Effect of alkali treatment on the wettability and tensile failure of twisted bamboo fiber/epoxy composites

-

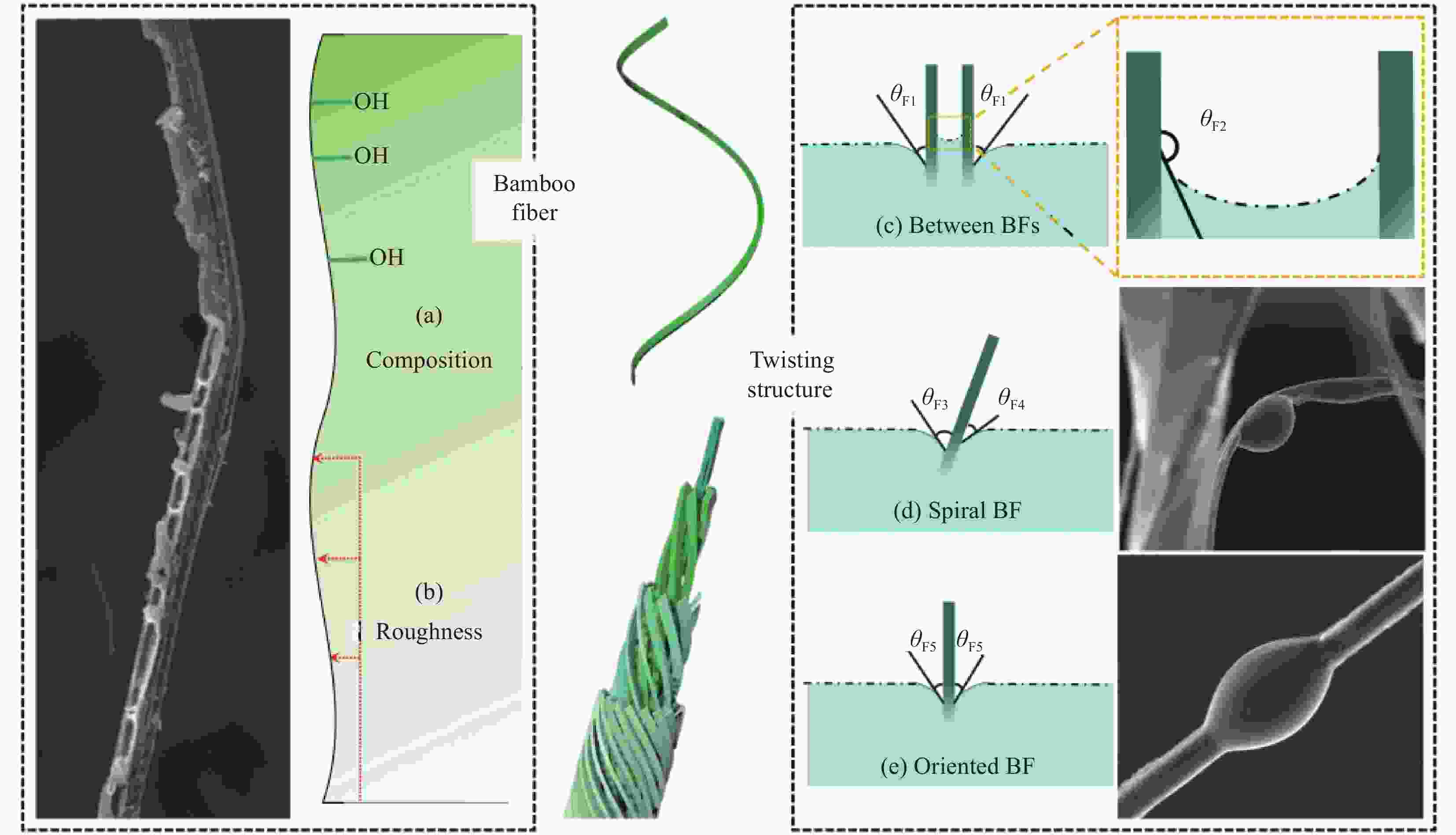

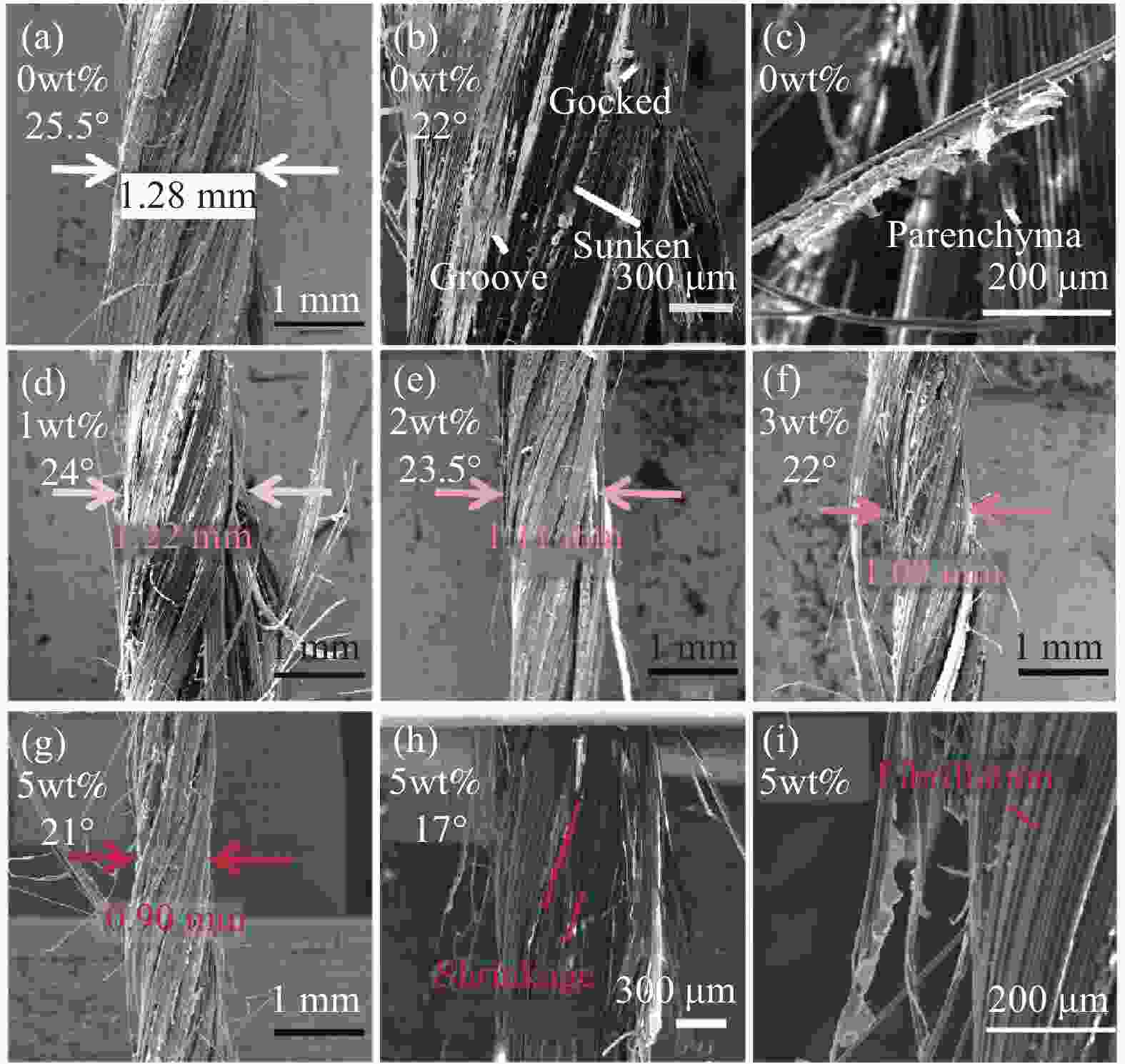

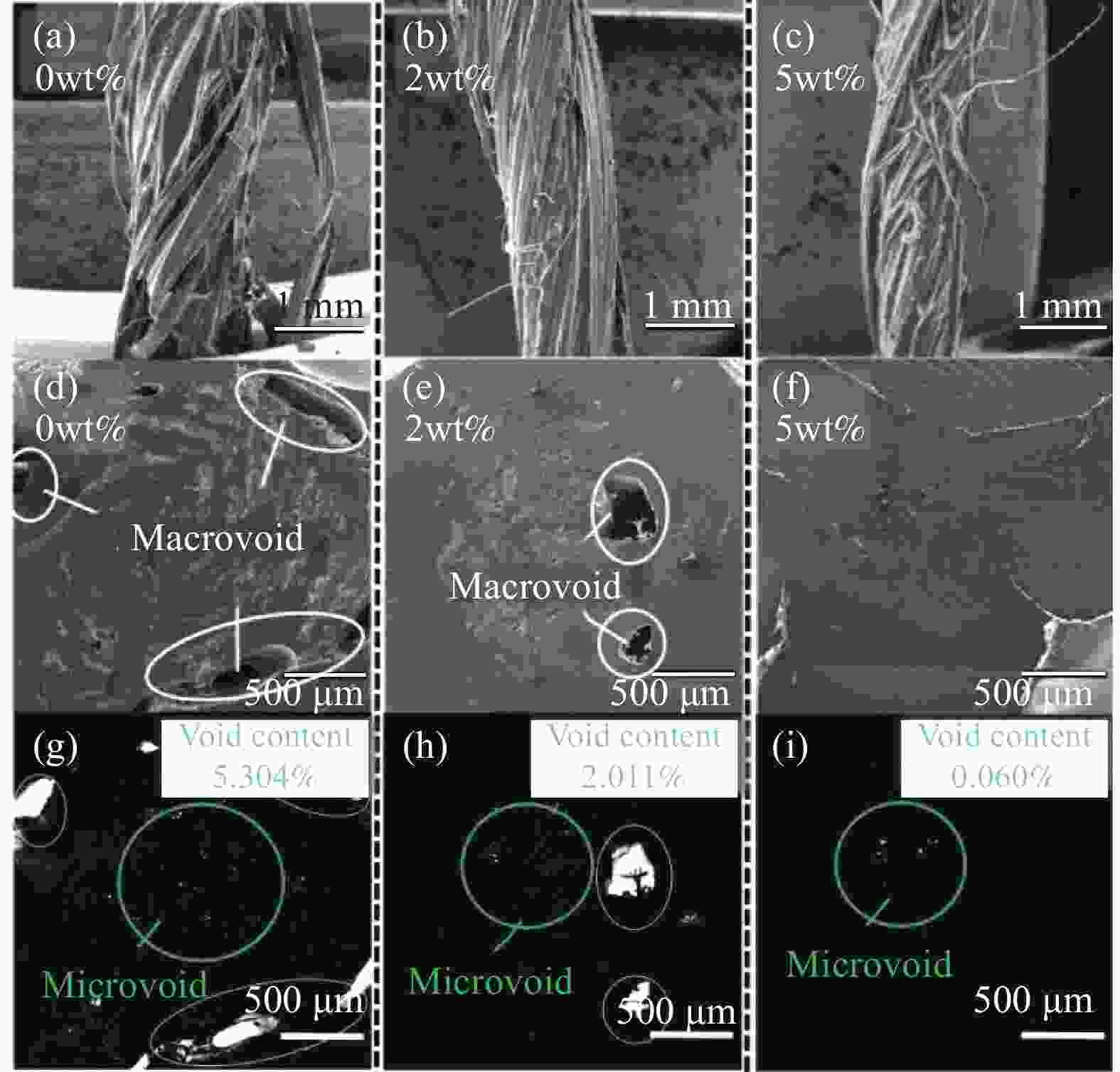

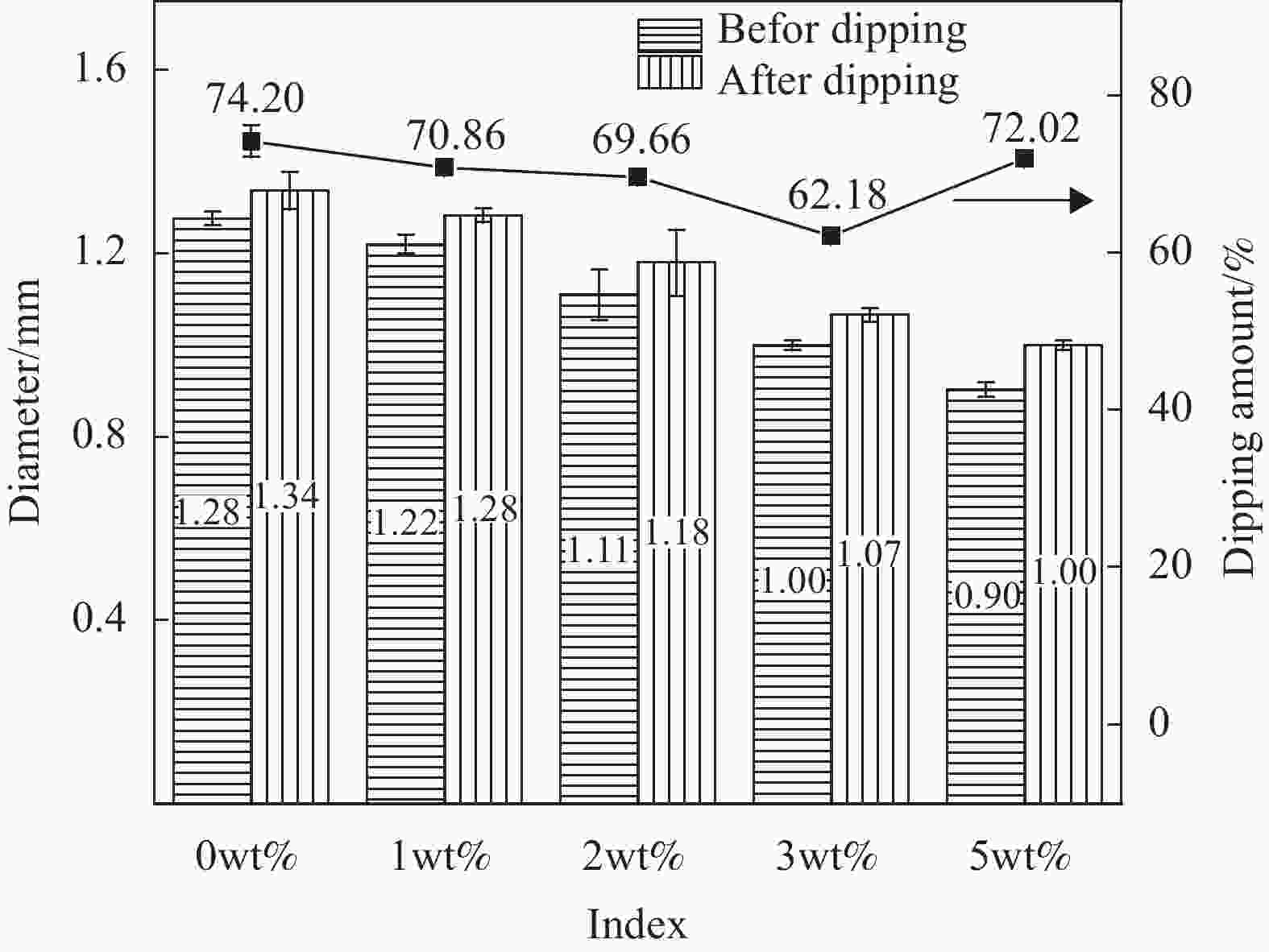

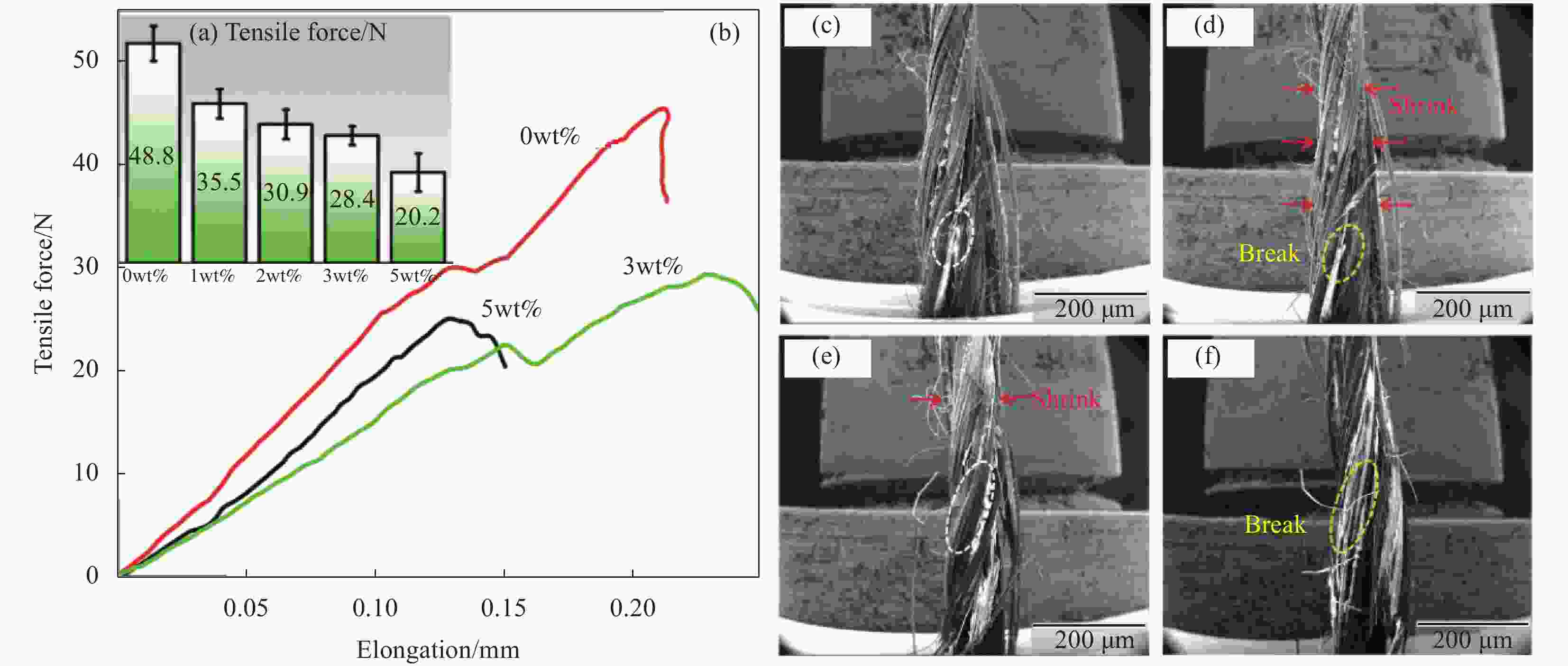

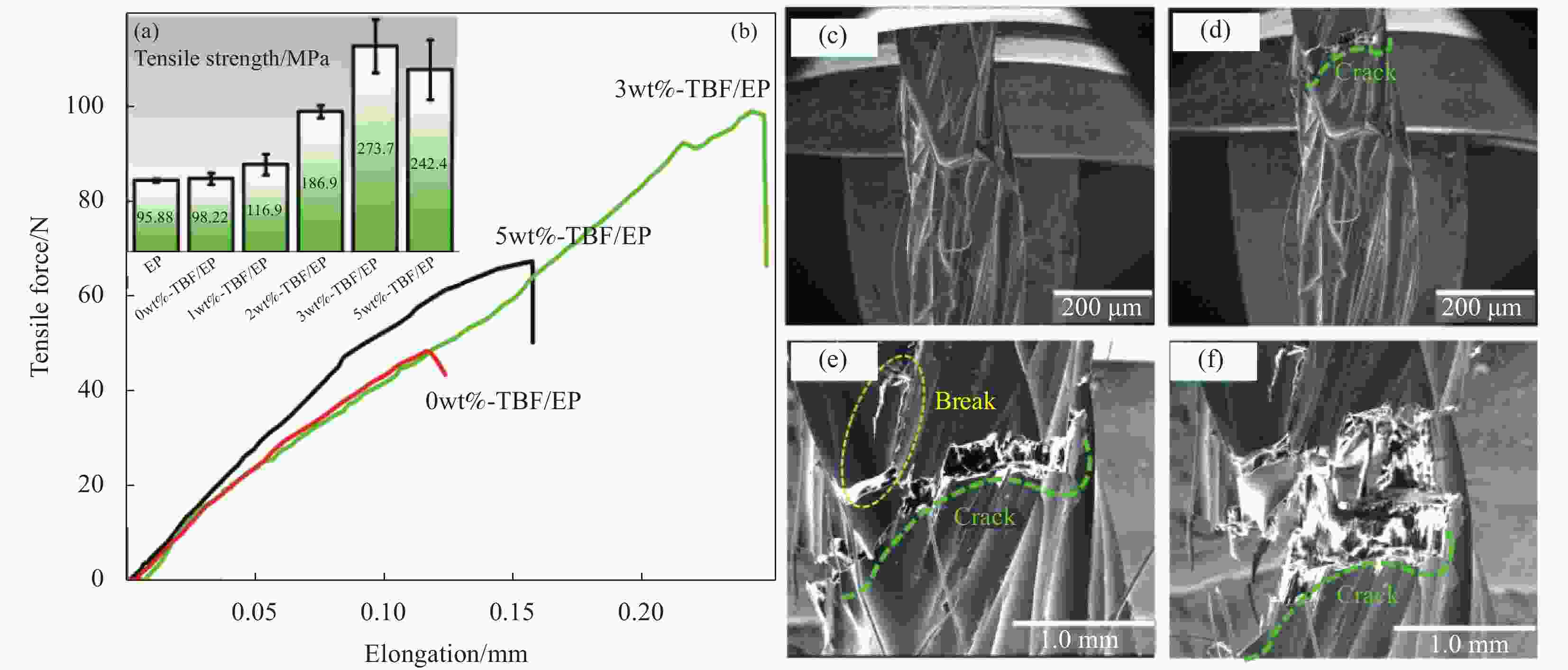

摘要: 采用加捻竹纤维(TBF)为增强相、环氧树脂-酸酐体系为基体相,制备加捻竹纤维/环氧树脂(TBF/EP)复合材料,通过改变NaOH溶液浓度(1wt%~5wt%),研究碱处理对TBF/EP复合材料润湿性和拉伸失效的影响。采用SEM、表面张力测试、原位加载等纳米和微观试验手段,对纤维-树脂结合状态、润湿性能和拉伸力学特性进行了分析。结果表明:碱处理降低了纤维表面能和极性,使TBF与基体润湿力从0.45 mN降至0.1 mN;3wt%NaOH溶液改性的TBF/EP复合材料含胶量降低至62%,拉伸强度(TS)达到273.70 MPa,比未处理复合材料提高178.64%;原位分析显示,TBF失效过程包括纤维断裂和纤维间滑移,而TBF/EP复合材料失效过程包括基体剪切屈服和纤维断裂,且随着浸润性提高,BF抑制屈服的效果增加。因此,TBF/EP复合材料的强度主要来源于纤维和界面的增强,受TBF与基体的浸润性、应力传递效果的影响。Abstract: The twisted bamboo fiber (TBF) was used as the reinforcement phase and the epoxy resin-anhydride system as the matrix phase to prepare the twisted bamboo fiber/epoxy resin (TBF/EP) composite. The effects of alkali treatment on the wettability and tensile failure of TBF/EP composites were investigated by varying the concentration of NaOH solution (1wt%-5wt%). Nano-scale and micro-scale experimental techniques, such as SEM, surface tension testing, and in-situ loading, were employed to analyze the fiber-resin interface, wetting properties, and tensile mechanical properties of the composites. The results show that alkali treatment reduces the surface energy and polarity of the fibers, resulting in a decrease in the wetting force between TBF and the matrix from 0.45 mN to 0.1 mN. The TBF/EP composite modified with 3wt%NaOH solution exhibits a tensile strength (TS) of 273.70 MPa, which is 178.64% higher than that of the untreated composite. In-situ analysis reveals that the failure process of TBF involves fiber fracture and fiber sliding, while the failure process of the TBF/EP composite includes matrix shear yielding and fiber fracture. Moreover, as the wetting properties improve, the inhibitory effect of the fibers on matrix yielding increase. Therefore, the strength of the TBF/EP composite is mainly derived from the reinforcement of the fibers and the interface, which is influenced by wetting properties and stress transfer effect between TBF and matrix.

-

Key words:

- bamboo fiber /

- twisted structure /

- composite /

- wettability /

- failure mechanism

-

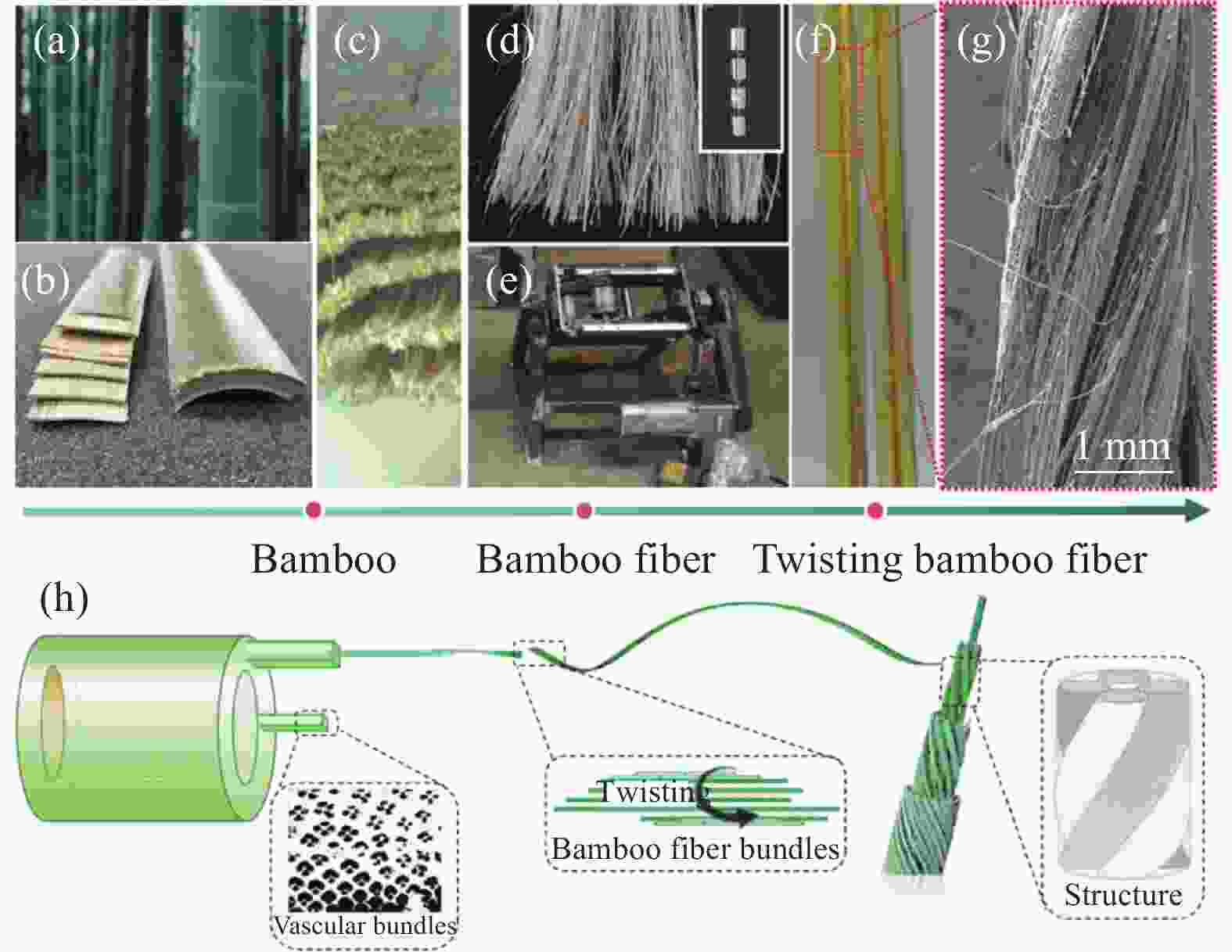

图 1 加捻竹纤维(TBF)的制备过程:(a) 竹材;(b) 竹条;(c) 竹纤维束;(d) 竹纤维(BF);(e) 加捻设备;(f) TBF;(g) TBF的SEM图像;(h) TBF制备示意图

Figure 1. Preparation process of twisted bamboo fiber (TBF): (a) Bamboo; (b) Bamboo strips; (c) Bamboo fiber bundles; (d) Bamboo fiber (BF); (e) Equipment of twisting; (f) TBF; (g) SEM image of TBF; (h) Schematic diagram of preparation of TBF

表 1 TBF的基本性质

Table 1. Basic properties of TBF

BF Length/cm Width/mm Thickness/mm Strength/MPa 10 0.36-0.7 0.13-0.2 180±16 TBF Diameter/mm Tensile/N Linear density/(g·m−1) Twist angle/(°) 1.28±0.12 48.8 12 64 表 2 加捻竹纤维的接触角和表面能

Table 2. Contact angle and surface energy of TBF

Index Wetting boundary/mm Advancing contact angle/(°) Owens-Wendt worth/mN Surface energy/mN Water Ethylene glycol Diiodomethane Dispersion Polar 0wt% 21.94 61.75 48.56 40.48 22.49 10.23 32.72 1wt% 11.46 61.67 41.96 44.34 22.73 8.51 31.24 2wt% 12.86 61.91 46.12 47.19 23.72 7.58 31.30 3wt% 10.42 64.76 45.70 54.58 21.00 7.09 28.08 5wt% 11.26 69.91 47.30 59.01 22.03 4.21 26.23 -

[1] BLLA V K, KATE K H, SATYAVOLU J, et al. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects[J]. Composites Part B: Engineering,2019,174:106956. doi: 10.1016/j.compositesb.2019.106956 [2] LI M, PU Y, THOMAS V M, et al. Recent advancements of plant-based natural fiber-reinforced composites and their applications[J]. Composites Part B: Engineering,2020,200(1):108254. [3] RADZI A M, ZAKI S A, HASSAN M Z, et al. Bamboo-fiber-reinforced thermoset and thermoplastic polymer composites: A review of properties, fabrication, and potential applications[J]. Polymers,2022,14(7):1387. doi: 10.3390/polym14071387 [4] LIU M, XU J, FU T, et al. Investigations on the internal curing process and mechanical properties of winding composite considering the structure of plant fiber[J]. Journal of Applied Polymer Science,2020,137(37):49114. doi: 10.1002/app.49114 [5] DUN M, HAO J, WANG W, et al. Sisal fiber reinforced high density polyethylene pre-preg for potential application in filament winding[J]. Composites Part B: Engineering,2019,159(15):369-377. [6] CHEN M, WENG Y, SEMPLE K, et al. Sustainability and innovation of bamboo winding composite pipe products[J]. Renewable and Sustainable Energy Reviews,2021,144(16):110976. [7] WU Y, ZHENG Y, YANG F, et al. Preparation process and characterization of mechanical properties of twisted bamboo spun fiber bundles[J]. Journal of Materials Research and Technology,2021,14(1):2131-2139. [8] SHAH D U, SCHUBEL P J, LICENCE P, et al. Determining the minimum, critical and maximum fibre content for twisted yarn reinforced plant fibre composites[J]. Composites Science and Technology,2012,72(15):1909-1917. doi: 10.1016/j.compscitech.2012.08.005 [9] ZHANG W, WANG C, GU S, et al. Physical-mechanical properties of bamboo fiber composites using filament winding[J]. Polymers,2021,13(17):2913. doi: 10.3390/polym13172913 [10] LEE C H, KHALINA A, LEE S H. Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: A review[J]. Polymers,2021,13(3):438. doi: 10.3390/polym13030438 [11] SHIH Y. Mechanical and thermal properties of waste water bamboo husk fiber reinforced epoxy composites[J]. Materials Science & Engineering A,2007,445-446:289-295. [12] HUANG J K, YOUNG W B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites[J]. Composites Part B: Engineering,2019,166:272-283. doi: 10.1016/j.compositesb.2018.12.013 [13] LEHTINIEMI P, DUFVA K, BERG T, et al. Natural fiber-based reinforcements in epoxy composites processed by filament winding[J]. Journal of Reinforced Plastics & Composites,2011,30(23):47-55. [14] ZAMRI M H, OSMAN M R, AKIL H M, et al. Development of green pultruded composites using kenaf fibre: Influence of linear mass density on weathering performance[J]. Journal of Cleaner Production,2016,125(1):320-330. [15] CHEN H, ZHANG W, WANG X, et al. Effect of alkali treatment on wettability and thermal stability of individual bamboo fibers[J]. Journal of Wood Science,2018,64(4):398-405. doi: 10.1007/s10086-018-1713-0 [16] WANG X, YUAN Z, ZHAN X, et al. Multi-scale characterization of the thermal-mechanically isolated bamboo fiber bundles and its potential application on engineered composites[J]. Construction and Building Materials,2020,262(10):120866. [17] FORTEA-VERDEJO M, BUMBARIS E, BURGSTALLER C, et al. Plant fibre-reinforced polymers: Where do we stand in terms of tensile properties?[J]. International Materials Reviews, 2017, 62(8): 441-464. [18] YAN L, CHOUW N, YUAN X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment[J]. Journal of Reinforced Plastics & Composites, 2012, 31(6): 425-437. [19] BARTOS A, UTOMO B P, KANYAR B, et al. Reinforcement of polypropylene with alkali-treated sugarcane bagasse fibers: Mechanism and consequences[J]. Composites Science and Technology, 2020, 200(10): 108428. [20] KUSHWAHA P, KUMAR R. Enhanced mechanical strength of BFRP composite using modified bamboos[J]. Journal of Reinforced Plastics & Composites, 2009, 28(23): 2851-2859. [21] DUJARDIN N, FOIS M, GRIMAU M, et al. Soft interface dynamics in flax-fabrics/epoxy composites[J]. Composite Structures, 2018, 202(10): 89-96. [22] PUCCI M F, LIOTIER P, DRAPIER S. Capillary effects on flax fibers—Modification and characterization of the wetting dynamics[J]. Composites Part A: Applied and Manufacturing, 2015, 77: 257-265. [23] FUENTES C A, TRAN L Q N, DUPONT-GILLAIN C, et al. Wetting behaviour and surface properties of technical bamboo fibres[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2011, 380(1-3): 89-99. [24] 顾少华, 陈季荷, 张文福, 等. 梯度结构对竹束纤维复合材料界面失效的影响[J]. 复合材料学报, 2022, 39(8):4065-4073.GU Shaohua, CHEN Jihe, ZHANG Wenfu, et al. Effect of gradient structure on the interface failure of bamboo bundle fiber composite material[J]. Acta Materiae Compositae Sinica,2022,39(8):4065-4073(in Chinese). [25] 江泽慧, 陈复明, 王戈, 等. 基于动态接触角分析的竹纤维表面能表征[J]. 北京林业大学学报, 2013, 35(3):6-9. doi: 10.13332/j.1000-1522.2013.03.006JIANG Zehui, CHEN Fuming, WANG Ge, et al. Surface energy characterization of bamboo fiber determined by dynamic contact angle analysis[J]. Journal of Beijing Forestry University,2013,35(3):6-9(in Chinese). doi: 10.13332/j.1000-1522.2013.03.006 [26] OWENS D K, WENDT R C. Estimation of the surface free energy of polymers[J]. Journal of Applied Polymer Science,1969,13(8):1741-1747. doi: 10.1002/app.1969.070130815 [27] WEI X, WANG G, SMITH L M, et al. The hygroscopicity of moso bamboo (Phyllostachys edulis) with a gradient fiber structure[J]. Journal of Materials Research and Technology,2021,15:4309-4316. doi: 10.1016/j.jmrt.2021.10.038 [28] CHEN H, WU J, SHI J, et al. Effect of alkali treatment on microstructure and thermal stability of parenchyma cell compared with bamboo fiber[J]. Industrial Crops and Products,2021,164(1):113380. [29] CHEN H, YU Y, ZHONG T, et al. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers[J]. Cellulose,2017,24(1):333-347. doi: 10.1007/s10570-016-1116-6 [30] HODGSON K, BERG J. Dynamic wettableility properties of single wood pulp fibers and their relationship to absorbency[J]. Wood & Fiber Science,1988,20(1):3-17. [31] CHOWDHURY M N K, BEG M D H, KHAN M R, et al. Modification of oil palm empty fruit bunch fibers by nanoparticle impregnation and alkali treatment[J]. Cellulose,2013,20(3):1477-1490. doi: 10.1007/s10570-013-9921-7 [32] YOUNG R A. Wettability of wood pulp fibers: Applicability of methodology[J]. Wood and Fiber Science,1976,8:120-128. [33] QIU S, FUENTES C A, ZHANG D, et al. Wettability of a single carbon fiber[J]. Langmuir,2016,32(38):9697-9705. doi: 10.1021/acs.langmuir.6b02072 [34] FUENTES C A, TRAN L Q N, VAN HELLEMONT M, et al. Effect of physical adhesion on mechanical behaviour of bamboo fibre reinforced thermoplastic composites[J]. Physicochemical and Engineering Aspects,2013,418:7-15. doi: 10.1016/j.colsurfa.2012.11.018 [35] BAI T, WANG D, YAN J, et al. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites[J]. Composites Science and Technology,2021,213:108951. doi: 10.1016/j.compscitech.2021.108951 [36] MA Y, SHEN S, TONG J, et al. Effects of bamboo fibers on friction performance of friction materials[J]. Journal of Thermoplastic Composite Materials,2013,26(6):845-859. doi: 10.1177/0892705712461513 -

下载:

下载: