Cyclic stress-strain relationship of CFRP-confined recycled aggregates concrete under different loading rates

-

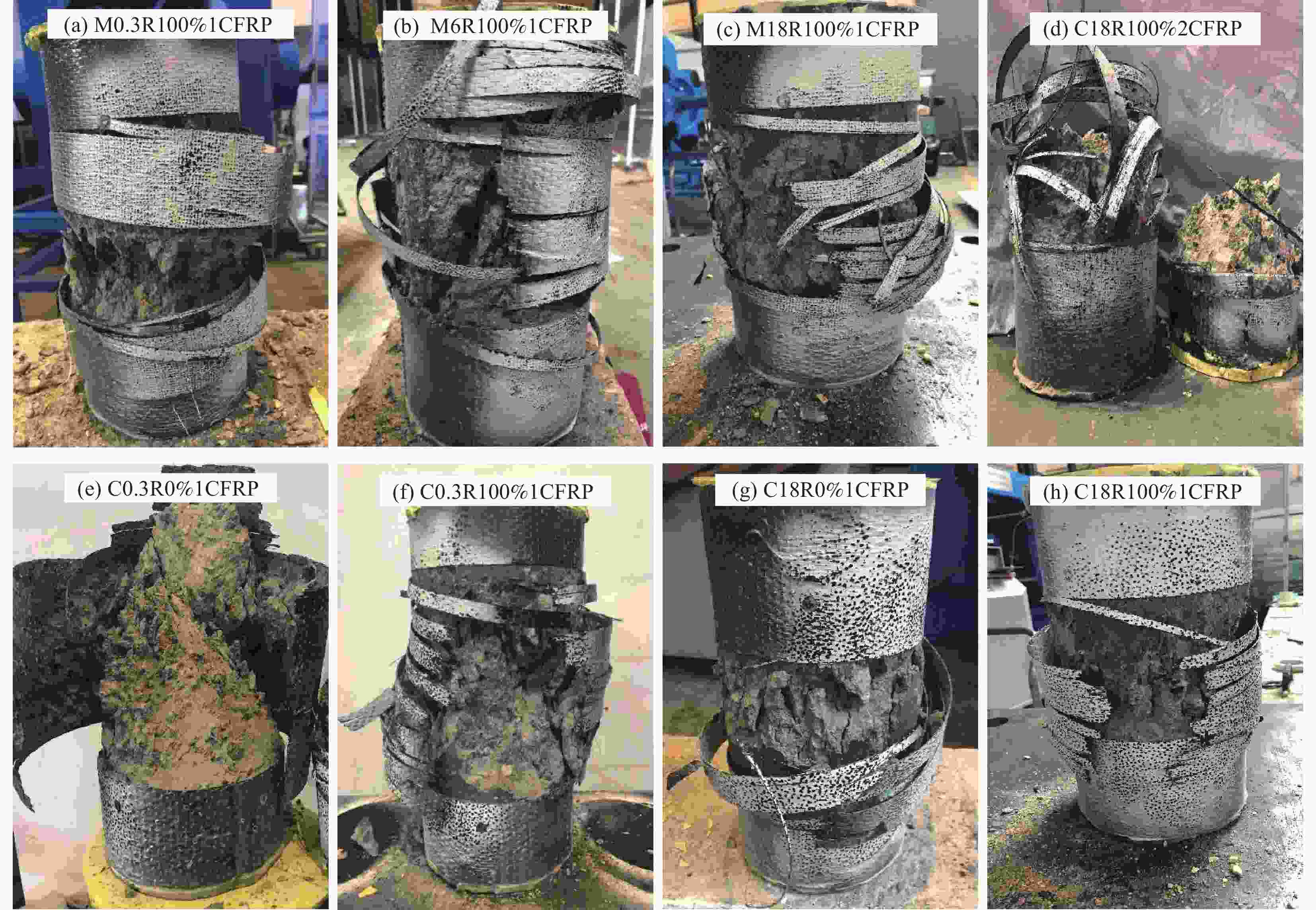

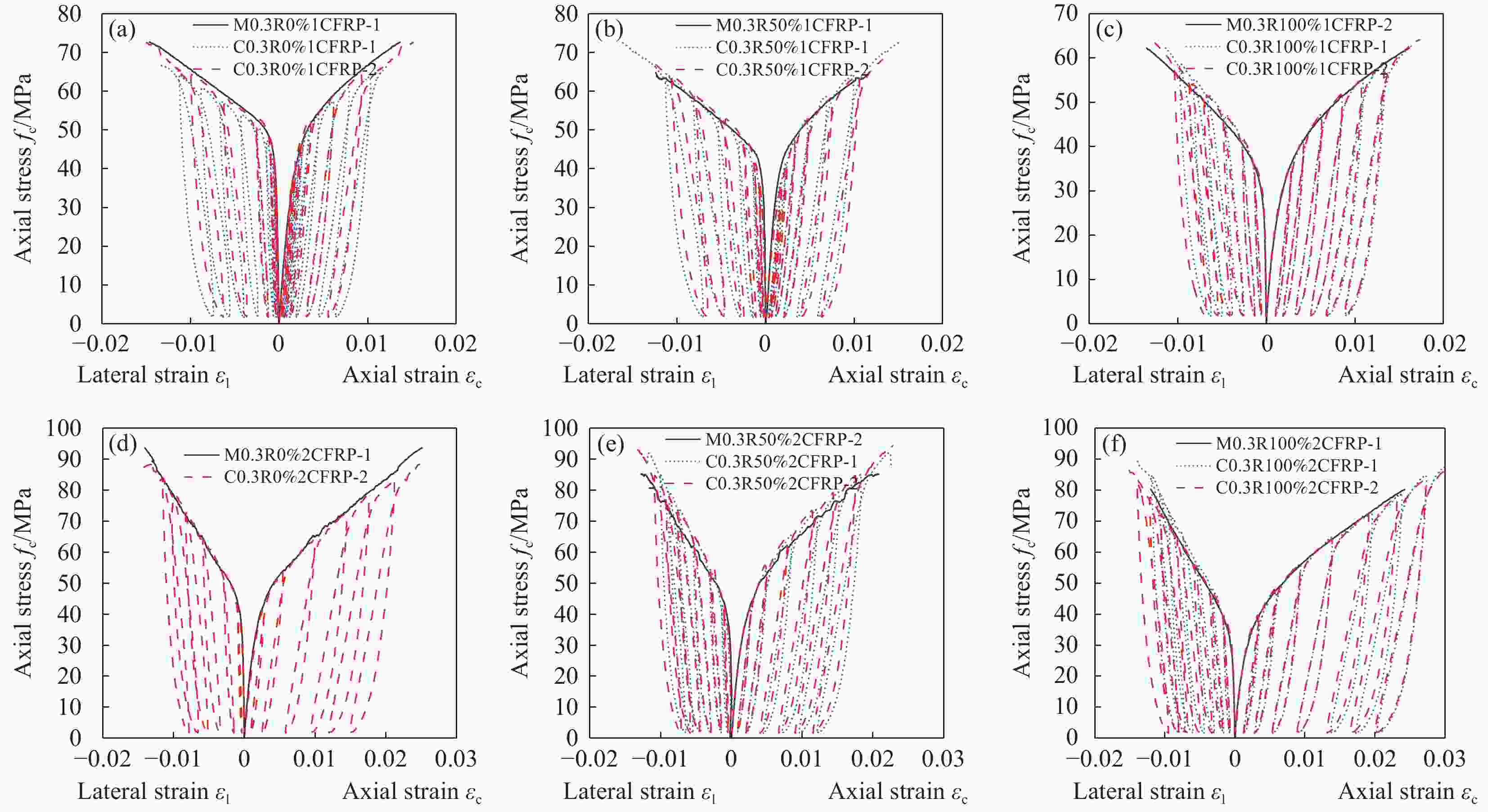

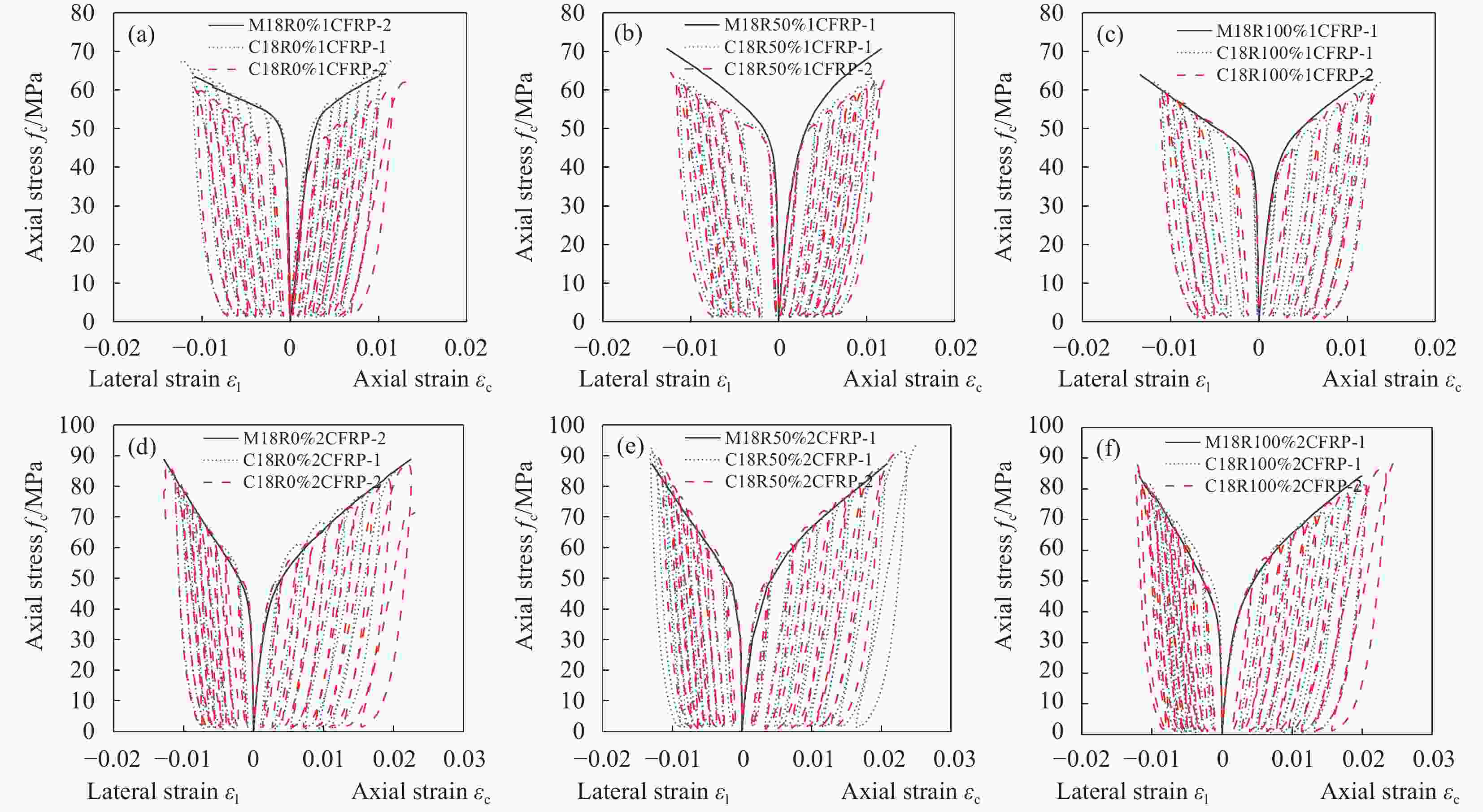

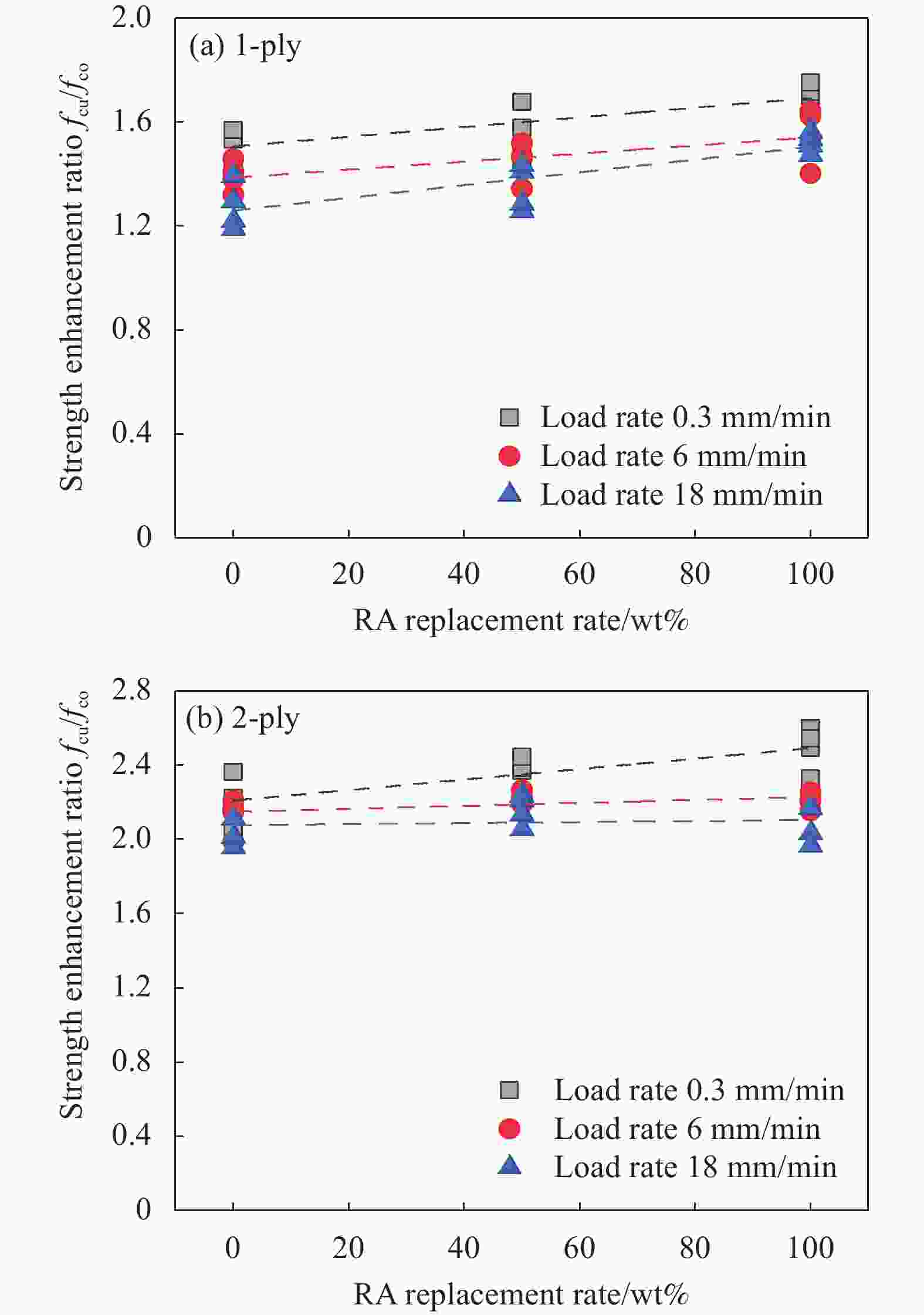

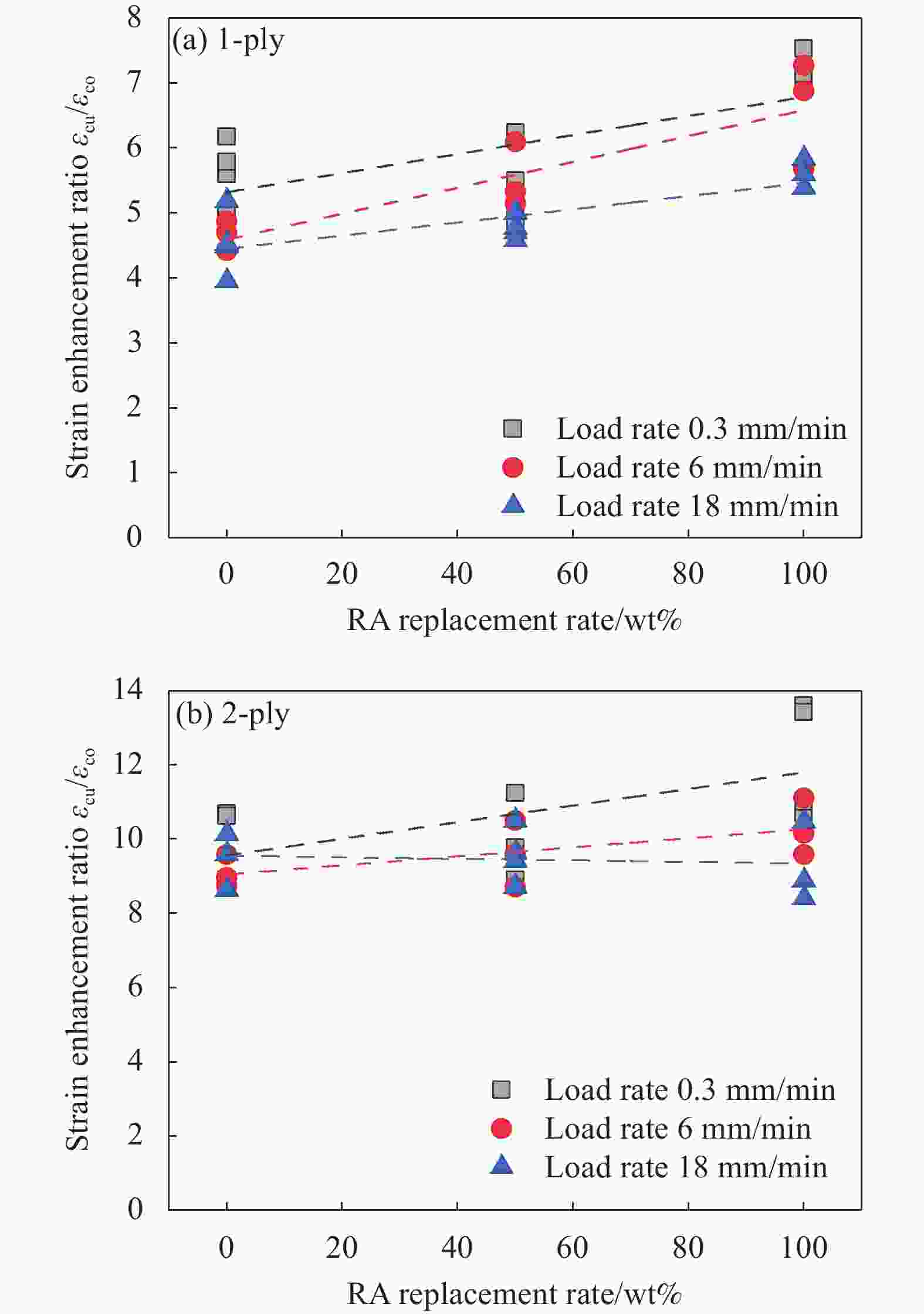

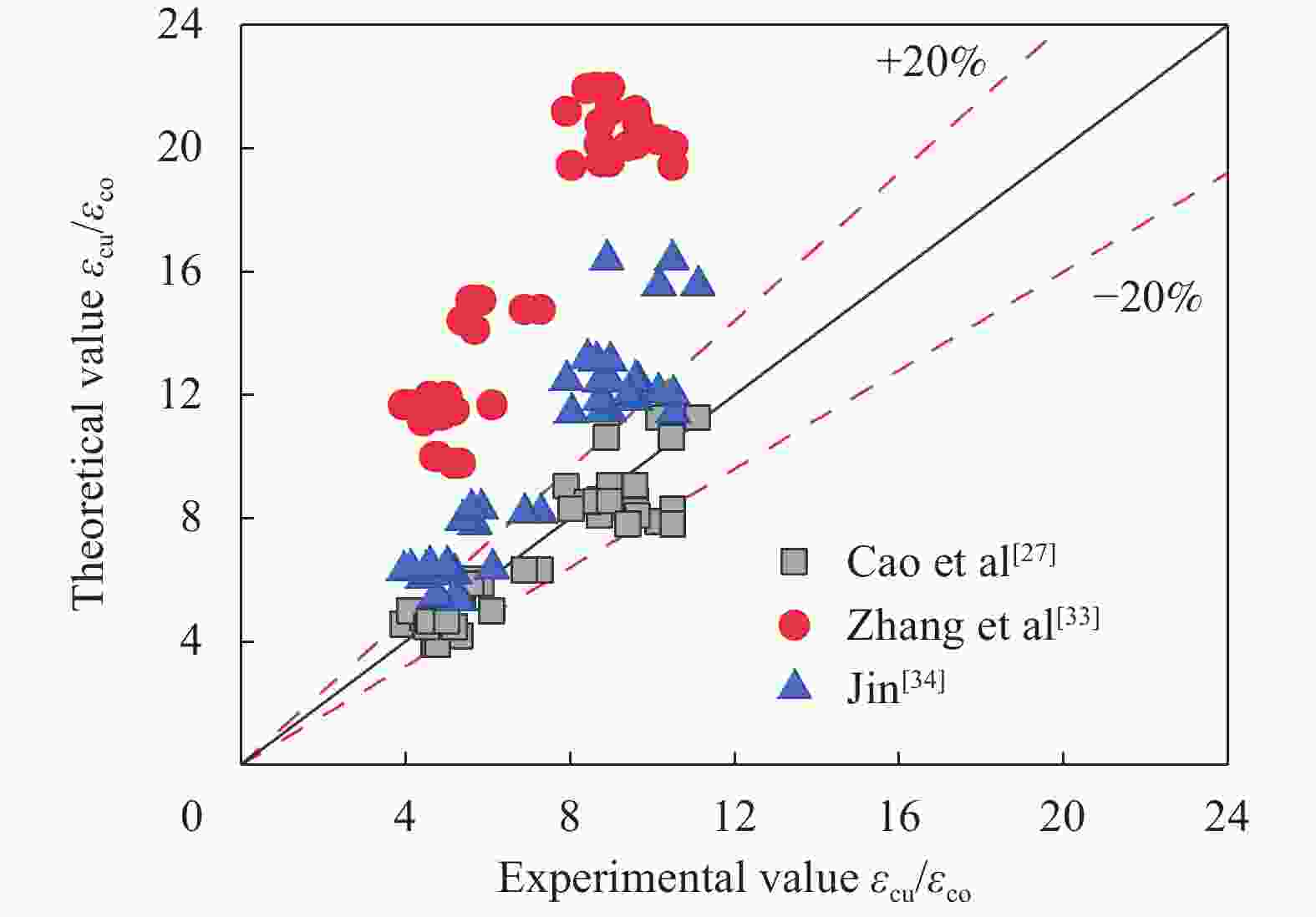

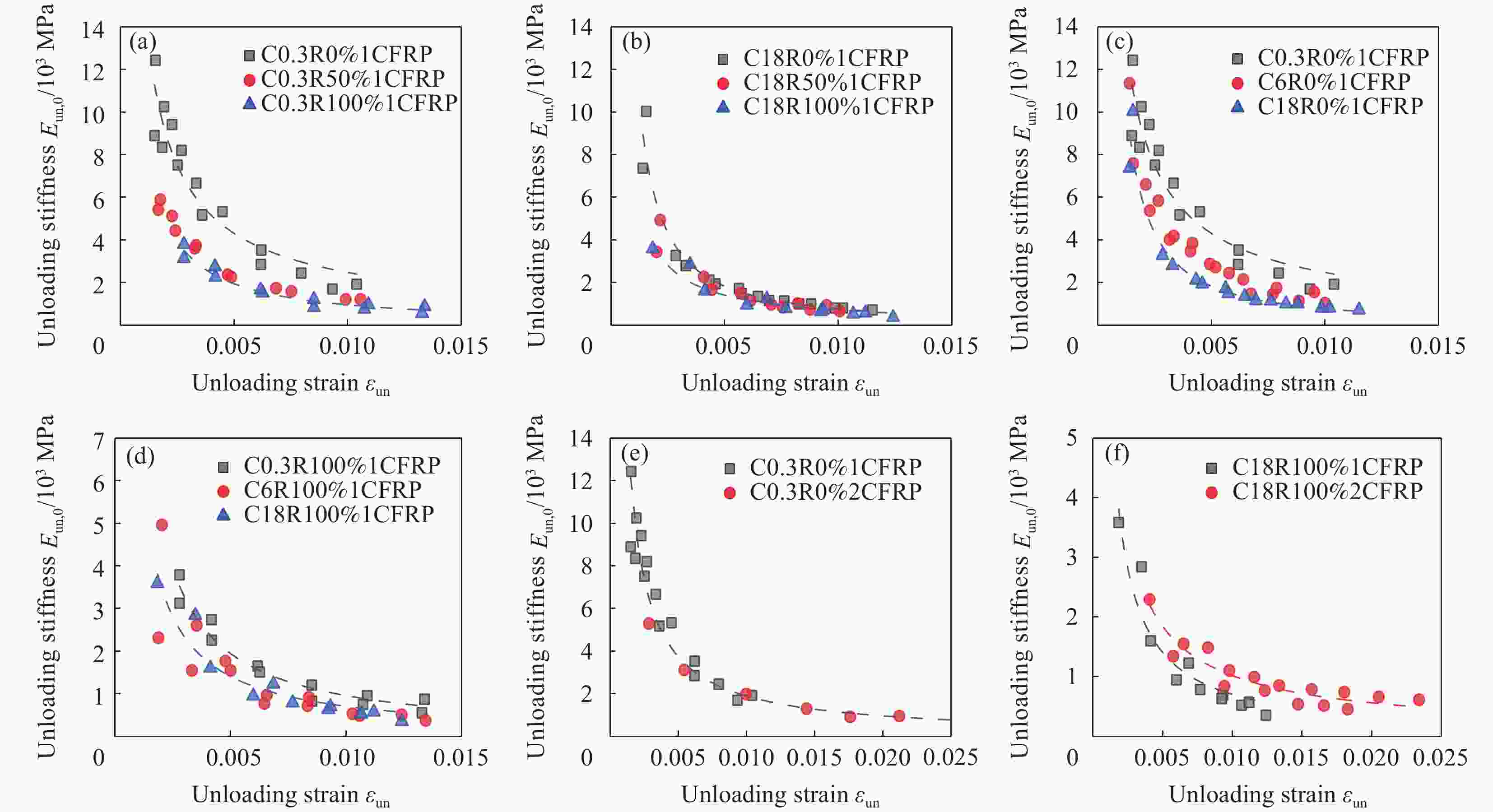

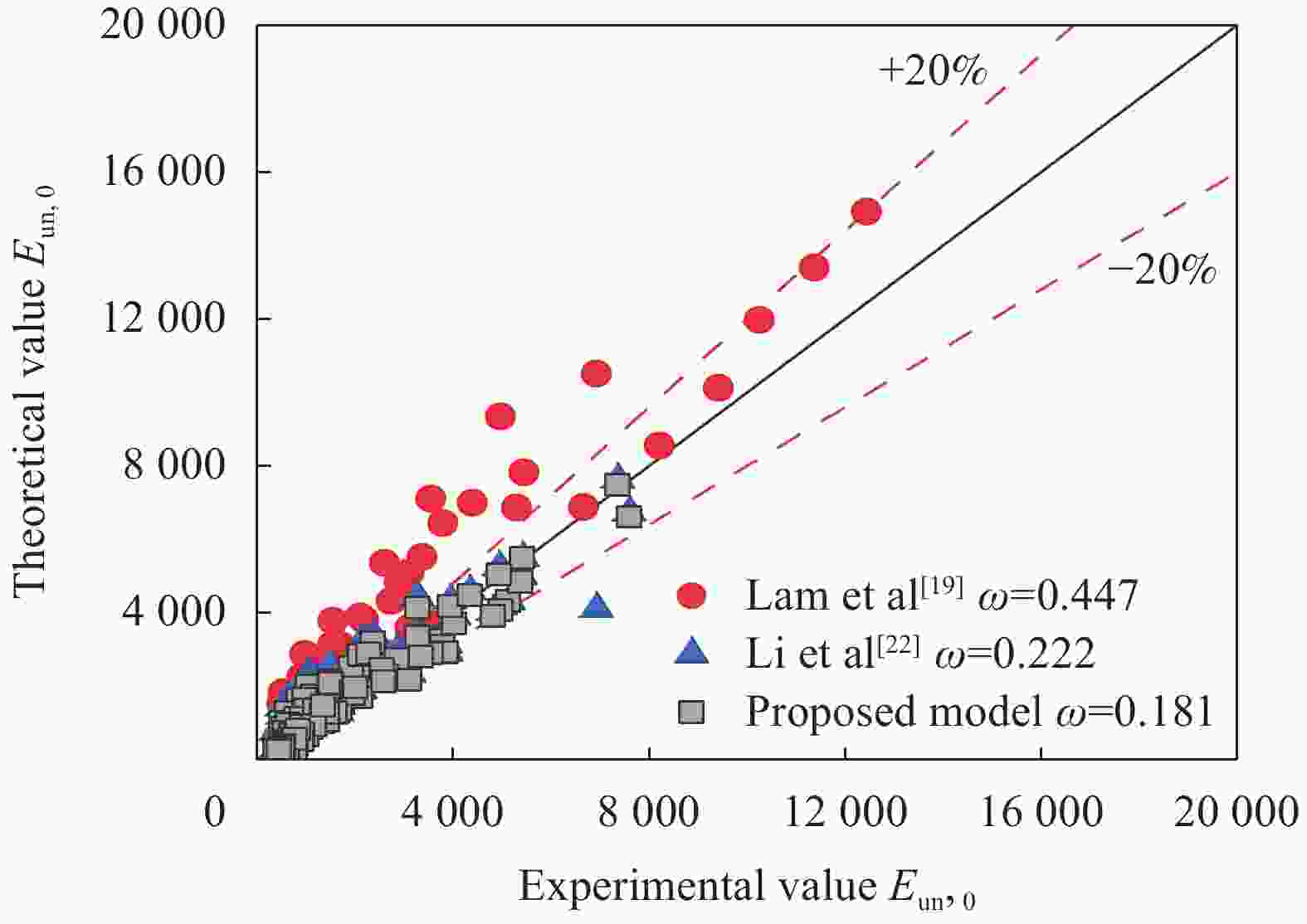

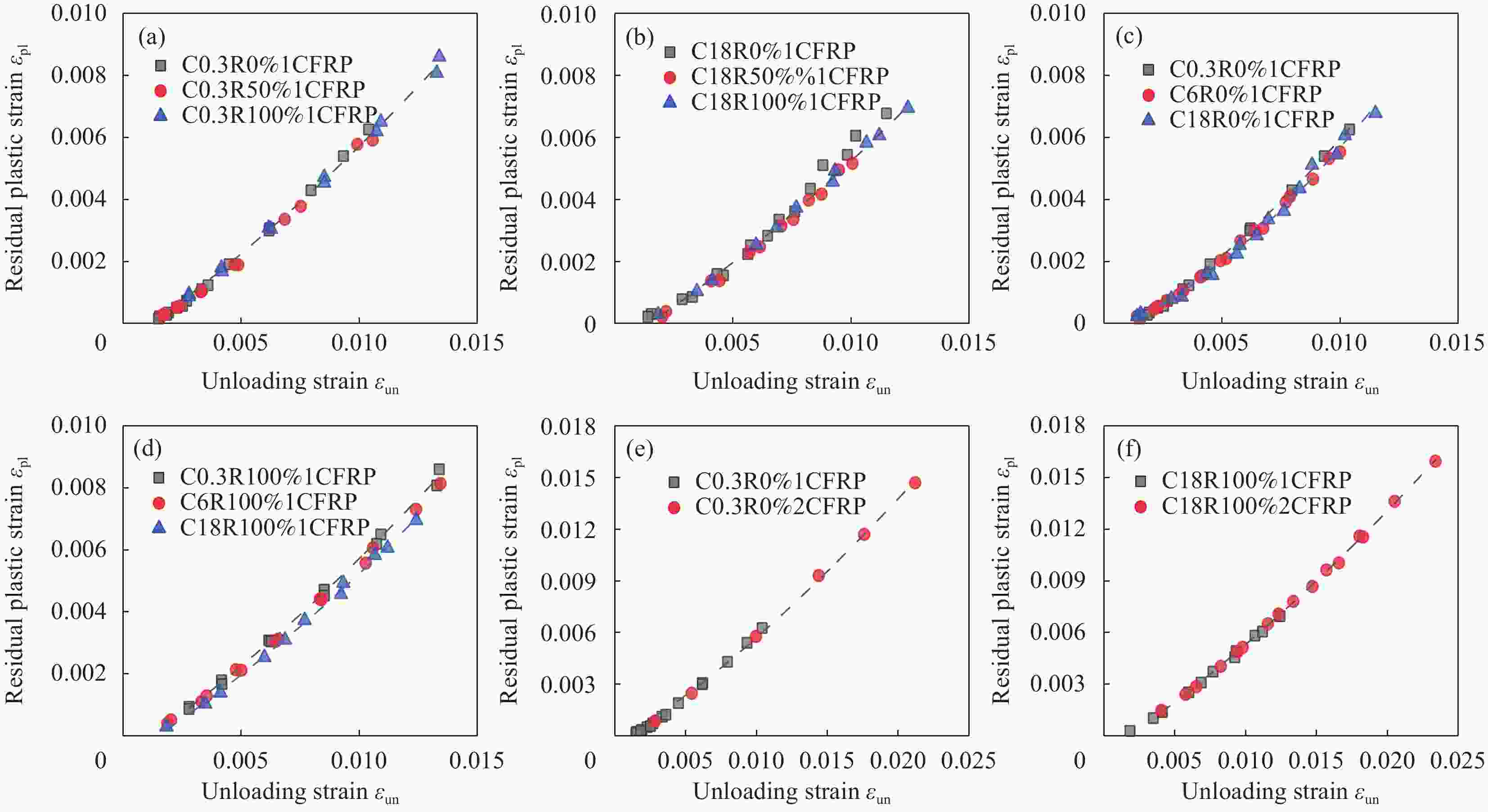

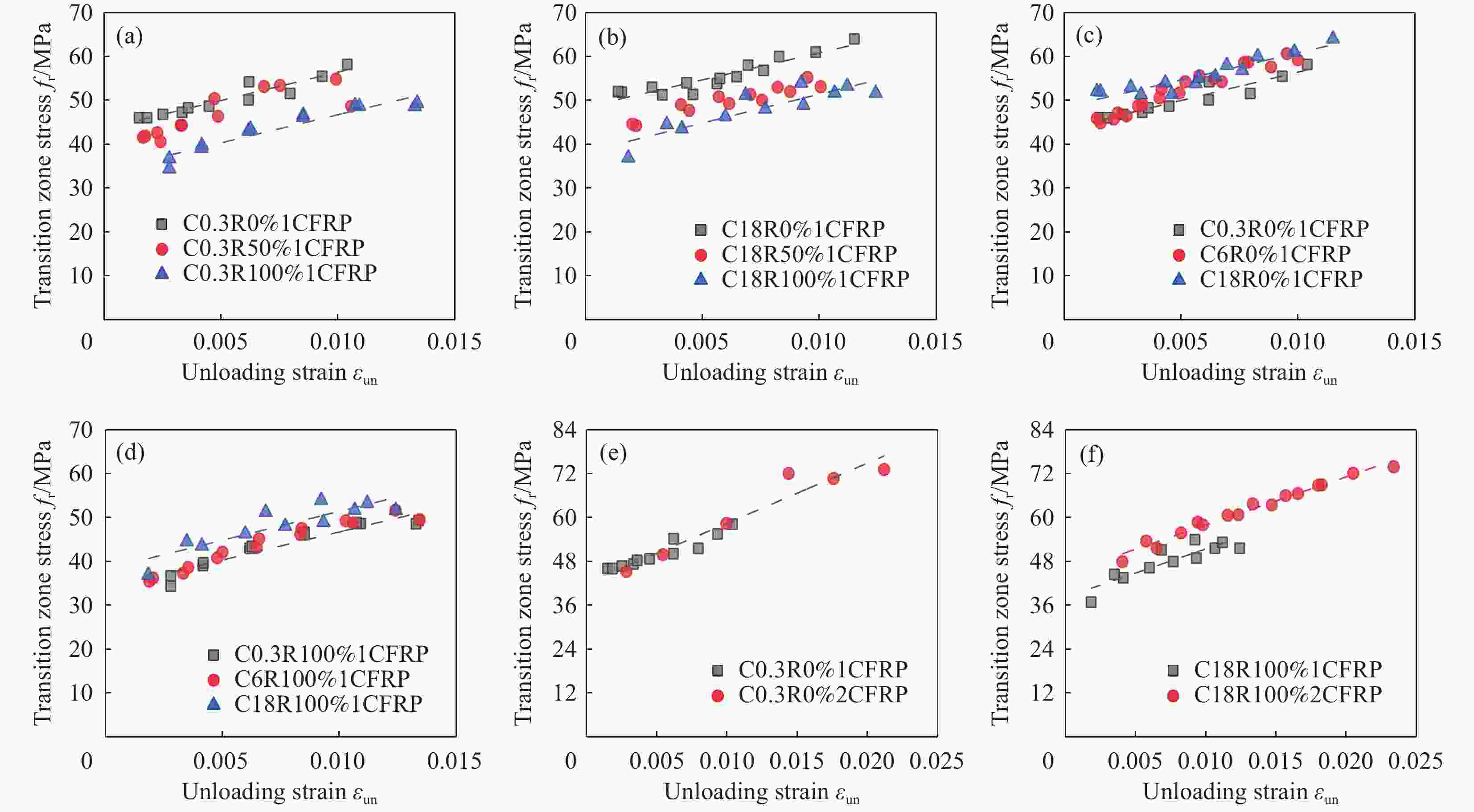

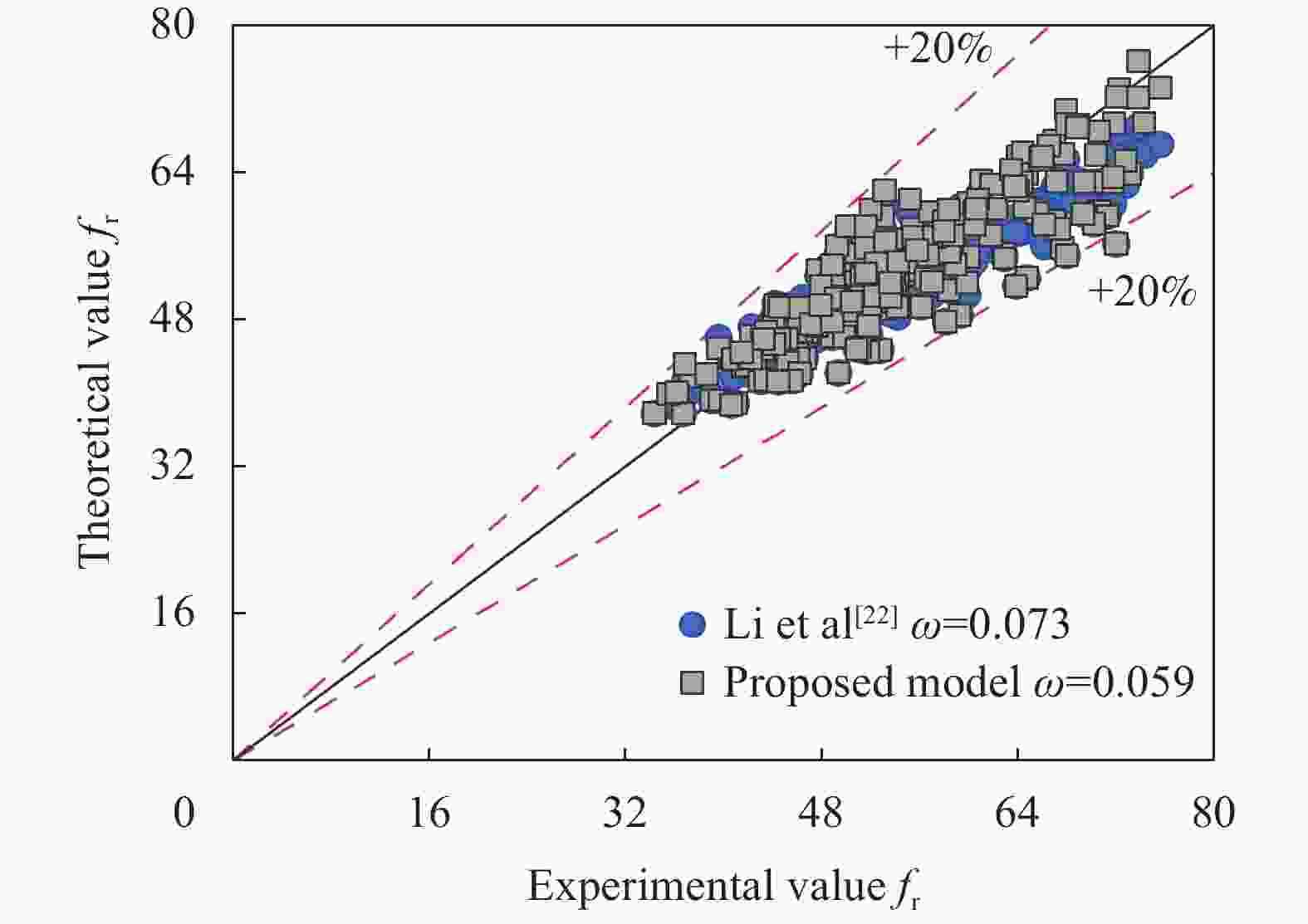

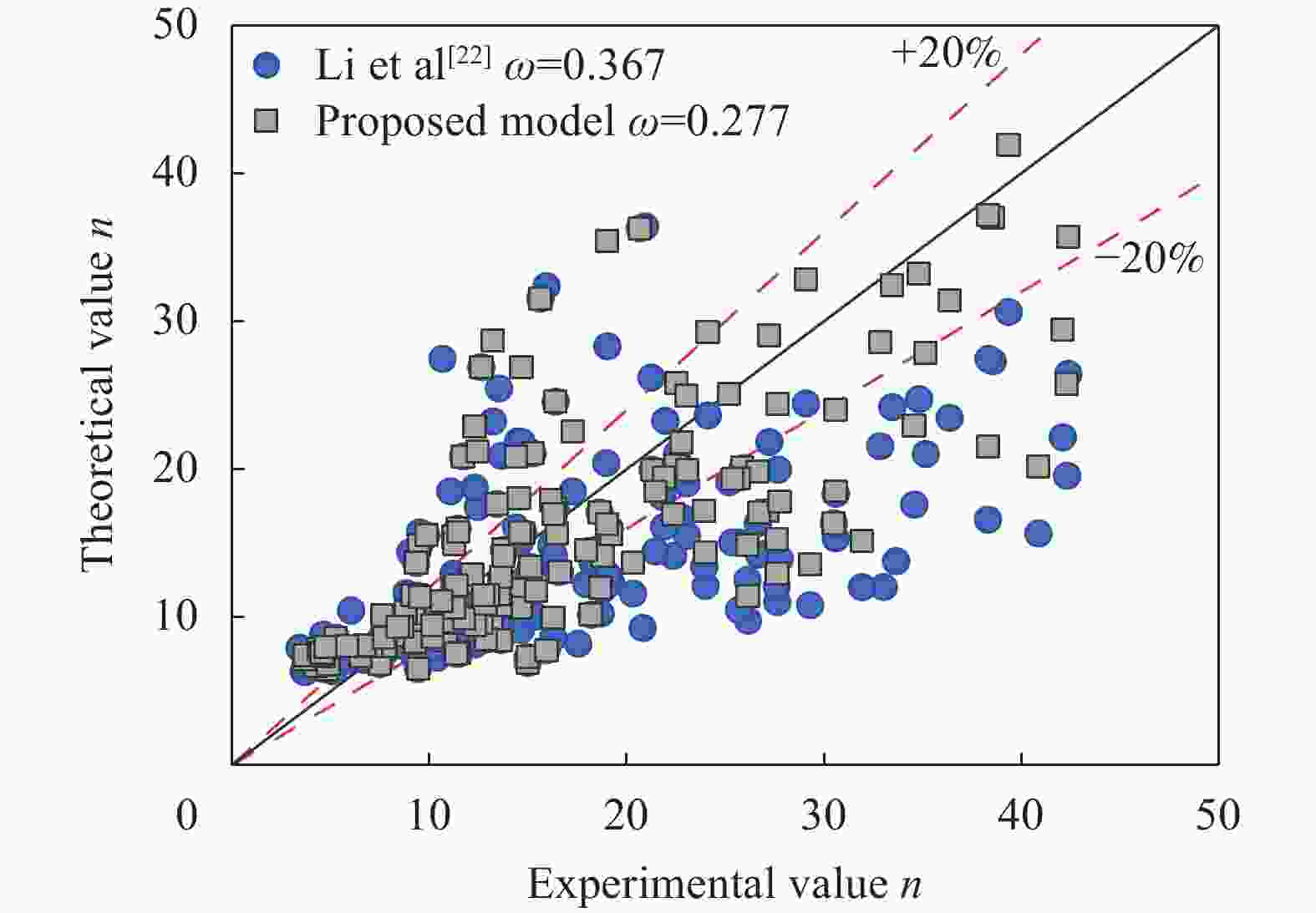

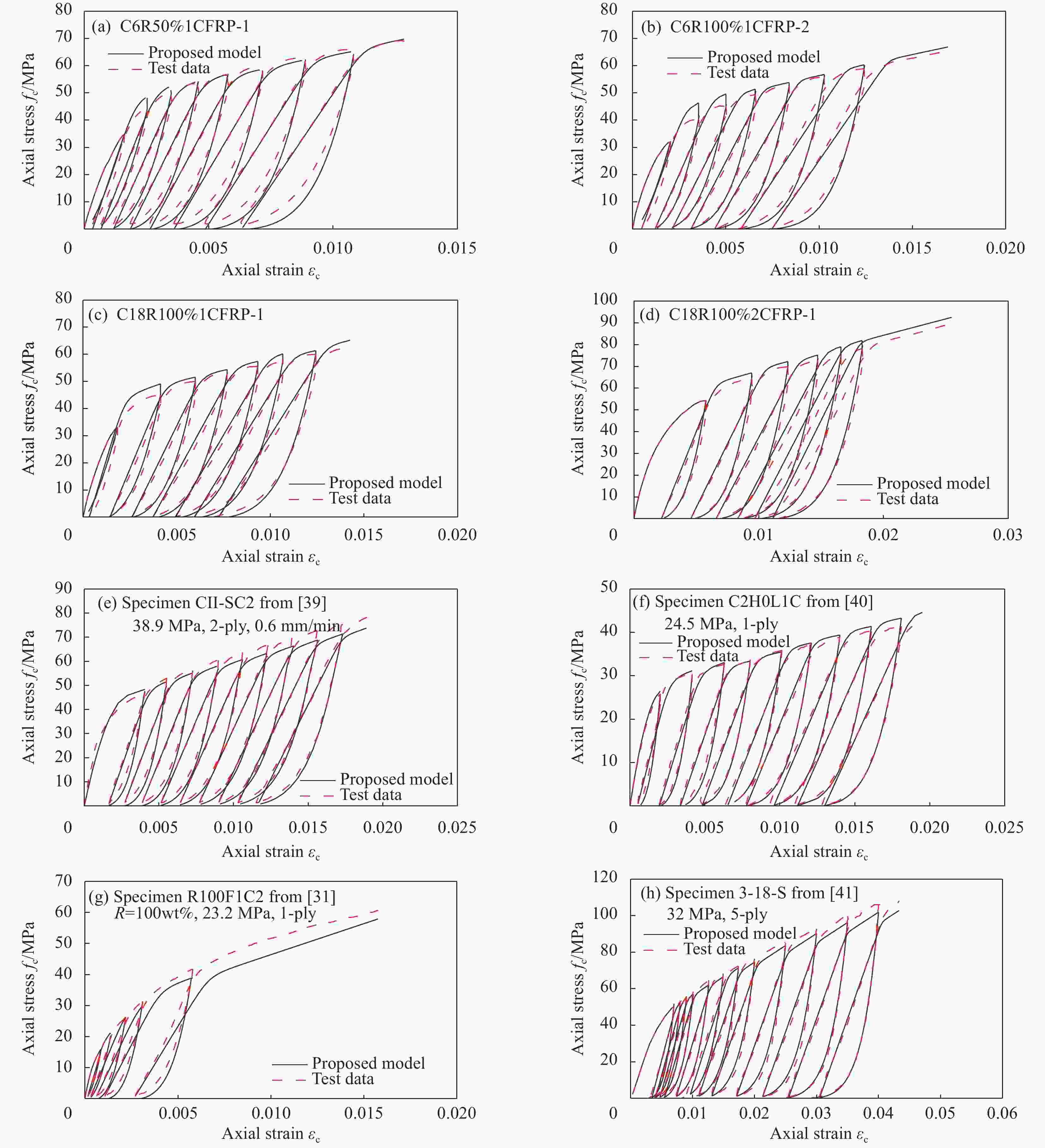

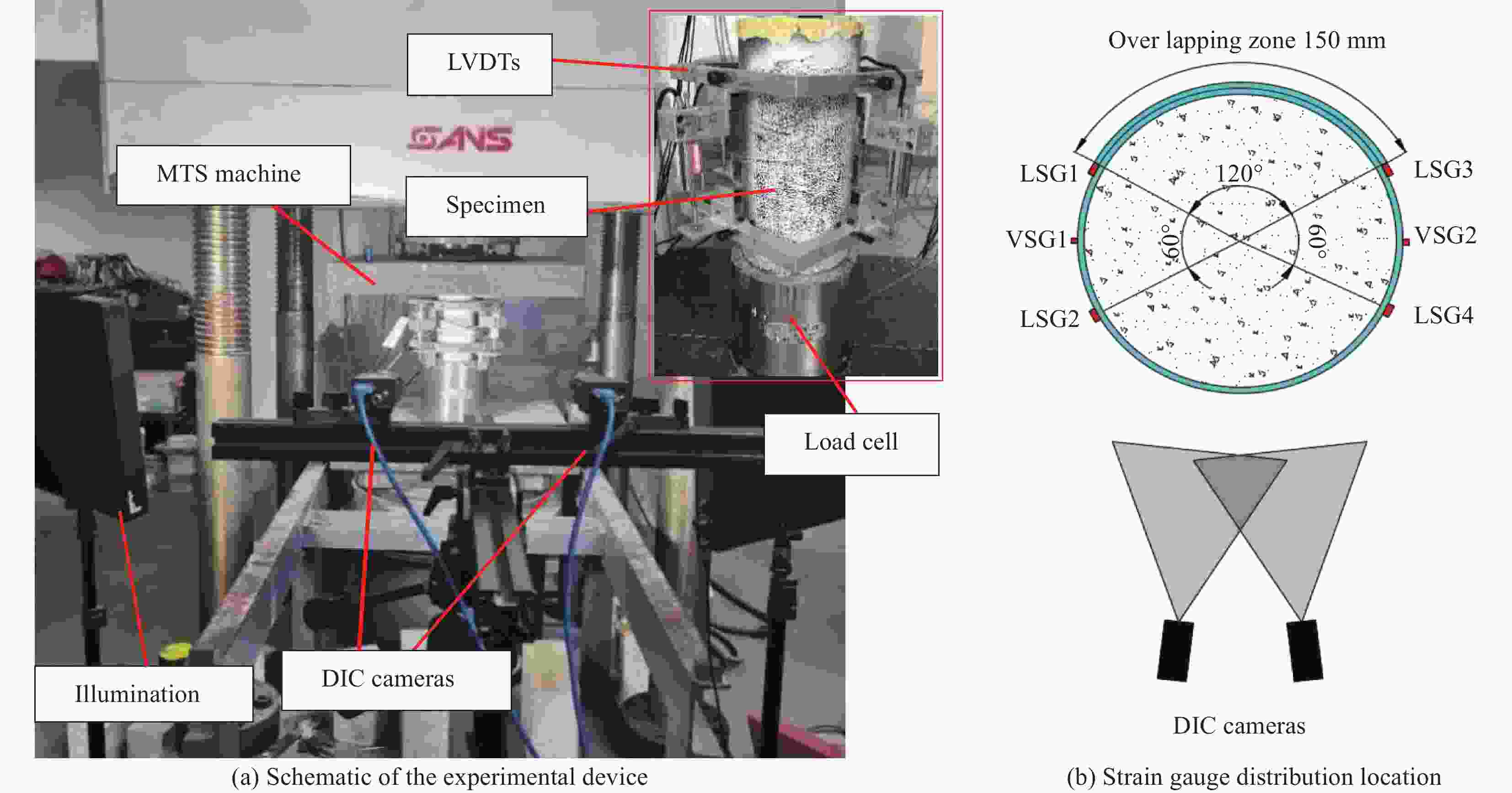

摘要: 为研究碳纤维增强树脂复合材料(CFRP)约束再生骨料混凝土(RAC)在重复轴向压缩作用下的力学性能,对72根CFRP约束RAC圆柱进行了不同加载速率下的单调及重复轴压试验,分析了加载速率、再生骨料(RA)替代率和CFRP层数对CFRP约束RAC的破坏模式、极限状态、重复应力-应变关系的影响。试验结果表明:CFRP约束对100wt%RA替代率混凝土极限状态的增强效果最为显著,但其增强效果随着加载速率的增大而减小。相比于3 mm/min的加载速率,2层CFRP约束100wt%RA替代率混凝土在18 mm/min的加载速率下,其极限强度增强比降低了16.2%,极限应变增强比降低了22.6%。此外,重复轴压荷载作用下,卸载刚度和再加载刚度均与RA替代率和加载速率呈负相关,但加载速率的提升会削弱RA替代率的影响。最后,通过对试验数据的回归分析,建立了考虑加载速率与RA替代率耦合作用的CFRP约束RAC重复轴压应力-应变模型,模型预测曲线与本文的试验曲线和现有文献收集的试验曲线匹配良好。Abstract: This study experimentally investigated the mechanical behavior of carbon fiber reinforced polymer (CFRP) confined recycled aggregate concrete (RAC) under cyclic loading. In total, 72 CFRP-confined circular RAC specimens were tested under monotonic and cyclic axial compression, with a focus on the various loading rates and recycled aggregate (RA) replacement ratios. Test results indicate that the reinforcing effect of CFRP confinement on the ultimate condition of the concrete with 100wt%RA replacement ratio is most pronounced. However, this enhancement diminishes as the loading rate increases. In comparison to a loading rate of 3 mm/min, for two layers of CFRP-confined concrete with 100wt%RA replacement ratio, the enhancement ratio in ultimate strength is reduced by 16.2%, and the enhancement ratio in ultimate strain is reduced by 22.6% at a loading rate of 18 mm/min. Furthermore, under cyclic axial compression loading, both the unloading stiffness and reloading stiffness exhibit a negative correlation with the RA replacement ratio and loading rate. Nevertheless, the loading rate increase weakens the RA ratio's influence. Based on a regression analysis of the experimental data, a new cyclic stress-strain model for CFRP-confined recycled aggregate concrete incorporating the coupled effects of loading rate and RA replacement ratio is proposed. The proposed model exhibits excellent agreement with the experimental curves in this paper and the collected stress-strain curves from the opening literature.

-

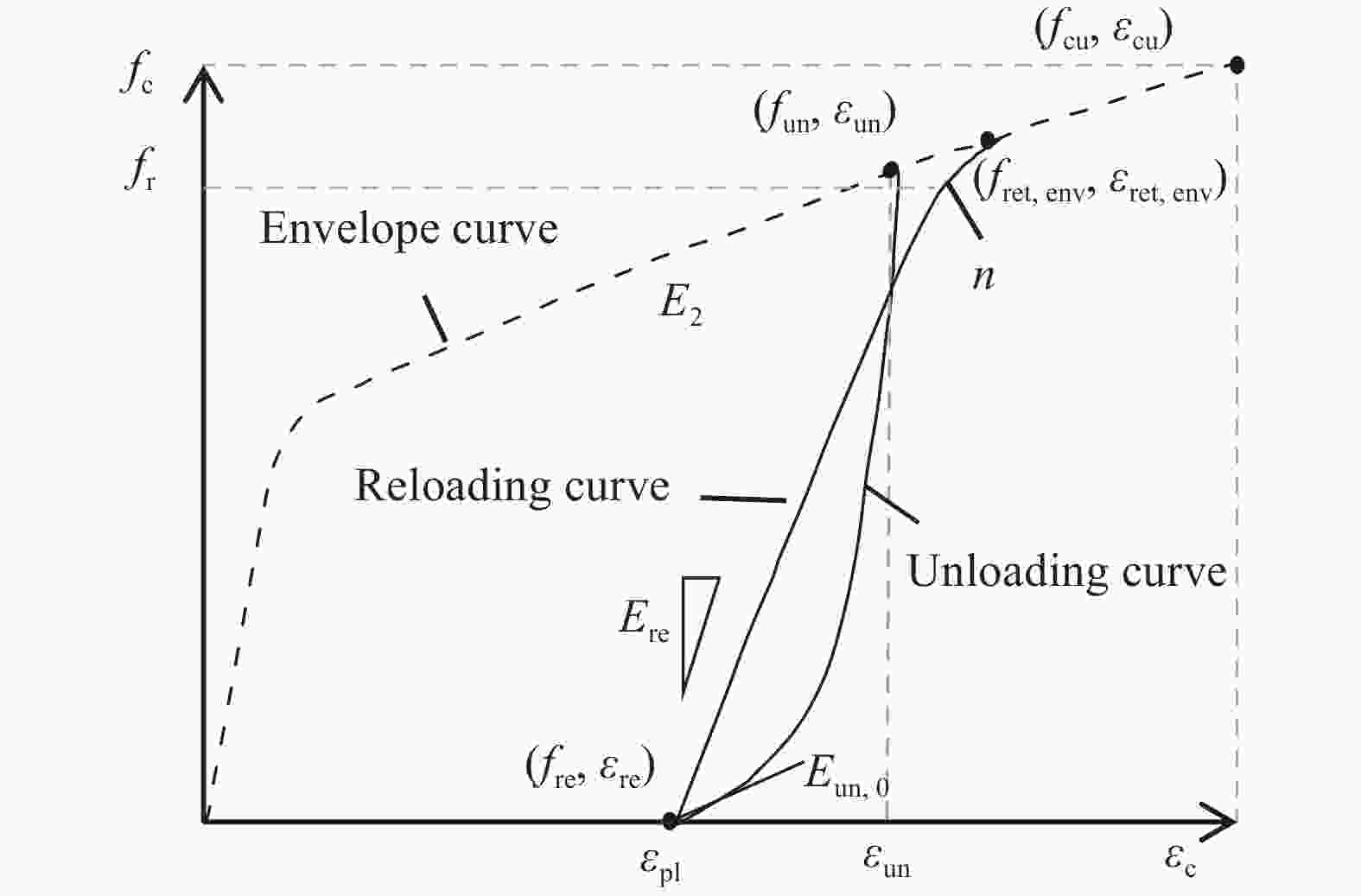

图 10 CFRP约束混凝土重复轴压下的典型应力-应变曲线

E2—The second stiffness; fun—Unloading stress; εun—Unloading strain; εp1—Plastic strain; Eun, 0—Unloading stiffness; Ere—Reloading stiffness; fr—Elastic limit stress; fre—Reloading stress; εre—Reloading strain; fret, env—Return envelope stress; εret, env—Return envelope strain; n—Curvature of transition zone

Figure 10. Typical stress-strain curve of CFRP-confined concrete under cyclic compression

表 1 碳纤维增强树脂复合材料(CFRP)约束再生骨料混凝土(RAC)试件设计参数

Table 1. Design parameters for carbon fiber reinforced polymer (CFRP)-confined recycled aggregate concrete (RAC) specimens

Specimen Loading type CFRP layer Loading rate/

(mm·min−1)RA replacement rate/wt% $ {f}_{\mathrm{c}\mathrm{o}} $/MPa $ {\varepsilon }_{\mathrm{c}\mathrm{o}} $/% M0.3R0%1CFRP Monotonic loading 1 0.3 0 46.3 0.244 M0.3R50%1CFRP 50 43.2 0.240 M0.3R100%1CFRP 100 36.6 0.230 M6R0%1CFRP 6 0 50.4 0.249 M6R50%1CFRP 50 47.3 0.245 M6R100%1CFRP 100 38.2 0.233 M18R0%1CFRP 18 0 52.1 0.252 M18R50%1CFRP 50 50.2 0.249 M18R100%1CFRP 100 41.0 0.237 M0.3R0%2CFRP 2 0.3 0 39.7 0.234 M0.3R50%2CFRP 50 38.6 0.233 M0.3R100%2CFRP 100 34.5 0.226 M6R0%2CFRP 6 0 42.9 0.239 M6R50%2CFRP 50 41.6 0.237 M6R100%2CFRP 100 40.8 0.236 M18R0%2CFRP 18 0 43.3 0.240 M18R50%2CFRP 50 42.5 0.239 M18R100%2CFRP 100 41.4 0.237 C0.3R0%1CFRP Cyclic loading 1 0.3 0 46.3 0.244 C0.3R50%1CFRP 50 43.2 0.240 C0.3R100%1CFRP 100 36.6 0.230 C6R0%1CFRP 6 0 50.4 0.249 C6R50%1CFRP 50 47.3 0.245 C6R100%1CFRP 100 38.2 0.233 C18R0%1CFRP 18 0 52.1 0.252 C18R50%1CFRP 50 50.2 0.249 C18R100%1CFRP 100 41.0 0.237 C0.3R0%2CFRP 2 0.3 0 39.7 0.234 C0.3R50%2CFRP 50 38.6 0.233 C0.3R100%2CFRP 100 34.5 0.226 C6R0%2CFRP 6 0 42.9 0.239 C6R50%2CFRP 50 41.6 0.237 C6R100%2CFRP 100 40.8 0.236 C18R0%2CFRP 18 0 43.3 0.240 C18R50%2CFRP 50 42.5 0.239 C18R100%2CFRP 100 41.4 0.237 Notes: M—Monotonic loading; C—Cyclic loading; The number after "M" or "C"—Loading rate; R—Recycled aggregate replacement rate; CFRP—Carbon fiber reinforced polymer; For example, C18R100%2CFRP—Two-layer CFRP-confined 100wt% recycled aggregate concrete columns with a cyclic loading rate of 18 mm/min; $ {f}_{\mathrm{c}\mathrm{o}} $—Compressive strength of unconfined RAC specimens; $ {\varepsilon }_{\mathrm{c}\mathrm{o}} $—Peak strain of unconfined RAC specimens; RA—Recycled aggregate. 表 2 RAC的配合比

Table 2. Mix ratio of RAC

RA replacement rate/wt% Water/

(kg·m−3)Cement/

(kg·m−3)NA/

(kg·m−3)RA/

(kg·m−3)Sand/

(kg·m−3)0 201 380 1128 0 691 50 201 380 564 564 691 100 201 380 0 1128 691 Note: NA—Natural aggregate. 表 3 CFRP的力学性能

Table 3. Mechanical properties of CFRP

Material $ {t}_{\mathrm{f}} $/mm $ {E}_{\mathrm{f}} $/GPa $ {f}_{\mathrm{f}} $/MPa $ {\varepsilon }_{\mathrm{f}} $/% CFRP 0.167 248.7 3820.5 1.54 Notes: $ {t}_{\mathrm{f}} $—Thickness of CFRP; $ {E}_{\mathrm{f}} $—Modulus of elasticity of CFRP; $ {f}_{\mathrm{f}} $—Ultimate tensile stress of CFRP; $ {\varepsilon }_{\mathrm{f}} $—Ultimate tensile strain of CFRP. 表 4 CFRP约束RAC试件试验结果

Table 4. Test results for CFRP-confined RAC specimens

Specimen $ {f}_{{{\rm{cu}}}} $/

MPa$ {{f}_{{{\rm{cu}}}}}/{{f}_{{{\rm{co}}}}} $ $ {\varepsilon }_{{{\rm{cu}}}} $/% $ {{\varepsilon }_{{{\rm{cu}}}}}/{{\varepsilon }_{{{\rm{co}}}}} $ $ {\varepsilon }_{{{\rm{h}}},{{\rm{rup}}}} $/% Specimen $ {f}_{{{\rm{cu}}}} $/

MPa$ {{f}_{{{\rm{cu}}}}}/{{f}_{{{\rm{co}}}}} $ $ {\varepsilon }_{{{\rm{cu}}}} $/% $ {{\varepsilon }_{{{\rm{cu}}}}}/{{\varepsilon }_{{{\rm{co}}}}} $ $ {\varepsilon }_{{{\rm{h}}},{{\rm{rup}}}} $/% M0.3R0%1CFRP-1 72.7 1.58 1.37 5.61 1.47 C0.3R0%1CFRP-1 66.7 1.44 1.23 5.03 1.42 M0.3R0%1CFRP-2 71.0 1.54 1.41 5.79 1.43 C0.3R0%1CFRP-2 72.6 1.57 1.51 6.18 1.50 M0.3R50%1CFRP-1 62.7 1.46 1.19 4.96 1.38 C0.3R50%1CFRP-1 72.5 1.68 1.50 6.23 1.61 M0.3R50%1CFRP-2 64.9 1.51 1.17 4.87 1.40 C0.3R50%1CFRP-2 68.2 1.58 1.32 5.50 1.28 M0.3R100%1CFRP-1 — — — — — C0.3R100%1CFRP-1 62.8 1.72 1.65 7.14 1.17 M0.3R100%1CFRP-2 62.3 1.73 1.61 7.04 1.36 C0.3R100%1CFRP-2 64.1 1.75 1.74 7.53 1.31 M6R0%1CFRP-1 71.0 1.42 1.17 4.71 1.36 C6R0%1CFRP-1 66.6 1.32 1.10 4.42 1.23 M6R0%1CFRP-2 73.6 1.47 1.22 4.89 0.99 C6R0%1CFRP-2 69.6 1.38 1.11 4.43 1.24 M6R50%1CFRP-1 69.5 1.48 1.27 5.16 1.14 C6R50%1CFRP-1 69.2 1.46 1.50 6.10 1.44 M6R50%1CFRP-2 71.9 1.53 1.31 5.34 1.12 C6R50%1CFRP-2 63.6 1.34 1.01 4.11 1.22 M6R100%1CFRP-1 53.6 1.41 1.06 4.56 1.25 C6R100%1CFRP-1 62.0 1.62 1.69 7.27 1.49 M6R100%1CFRP-2 58.1 1.53 1.32 5.69 1.27 C6R100%1CFRP-2 62.7 1.64 1.60 6.88 1.23 M18R0%1CFRP-1 63.6 1.22 1.00 3.96 1.09 C18R0%1CFRP-1 67.6 1.30 1.14 4.52 1.22 M18R0%1CFRP-2 72.6 1.40 1.13 4.49 1.47 C18R0%1CFRP-2 62.1 1.19 1.31 5.19 1.15 M18R50%1CFRP-1 70.8 1.42 1.17 4.71 0.99 C18R50%1CFRP-1 63.1 1.26 1.14 4.58 1.12 M18R50%1CFRP-2 72.1 1.44 1.19 4.78 1.42 C18R50%1CFRP-2 64.6 1.29 1.25 5.01 1.23 M18R100%1CFRP-1 64.1 1.56 1.28 5.39 1.35 C18R100%1CFRP-1 62.0 1.51 1.38 5.83 1.19 M18R100%1CFRP-2 62.9 1.54 1.28 5.39 1.28 C18R100%1CFRP-2 60.5 1.48 1.33 5.60 1.13 M0.3R0%2CFRP-1 93.7 2.40 2.51 10.74 1.41 C0.3R0%2CFRP-1 88.3 2.22 2.50 10.62 1.34 M0.3R0%2CFRP-2 80.8 2.07 2.09 8.94 1.17 C0.3R0%2CFRP-2 — — — — — M0.3R50%2CFRP-1 91.4 2.40 2.63 11.29 1.39 C0.3R50%2CFRP-1 92.0 2.38 2.26 9.68 1.12 M0.3R50%2CFRP-2 85.2 2.24 2.08 8.95 1.28 C0.3R50%2CFRP-2 94.4 2.45 2.28 9.78 1.36 M0.3R100%2CFRP-1 80.4 2.36 2.43 10.73 1.31 C0.3R100%2CFRP-1 89.6 2.60 3.09 13.60 1.40 M0.3R100%2CFRP-2 86.0 2.53 2.50 11.06 1.22 C0.3R100%2CFRP-2 87.6 2.54 3.05 13.42 1.54 M6R0%2CFRP-1 92.9 2.19 2.15 8.97 1.31 C6R0%2CFRP-1 94.8 2.21 2.15 8.96 1.35 M6R0%2CFRP-2 85.3 2.01 2.10 8.77 1.29 C6R0%2CFRP-2 92.1 2.15 2.30 9.59 1.38 M6R50%2CFRP-1 91.2 2.20 2.28 9.60 1.45 C6R50%2CFRP-1 92.6 2.23 2.50 10.50 1.13 M6R50%2CFRP-2 94.3 2.27 2.07 8.72 1.44 C6R50%2CFRP-2 92.5 2.22 1.91 8.03 1.13 M6R100%2CFRP-1 87.8 2.17 1.87 7.93 1.36 C6R100%2CFRP-1 90.1 2.21 2.63 11.11 1.25 M6R100%2CFRP-2 92.0 2.27 2.27 9.60 1.39 C6R100%2CFRP-2 90.3 2.21 2.41 10.16 1.41 M18R0%2CFRP-1 — — — — — C18R0%2CFRP-1 84.8 1.96 2.08 8.64 1.21 M18R0%2CFRP-2 91.5 2.13 2.44 10.16 1.36 C18R0%2CFRP-2 87.2 2.01 2.31 9.59 1.26 M18R50%2CFRP-1 87.4 2.08 2.09 8.74 1.13 C18R50%2CFRP-1 93.9 2.21 2.51 10.51 1.25 M18R50%2CFRP-2 95.1 2.26 2.31 9.67 1.22 C18R50%2CFRP-2 90.7 2.13 2.25 9.42 1.25 M18R100%2CFRP-1 84.2 2.05 2.00 8.43 1.23 C18R100%2CFRP-1 81.5 1.97 2.11 8.89 0.99 M18R100%2CFRP-2 — — — — — C18R100%2CFRP-2 89.8 2.17 2.49 10.47 1.22 Notes: $ {f}_{{{\rm{cu}}}} $—Ultimate strength of specimens; $ {f}_{{{\rm{cu}}}}/{f}_{{{\rm{co}}}} $—Ultimate strength enhancement ratio of the specimens; $ {\varepsilon }_{{{\rm{cu}}}} $—Ultimate strain of specimens; $ {\varepsilon }_{{{\rm{cu}}}}/{\varepsilon }_{{{\rm{co}}}} $—Ultimate strain enhancement ratio of the specimens; $ {\varepsilon }_{{{\rm{h}}},{{\rm{rup}}}} $—Hoop rupture strain of specimens; "—"—Data not measured; Two specimens with the same parameters were prepared, and they were distinguished by "-1" and "-2". 表 5 CFRP约束混凝土极限强度模型

Table 5. Ultimate strength model of CFRP-confined concrete

References Ultimate strength model $ \omega $ [27] $\dfrac{ {f}_{ { {\rm{cc} } } }^{ { {\rm{d} } } }}{ {f}_{ { {\rm{cc} } },0} }=1+0.1\left({ { {\rm{lg} } } }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)\right){\left(\dfrac{ {f}_{30} }{ {f}_{ { {\rm{co} } } }}\right)}^{0.73}$ 0.1203 [33, 35] $\dfrac{ {f}_{ { {\rm{cc} } } }^{ { {\rm{d} } } }}{ {f}_{ { {\rm{cc} } },0} }=1+(0.06{ {\rm{ln} } }\left(\dfrac{ {f}_{ { {\rm{l} } } }}{ {f}_{ { {\rm{co} } } }}\right)+0.274){ { {\rm{lg} } } }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)$ 0.3077 [34] $\dfrac{ {f}_{ { {\rm{cc} } } }^{ { {\rm{d} } } }}{ {f}_{ { {\rm{cc} } },0} }=1+\left(0.204+0.056{ {\rm{ln} } }\left(\dfrac{ {f}_{ {{\rm{l}}} } }{ {f}_{ { {\rm{co} } } }}\right)\right){ { {\rm{lg} } } }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)$ 0.2083 Notes: $ {f}_{{{\rm{l}}}} $—Confinement stress of CFRP; $ {f}_{{{\rm{cc}}},0} $—Ultimate strength of CFRP-confined recycled aggregate concrete columns in quasi-static conditions; $ {f}_{{{\rm{cc}}}}^{{{\rm{d}}}} $—Ultimate strength of CFRP-confined recycled aggregate concrete columns in a non-quasistatic conditions; $ \dot{\varepsilon } $—Dynamic strain rate; $ {\varepsilon }_{0} $—Quasi-static strain rate, taking a value of 1.67×10–5 s–1; $ {f}_{30} $—Compressive strength of C30 concrete, taken as 30 MPa. 表 6 CFRP约束混凝土的极限应变模型

Table 6. Ultimate strain model of CFRP-confined concrete

References Ultimate strain model $ \omega $ [27] $\dfrac{ {\varepsilon }_{\mathrm{c}\mathrm{c} }^{\mathrm{d} } }{ {\varepsilon }_{\mathrm{c}\mathrm{c},0} }=1-0.1{\mathrm{l}\mathrm{g} }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)$ 0.0940 [33, 35] $\dfrac{ {\varepsilon }_{\mathrm{c}\mathrm{c} }^{\mathrm{d} } }{ {\varepsilon }_{\mathrm{c}\mathrm{c},0} }=1.822+0.165{\mathrm{l}\mathrm{g} }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)$ 1.3436 [34] $\dfrac{ {\varepsilon }_{\mathrm{c}\mathrm{c} }^{\mathrm{d} } }{ {\varepsilon }_{\mathrm{c}\mathrm{c},0} }=1+(0.2887\dfrac{ {f}_{\mathrm{l} } }{ {f}_{\mathrm{c}\mathrm{o} } }+0.0329){\mathrm{l}\mathrm{g} }\left(\dfrac{\dot{\varepsilon } }{ {\varepsilon }_{0} }\right)$ 0.3481 Notes: $ {\varepsilon }_{\mathrm{c}\mathrm{c},0} $—Ultimate strain of CFRP-confined concrete columns in quasi-static conditions; $ {\varepsilon }_{\mathrm{c}\mathrm{c}}^{\mathrm{d}} $—Ultimate strain of CFRP-confined concrete columns in a non-quasi-static conditions. -

[1] ZHOU Y, HU J, LI M, et al. FRP-confined recycled coarse aggregate concrete: Experimental investigation and model comparison[J]. Polymers,2016,8(10):375. doi: 10.3390/polym8100375 [2] GÜNÇAN N F. Using waste concrete as aggregate[J]. Cement and Concrete Research,1995,25(7):1385-1390. doi: 10.1016/0008-8846(95)00131-U [3] XIAO J, WANG C, DING T, et al. A recycled aggregate concrete high-rise building: Structural performance and embodied carbon footprint[J]. Journal of Cleaner Production,2018,199:868-881. doi: 10.1016/j.jclepro.2018.07.210 [4] BARNHOUSE P W, SRUBAR III W V. Material characterization and hydraulic conductivity modeling of macroporous recycled-aggregate pervious concrete[J]. Construction and Building Materials,2016,110:89-97. doi: 10.1016/j.conbuildmat.2016.02.014 [5] EVANGELISTA L, DE BRITO J. Concrete with fine recycled aggregates: A review[J]. European Journal of Environmental and Civil Engineering,2014,18(2):129-172. doi: 10.1080/19648189.2013.851038 [6] BAI Y L, DAI J G, MOHAMMADI M, et al. Stiffness-based design-oriented compressive stress-strain model for large-rupture-strain (LRS) FRP-confined concrete[J]. Compo-site Structures,2019,223:110953. doi: 10.1016/j.compstruct.2019.110953 [7] HU B, ZHOU Y, XING F, et al. Experimental and theoretical investigation on the hybrid CFRP-ECC flexural strengthening of RC beams with corroded longitudinal reinforcement[J]. Engineering Structures,2019,200:109717. doi: 10.1016/j.engstruct.2019.109717 [8] WEI Y, ZHANG X, WU G, et al. Behaviour of concrete confined by both steel spirals and fiber-reinforced polymer under axial load[J]. Composite Structures,2018,192:577-591. doi: 10.1016/j.compstruct.2018.03.041 [9] ZHU Y G, KOU S C, POON C S, et al. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete[J]. Cement and Concrete Composites,2013,35(1):32-38. doi: 10.1016/j.cemconcomp.2012.08.008 [10] SHAYAN A, XU A. Performance and properties of structural concrete made with recycled concrete aggregate[J]. Materials Journal,2003,100(5):371-380. [11] KOU S C, ZHAN B J, POON C S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates[J]. Cement and Concrete Composites,2014,45:22-28. doi: 10.1016/j.cemconcomp.2013.09.008 [12] KONG D, LEI T, ZHENG J, et al. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete[J]. Construction and Building Materials,2010,24(5):701-708. doi: 10.1016/j.conbuildmat.2009.10.038 [13] CHEN G, HE Y, JIANG T, et al. Behavior of CFRP-confined recycled aggregate concrete under axial compression[J]. Construction and Building Materials,2016,111:85-97. doi: 10.1016/j.conbuildmat.2016.01.054 [14] ZHAO J, YU T, TENG J. Stress-strain behavior of FRP-confined recycled aggregate concrete[J]. Journal of Composites for Construction,2015,19(3):04014054. doi: 10.1061/(ASCE)CC.1943-5614.0000513 [15] XIE T, OZBAKKALOGLU T. Behavior of recycled aggregate concrete-filled basalt and carbon FRP tubes[J]. Construction and Building Materials,2016,105:132-143. doi: 10.1016/j.conbuildmat.2015.12.068 [16] SHAO Y, ZHU Z, MIRMIRAN A. Cyclic modeling of FRP-confined concrete with improved ductility[J]. Cement and Concrete Composites,2006,28(10):959-968. doi: 10.1016/j.cemconcomp.2006.07.009 [17] OZBAKKALOGLU T, AKIN E. Behavior of FRP-confined normal-and high-strength concrete under cyclic axial compression[J]. Journal of Composites for Construction,2012,16(4):451-463. doi: 10.1061/(ASCE)CC.1943-5614.0000273 [18] ABBASNIA R, AHMADI R, ZIAADINY H. Effect of confinement level, aspect ratio and concrete strength on the cyclic stress-strain behavior of FRP-confined concrete prisms[J]. Composites Part B: Engineering,2012,43(2):825-831. doi: 10.1016/j.compositesb.2011.11.008 [19] LAM L, TENG J. Stress-strain model for FRP-confined concrete under cyclic axial compression[J]. Engineering Structures,2009,31(2):308-321. doi: 10.1016/j.engstruct.2008.08.014 [20] LI P, WU Y F. Stress-strain behavior of actively and passively confined concrete under cyclic axial load[J]. Composite Structures,2016,149:369-384. doi: 10.1016/j.compstruct.2016.04.033 [21] LI P, WU Y F, ZHOU Y, et al. Cyclic stress-strain model for FRP-confined concrete considering post-peak softening[J]. Composite Structures,2018,201:902-915. doi: 10.1016/j.compstruct.2018.06.088 [22] LI P, WU Y F. Stress-strain model of FRP confined concrete under cyclic loading[J]. Composite Structures,2015,134:60-71. doi: 10.1016/j.compstruct.2015.08.056 [23] ZHOU H Y, YANG C K, CI J C, et al. Rate correlation research situation of ordinary concrete about strain-rate within the scope of the earthquake[J]. Applied Mechanics and Materials,2017,858:151-156. [24] DENG J W, LIU C W, LIU J F. Effect of dynamic loading on mechanical properties of concrete[J]. Advanced Materials Research,2012,568:147-153. doi: 10.4028/www.scientific.net/AMR.568.147 [25] FU H, ERKI M, SECKIN M. Review of effects of loading rate on concrete in compression[J]. Journal of Structural Engineering,1991,117(12):3645-3659. doi: 10.1061/(ASCE)0733-9445(1991)117:12(3645) [26] FU H, ERKI M, SECKIN M. Review of effects of loading rate on reinforced concrete[J]. Journal of Structural Engineering,1991,117(12):3660-3679. doi: 10.1061/(ASCE)0733-9445(1991)117:12(3660) [27] CAO Y, LIU M, WU Y F. Effect of low strain rate on the axial behavior of concrete in CFRP-confined circular cylinders[J]. Construction and Building Materials,2020,255:119351. doi: 10.1016/j.conbuildmat.2020.119351 [28] LI P, YANG T, ZENG Q, et al. Axial stress-strain behavior of carbon FRP-confined seawater sea-sand recycled aggregate concrete square columns with different corner radii[J]. Composite Structures,2021,262:113589. doi: 10.1016/j.compstruct.2021.113589 [29] BISCHOFF P, PERRY S. Compressive behaviour of concrete at high strain rates[J]. Materials and Structures,1991,24:425-450. doi: 10.1007/BF02472016 [30] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People's Republic of China. Test method for tensile properties of directional fiber reinforced polymer matrix composites: GB/T 3354—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [31] LI P, SUI L, XING F, et al. Static and cyclic response of low-strength recycled aggregate concrete strengthened using fiber-reinforced polymer[J]. Composites Part B: Engineering,2019,160:37-49. doi: 10.1016/j.compositesb.2018.10.002 [32] ILKI A, PEKER O, KARAMUK E, et al. FRP retrofit of low and medium strength circular and rectangular reinforced concrete columns[J]. Journal of Materials in Civil Engi-neering,2008,20(2):169-188. doi: 10.1061/(ASCE)0899-1561(2008)20:2(169) [33] 张宝超, 潘景龙. FRP 约束混凝土快速荷载下应力应变关系初探[J]. 爆炸与冲击, 2003, 23(5):466-471. doi: 10.3321/j.issn:1001-1455.2003.05.014ZHANG Baochao, PAN Jinglong. Preliminary study on stress-strain relationship of FRP confined concrete under rapid loading[J]. Explosion and Shock Waves,2003,23(5):466-471(in Chinese). doi: 10.3321/j.issn:1001-1455.2003.05.014 [34] 金希荣. FRP 约束混凝土柱快速荷载下力学性能试验研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.JIN Xirong. Experimental studies on behavior of FRP confined concrete columns under rapid loading [D]. Harbin: Harbin Institute of Technology, 2007(in Chinese). [35] 张宝超, 潘景龙, 姜洪斌. FRP 约束混凝土快速荷载下的强度计算[J]. 哈尔滨工业大学学报, 2003, 35(8):958-961. doi: 10.3321/j.issn:0367-6234.2003.08.017ZHANG Baochao, PAN Jinglong, JIANG Hongbin. Strength calculation of FRP confined concrete under rapid loading[J]. Journal of Harbin Institute of Technology,2003,35(8):958-961(in Chinese). doi: 10.3321/j.issn:0367-6234.2003.08.017 [36] LEMAITRE J. How to use damage mechanics[J]. Nuclear Engineering and Design,1984,80(2):233-245. doi: 10.1016/0029-5493(84)90169-9 [37] WU Y F, YUN Y, WEI Y, et al. Effect of predamage on the stress-strain relationship of confined concrete under monotonic loading[J]. Journal of Structural Engineering,2014,140(12):04014093. doi: 10.1061/(ASCE)ST.1943-541X.0001015 [38] SIDOROFF F. Description of anisotropic damage application to elasticity[C]. Physical Non-Linearities in Structural Analysis: Symposium Senlis. Berlin: Springer Berlin Heidelberg, 1981: 237-244. [39] LAM L, TENG J, CHEUNG C, et al. FRP-confined concrete under axial cyclic compression[J]. Cement and Concrete Composites,2006,28(10):949-958. doi: 10.1016/j.cemconcomp.2006.07.007 [40] WANG Z, WANG D, SMITH S T, et al. Experimental testing and analytical modeling of CFRP-confined large circular RC columns subjected to cyclic axial compression[J]. Engineering Structures,2012,40:64-74. doi: 10.1016/j.engstruct.2012.01.004 [41] ILKI A, KUMBASAR N. Behavior of damaged and undamaged concrete strengthened by carbon fiber composite sheets[J]. Structural Engineering and Mechanics,2002,13(1):75-90. doi: 10.12989/sem.2002.13.1.075 -

下载:

下载: