Research on impact behavior of CFRP aluminum alloy adhesive plate based on multiscale damage mechanism

-

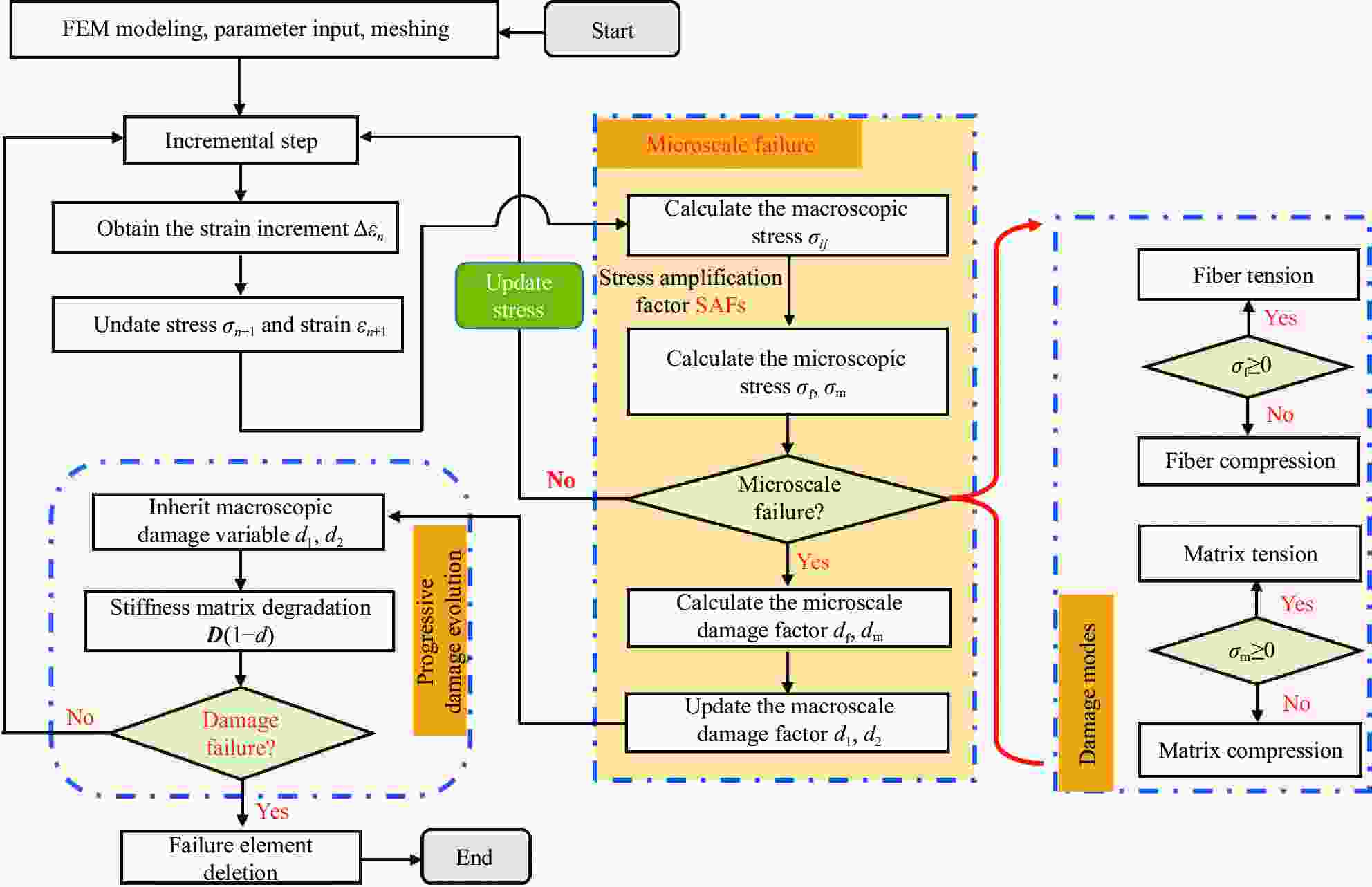

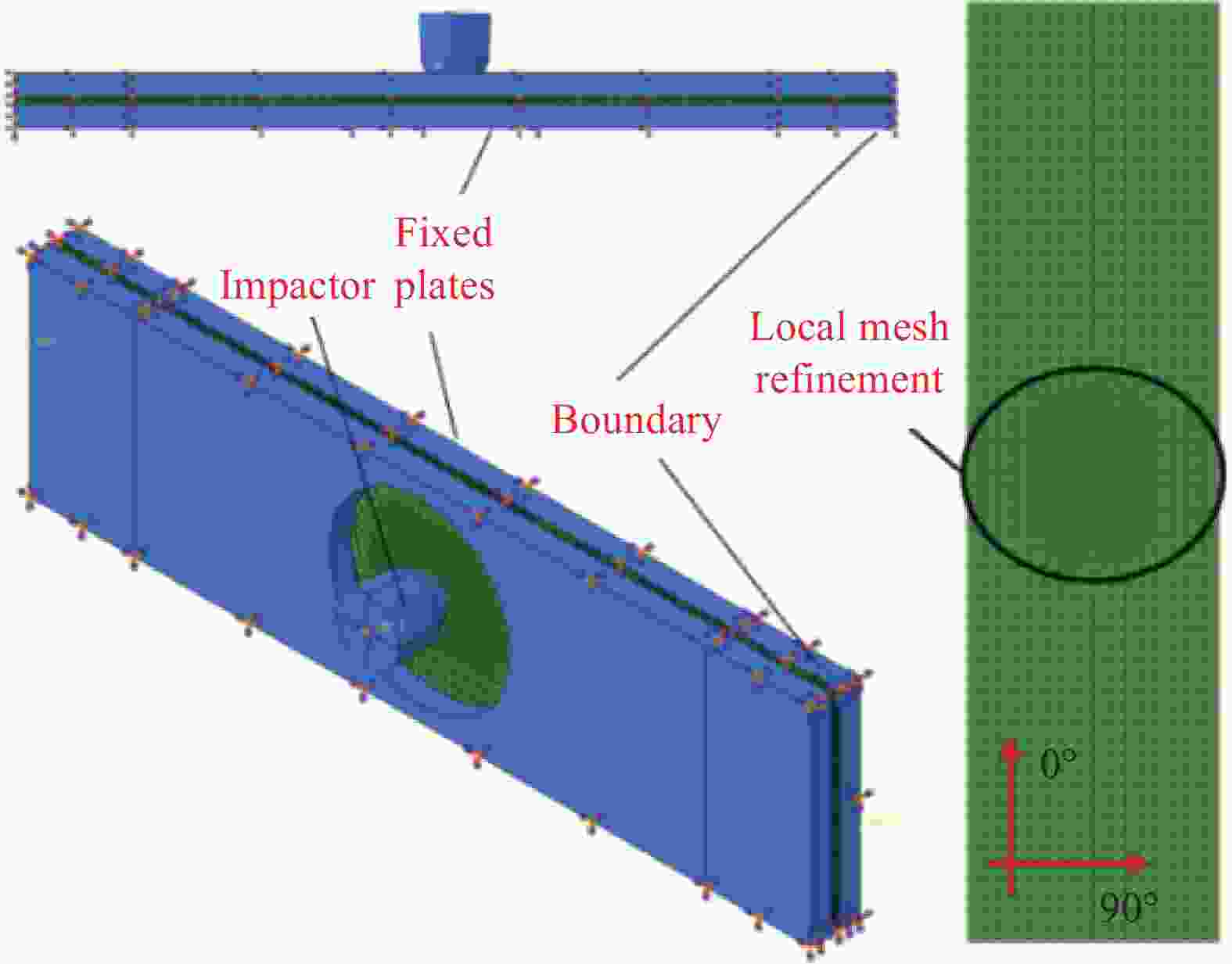

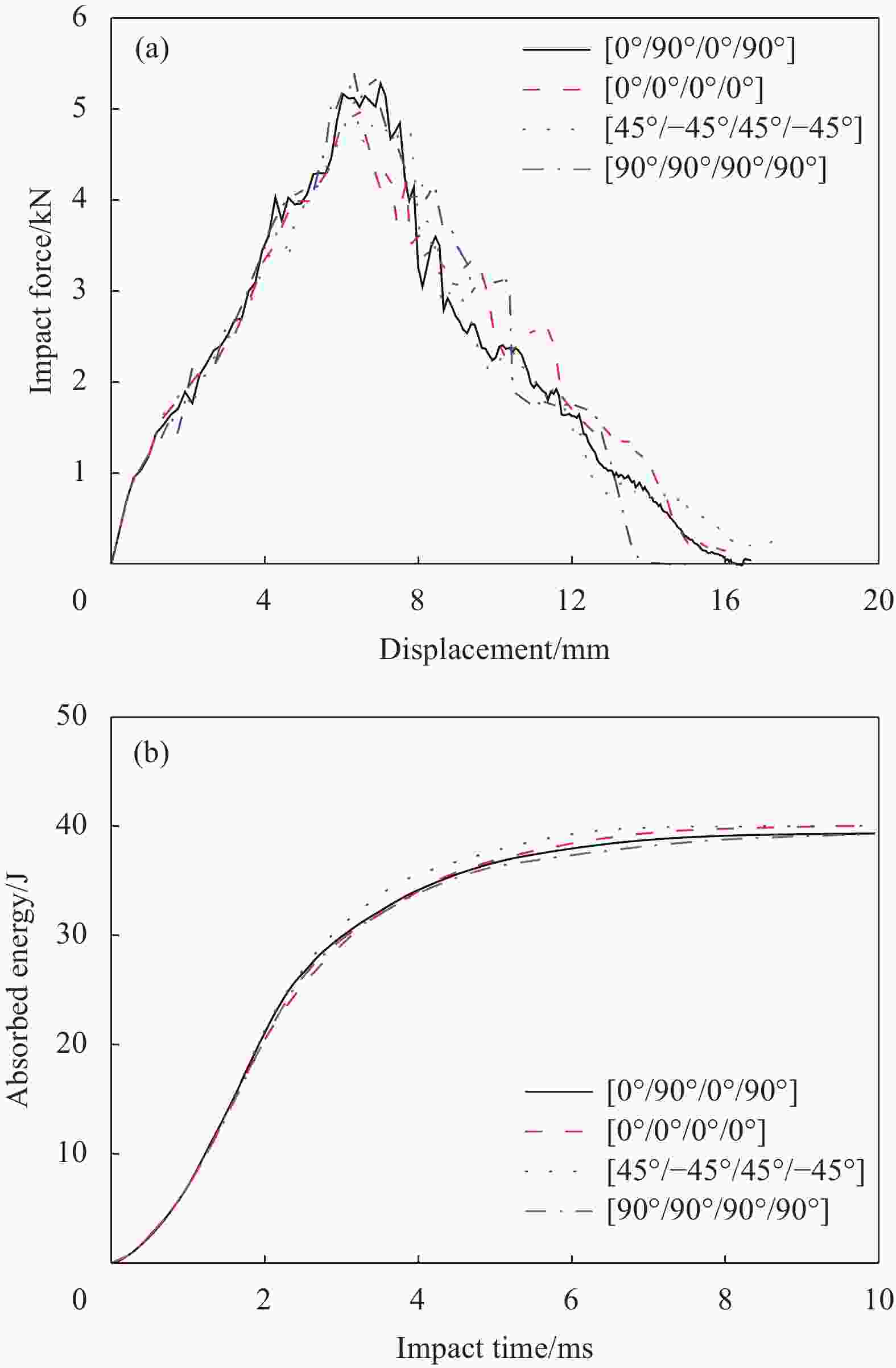

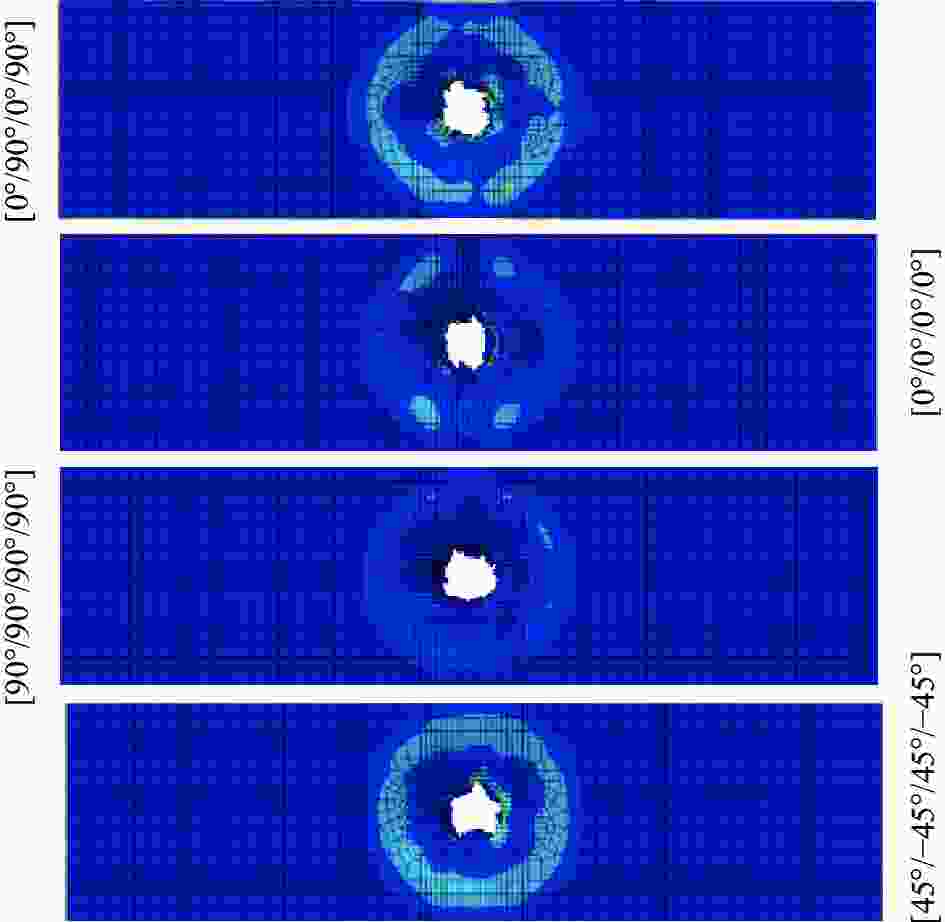

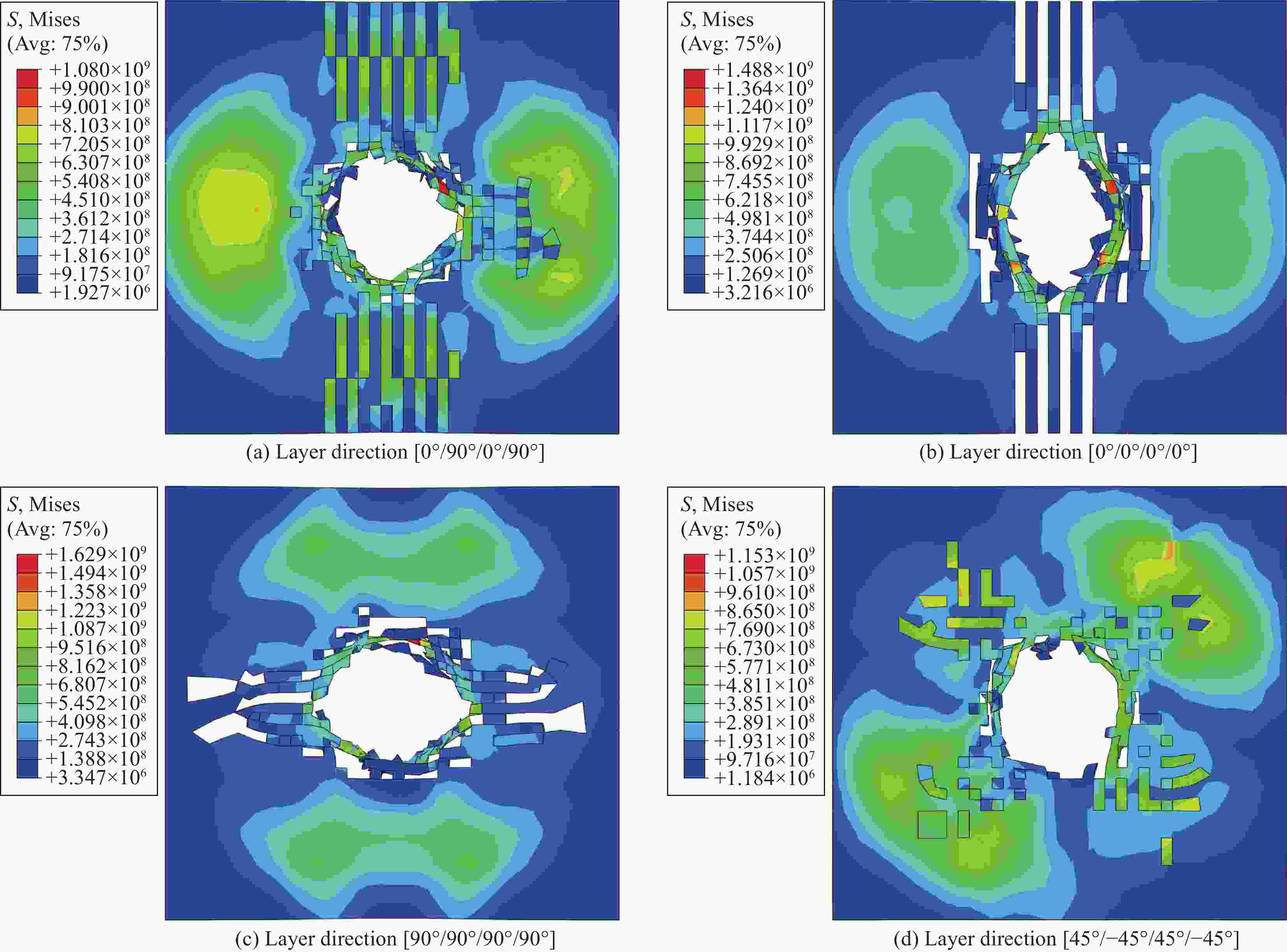

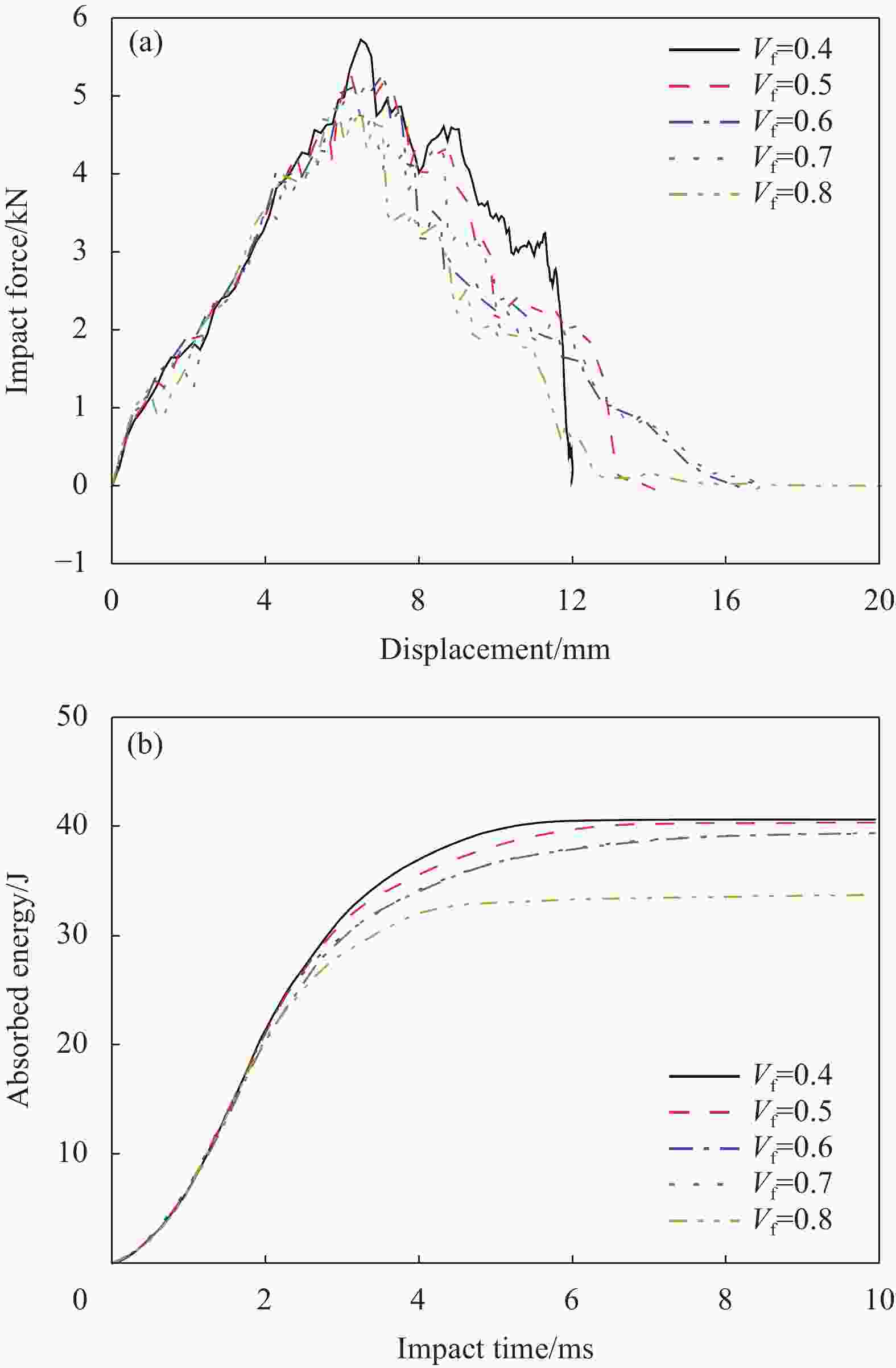

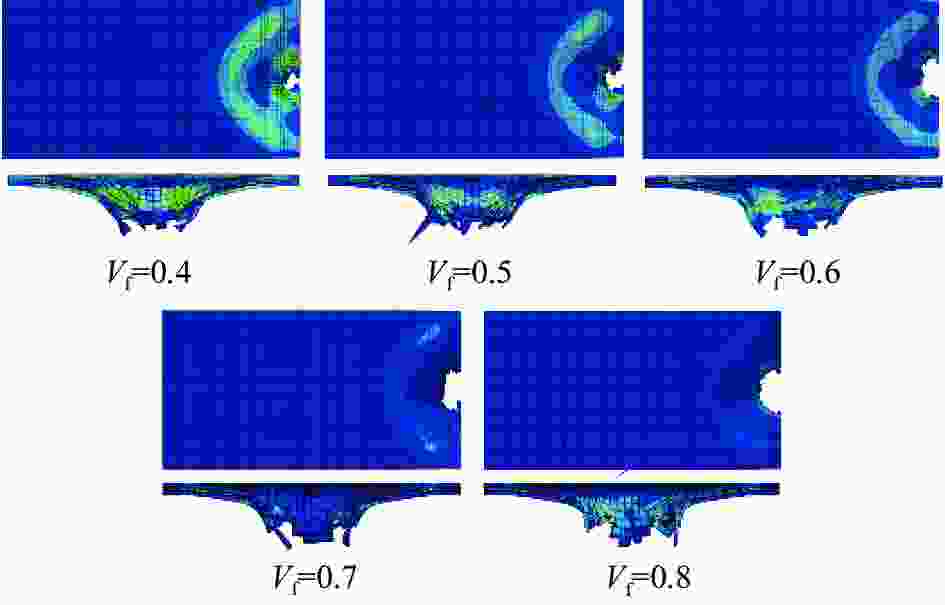

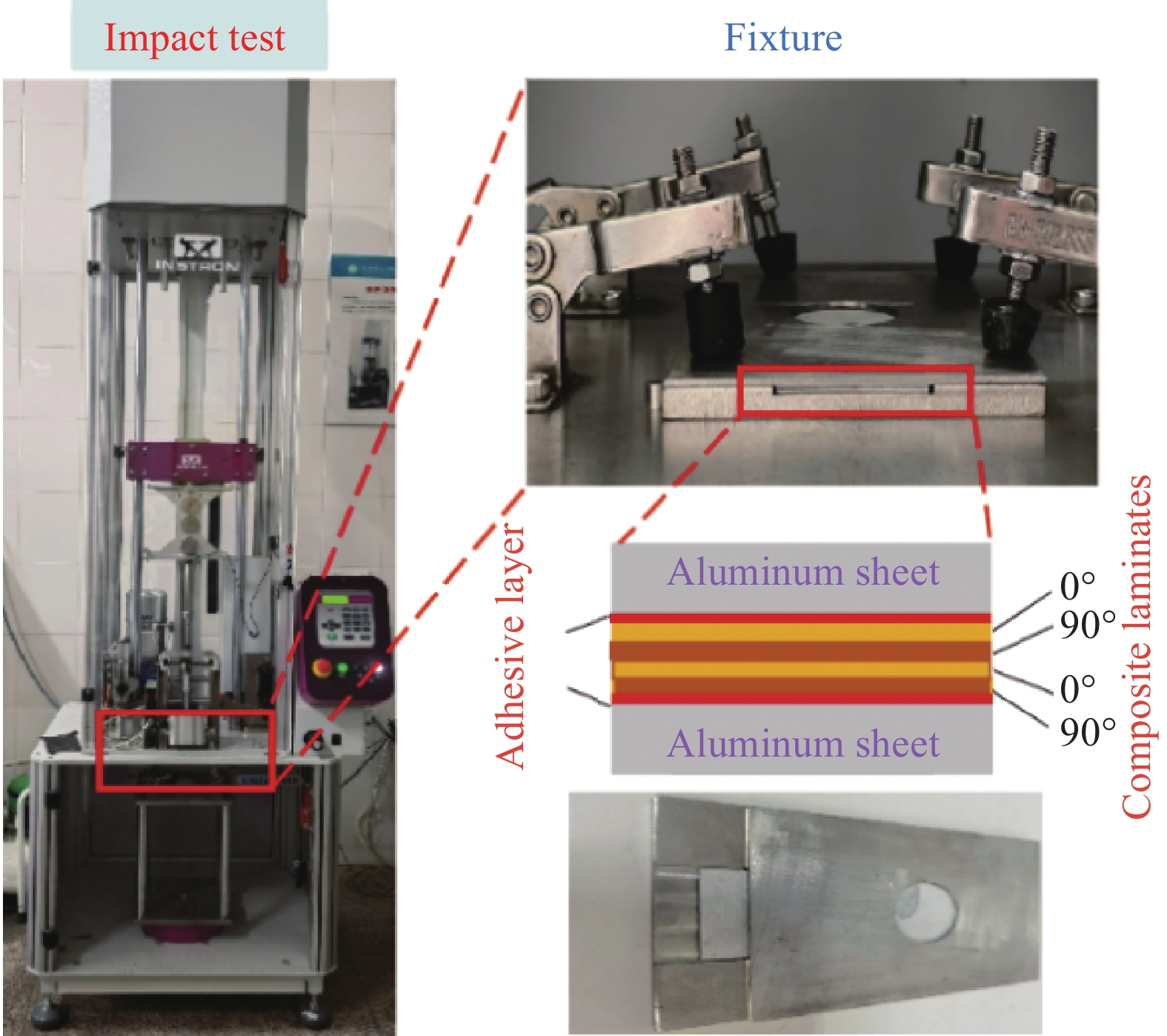

摘要: 碳纤维增强聚合物(CFRP)铝合金粘接板作为一种轻质高强的材料,被广泛用在飞机、汽车、高速列车等轻量化结构上。研究首先基于纤维/基体微观尺度建立代表性体积单元(RVE)单胞模型,预测单向CFRP的基本弹性力学参数,并通过RVE模型施加宏观单位载荷计算宏-微观应力放大系数。其次考虑纤维基体微观失效准则与演化规律,开发复合材料宏-微观渐进损伤演化程序,再结合金属与复合材料粘接面的损伤模型,建立多尺度损伤机制的CFRP铝合金粘接板冲击仿真模型,并通过实验验证了数值模型的准确性与可靠性。最后通过数值模拟对CFRP铝合金粘接板在不同纤维铺层角度与不同纤维体积分数下的抗冲击行为进行参数化研究,结果表明纤维铺层方向对粘接板的抗冲击力学性能影响不大,而纤维体积分数对结构的冲击行为影响较大。

-

关键词:

- CFRP铝合金粘接板 /

- 复合材料 /

- 低速冲击 /

- 微观失效 /

- 多尺度模拟

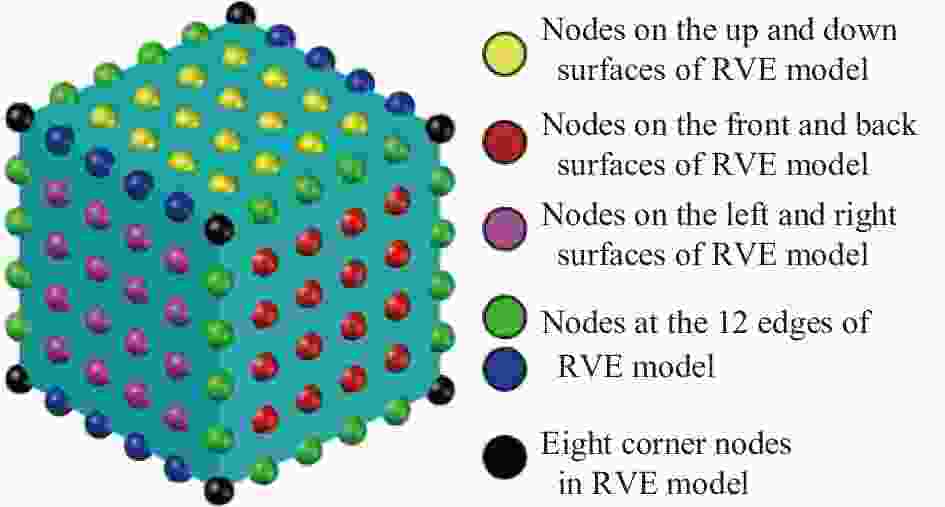

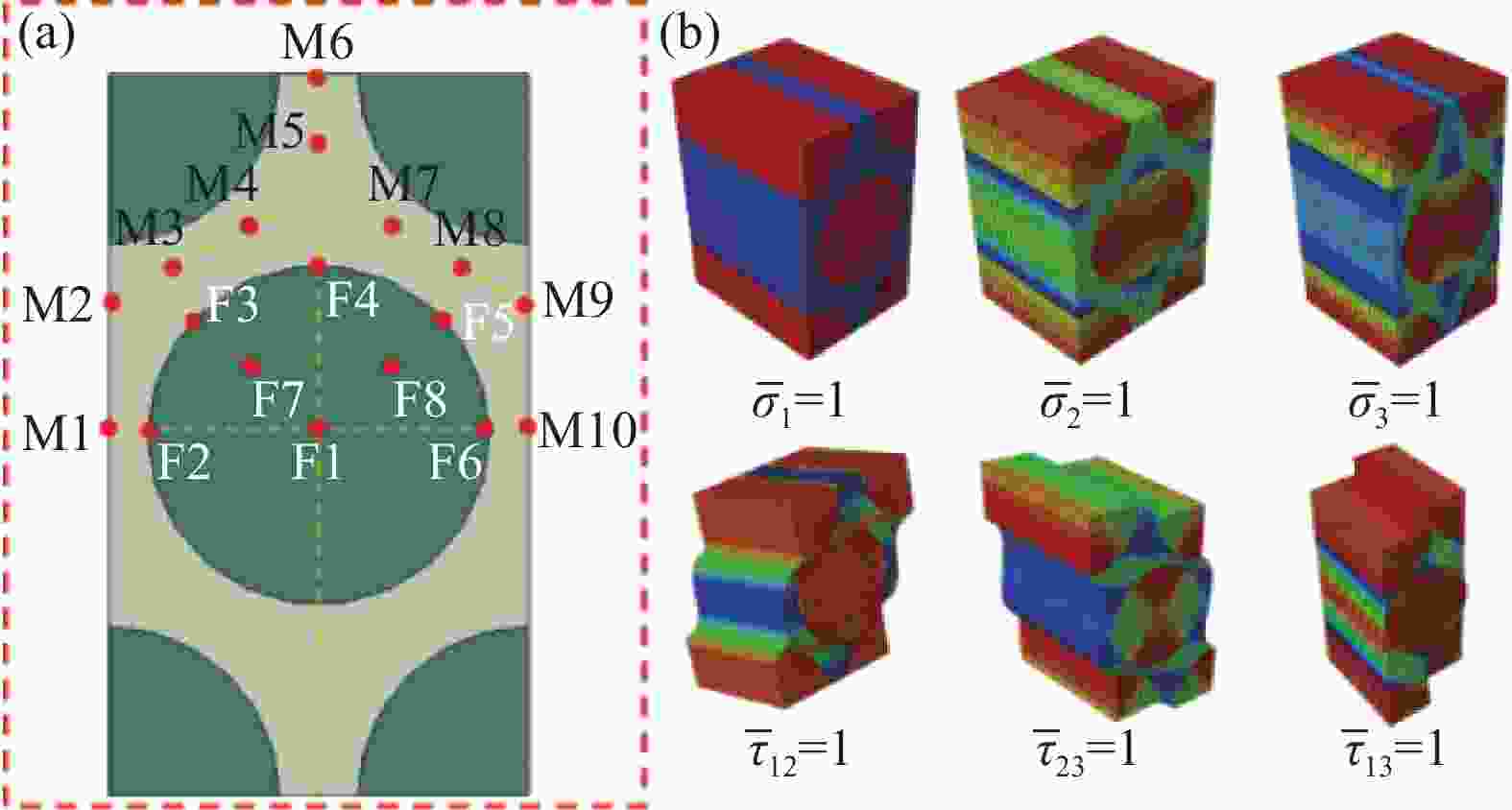

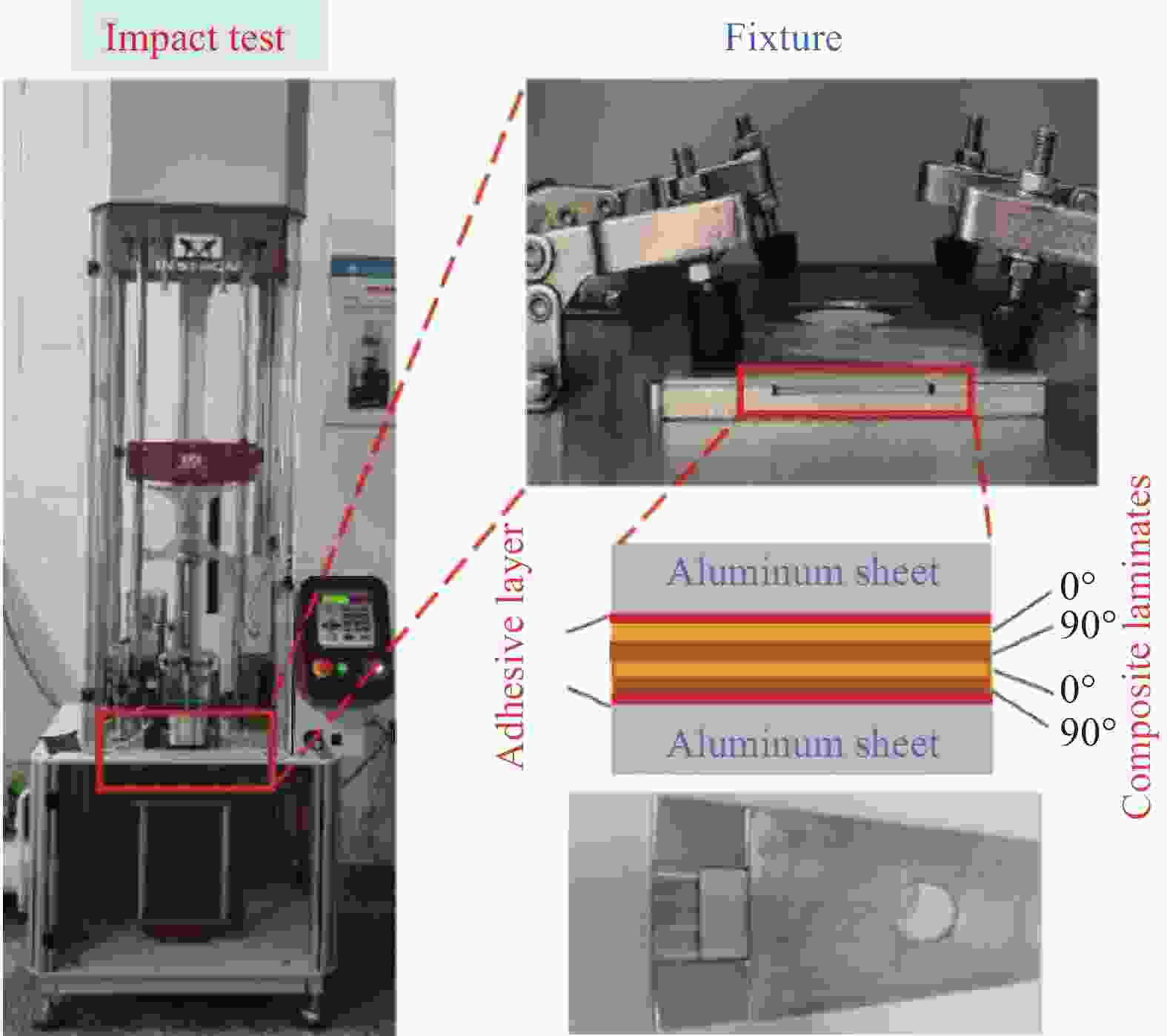

Abstract: Carbon fiber reinforced polymer (CFRP) aluminum alloy adhesive plate is a lightweight and high-strength material, which has been widely applied in lightweight structures, such as airplanes, cars, and high-speed trains. This research first established an representative volume element (RVE) single cell model based on the microscale from fiber/matrix, predicted the elastic mechanical parameters of unidirectional CFRP, and calculated the macro-micro stress amplification coefficient by applying a macroscopic unit load to the RVE model. Secondly, considering the micro-failure criteria and evolution rules of fiber and matrix, the macro-micro progressive damage evolution program of CFRP unidirectional plates was developed. Then combining with the damage model of metal and adhesive interface, a multiscale damage mechanism impacted model of CFRP aluminum alloy adhesive plate was established, then the accuracy and reliability of the numerical model were verified through the experimental tests. Finally, based on the numerical simulation, the influences of fiber angle and fiber volume fraction on the impact behavior of CFRP aluminum alloy adhesive plate were studied in detail. The results show that the fiber layup direction has little effect on the impact mechanical performance of the adhesive plate, while the fiber volume fraction has a greater effect on the impact behavior of the structure. -

表 1 T300碳纤维与基体的力学性能参数

Table 1. Material properties of T300 carbon fiber and matrix

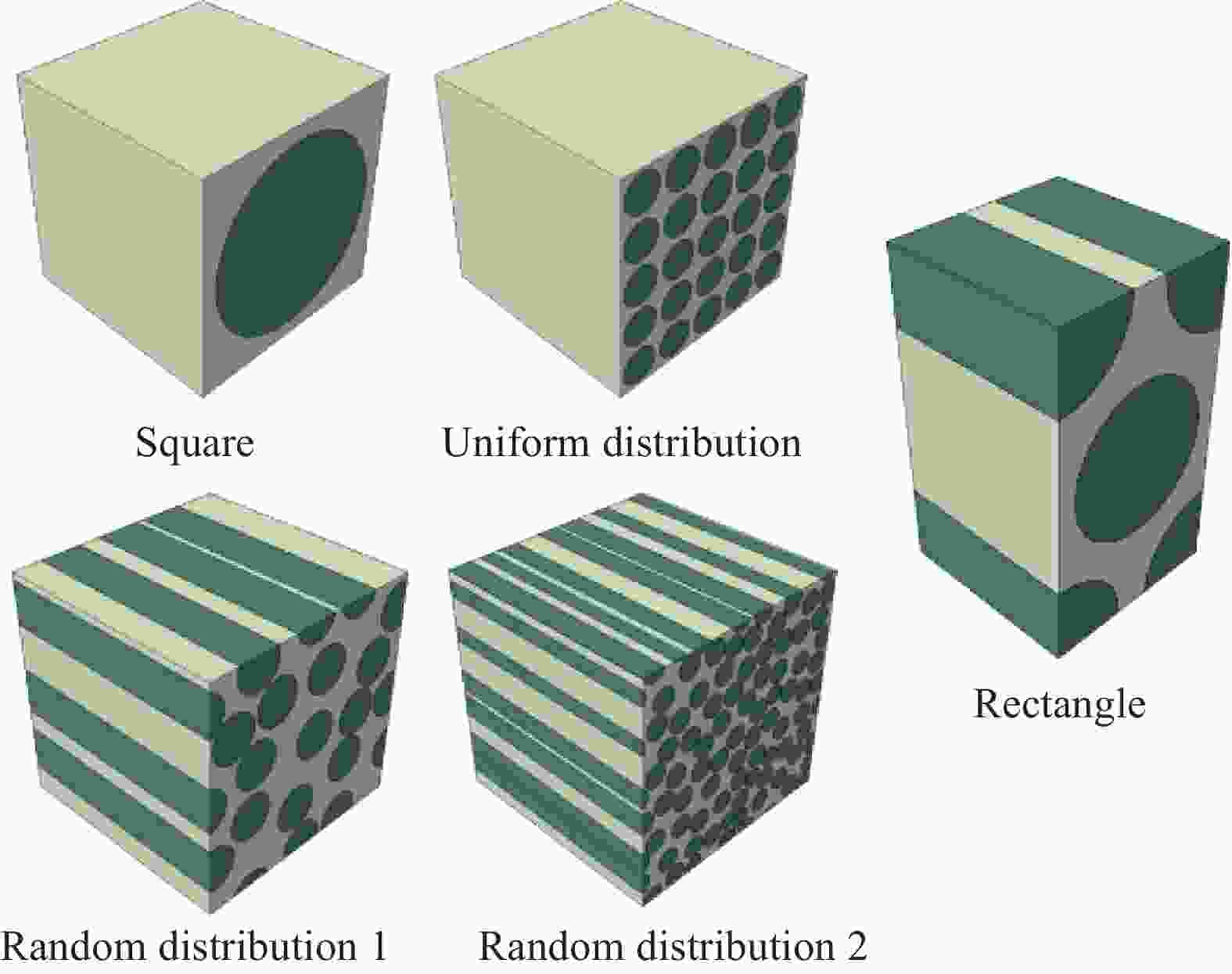

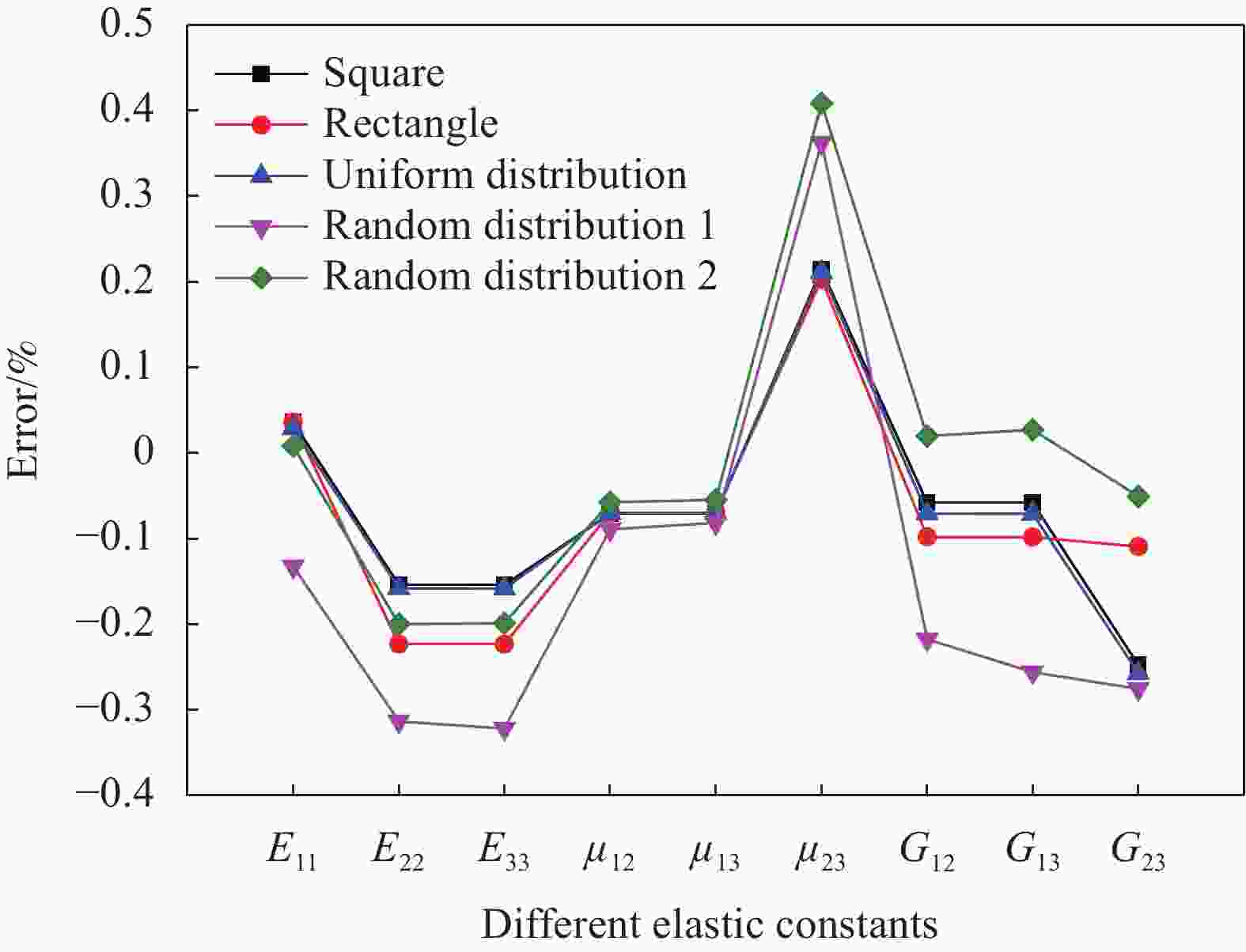

Material Name Value Carbon fiber Ef11/GPa 185 Ef22/GPa 13 Ef33/GPa 15 Gf12/GPa 15 Gf13/GPa 15 Gf23/GPa 9 μf12 0.28 μf13 0.35 μf23 0.35 Matrix Em/GPa 2.6 μm 0.33 Notes: Ef11, Ef22, Ef33, Gf12, Gf23, Gf13—Elastic moduli of T300 carbon fiber in the 1, 2, 3, 12, 23, 13 directions, respectively; μf12, μf13, μf23—Poisson's ratios in the 12, 13, 23 directions, respectively; Em and μm—Micro elastic modulus and Poisson's ratio of the matrix, respectively. 表 2 CFRP RVE模型力学性能参数与实验对比

Table 2. Comparison of RVE models of CFRP and experimental tests

E11/GPa E22/GPa E33/GPa μ12 μ13 μ23 G12/MPa G13/MPa G23/MPa Experiments 108 8 8 0.320 0.320 0.300 3500 3500 3000 Square 111.9 6.8 6.8 0.297 0.297 0.364 3297 3297 2257 Rectangle 111.9 6.2 6.2 0.298 0.298 0.361 3157 3156 2672 Uniform distribution 111.1 6.7 6.7 0.298 0.298 0.363 3252 3251 2228 Random distribution 1 937.0 5.5 5.4 0.292 0.294 0.409 2739 2604 2174 Random distribution 2 108.9 6.4 6.4 0.302 0.303 0.423 3570 3596 2849 Notes: E11, E22, E33, G12, G23, G13—Elastic moduli of carbon fiber prepreg in the 1, 2, 3, 12, 23, 13 directions, respectively; μ12, μ13, μ23—Poisson's ratios in the 12, 13, 23 directions, respectively. 表 3 CFRP多尺度模型的需求参数

Table 3. Parameters of CFRP multiscale model

E11/GPa E33/GPa μ13 G12/GPa G23/GPa $X_{\text{f}}^{0,{\text{T}}}/{\rm{MPa}}$ $X_{\text{f}}^{0,{\text{C}}}/{\rm{MPa}}$ $\gamma $ E22/GPa μ12 μ23 G13/GPa $Y_{\text{m}}^{0,{\text{T}}}/{\rm{MPa}}$ $Y_{\text{m}}^{0,{\text{C}}}/{\rm{MPa}}$ 108 8 0.32 3.5 3 2100 800 1.5 8 0.32 0.3 3.5 25 120 Notes: $X_{\text{f}}^{0,{\text{T}}}$, $X_{\text{f}}^{0,{\text{C}}}$—Longitudinal tensile strength and compres-sive strength, respectively; $Y_{\text{m}}^{0,{\text{T}}}$, $Y_{\text{m}}^{0,{\text{C}}}$—Transverse tensile strength and compressive strength, respectively; $\gamma $—Damage shape parameter of matrix. 表 4 2024-T3铝合金板的材料属性

Table 4. Material properties of 2024-T3 aluminum

Density/(kg·m−3) 2700 Young's modulus/GPa 70 Poisson's ratio 0.3 Yield strength/MPa 292 Fracture strain 0.15 Fracture energy/(J·m−2) 10200 表 5 内聚力单元参数

Table 5. Material properties of cohesive elements

E/GPa ${t}_{}^{\text{0}}/{\rm{MPa}}$ $ {G^{\text{c} }}/({\rm{N} }\cdot{\rm{mm} }^{-1})$ Density/(kg·m−3) ${E_{{\text{nn}}}}$ ${E_{{\text{ss}}}}$ ${E_{{\text{tt}}}}$ ${t}_{\text{n}}^{\text{0}}$ ${t}_{\text{s}}^{\text{0}}$ ${t}_{\text{t} }^{\text{0} }$ $ G_{\text{n}}^{\text{c}} $ $ G_{\text{s}}^{\text{c}} $ $ G_{\text{t}}^{\text{c}} $ $\rho $ 20500 7200 7200 140 300 300 2000 3000 3000 0.092 Notes: $ {E}_{\text{nn}}, {E}_{\text{ss}}, {E}_{\text{tt}} $—Stiffness coefficient in the normal and shear directions; ${t}_{\text{n} }^{\text{0} }, {t}_{\text{s} }^{\text{0} }, {t}_{\text{t} }^{\text{0} }$—Nominal stress in the normal and shear directions; $ G_{\text{n}}^{\text{c}} , G_{\text{s}}^{\text{c}} , G_{\text{t}}^{\text{c}} $—Critical fracture energies in the normal and shear directions. 表 6 CFRP铝合金粘接板RVE模型力学性能参数与实验对比

Table 6. Comparison of mechanical parameters of RVE model of CFRP aluminum alloy adhesive plate and experimental tests

Fiber volume fraction (Vf) E11/GPa E22/GPa E33/GPa μ12 μ13 μ23 G12/MPa G13/MPa G23/MPa 0.4 75.4 4.6 4.6 0.308 0.308 0.440 2031 2031 1780 0.5 93.6 5.3 5.3 0.302 0.302 0.427 2503 2503 2154 0.6 111.9 6.2 6.2 0.298 0.298 0.361 3157 3156 2672 0.7 130.1 7.3 7.3 0.293 0.293 0.394 4136 4133 3404 0.8 148.3 8.7 8.7 0.288 0.288 0.380 5824 5824 4470 -

[1] 陶杰, 李华冠, 潘蕾, 等. 纤维金属层板的研究与发展趋势[J]. 南京航空航天大学学报, 2015, 47(5):626-636.TAO Jie, LI Huaguan, PAN Lei, et al. Review on research and development of fiber metal laminates[J]. Journal of Nanjing University of Aeronautics and Astronautics,2015,47(5):626-636(in Chinese). [2] HA N S, LU G X. A review of recent research on bio-inspired structures and materials for energy absorption applications[J]. Composites Part B: Engineering,2020,181:107496. doi: 10.1016/j.compositesb.2019.107496 [3] SUN G Y, CHEN D D, ZHU G H, et al. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook[J]. Thin-Walled Structures,2022,172:108760. doi: 10.1016/j.tws.2021.108760 [4] HE W T, WANG C Z, WANG S Q, et al. Characterizing and predicting the tensile mechanical behavior and failure mechanisms of notched FMLs-combined with DIC and numerical techniques[J]. Composite Structures,2020,254:112893. doi: 10.1016/j.compstruct.2020.112893 [5] YAO L, MAO L Z, WANG Y C, et al. In-situ damage monitoring and numerical characterization of three-point bending and incremental cycle flexural behavior of FMLs[J]. Mechanics of Advanced Materials and Structures,2023:1-19. doi: 10.1080/15376494.2023.2204095 [6] ZOPP C, DITTES A, NESTLER D, et al. Quasi-static and fatigue bending behavior of a continuous fiber-reinforced thermoplastic/metal laminate[J]. Composites Part B: Engineering,2019,174:107043. doi: 10.1016/j.compositesb.2019.107043 [7] HE W T, WANG L F, LIU H C, et al. On impact behavior of fiber metal laminate (FML) structures: A state-of-the-art review[J]. Thin-Walled Structures,2021,167:108026. doi: 10.1016/j.tws.2021.108026 [8] YU G C, WU L Z, MA L, et al. Low velocity impact of carbon fiber aluminum laminates[J]. Composite Structures,2015,119:757-766. doi: 10.1016/j.compstruct.2014.09.054 [9] YANG L, WU Z J, GAO D Y, et al. Microscopic damage mechanisms of fibre reinforced composite laminates subjected to low velocity impact[J]. Computational Materials Science,2016,111:148-156. doi: 10.1016/j.commatsci.2015.09.039 [10] QI Z C, LIU Y, CHEN W L. An approach to predict the mechanical properties of CFRP based on cross-scale simulation[J]. Composite Structures,2019,210:339-347. doi: 10.1016/j.compstruct.2018.11.056 [11] GE L, LI H M, LIU B S, et al. Multi-scale elastic property prediction of 3D five-directional braided composites considering pore defects[J]. Composite Structures,2020,244:112287. doi: 10.1016/j.compstruct.2020.112287 [12] GHOLAMI M, AFRASIAB H, BAGHESTANI A M, et al. A novel multiscale parallel finite element method for the study of the hygrothermal aging effect on the composite materials[J]. Composites Science and Technology,2022,217:109120. doi: 10.1016/j.compscitech.2021.109120 [13] 王猛. 碳纤维增强复合材料宏-细-微观损伤失效研究[D]. 南京: 东南大学, 2020.WANG Meng. Damage and failure analysis of carbon fiber reinforced composites across macro-meso-micro scales[D]. Nanjing: Southeast University, 2020(in Chinese). [14] WANG M, HANG X C. Modified micro-mechanics based multiscale model for damage analysis of open-hole composite laminates under compression[J]. Materials,2022,15(15):5105. doi: 10.3390/ma15155105 [15] 蒋宏勇. CFRP薄壁结构耐撞性与失效机理研究[D]. 长沙: 湖南大学, 2021.JIANG Hongyong. Research on crashworthiness and failure mechanisms of carbon-fiber reinforced polymer composite thin-walled structures[D]. Changsha: Hunan University, 2021(in Chinese). [16] HA S K, JIN K K, HUANG Y C. Micro-mechanics of failure (MMF) for continuous fiber reinforced composites[J]. Journal of Composite Materials,2008,42(18):1873-1895. doi: 10.1177/0021998308093911 [17] LIAO B B, TAN H C, ZHOU J W, et al. Multi-scale modelling of dynamic progressive failure in composite laminates subjected to low velocity impact[J]. Thin-Walled Structures,2018,131:695-707. doi: 10.1016/j.tws.2018.07.047 [18] LOU X F, CAI H N, YU P F, et al. Failure analysis of composite laminate under low-velocity impact based on micromechanics of failure[J]. Composite Structures,2017,163:238-247. doi: 10.1016/j.compstruct.2016.12.030 [19] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M—12[S]. West Conshohocken: ASTM International, 2012. [20] XIA Z H, ZHANG Y F, ELLYIN F. A unified periodical boundary conditions for representative volume elements of composites and applications[J]. International Journal of Solids and Structures,2003,40(8):1907-1921. doi: 10.1016/S0020-7683(03)00024-6 [21] 李星, 关志东, 刘璐, 等. 复合材料跨尺度失效准则及其损伤演化[J]. 复合材料学报, 2013, 30(2):152-158.LI Xing, GUAN Zhidong, LIU Lu, et al. Composite multiscale failure criteria and damage evolution[J]. Acta Materiae Compositae Sinica,2013,30(2):152-158(in Chinese). [22] 刘勇. 面向CFRP钻削的跨尺度数值模拟技术研究[D]. 南京: 南京航空航天大学, 2020.LIU Yong. Research on scale-span numerical simulation techniques for CFRP drilling[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020(in Chinese). [23] JIN K K, HUANG Y C, LEE Y H, et al. Distribution of micro stresses and interfacial tractions in unidirectional composites[J]. Journal of Composite Materials,2008,42(18):1825-1849. doi: 10.1177/0021998308093909 [24] 朱国华, 竺森森, 胡珀, 等. CFRP薄壁结构多尺度建模及耐撞性分析[J]. 复合材料学报, 2023, 40(6):3626-3639.ZHU Guohua, ZHU Sensen, HU Po, et al. Multi-scale modeling and crashworthiness analysis of CFRP thin-walled structures[J]. Acta Materiae Compositae Sinica,2023,40(6):3626-3639(in Chinese). [25] YAO L, YU H, WANG C Z, et al. Numerical and experimental investigation on the oblique successive impact behavior and accumulated damage characteristics of fiber metal laminates[J]. Thin-Walled Structures,2021,166:108033. doi: 10.1016/j.tws.2021.108033 [26] YAO L, WANG C Z, HE W T, et al. Influence of impactor shape on low-velocity impact behavior of fiber metal laminates combined numerical and experimental approaches[J]. Thin-Walled Structures,2019,145:106399. doi: 10.1016/j.tws.2019.106399 -

下载:

下载: