066.2020.03.075KONG Xiaoyin. Research progress of long glass fiber reinforced polypropylene composites[J]. Papermaking Equipment & Materials, 2020, 49(3): 52, 72(in Chinese). doi: 10.3969/j.issn.1672-3066.2020.03.075 [11] WANG Z Q, WANG X Q, ZHANG J F, et al. Automatic generation of random distribution of fibers in long-fiber-reinforced composites and mesomechanical simulation[J]. Materials & Design, 2011, 32(2): 885-891. [12] CREMA L, SORGATO M, ZANINI F, et al. Experimental analysis of mechanical properties and microstructure of long glass fiber reinforced polypropylene processed by rapid heat cycle injection molding[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 366-373. doi: 10.1016/j.compositesa.2018.01.019 [13] YANG J G, ZHOU X H. Numerical simulation on residual wall thickness of tubes with dimensional transitions and curved sections in water-assisted injection molding[J]. Journal of Applied Polymer Science, 2013, 128(3):1987-1994. [14] SANNEN S, DE MUNCK M, VAN PUYVELDE P, et al. Water penetration behavior in water-assisted injection molding (WAIM): A study of product quality for different process and material parameters[J]. International Polymer Processing, 2012, 27(5): 602-616. [15] SANNEN S, DE KEYZER J, VAN PUYVELDE P. The influence of melt and process parameters on the quality and occurrence of part defects in water-assisted injection molded tubes[J]. International Polymer Processing Journal of the Polymer Processing Society, 2011, 26(5): 551-559. doi: 10.3139/217.2490 [16] KUANG T Q, FENG Q, LIU T, et al. Numerical simulation on the penetration behavior of the projectile during the water injection stage of water-projectile-assisted injection molding process[J]. Advances in Polymer Technology, 2020, 2020(9): 1-15. [17] KUANG T Q, LIU T, FENG Q, et al. Fluid-powered projectile-assisted injection molding: Principles and developments[J]. International Polymer Processing, 2020, 35(1): 2-15. doi: 10.3139/217.3882 [18] HOPMANN C, RECHT U. Manufacturing of fibre-reinforced, elastomeric parts using the injection moulding process [C]//Society of Plastics Engineering Technical Conference. Florida: Institute of Plastics Processing at RWTH Aachen University (IKV), 2015: 1728-1732. [19] ISAO I. Manufacture of hollow body: JP Patent, H04208425[P]. 1992-07-30. [20] OLIVEIRA D, MATEUS A, CARREIRA P, et al. Water assisted injection molding for single and multi-branched tubular components[J]. Procedia Manufacturing, 2017, 12: 141-149. doi: 10.1016/j.promfg.2017.08.018 [21] HOPMANN C, WIESEL C, DRACH M, et al. Material selection for projectile injection technology in the elastomer injection moulding process[J]. KGK Kautschuk Gummi Kunststoffe, 2022, 75(2): 45-51. [22] 丁加新, 陈英龙, 周华. 水辅成型浮动芯注射对制品残余壁厚的影响[J]. 浙江大学学报(工学版), 2017, 51(5): 937-945. doi: 10.3785/j.issn.1008-973X.2017.05.013DING Jiaxin, CHEN Yinglong, ZHOU Hua. Effect on residual wall thickness of parts with floating core injection of water assisted injection molding[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(5): 937-945(in Chinese). doi: 10.3785/j.issn.1008-973X.2017.05.013 [23] KUANG T Q, PAN J Y, FENG Q, et al. Residual wall thickness of water-powered projectile-assisted injection molding pipes[J]. Polymer Engineering & Science, 2019, 59(2): 295-303. [24] 张增猛, 周华, 高院安, 等. 水辅助注射成型充模流动的仿真与分析[J]. 机械工程学报, 2010, 46(8): 140-146. doi: 10.3901/JME.2010.08.140ZHANG Zengmeng, ZHOU Hua, GAO Yuan'an, et al. Simulation analysis on cavity filling process in water-assisted injection molding[J]. Journal of Mechanical Engineering, 2010, 46(8): 140-146(in Chinese). doi: 10.3901/JME.2010.08.140 [25] 胡礼彬. 水驱动弹头辅助共注塑工艺相间穿透的数值模拟研究 [D]. 南昌: 华东交通大学, 2022.HU Libin. Numerical simulation of interphase penetration in water projectile assisted co-injection molding process[D]. Nanchang: East China Jiaotong University, 2022(in Chinese). [26] 钟罗浩, 匡唐清, 赖家美, 等. 成型工艺对短玻璃纤维增强聚丙烯注塑管件的壁厚分布及玻璃纤维取向的影响[J]. 中国塑料, 2021, 35(5): 11-16. doi: 10.19491/j.issn.1001-9278.2021.05.003ZHONG Luohao, KUANG Tangqing, LAI Jiamei, et al. Effect of molding process on wall residual thickness distribution and glass-fiber orientation of short-glass-fiber-reinforced polypropylene molded pipes[J]. China Plastics, 2021, 35(5): 11-16(in Chinese). doi: 10.19491/j.issn.1001-9278.2021.05.003 -

下载:

下载: