Preparation of SiO2-coated monostearate/polyvinyl blended membrane and thereof long-lasting anti-fog performance

-

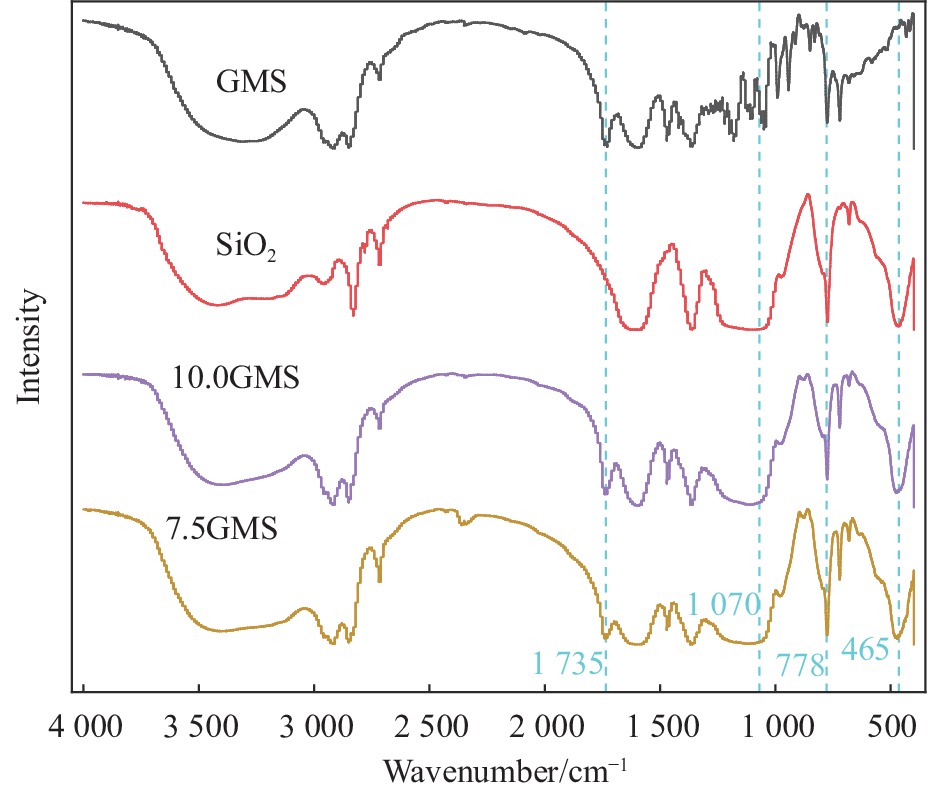

摘要: 防雾薄膜包装可以降低包装内的水分活度,减少果蔬腐败变质产生的大量浪费,因此具有十分重要的研究意义。本文以SiO2为壁材,采用乳液聚合法对单硬脂酸甘油酯(GMS)芯材进行包覆,并将其与线型低密度聚乙烯(LLDPE)混合,制备出了一种长效防雾薄膜。结果表明:通过FTIR和XRD对制备样品进行了化学成分、晶型结构分析,证明了GMS被成功包覆;通过SEM对样品的微观形貌和防雾膜截面微观结构进行分析,所制备的GMS@SiO2为类球形,在薄膜中分散较好;粒径、DSC测试表明,GMS和正硅酸四乙酯(TEOS)使用量在1∶2条件下制备的GMS@SiO2样品的粒径均一性较好,83.05%集中在20~100 nm,且有着最高的包覆率,为69.9%;N2吸附-脱附结果显示:GMS@SiO2表面存在许多的介孔结构,孔径为17.918 nm,可以有效延缓GMS的释放;通过TG对样品的热性能进行分析,发现SiO2壁材对GMS起到了较好的保护作用,GMS的最大损失温度由298℃提高到了405℃,提升了约107℃;通过热防雾测试发现,所制备的薄膜可有效延长薄膜的防雾时间且防雾性能优越,在1~11 h内,薄膜防雾等级为DE级;11~60 h内,薄膜防雾等级为E级,而直接加入GMS制备的防雾薄膜在1~11 h防雾等级为E级,在11~60 h内防雾等级为D级,所制备的防雾膜在果蔬保鲜等领域将有着广阔的应用前景。Abstract: Anti-fog film packaging can reduce the water activity in the package and reduce the large amount of waste caused by fruit and vegetable spoilage, so it is of great research significance. In this study, SiO2 was used as the wall material, and the core material of glyceryl monostearate (GMS) was coated by emulsion polymerization and mixed with linear low-density polyethylene (LLDPE) to prepare a long-term anti-fog film. The results show that the chemical composition and crystal structure of the prepared samples are analyzed by FTIR and XRD, which proves that GMS is successfully covered. The micromorphology and cross-sectional microstructure of the samples are analyzed by SEM, and the prepared GMS@SiO2 is spherical, which is well dispersed in the film. The particle size and DSC tests show that the GMS@SiO2 samples prepared under the condition of 1:2 using GMS and tetraethyl orthosilicate (TEOS) have good particle size uniformity, 83.05% are concentrated at 20-100 nm, and have the highest coating rate, 69.9%. The results of N2 adsorption and desorption show that there are many mesoporous structures on the surface of the GMS@SiO2. The pore size is 17.918 nm, which can effectively delay the release of GMS. Through the analysis of the thermal properties of the sample by TG, it is found that SiO2 wall material has a better protective effect on GMS, and the maximum loss temperature of GMS is increased from 298℃ to 405℃, which is increased by about 107℃. Through thermal anti-fog test, it is found that the prepared film can effectively extend the anti-fog time of the film and has superior anti-fog performance, in 1-11 h, the film anti-fog grade is DE grade; Within 11-60 h, the film anti-fog grade is E grade, and the anti-fog film prepared directly added to GMS is E grade in 1-11 h. The anti-fog grade is grade D within 11-60 h, and the prepared anti-fog film will have broad application prospects in the fields of fruit and vegetable preservation.

-

Key words:

- glyceryl monostearate /

- capsulation /

- silica /

- emulsion polymerization /

- long-lasting anti-fog film

-

表 1 不同单硬脂酸甘油酯(GMS)含量样品制备方案

Table 1. Preparation scheme for different content of glyceryl monostearate (GMS)

Sample GMS/g Tetraethyl orthosilicate/g Deionized water/mL Type of surfactant Surfactant/g 10.0GMS 10.0 15.0 200 OP-10+CTAB 0.8 7.5GMS 7.5 15.0 200 OP-10+CTAB 0.8 Notes: OP-10—Octyl phenol polyoxyethylene ether-1; CTAB—Cetyl trimethyl ammonium bromide. 表 2 薄膜配方

Table 2. Formula of films

Sample LLDPE/g GMS/wt% GMS@SiO2/wt% LLDPE 2.0000 0 0 1.5%GMS/LLDPE 1.9700 1.5 0 0.2%GMS@SiO2/LLDPE 1.9942 0 0.2 0.4%GMS@SiO2/LLDPE 1.9884 0 0.4 0.6%GMS@SiO2/LLDPE 1.9826 0 0.6 0.8%GMS@SiO2/LLDPE 1.9768 0 0.8 1.5%GMS@SiO2/LLDPE 1.9565 0 1.5 Note: LLDPE—Linear low-density polyethylene. 表 3 不同样品的DSC参数

Table 3. DSC parameters for different samples

Sample $ {T}_{{\rm{m}}} $/℃ $ {T}_{{\rm{peak}}} $/℃ $ {\Delta H}_{\rm{{m}}} $/(W·g−1) Tc/℃ R/% GMS 55.6 66.1 1.53 65.1 — 10.0GMS 25.5 52.6/60.0 0.82 58.7 53.6 7.5GMS 31.1 52.0/60.3 1.07 59.3 69.9 Notes: $ {T}_{{\rm{m}}} $—Melting temperature; $ {T}_{{\rm{peak}}} $—Peak melting temperature; $ {\Delta H}_{{\rm{m}}} $—Melting enthalpy; $ {T}_{{\rm{c}}} $—Crystallization temperature; R—Microencapsulation rate. 表 4 不同样品的比表面积、孔容和孔径

Table 4. Specific surface area, pore volume and pore size of different samples

Sample SBET/(m2·g−1) Vt/(cm3·g−1) d/nm SiO2 332.730 1.417 17.039 7.5GMS 1.778 0.008 17.918 10.0GMS 4.053 0.018 17.619 Notes: SBET—Total area per unit mass of the item; Vt—Total pore volume (p/p0=0.990); d—Mean pore diameter. -

[1] 安朝霞, 苗雨阳, 杜玉婉, 等. 食品腐败变质生物因素相关机制研究进展[J]. 食品安全质量检测学报, 2022, 13(1):86-93. doi: 10.3969/j.issn.2095-0381.2022.1.spaqzljcjs202201012AN Zhaoxia, MIAO Yuyang, DU Yuwan, et al. Research progress on the related mechanisms of biological factors in food spoilage and deterioration[J]. Journal of Food Safety and Quality Detection,2022,13(1):86-93(in Chinese). doi: 10.3969/j.issn.2095-0381.2022.1.spaqzljcjs202201012 [2] MORE A S, RANADHEERA C S, FANG Z X, et al. Biomarkers associated with quality and safety of fresh-cut produce[J]. Food Bioscience, 2020, 34: 100524. [3] JIANG H Y, ZHANG M, BHANDARI B, et al. Application of electronic tongue for fresh foods quality evaluation: A review[J]. Food Reviews International,2018,34(8):746-769. doi: 10.1080/87559129.2018.1424184 [4] 朱宏莉, 杨彬彬, 张秀齐, 等. 果蔬保鲜加工现状及发展浅析[J]. 食品科学, 2006, 27(10):596-600. doi: 10.3321/j.issn:1002-6630.2006.10.153ZHU Hongli, YANG Binbin, ZHANG Xiuqi, et al. The present situation and development of fresh maintaining and processing technology of fruit and vegetable[J]. Food Science,2006, 27(10):596-600(in Chinese). doi: 10.3321/j.issn:1002-6630.2006.10.153 [5] ZHANG M, TANG J, MUJUMDAR A S, et al. Trends in microwave-related drying of fruits and vegetables[J]. Trends in Food Science & Technology,2006,17(10):524-534. [6] 杨文忠, 伍杰锋, 冯润财, 等. 聚乙烯薄膜加工方法及BOPE新产品[J]. 塑料工业, 2013, 41(3):116-119. doi: 10.3969/j.issn.1005-5770.2013.03.023YANG Wenzhong, WU Jiefeng, FENG Runcai, et al. Process of polyethylene film and BOPE new product[J]. China Plastics Industry,2013,41(3):116-119(in Chinese). doi: 10.3969/j.issn.1005-5770.2013.03.023 [7] DURÁN I R, LAROCHE G. Water drop-surface interactions as the basis for the design of anti-fogging surfaces: Theory, practice, and applications trends[J]. Advances in Colloid and Interface Science,2019,263:68-94. doi: 10.1016/j.cis.2018.11.005 [8] ZHU K X, WANG H D, CHEN C W, et al. Development of polyethylene antifogging and antibacterial packaging films for lettuce preservation[J]. LWT, 2023, 181: 114772. [9] 周立国, 刘晓妍, 王玉兵. 一种Gemini表面活性剂合成及其在薄膜中的应用[J]. 化学研究与应用, 2012, 24(6):890-894. doi: 10.3969/j.issn.1004-1656.2012.06.010ZHOU Liguo, LIU Xiaoyan, WANG Yubing. A Gemini surfactants synthesizes and it at the application in the thin film[J]. Chemical Research and Application,2012,24(6):890-894(in Chinese). doi: 10.3969/j.issn.1004-1656.2012.06.010 [10] 魏丽娟, 杨福馨, 杜运鹏. 改性聚乙烯防雾薄膜的性能研究[J]. 功能材料, 2017, 48(2):2215-2220. doi: 10.3969/j.issn.1001-9731.2017.02.041WEI Lijuan, YANG Fuxin, DU Yunpeng. Study on antifogging properties of modified polyethylene films[J]. Journal of Functional Materials,2017,48(2):2215-2220(in Chinese). doi: 10.3969/j.issn.1001-9731.2017.02.041 [11] ROSEN-KLIGVASSER J, SUCKEVERIENE R Y, TCHOUDAKOV R, et al. A novel methodology for controlled migration of antifog from thin polyolefin films[J]. Polymer Engineering & Science,2014,54(9):2023-2028. [12] YAO Z H, YIN J H, SONG Y X, et al. Preparation and properties of a novel nonionic surfactant grafted linear low density polyethylene[J]. Journal of Macromolecular Science, Part A,2007,44(9):963-968. doi: 10.1080/10601320701424248 [13] GE X S, CHU M, QU L H, et al. Long-lasting intrinsic polyethylene antifogging films generated by incorporating SiO2 nanoparticles into covalently grafted antifog agents[J]. Journal of Macromolecular Science, Part A,2020,57(12):826-836. doi: 10.1080/10601325.2020.1796493 [14] SHLOSMAN K, ROSEN-KLIGVASSER J, SUCKEVERIENE R, et al. Novel antifog modification for controlled migration and prolonged wetting of LLDPE thin films[J]. European Polymer Journal,2017,90:220-230. doi: 10.1016/j.eurpolymj.2017.03.025 [15] YANG S Q, ZHU D T, YANG F H, et al. An effective method for delayed migration of dripping agent from linear low-density polyethylene films[J]. Polymers for Advanced Technologies,2021,32(4):1560-1567. [16] YAN K, CHEN D, WANG L, et al. A facile method for delaying the migration of antifogging agents in polyethylene films[J]. Industrial & Engineering Chemistry Research,2022,61(20):6945-6956. [17] CHEN K L, XU C Y, ZHOU J L, et al. Multifunctional fabric coatings with slow-releasing fragrance and UV resistant properties from ethyl cellulose/silica hybrid microcapsules[J]. Carbohydrate Polymers,2020,232:115821. doi: 10.1016/j.carbpol.2019.115821 [18] SOUSA F L, SANTOS M, ROCHA S M, et al. Encapsulation of essential oils in SiO2 microcapsules and release behaviour of volatile compounds[J]. Journal of Microencapsulation,2014,31(7):627-635. doi: 10.3109/02652048.2014.911376 [19] YANG X, LIU Y, LYU Z H, et al. Synthesis of high latent heat lauric acid/silica microcapsules by interfacial polymerization method for thermal energy storage[J]. Journal of Energy Storage, 2021, 33: 102059. [20] 李佳佳, 陆艺超, 叶光斗, 等. 纺丝原液原位合成相变材料微胶囊制备石蜡/PVA储能纤维[J]. 复合材料学报, 2012, 29(3):79-84. doi: 10.13801/j.cnki.fhclxb.2012.03.020LI Jiajia, LU Yichao, YE Guangdou, et al. In-situ synthesis of energy storage paraffin/PVA fibre with phase change microcapsules in the spinning solution[J]. Acta Materiae Compositae Sinica,2012,29(3):79-84(in Chinese). doi: 10.13801/j.cnki.fhclxb.2012.03.020 [21] 中国国家标准化管理委员会. 塑料薄膜防雾性试验方法: GB/T 31726—2015[S]. 北京: 中国标准出版社, 2015.Standardization Administration of the People's Republic of China. Test method for anti-fogging of plastic film: GB/T 31726—2015[S]. Beijing: China Standard Press, 2015(in Chinese). [22] 中国国家标准化管理委员会. 塑料拉伸性能的测定第3部分: 薄膜和薄片的试验条件: GB/T 1043.3—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People's Republic of China. Determination of tensile properties of plastics—Part 3: Test conditions for films and sheets: GB/T 1043.3—2006[S]. Beijing: China Standard Press, 2006(in Chinese). [23] 中国国家标准化管理委员会. 透明塑料透光率和雾度的测定: GB/T 2410—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Determination of light transmittance and haze of transparent plastics: GB/T 2410—2008[S]. Beijing: China Standard Press, 2008(in Chinese). [24] 袁文俊, 周勇敏. 纳米颗粒团聚的原因及解决措施[J]. 材料导报, 2008, 22(S3):59-61.YUAN Wenjun, ZHOU Yongmin. Causes and solutions of nanoparticle agglomeration[J]. Materials Reports,2008,22(S3):59-61(in Chinese). [25] GARCIA M C, PEREIRA-DA-SILVA M A, TABOGA S, et al. Structural characterization of complexes prepared with glycerol monoestearate and maize starches with different amylose contents[J]. Carbohydrate Polymers,2016,148:371-379. doi: 10.1016/j.carbpol.2016.04.067 [26] SUN L N, LU L X, WANG L Q, et al. Influence of α-tocopherol/MCM-41 assembly on physical and antioxidant release properties of low-density polyethylene antioxidant active films[J]. Polymer Engineering & Science,2018,58(10):1710-1716. [27] DURMUŞ A, WOO M, KAŞGÖZ A, et al. Intercalated linear low density polyethylene (LLDPE)/clay nanocomposites prepared with oxidized polyethylene as a new type compatibilizer: Structural, mechanical and barrier properties[J]. European Polymer Journal,2007,43(9):3737-3749. doi: 10.1016/j.eurpolymj.2007.06.019 [28] GARCÍA M, BARSEMA J, GALINDO R E, et al. Hybrid organic inorganic Nylon-6/SiO2 nanocomposites: Transport properties[J]. Polymer Engineering & Science,2004,44(7):1240-1246. [29] YAJIMA T, ITAI S, TAKEUCHI H, et al. Determination of optimum processing temperature for transformation of glyceryl monostearate[J]. Chemical & Pharmaceutical Bulletin,2002,50(11):1430-1433. doi: 10.1248/cpb.50.1430 [30] ADAM-BERRET M, RIAUBLANC A, RONDEAU-MOURO C, et al. Effects of crystal growth and polymorphism of triacylglycerols on NMR relaxation parameters. 1. Evidence of a relationship between crystal size and spin-lattice relaxation time[J]. Crystal Growth & Design,2009,9(10):4273-4280. [31] 姚云平, 宁灵, 于佳睿, 等. 乳化剂对米糠蜡凝胶油理化特性的影响[J]. 中国粮油学报, 2022, 37(11):184-190.YAO Yunping, NING Ling, YU Jiarui, et al. Effects of three emulsifiers on structure and properties of rice bran wax oleogel[J]. Journal of the Chinese Cereals and Oils Association,2022,37(11):184-190(in Chinese). [32] KIM M, HYUN K. Characterization of polyethylene/silica nanocomposites using different rheological analyses[J]. Korea-Australia Rheology Journal,2021,33(1):25-36. doi: 10.1007/s13367-021-0003-3 -

下载:

下载: