Preparation and properties of sulfonated poly(vinyl alcohol)/sulfonated poly(aryl ether ketone) copolymer with pendant crosslinked structure composite membranes

-

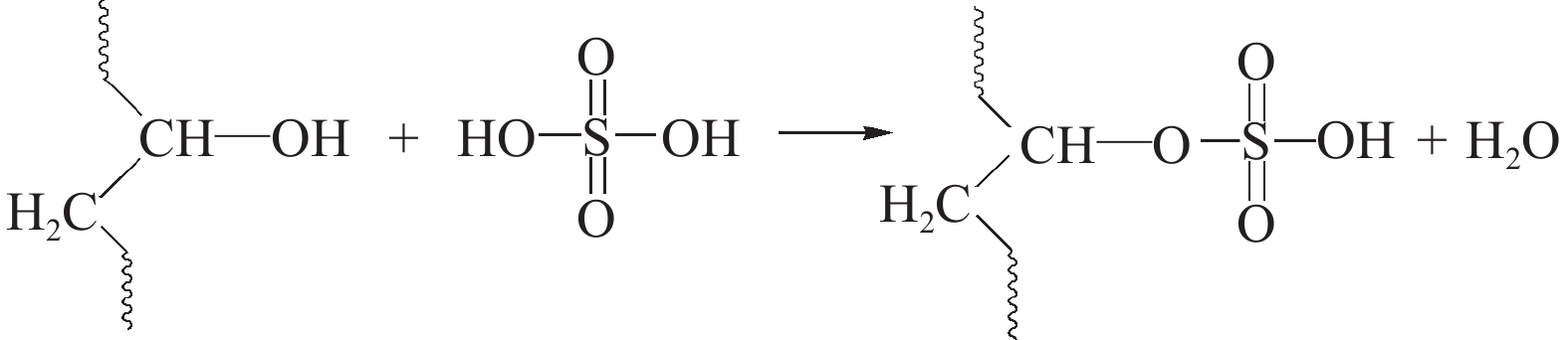

摘要: 磺化芳香类聚合物质子交换膜(PEM)为了达到较好的质子传导性能就必需具有较高的磺化度,然而较高的磺化度就会增加PEM的溶胀率、降低PEM的尺寸稳定性及增加PEM的甲醇渗透率等一系列问题。为此,通过直接缩聚的方法合成了含有羧基的聚芳醚酮共聚物(PAEK-x),利用刚果红作为交联剂并引入磺酸基团,与磺化聚乙烯醇(SPVA)复合制备磺化聚乙烯醇/磺化聚芳醚酮交联复合膜(Cr-SPAEK-x),通过红外光谱对交联复合膜进行了表征。对膜的性能测试发现,该系列交联复合膜表现出了良好的热性能、力学性能、氧化稳定性和适度的吸水性。交联结构形成于PAEK-x的羧基与刚果红的氨基及SPVA的羟基之间,不消耗膜中的传导基团磺酸基,因此该系列交联复合膜表现出了较高的质子传导率,酚酞啉(PPL)摩尔含量为100mol%的磺化聚乙烯醇/磺化聚芳醚酮交联复合膜Cr-SPAEK-100在25℃和80℃分别达到了0.053 S·cm−1和0.109 S·cm−1。交联网络结构的形成,抑制了膜的水溶胀性,提高了膜的尺寸稳定性,即使是吸水率最高的Cr-SPAEK-100膜的溶胀率室温下也只有5.26%,同时由于致密的交联网络结构的形成及具有高阻醇性能的SPVA的引入,有效地降低了该系列交联复合膜的甲醇渗透系数,最高也只有3.92×10−7 cm2·s−1,可见该系列交联复合膜有望在直接甲醇燃料电池中得到应用。

-

关键词:

- 侧链交联型磺化聚芳醚酮 /

- 磺化聚乙烯醇 /

- 交联复合质子交换膜 /

- 尺寸稳定性 /

- 阻醇性能

Abstract: A high degree of sulfonation is necessary for sulfonated aromatic polymer proton exchange membranes to achieve high proton conductivity. Nevertheless, an elevated sulfonation level will give rise to a range of complications, including heightened swelling ratio, reduced dimensional stability, and greater methanol permeability. To address this challenge, the poly(aryl ether ketone) containing carboxyl group (PAEK-x) was synthesized using the direct condensation method. Subsequently, the sulfonated poly(vinyl alcohol) (SPVA)/crosslinked sulfonated poly(aryl ether ketone) proton exchange membranes (Cr-SPAEK-x) were prepared with Congo red as the crosslinking agent. The crosslinked composite membranes were characterized by infrared spectroscopy. It is found that these series of crosslinked composite membranes show excellent thermal properties, mechanical properties, oxidation stability and appropriate water absorption. The crosslinked structure formed between the carboxyl group of PAEK-x and the amidogen of Congo red, along with the hydroxyl of SPVA. Notably, the crosslinking reaction does not consume the sulfonic acid groups in the crosslinked composite membrane. Therefore, these series of crosslinked composite membranes show a high proton conductivity. The sulfonated poly(vinyl alcohol)/sulfonated poly(aryl ether ketone) crosslinked composite membrane with a phenolphthalin content of 100mol% (Cr-SPAEK-100) demonstrated a proton conductivity of 0.053 S·cm−1 at 25℃ and 0.109 S·cm−1 at 80℃. The crosslinked network structure effectively inhibits the water swelling of the membrane and improves the dimensional stability of the crosslinked composite membrane. At 20℃, the Cr-SPAEK-100 membrane with the highest water uptake exhibits a minimal swelling ratio of only 5.26%. Moreover, the dense crosslinked network structure and the inclusion of SPVA with excellent methanol barrier properties significantly reduce the methanol diffusion coefficients in the crosslinked membranes, with the highest methanol diffusion coefficients being only 3.92×10−7 cm2·s−1. These series crosslinked composite membranes hold promise for applications in direct methanol fuel cells. -

表 1 交联复合膜Cr-SPAEK-x的力学性能、凝胶分数和氧化稳定性数据

Table 1. Mechanical properties, gel fraction and oxidative stability of crosslinked composite membranes Cr-SPAEK-x

Sample PPL/DFB

mol/molYoung's

modulus/MPaTensile

strength/MPaElongation

at break/%Gel fraction/% Oxidative

stability/%Cr-SPAEK-100 100/0 1549.31 73.57 5.32 93.92 97.98 Cr-SPAEK-80 80/20 1388.43 62.65 6.94 78.15 92.11 Cr-SPAEK-60 60/40 1264.57 50.84 9.39 72.14 84.62 Cr-SPAEK-40 40/60 1085.28 45.87 11.74 57.27 80.37 Notes: PPL—Phenolphthalin; DFB—4, 4'-difluorobenzophenone. 表 2 交联复合膜Cr-SPAEK-x的离子交换容量(IEC)、质子传导率、甲醇渗透率、质子选择性及活化能(Ea)数据

Table 2. Ion exchange capacity (IEC), proton conductivity, methanol permeability, proton selectivity and activation energy (Ea) of crosslinked composite membranes Cr-SPAEK-x

Sample IEC/

(mmol·g−1)Proton conductivity/

(S·cm−1)Methanol diffusion

coefficient/(cm2·s−1)Proton selectivity/

(104 S·cm−3)Ea/

(kJ·mol−1)25℃ 80℃ Cr-SPAEK-100 1.58 0.053 0.109 3.92×10−7 13.52 11.37 Cr-SPAEK-80 1.36 0.040 0.086 2.53×10−7 15.81 12.08 Cr-SPAEK-60 1.19 0.029 0.064 1.14×10−7 25.44 12.50 Cr-SPAEK-40 0.81 0.017 0.045 0.39×10−7 43.59 15.85 Nafion 117a) — 0.076 0.146 23.8×10−7 3.67 9.10 Note: a)—Data adapted from the Ref.[32]. -

[1] XIE T T, PANG Y, FAN H, et al. Controlling the microphase morphology and performance of cross-linked highly sulfonated polyimide membranes by varying the molecular structure and volume of the hydrophobic cross-linkable diamine monomers[J]. Journal of Membrane Science,2023,666:121177. doi: 10.1016/j.memsci.2022.121177 [2] YE C C, WANG A Q, BREAKWELL C, et al. Development of efficient aqueous organic redox flow batteries using ion-sieving sulfonated polymer membranes[J]. Nature Communications,2022,13(1):3184-3188. doi: 10.1038/s41467-022-30943-y [3] JIA W, TANG B B, WU P Y. Novel composite proton exchange membrane with connected long-range ionic nanochannels constructed via exfoliated nafion-boron nitride nanocomposite[J]. ACS Applied Materials & Interfaces,2017,9(17):14791-14800. [4] LIU X, LI Y, XUE J D, et al. Magnetic field alignment of stable proton-conducting channels in an electrolyte membrane[J]. Nature Communications,2019,10(1):842. doi: 10.1038/s41467-019-08622-2 [5] ZHANG H Q, YAN X M, GAO L, et al. Novel triple tertiary amine polymer-based hydrogen bond network inducing highly efficient proton-conducting channels of amphoteric membranes for high-performance vanadium redox flow battery[J]. ACS Applied Materials & Interfaces,2019,11(5):5003-5014. [6] PRYKHODKO Y, FATYEYEVA K, HESPEL L, et al. Progress in hybrid composite Nafion®-based membranes for proton exchange fuel cell application[J]. Chemical Engineering Journal,2021,409:127329. doi: 10.1016/j.cej.2020.127329 [7] NEDERSTEDT H, JANNASCH P. Poly(p-terphenyl alkylene)s grafted with highly acidic sulfonated polypentafluorostyrene side chains for proton exchange membranes[J]. Journal of Membrane Science,2022,647:120270. doi: 10.1016/j.memsci.2022.120270 [8] LIU D, XIE Y J, ZHONG J D, et al. High methanol resistance semi-crystalline sulfonated poly(ether ketone) proton exchange membrane for direct methanol fuel cell[J]. Journal of Membrane Science,2022,650:120413. doi: 10.1016/j.memsci.2022.120413 [9] BAN T, GUO M L, WANG Y J, et al. Densely functionalized proton exchange membrane from sulfonated poly(aryl ether ketone) containing multiple fexible side chains for fuel cell[J]. Solid State Ion,2021,372:115777. doi: doi.org/10.1016/j.ssi.2021.115777 [10] LIU D, XIE Y J, CUI N, et al. Structure and properties of sulfonated poly(arylene ether)s with densely sulfonated segments containing mono-, di- and tri-tetraphenylmethane as proton exchange membrane[J]. Journal of Membrane Science,2021,620:118856. doi: 10.1016/j.memsci.2020.118856 [11] CAI S J, WANG C Y, TAO Z W, et al. Proton exchange membranes containing densely alkyl sulfide sulfonated side chains for vanadium redox flow battery[J]. International Journal of Hydrogen Energy,2022,47(15):9319-9330. doi: 10.1016/j.ijhydene.2021.12.263 [12] DIVYA K M, SRI ABIRAMI SARASWATHI M S, RANA D, et al. Custom-made sulfonated poly(ether sulfone) nanocomposite proton exchange mambranes using exfoliated molybdenum disulfide nanosheets for DMFC applications[J]. Polymer,2018,147:48-55. doi: 10.1016/j.polymer.2018.05.054 [13] 韩光鲁, 陈哲, 蔡立芳, 等. 磺化来瓦希尔骨架(MIL-101(Cr)-SO3H)/磺化酚酞侧基聚芳醚砜杂化质子交换膜的制备及性能[J]. 复合材料学报, 2020, 37(3):504-511.HAN Guanglu, CHEN Zhe, CAI Lifang, et al. Preparation and properties of sulfonated lavoisier framework (MIL-101(Cr)-SO3H)/sulfonated polyarylethersulfone with cardo hybrid proton exchange membranes[J]. Acta Materiae Compositae Sinica,2020,37(3):504-511(in Chinese). [14] WANG C Y, SHEN B, ZHOU Y, et al. Sulfonated aromatic polyamides containing nitrile groups as proton exchange fuel cell membranes[J]. International Journal of Hydrogen Energy,2015,40(19):6422-6429. doi: 10.1016/j.ijhydene.2015.03.078 [15] JO T S, OZAWA C H, EAGAR B R, et al. Synthesis of sulfonated aromatic poly(ether amide)s and their application to proton exchange membrane fuel cells[J]. Journal of Polymer Science Part A: Polymer Chemistry,2009,47(2):485-496. doi: 10.1002/pola.23165 [16] WANG G, LI J L, LI H B, et al. In situ crosslinking of polyoxometalate-polymer nanocomposites for robust high-temperature proton exchange membranes[J]. Chinese Chemical Letters,2023,34(2):107497. doi: 10.1016/j.cclet.2022.05.011 [17] LUO H C. Crosslinked polybenzimidazole by [2+3] Huisgen cycloaddition for proton exchange membrane[J]. Polymer Testing,2021,103:107353. doi: 10.1016/j.polymertesting.2021.107353 [18] DANYLIV O, IOJOIU C, LYONNARD S, et al. Highly phase separated aromatic ionomers bearing perfluorosulfonic acids by bottom-up synthesis: Effect of cation on membrane morphology and functional properties[J]. Macromolecules,2016,49(11):4164-4177. doi: 10.1021/acs.macromol.6b00629 [19] WEI P, HUANG D, LUO C, et al. High-performance sandwich-structure PI/SPEEK+HPW nanofiber composite membrane with balanced proton conductivity and stability[J]. Polymer,2023,271:125800. doi: 10.1016/j.polymer.2023.125800 [20] CUI W H, LYU Y N, SUN P, et al. SPEEK/CMABPBI ionic and self-covalent cross-linked composite membrane: A method to comprehensively enhance the properties of high-temperature proton exchange membranes[J]. ACS Applied Energy Materials,2020,3(12):12115-12126. doi: 10.1021/acsaem.0c02224 [21] 程海龙, 徐晶美, 王哲, 等. 侧链型磺化聚芳醚酮/磺化聚乙烯醇复合型直接甲醇燃料电池用质子交换膜[J]. 物理化学学报, 2013, 29(7):1515-1523. doi: 10.3866/PKU.WHXB201304261CHENG Hailong, XU Jingmei, WANG Zhe, et al. Sulfonated poly(aryl ether ketone) on side chain/sulfonated poly(vinyl alcohol) composite proton exchange membrane for direct methanol fuel cells[J]. Acta Physico-Chimica Sinica,2013,29(7):1515-1523(in Chinese). doi: 10.3866/PKU.WHXB201304261 [22] 徐晶美, 程海龙, 任春丽, 等. 用于直接甲醇燃料电池的侧链型磺化聚芳醚酮/聚乙烯醇交联膜的制备与性能研究[J]. 高分子学报, 2013, 44(8):999-1005.XU Jingmei, CHENG Hailong, REN Chunli, et al. Preparation and properties of sulfonated poly(aryl ether ketone) bearing pendant sulfonic acid groups/PVA crosslinked composite membranes for direct methanol fuel cells[J]. Acta Polymerica Sinica,2013, 44(8):999-1005(in Chinese). [23] XUAN Y N, GAO Y, HUANG Y, et al. Synthesis and characterization of a novel phthalazinone poly(aryl ether sulfone ketone) with carboxyl group[J]. Journal of Applied Polymer Science,2003,88(5):1111-1114. doi: 10.1002/app.12039 [24] GU S, HE G H, WU X M, et al. Preparation and characteristics of crosslinked sulfonated poly(phthalazinone ether sulfone ketone) with poly(vinyl alcohol) for proton exchange membrane[J]. Journal of Membrane Science,2008,312(1-2):48-58. doi: 10.1016/j.memsci.2007.12.053 [25] XU J M, MA L, HAN H L, et al. Synthesis and properties of a novel sulfonated poly(arylene ether ketone sulfone) membrane with a high β-value for direct methanol fuel cell applications[J]. Electrochimica Acta,2014,146:688-696. doi: 10.1016/j.electacta.2014.09.071 [26] LIU D, DONG B, ZHANG H B, et al. High methanol resistant polyelectrolyte membrane based on semi-crystalline poly(ether ketone) with densely sulfonated side chain for direct methanol fuel cell [J]. Journal of Power Sources, 2021, 482: 228982. [27] 姜永燚, 杨溟洋, 侯明, 等. 面向氢空、无增湿操作条件的高保水性质子交换膜的制备与性能[J]. 复合材料学报, 2021, 38(11):3884-3895. doi: 10.13801/j.cnki.fhclxb.20210302.001JIANG Yongyi, YANG Mingyang, HOU Ming, et al. Preparation and application research of super absorbent polymer membrane for proton exchange membrane fuel cells[J]. Acta Materiae Compositae Sinica,2021,38(11):3884-3895(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210302.001 [28] ZHANG Y, WAN Y, ZHAO C J, et al. Novel side-chain-type sulfonated poly(arylene ether ketone)with pendant sulfoalkyl groups for direct methanol fuel cells[J]. Polymer,2009,50(19):4471-4478. doi: 10.1016/j.polymer.2009.07.036 [29] GUO M M, LIU B J, LI L, et al. Preparation of sulfonated poly(ether ether ketone)s containing amino groups/epoxy resin composite membranes and their in situ crosslinking for application in fuel cells [J]. Journal of Power Sources, 2010, 195(1): 11-20. [30] CHEN L, REN Y W, FAN F Y, et al. Artificial frameworks towards ion-channel construction in proton exchange membranes[J]. Journal of Power Sources,2023,574:233081. doi: 10.1016/j.jpowsour.2023.233081 [31] MIYAKE T, ROLANDI M. Grotthuss mechanisms: From proton transport in proton wires to bioprotonic devices[J]. Journal of Physics: Condensed Matter,2016,28(2):023001. doi: 10.1088/0953-8984/28/2/023001 [32] CHENG H L, XU J M, MA L, et al. Preparation and characterization of sulfonated poly(arylene ether ketone) copolymers with pendant sulfoalkyl groups as proton exchange membranes[J]. Journal of Power Sources,2014,260:307-316. doi: 10.1016/j.jpowsour.2014.03.023 [33] DUAN Y T, RU C Y, LI J L, et al. Enhancing proton conductivity and methanol resistance of SPAEK membrane by incorporating MOF with flexible alkyl sulfonic acid for DMFC[J]. Journal of Membrane Science,2022,641:119906. doi: 10.1016/j.memsci.2021.119906 [34] KIM D S, PARK H B, RHIM J W, et al. Preparation and characterization of crosslinked PVA/SiO2 hybrid membranes containing sulfonic acid groups for direct methanol fuel cell applications[J]. Journal of Membrane Science,2004,240(1-2):37-48. doi: 10.1016/j.memsci.2004.04.010 [35] ZHANG H W, SHEN P K. Recent development of polymer electrolyte membranes for fuel cells[J]. Chemical Reviews,2012,112(5):2780-2832. doi: 10.1021/cr200035s -

下载:

下载: