Study on the surface modification of wetting penetrant and nonlinear creep of continuous basalt fiber/epoxy resin composites

-

摘要: 采用润湿渗透剂协同硅烷偶联剂对玄武岩纤维(BF)进行表面改性,并缠绕成型制备了玄武岩纤维/环氧树脂(BF/EP)复合材料。采用万能材料试验机测定了BF/EP的弯曲性能及在不同应力水平下测定了BF/EP复合材料240 min的蠕变性能,借助场发射扫描电子显微镜(FESEM)观察了纤维及弯曲断裂断口的表面形貌,并分析了纤维表面改性对各项力学性能的影响。结果表明:采用润湿渗透剂协同硅烷偶联剂对BF进行表面改性后,BF/EP弯曲性能得到有效改善,层间剪切强度得到提高,FESEM形貌显示BF的协同改性提高了纤维与树脂之间的界面性能;在多种应力水平下的短期蠕变实验中,均表现出蠕变柔量增量的显著降低。使用改进Findley模型可描述BF/EP复合材料在低于其断裂应力水平下的蠕变性能,以此可进行其在不同应力水平下的蠕变性能预测。

-

关键词:

- 表面改性 /

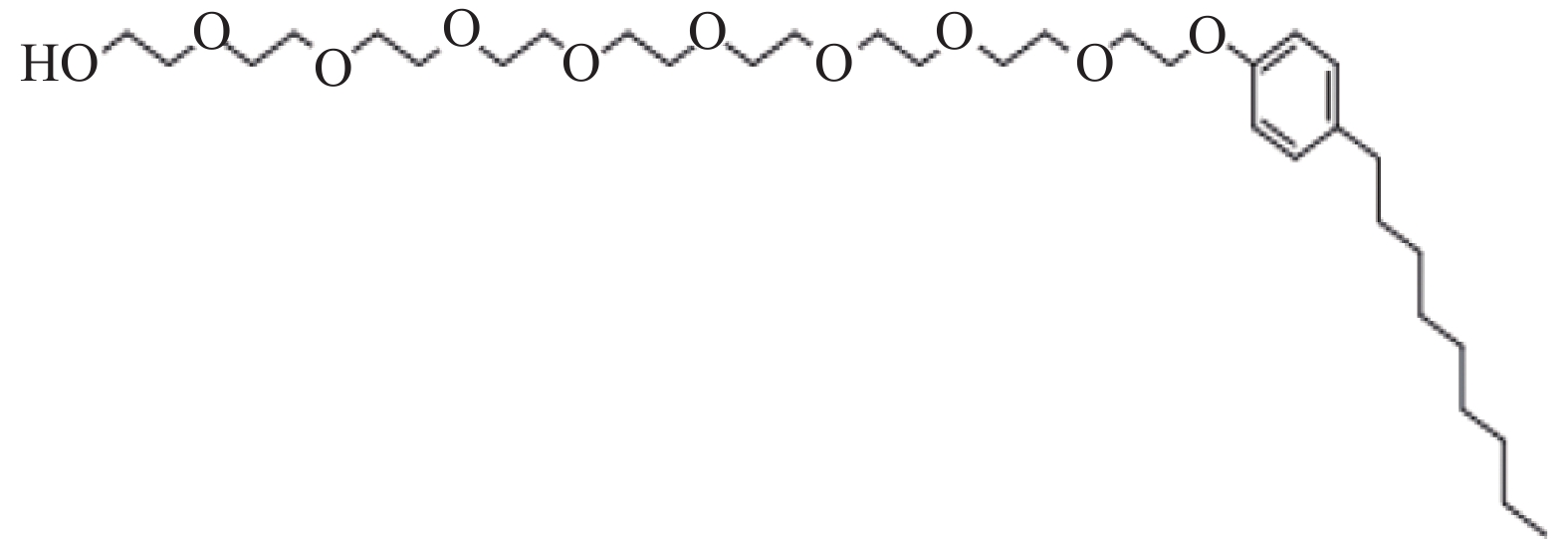

- 润湿渗透剂 /

- BF/EP复合材料 /

- 非线性蠕变 /

- 改进Findley模型

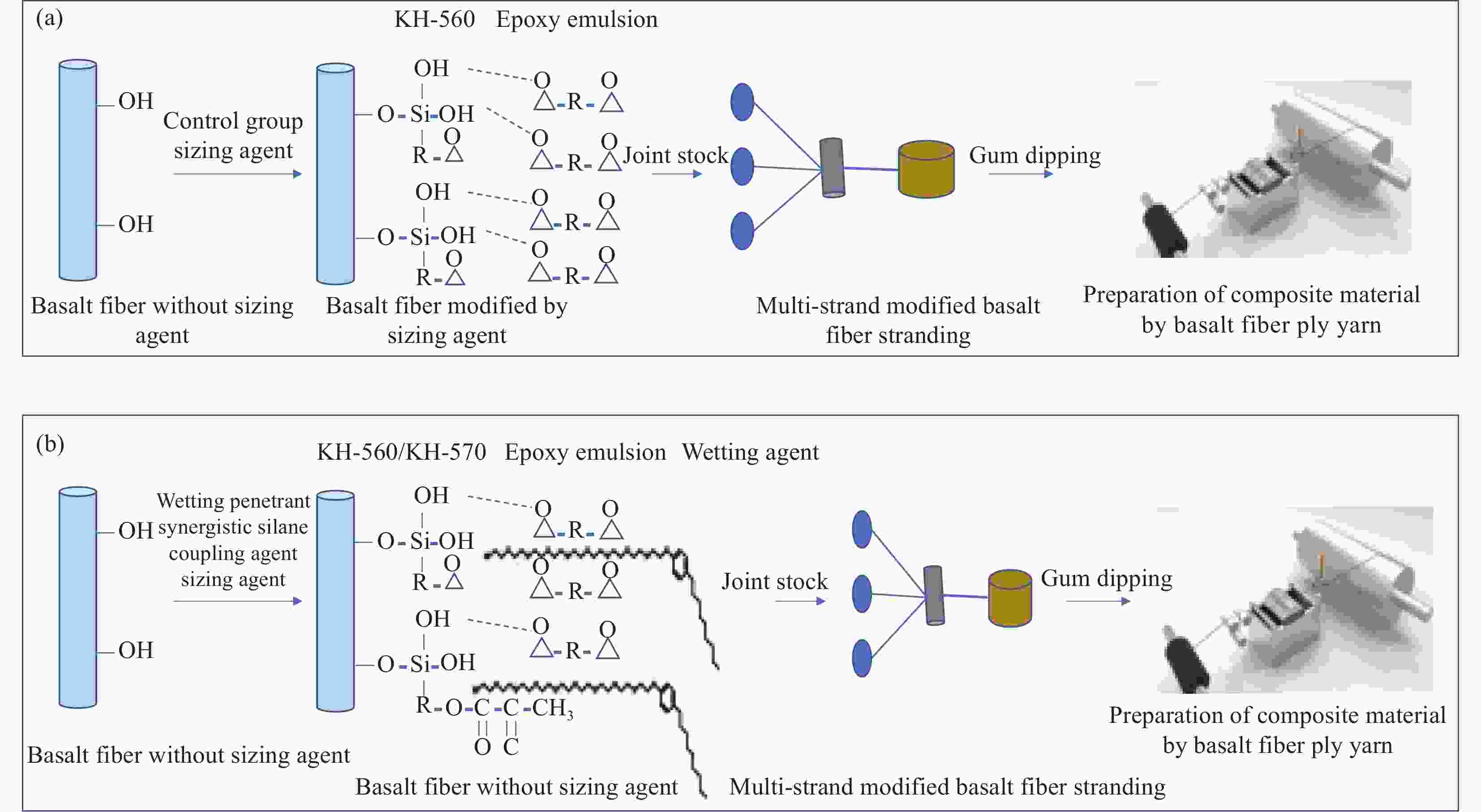

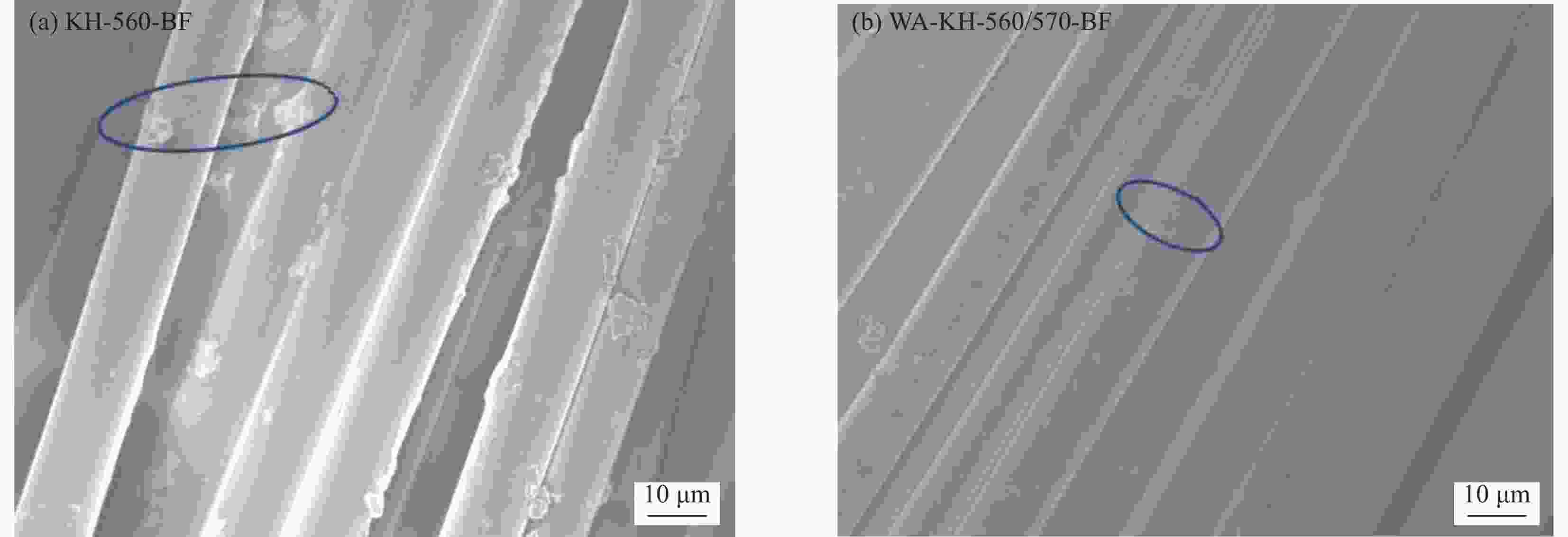

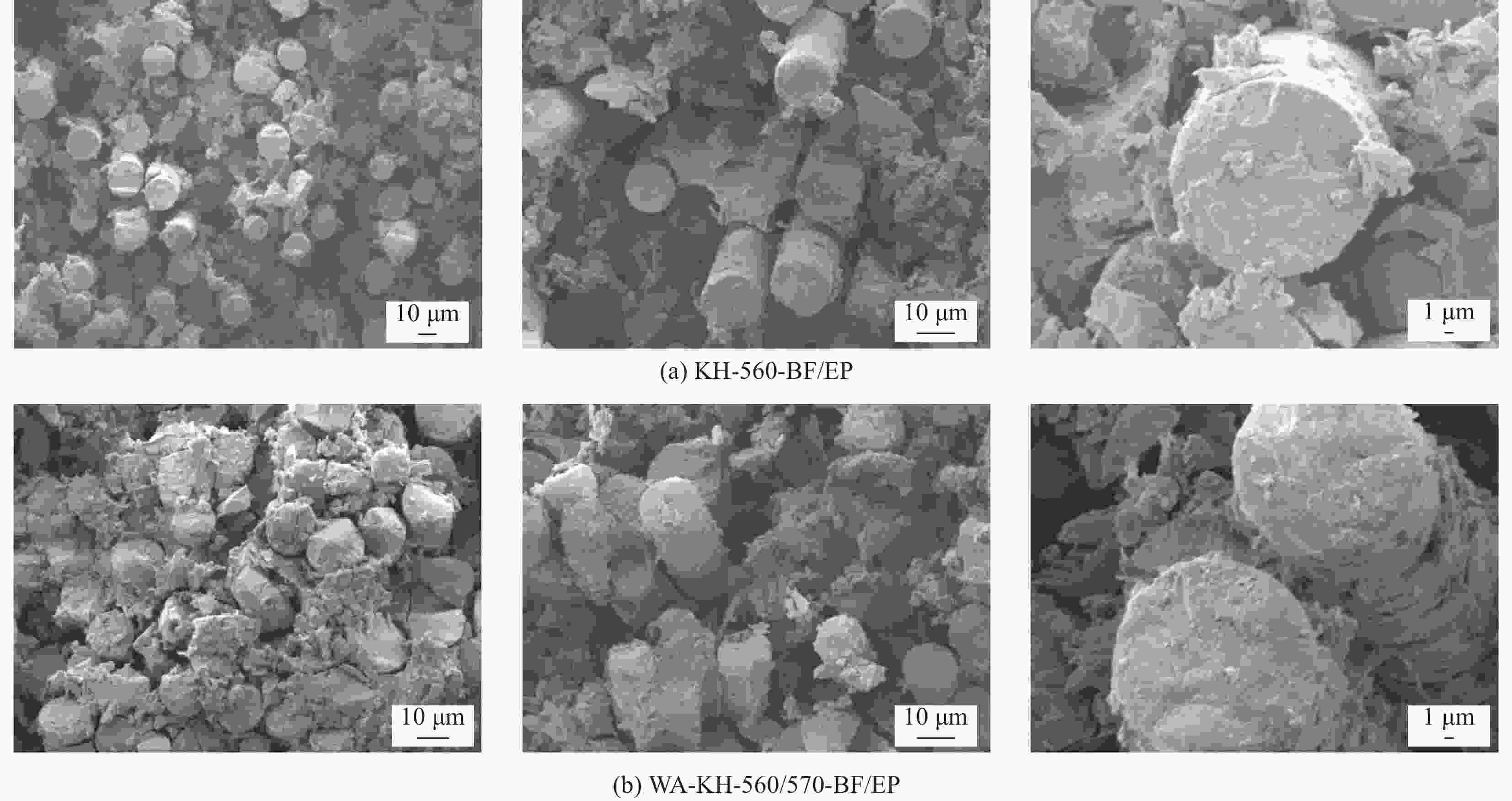

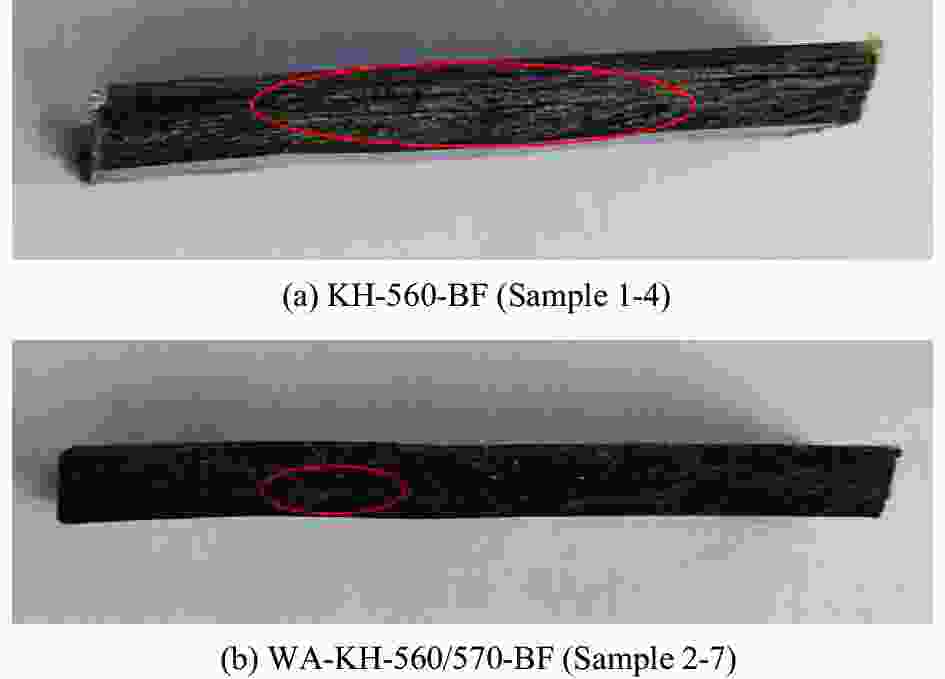

Abstract: The surface modification of basalt fiber (BF) was carried out by using a wetting and penetrating agent in conjunction with a silane coupling agent, followed by winding and molding to prepare basalt fiber/epoxy resin (BF/EP) composite materials. The bending performance of BF/EP was determined using a universal material testing machine, and the creep properties of BF/EP composite materials were measured at different stress levels for 240 min. The surface morphology of the fiber and the bending fracture surface were observed by field emission scanning electron microscopy (FESEM), and the effect of fiber surface modification on various mechanical properties was analyzed. The results show that the surface modification of BF using a wetting and penetrating agent in combination with a silane coupling agent is an effective approach to enhance the bending performance and interlaminar shear strength of BF/EP composites. The FESEM morphology analysis reveals that this synergistic modification of BF enhances the interfacial properties between the fiber and the resin, which contributes to the improved mechanical properties of the composite material. Moreover, the short-term creep experiments conducted at various stress levels indicate a significant reduction in creep compliance increment, which suggests that the modified BF/EP composite material has better creep resistance. The improved Findley model provides a useful tool to predict the creep properties of BF/EP composites at different stress levels, which can help optimize their design and performance in practical applications. -

表 1 硅烷偶联剂改性法(对照组)的上浆剂成分

Table 1. Sizing agent composition of silane coupling agent modified method (control group)

Type of reagent Mass fraction/wt% Silane coupling agent (KH-560) 0.50 Glacial acetic acid 0.05 Epoxy emulsion 6.00 Film-forming additive 0.30 表 2 润湿渗透剂/硅烷偶联剂协同改性法的上浆剂成分

Table 2. Sizing agent composition of wetting penetrant/silane coupling agent synergistic modification method

Type of reagent Mass fraction/wt% Silane coupling agent (KH-560) 0.30 Silane coupling agent (KH-570) 0.20 Glacial acetic acid 0.08 Epoxy emulsion 6.00 Film-forming additive 0.30 Wetting agent 0.50 Lubricant 0.20 表 3 BF丝束及其浸胶纱的拉伸性能

Table 3. Tensile properties of BF tow and its resin-impregnated yarn

Sample P/(N·tex−1) σt/MPa Et/GPa KH-560-BF 0.570 2722.8 89.1 WA-KH-560/570-BF 0.674 2938.2 92.0 Notes: P—Tensile strength of BF bundle; σt—Tensile strength of BF resin-impregnated yarn; Et—Tensile modulus of BF resin-impregnated yarn. 表 4 BF/EP复合材料弯曲性能

Table 4. Banding property of BF/EP composites

Sample σf /MPa Ef /GPa KH-560-BF/EP 837.5 26.6 WA-KH-560/570-BF/EP 1157.0 32.2 Notes: σf—Flexural strength; Ef—Flexural modulus. 表 5 BF/EP复合材料层间剪切强度

Table 5. Inter-laminar shear strength of BF/EP composites

Sample τs/MPa KH-560-BF/EP 39.0 WA-KH-560/570-BF/EP 49.9 Note: τs—Interlaminar shear strength. 表 6 不同应力水平下BF/EP复合材料的蠕变柔量增量(240 min)

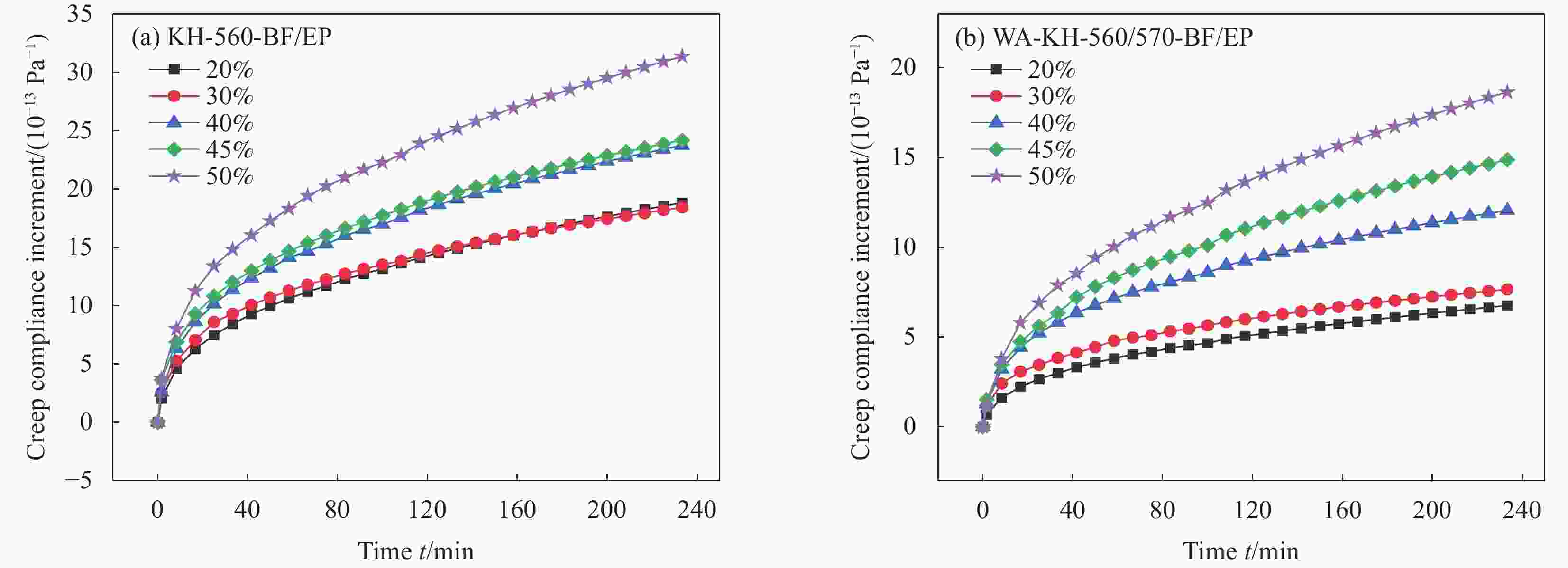

Table 6. Creep compliance increment of BF/EP composites at various stress levels (240 min)

Stress level Creep compliance increment/(10−12 Pa−1) KH-560-BF/EP WA-KH-560/570-BF/EP 20% 1.882 0.675 30% 1.842 0.765 40% 2.375 1.210 45% 2.420 1.490 50% 3.140 1.870 表 7 不同应力水平下h(σ)的拟合值

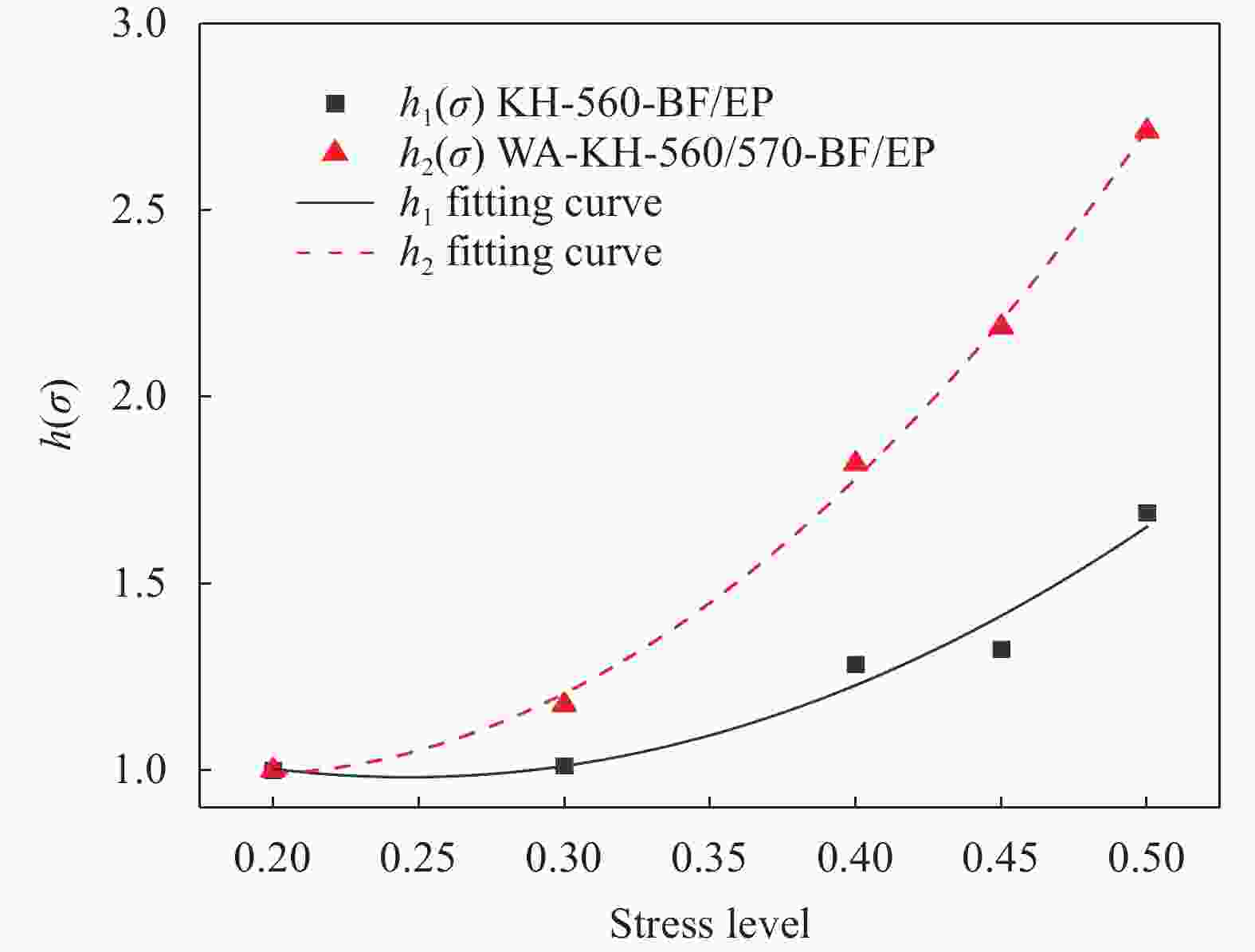

Table 7. Fitting values of h(σ) at different stress levels

Stress level h(σ) KH-560-BF/EP WA-KH-560/570-BF/EP 20% 1 1 30% 1.01 1.18 40% 1.28 1.82 45% 1.32 2.19 50% 1.69 2.71 Note: h(σ)—Functions related to stress level. 表 8 BF/EP复合材料不同应力水平的拟合优度R2

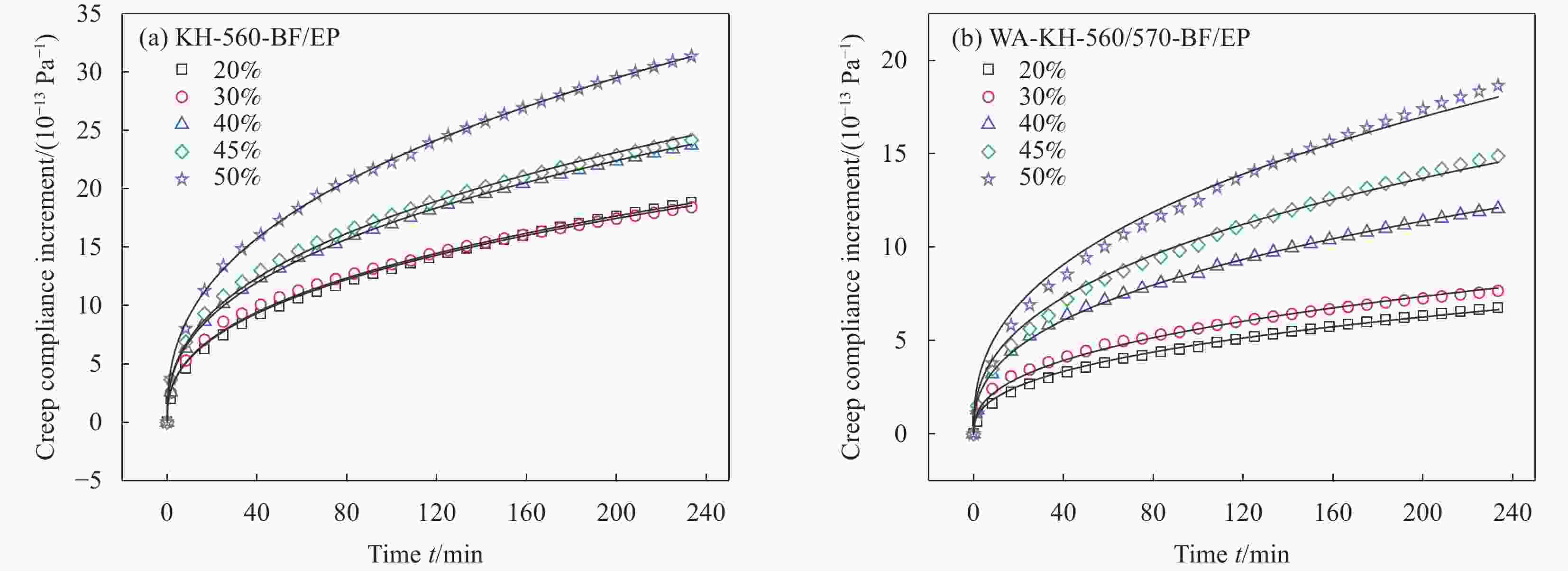

Table 8. Goodness-of-fit R2 of BF/EP composites at different stress levels

Stress level R2 KH-560-BF/EP WA-KH-560/570-BF/EP 20% 0.998 0.997 30% 0.994 0.994 40% 0.999 0.999 45% 0.997 0.994 50% 0.999 0.988 表 9 BF/EP复合材料蠕变柔量增量预测值误差(240 min)

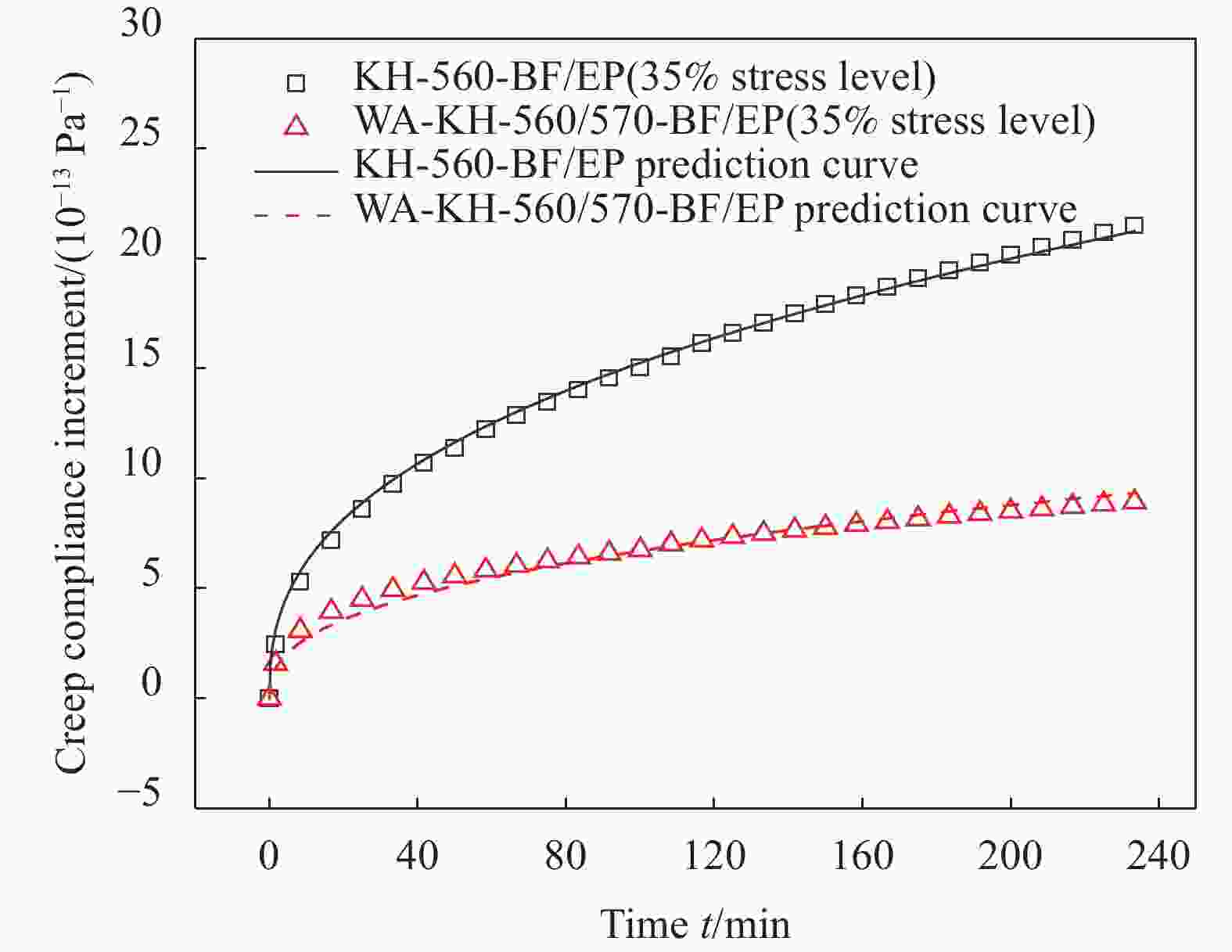

Table 9. Predicted value error of creep compliance increment in BF/EP composites (240 min)

Sample Jt/(10−13 Pa−1) Jc/(10−13 Pa−1) Deviation/% KH-560-BF/EP 20.70 20.50 0.90 WA-KH-560/570-BF/EP 9.53 9.74 2.18 Notes: Jt—Experimental value of creep compliance; Jc—Calculated value of creep compliance. -

[1] LIU C B, FAN X Q, ZHU M H. Regulating the grinding performance of grindstones via using basalt fibers[J]. Tribology International,2022,173:107611. doi: 10.1016/j.triboint.2022.107611 [2] KATOUZIAN M, VLASE S, MARIN M, et al. Modeling study of the creep behavior of carbon-fiber-reinforced composites: A review[J]. Polymers,2023,15(1):194. doi: 10.3390/polym15010194 [3] 叶国锐, 晏义伍, 曹海琳. 氧化石墨烯改性玄武岩纤维及其增强环氧树脂复合材料性能[J]. 复合材料学报, 2014, 31(6):1402-1408. doi: 10.13801/j.cnki.fhclxb.20141202.001YE Guorui, YAN Yiwu, CAO Hailin. Basalt fiber modified with graphene oxide and properties of its reinforced epoxy composites[J]. Acta Materiae Compositae Sinica,2014,31(6):1402-1408(in Chinese). doi: 10.13801/j.cnki.fhclxb.20141202.001 [4] SAMAREH-MOUSAVI S S, TAHERI-BEHROOZ F. A novel creep-fatigue stiffness degradation model for composite materials[J]. Composite Structures,2020,237:111955. doi: 10.1016/j.compstruct.2020.111955 [5] 靳婷婷, 申士杰, 李静, 等. 低温等离子处理对玄武岩纤维表面及复合材料性能的影响[J]. 玻璃钢/复合材料, 2015, 6(6):29-35.JIN Tingting, SHEN Shijie, LI Jing, et al. Impact on the surface of basalt fiber and composite material properties of low-temperature plasma treatment[J]. Fiber Reinforced Plastics/Composites,2015,6(6):29-35(in Chinese). [6] 别依诺, 朱四荣, 贺攀, 等. 纳米SiO2-硅烷协同改性对玄武岩纤维/环氧树脂复合材料力学性能及蠕变性能的影响[J]. 复合材料学报, 2022, 39(8):3723-3732.BIE Yinuo, ZHU Sirong, HE Pan, et al. Effect of nano-SiO2 particles-silane synergistic modification on mechanical properties and creep properties of basalt fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3723-3732(in Chinese). [7] BERARDI V P, PERRELLA M, ARMENTANI E, et al. Experimental investigation and numerical modeling of creep response of glass fiber reinforced polymer composites[J]. Fatigue & Fracture of Engineering Materials & Structures,2021,44(4):1085-1095. [8] 王晓东, 云斯宁, 张太宏, 等. 硅烷偶联剂表面改性玄武岩纤维增强复合材料研究进展[J]. 材料导报, 2017, 31(5):77-83.WANG Xiaodong, YUN Sining, ZHANG Taihong, et al. Advances in basalt fiber-reinforced composites modified by silane coupling agents[J]. Materials Reports,2017,31(5):77-83(in Chinese). [9] 张运华, 姚丽萍, 徐仕进, 等. 表面处理玄武岩纤维增强水泥基复合材料力学性能[J]. 复合材料学报, 2017, 34(5):1159-1166. doi: 10.13801/j.cnki.fhclxb.20170302.003ZHANG Yunhua, YAO Liping, XU Shijin, et al. Mechanical properties of cement matrix composites reinforced with surface treated basalt fibers[J]. Acta Materiae Compositae Sinica,2017,34(5):1159-1166(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170302.003 [10] BEHERA S, GAUTAM R K, MOHAN S. Polylactic acid and polyhydroxybutyrate coating on hemp fiber: Its effect on hemp fiber reinforced epoxy composites performance[J]. Journal of Composite Materials,2022,56(6):929-939. doi: 10.1177/00219983211066991 [11] ZANKER H, RAJABIPOUR A, HUANG D S, et al. Creep analysis of bamboo composite for structural applications[J]. Polymers,2023,15(3):711. doi: 10.3390/polym15030711 [12] OĞUZ Z A, ERKLIĞ A. Evaluation of the hydrothermal aging effect on the buckling behavior of hybrid glass/aramid/epoxy composite plates: Comparison of distilled water and seawater[J]. Polymer Composites,2022,43(7):4463-4477. doi: 10.1002/pc.26705 [13] WANG Z T, LUO H J, ZHANG J, et al. Water-soluble polysiloxane sizing for improved heat resistance of basalt fiber[J]. Materials Chemistry and Physics,2021,272:125024. doi: 10.1016/j.matchemphys.2021.125024 [14] IBRAHIM N A, EID B M, EL-ZAIRY E M, et al. Development of eco-friendly colored/multifunctionalized cellulose/polyester blended fabrics using plasma preactivation and subsequent coloration/multifunctionalization in single stage[J]. Polymer Bulletin, 2023, 80(11): 12353-12372. [15] LI M, XING F, LI T S, et al. Multiscale interfacial enhancement of surface grown carbon nanotubes carbon fiber composites[J]. Polymer Composites, 2023, 44(5): 2766-2777. [16] TAMRAKAR S, GANESH R, SOCKALINGAM S, et al. Strain rate-dependent large deformation inelastic behavior of an epoxy resin[J]. Journal of Composite Materials,2020,54(1):71-87. doi: 10.1177/0021998319859054 [17] 梁娜, 朱四荣, 陈建中. 一种新的聚合物基复合材料应力松弛经验模型[J]. 复合材料学报, 2017, 34(10):2205-2210. doi: 10.13801/j.cnki.fhclxb.20170302.008LIANG Na, ZHU Sirong, CHEN Jianzhong. A new empirical model for stress relaxation of polymer matrix[J]. Acta Materiae Compositae Sinica,2017,34(10):2205-2210(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170302.008 [18] 贾彩霞, 王乾, 任荣, 等. 超高分子量聚乙烯(UHMWPE)纤维表面处理对UHMWPE/环氧树脂复合材料界面性能的影响机制[J]. 复合材料学报, 2020, 37(3): 573-580.JIA Caixia, WANG Qian, REN Rong, et al. Influence mechanism of ultra high molecular weight polyethylene (UHMWPE) fiber surface modification on interfacial performance of UHMWPE/epoxy composites[J]. Acta Materiae Compositae Sinica, 2020, 37(3): 573-580(in Chinese). [19] 栗越, 张京发, 易顺民, 等. 改性芳纶纤维增强木粉/高密度聚乙烯复合材料的力学性能[J]. 复合材料学报, 2019, 36(3):638-645. doi: 10.13801/j.cnki.fhclxb.20180530.006LI Yue, ZHANG Jingfa, YI Shunmin, et al. Mechanical properties of modified aramid fiber reinforced wood flour/high density polyethylene composites[J]. Acta Materiae Compositae Sinica,2019,36(3):638-645(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180530.006 [20] 黄灵丽, 侯锐钢, 刘育建. 弯曲应力/混酸溶液共同作用对FRP性能的影响[J]. 热固性树脂, 2020, 35(6): 33-37.HUANG Lingli, HOU Ruigang, LIU Yujian. Synergetic effects of flexural stress and mixed acid solution on the properties of FRP[J]. Thermosetting Resin, 2020, 35(6): 33-37(in Chinese). [21] ZHANG S F, XING T Z, ZHU H B, et al. Experimental identification of statistical correlation between mechanical properties of FRP composite[J]. Materials,2020,13(3):674. doi: 10.3390/ma13030674 [22] 马燕, 刘秀, 罗利, 等. 双轴拉伸下高聚物的时间-应力等效原理试验研究[J]. 材料导报, 2019, 33(24):4188-4192.MA Yan, LIU Xiu, LUO Li, et al. Time-stress superposition principle of polymers under biaxial tension: Experimental study[J]. Materials Reports,2019,33(24):4188-4192(in Chinese). [23] KRAUKLIS A E, AKULICHEV A G, GAGANI A I, et al. Time-temperature-plasticization superposition principle: Predicting creep of a plasticized epoxy[J]. Polymers,2019,11(11):1848. doi: 10.3390/polym11111848 [24] 中国国家标准化管理委员会. 玄武岩纤维无捻粗纱: GB/T 25045—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of the People's Republic of China. Basalt fiber roving: GB/T 25045—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [25] 中国国家标准化管理委员会. 玻璃纤维无捻粗纱浸胶纱试样的制作和拉伸强度的测定: GB/T 20310—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People's Republic of China. Textile glass—Rovings—Manufacture of test specimens and determination of tensile strength of impregnated rovings: GB/T 20310—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [26] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Fibre-reinforced plastic composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese) [27] 中国国家标准化管理委员会. 纤维缠绕增强塑料环形试样力学性能试验方法: GB/T 1458—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Test method for mechanical properties of ring of filament-winding reinforced plastics: GB/T 1458—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [28] The British Standards Institution. GRP tanks and vessels for use above ground—Part 3: Design and workmanship: EN 13121-3—2016[S]. London: BSI Standards Limited, 2016. [29] FINDLEY W N, DAVIS F A. Creep and relaxation of nonlinear viscoelastic materials[M]. New York: Courier Corporation, 2013. [30] TOMLINS P E, READ B E. Creep and physical ageing of polypropylene: A comparison of models[J]. Polymer,1998,39(2):355-367. doi: 10.1016/S0032-3861(97)00258-9 -

下载:

下载: