Electromagnetic ultrasonic on-line monitoring method and failure mechanism of carbon fiber reinforced resin matrix composite material gas cylinder

-

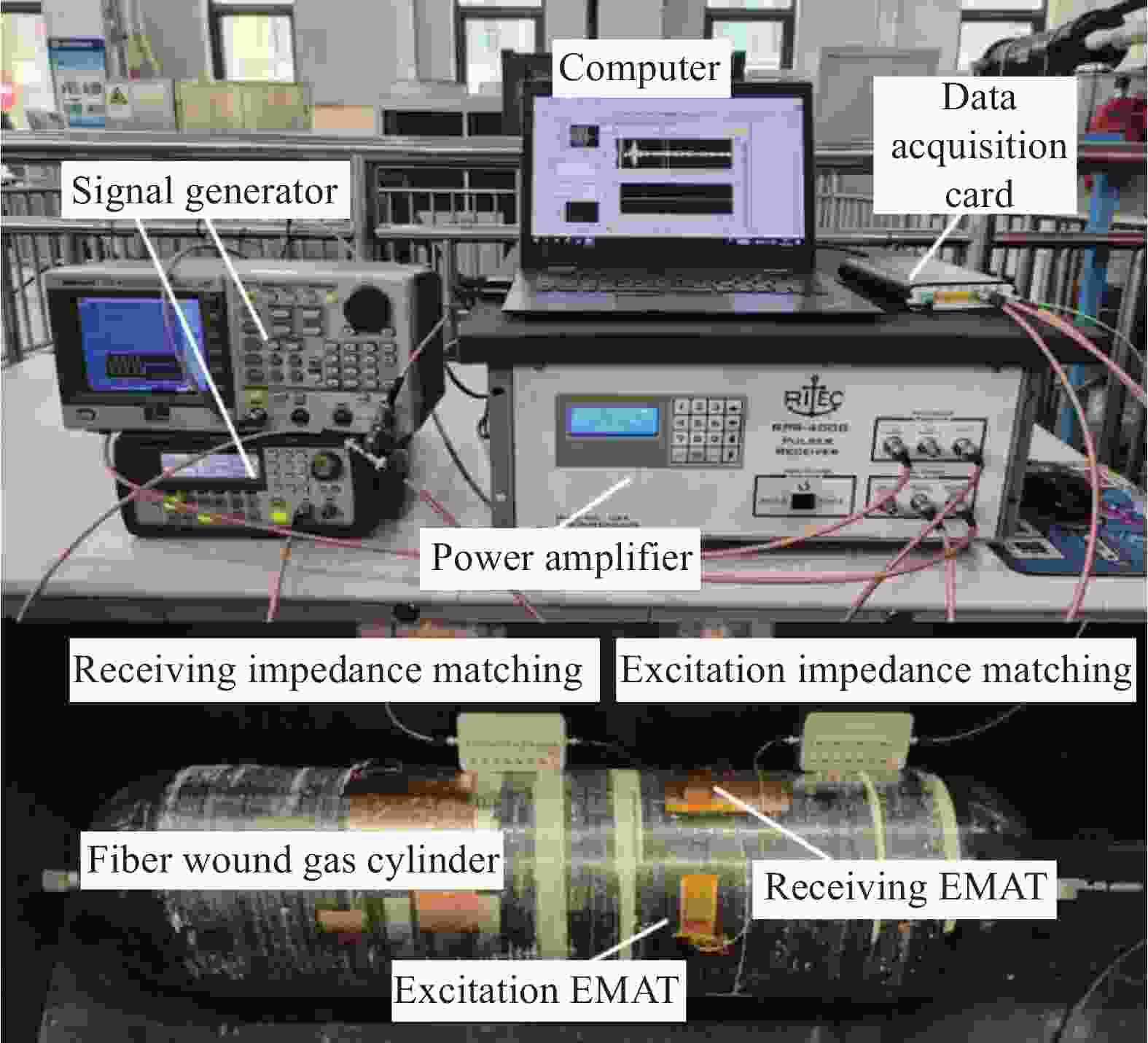

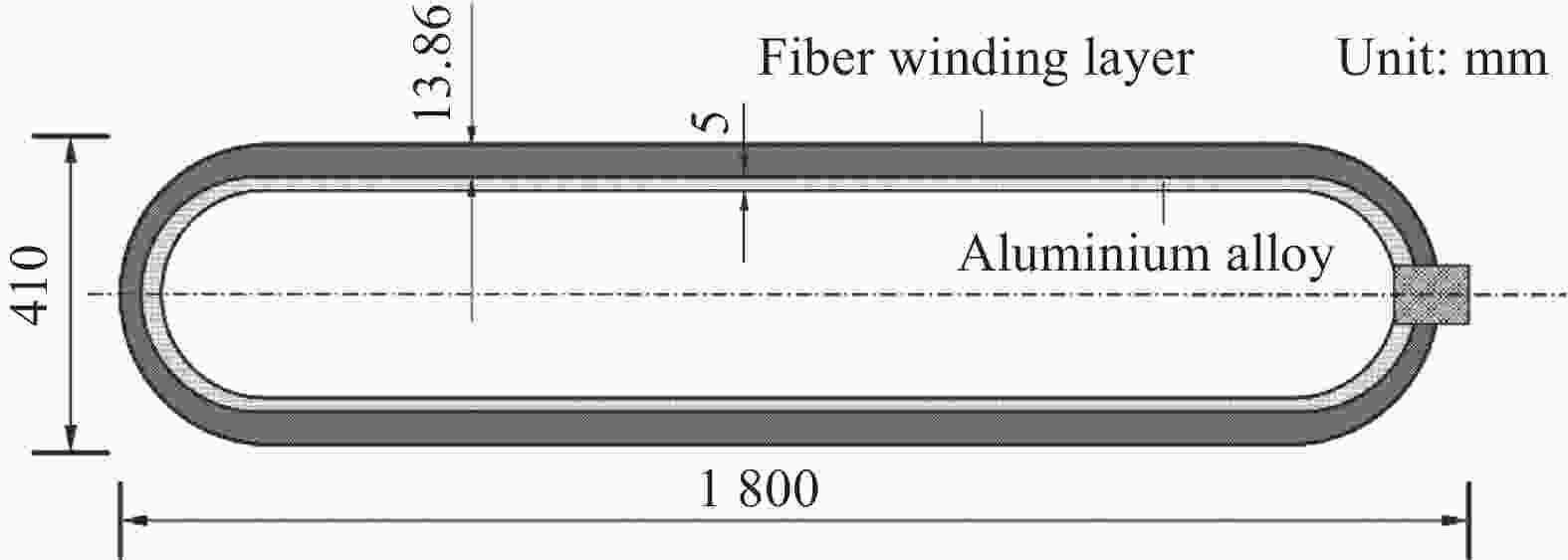

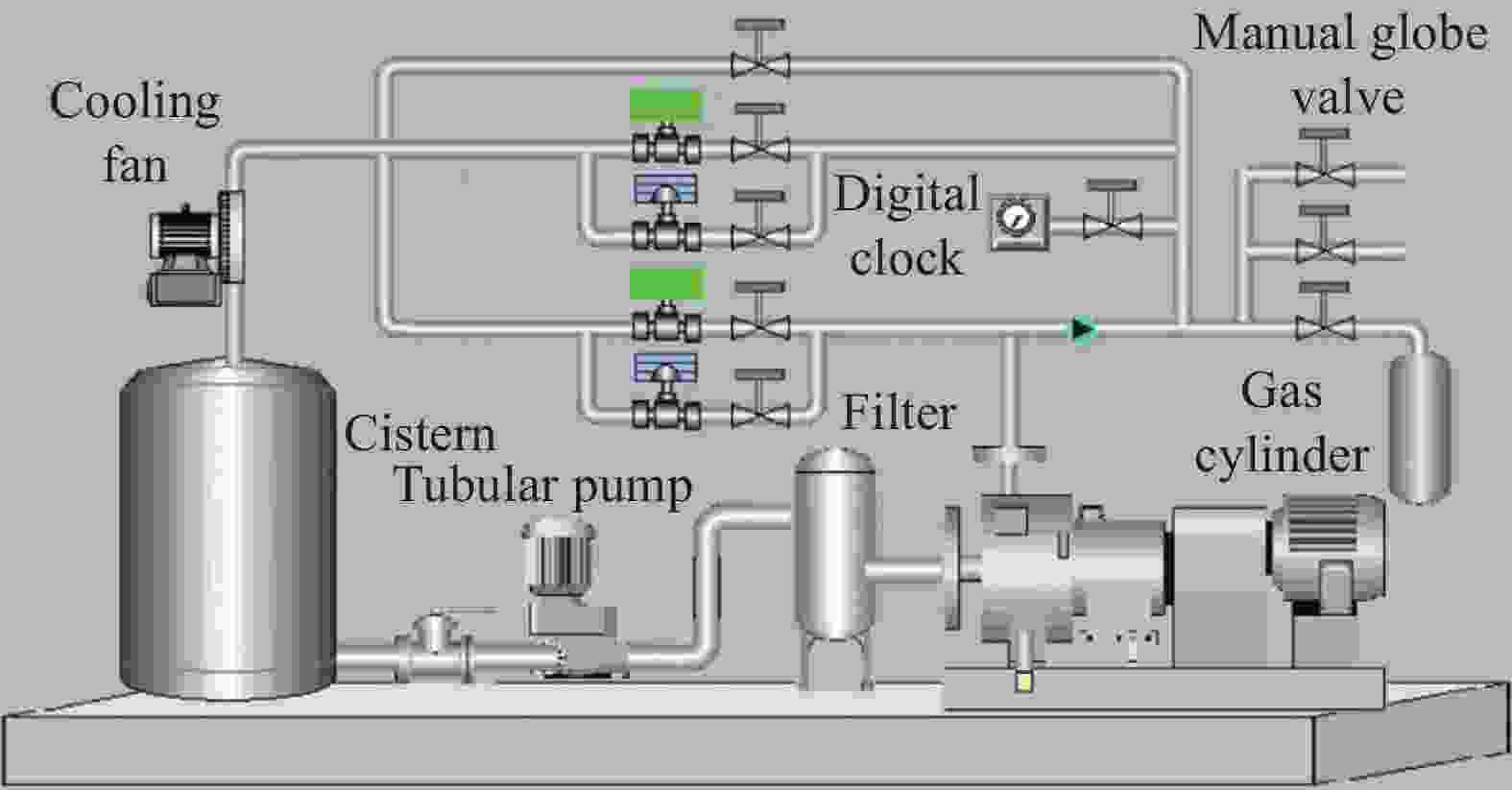

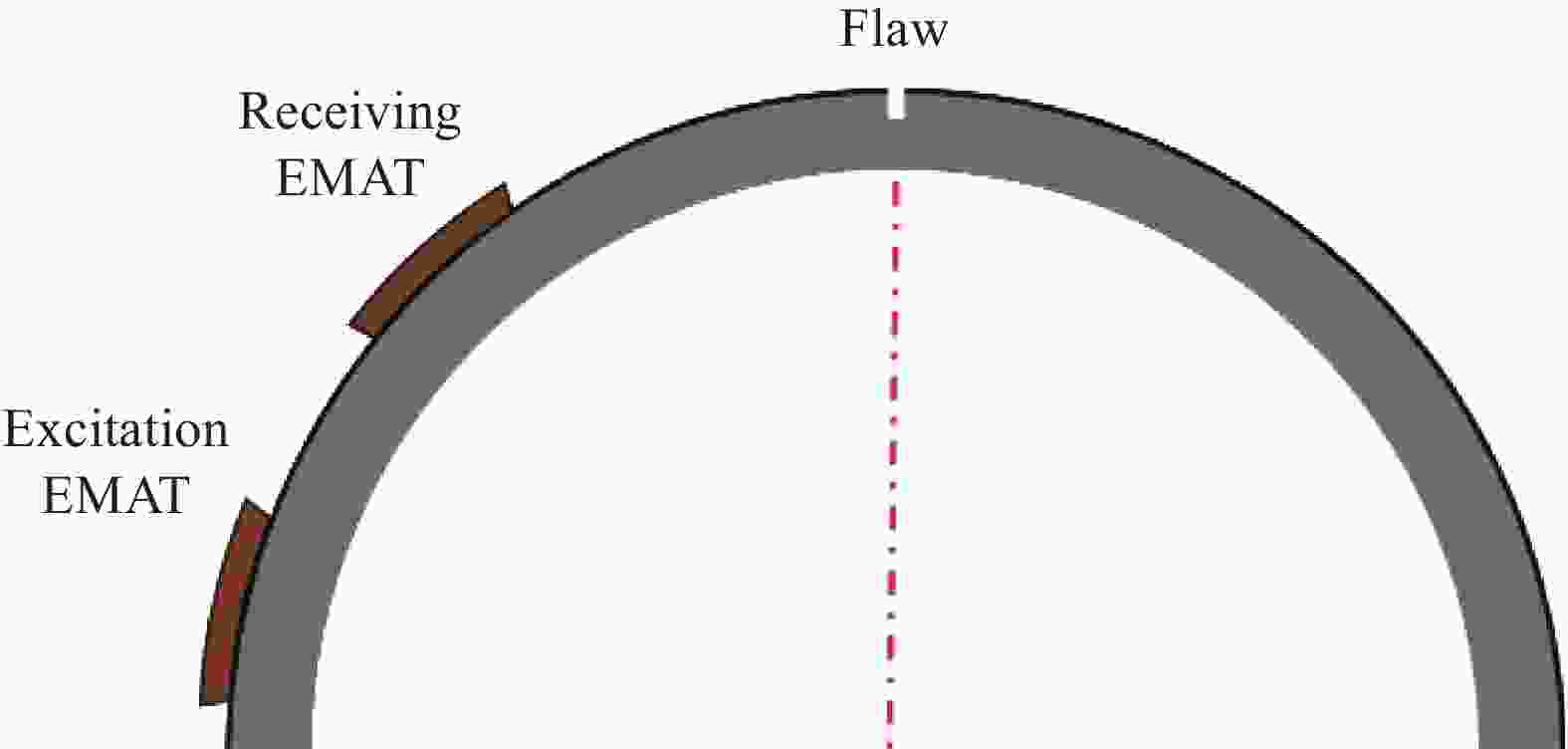

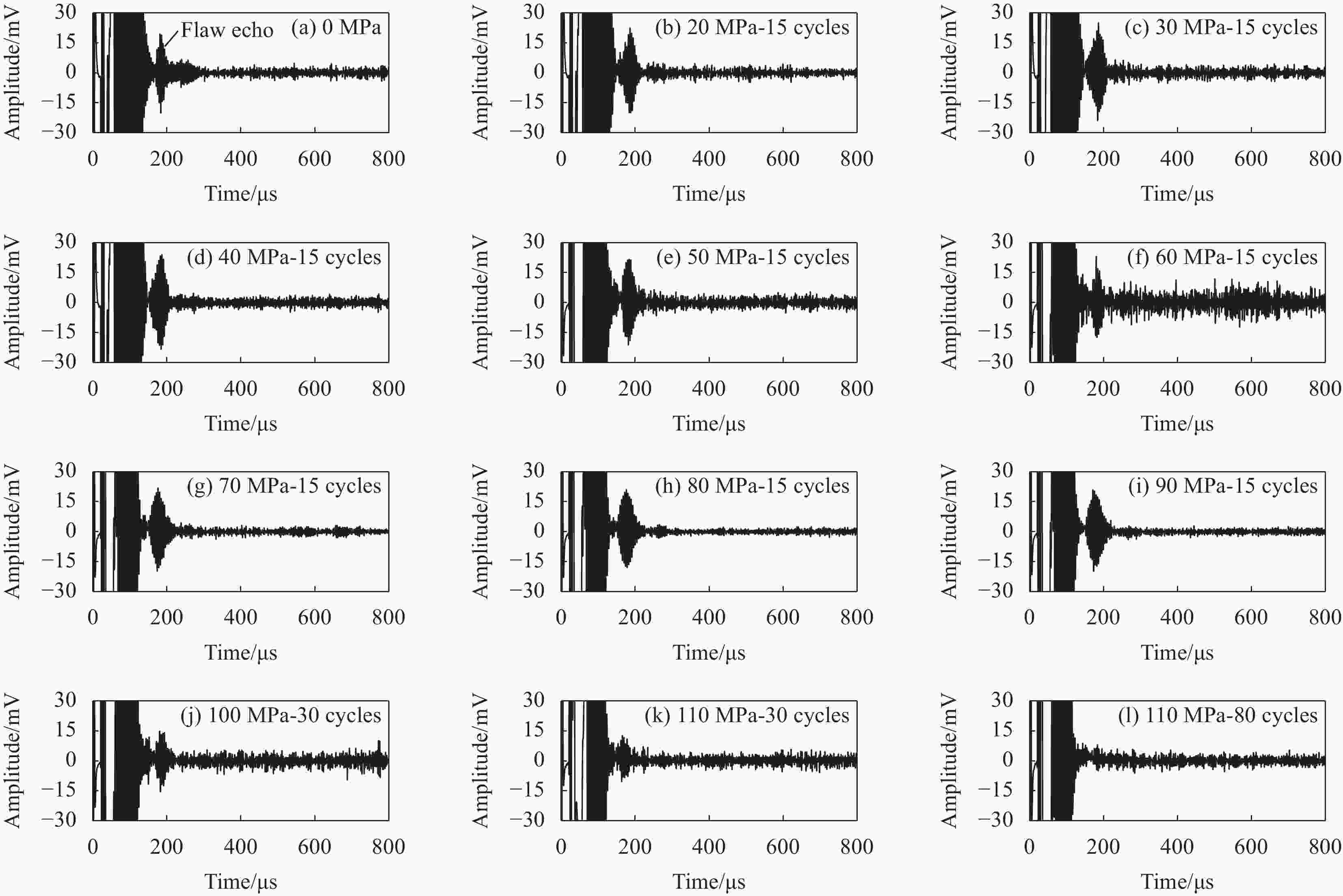

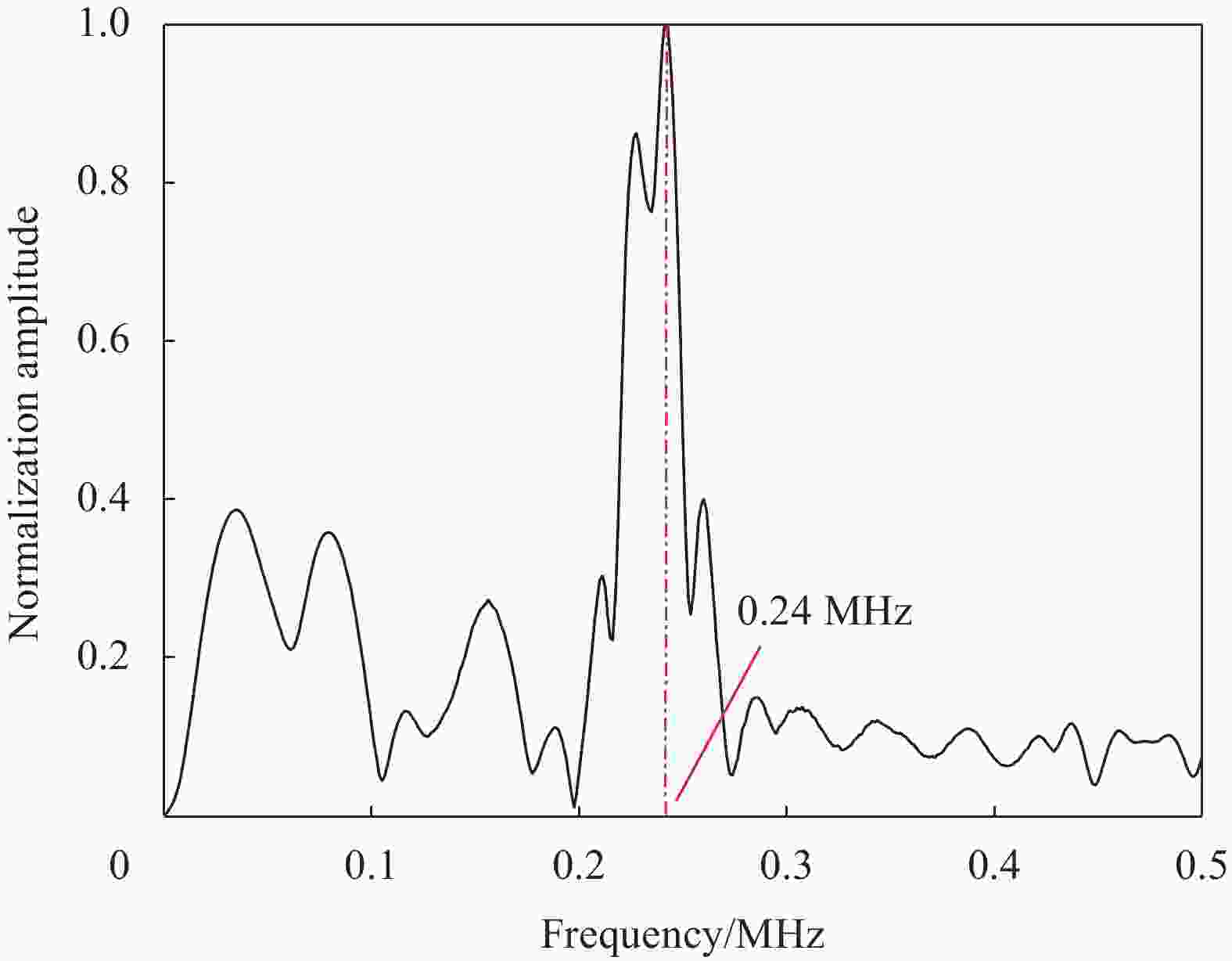

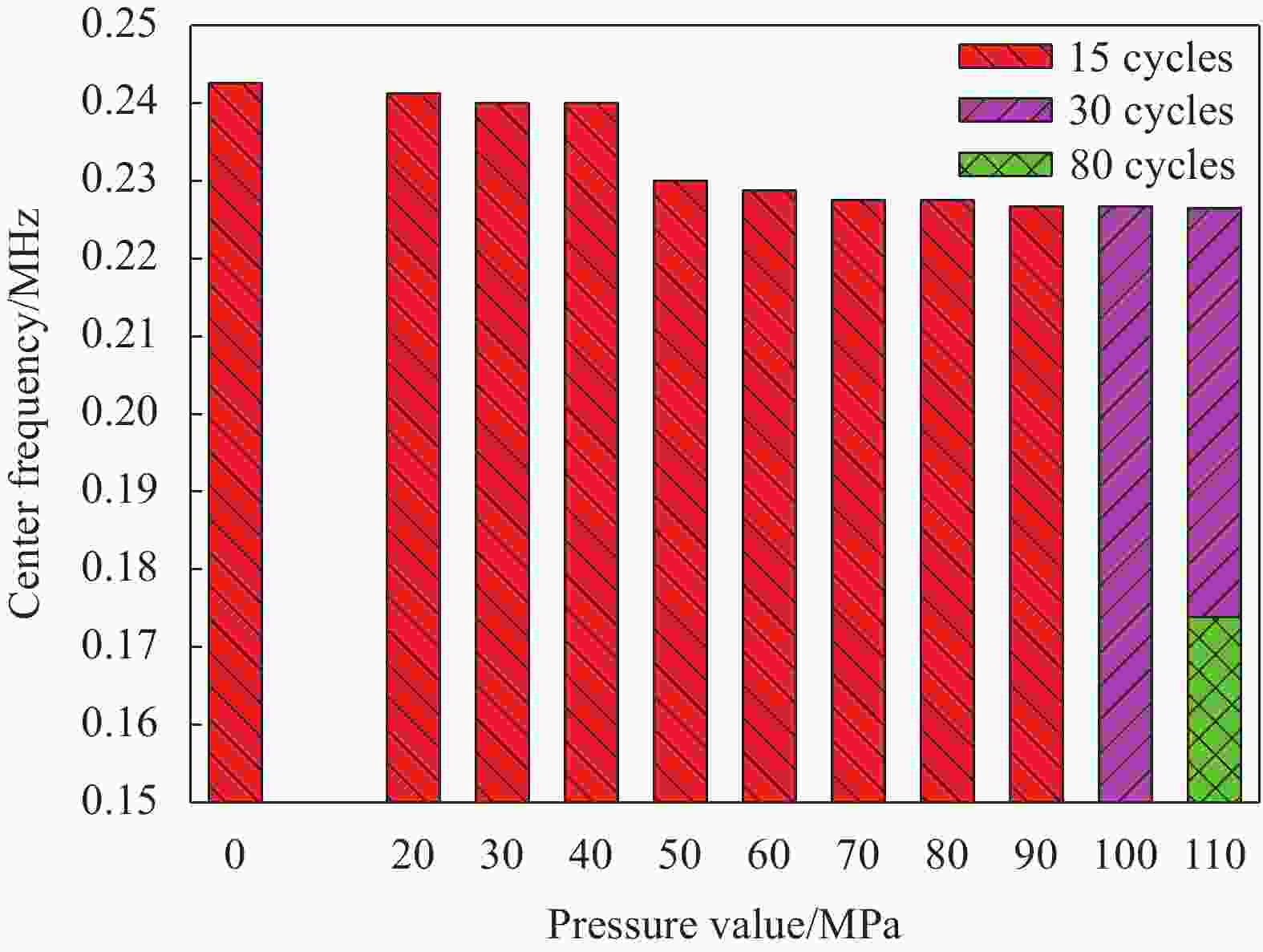

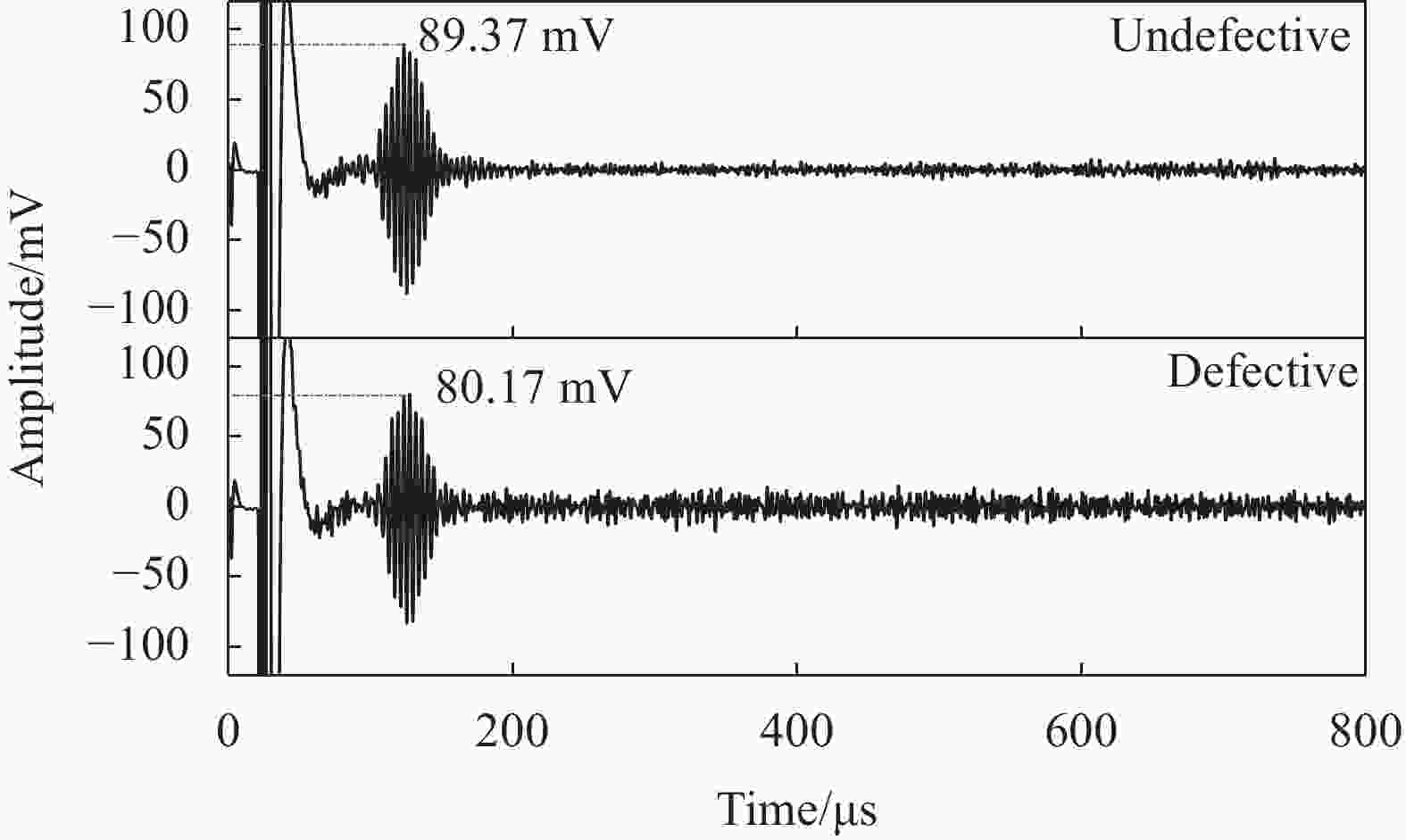

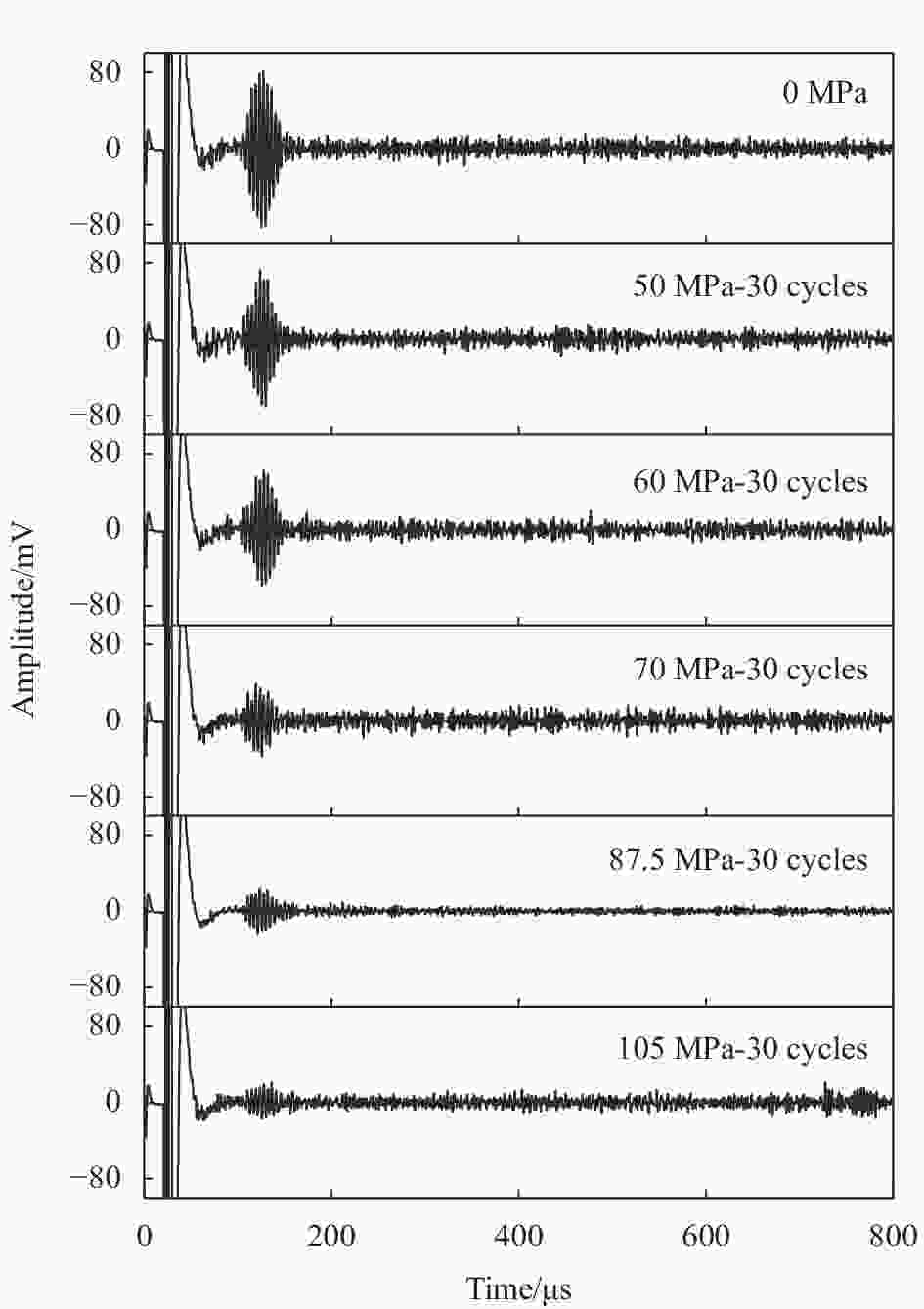

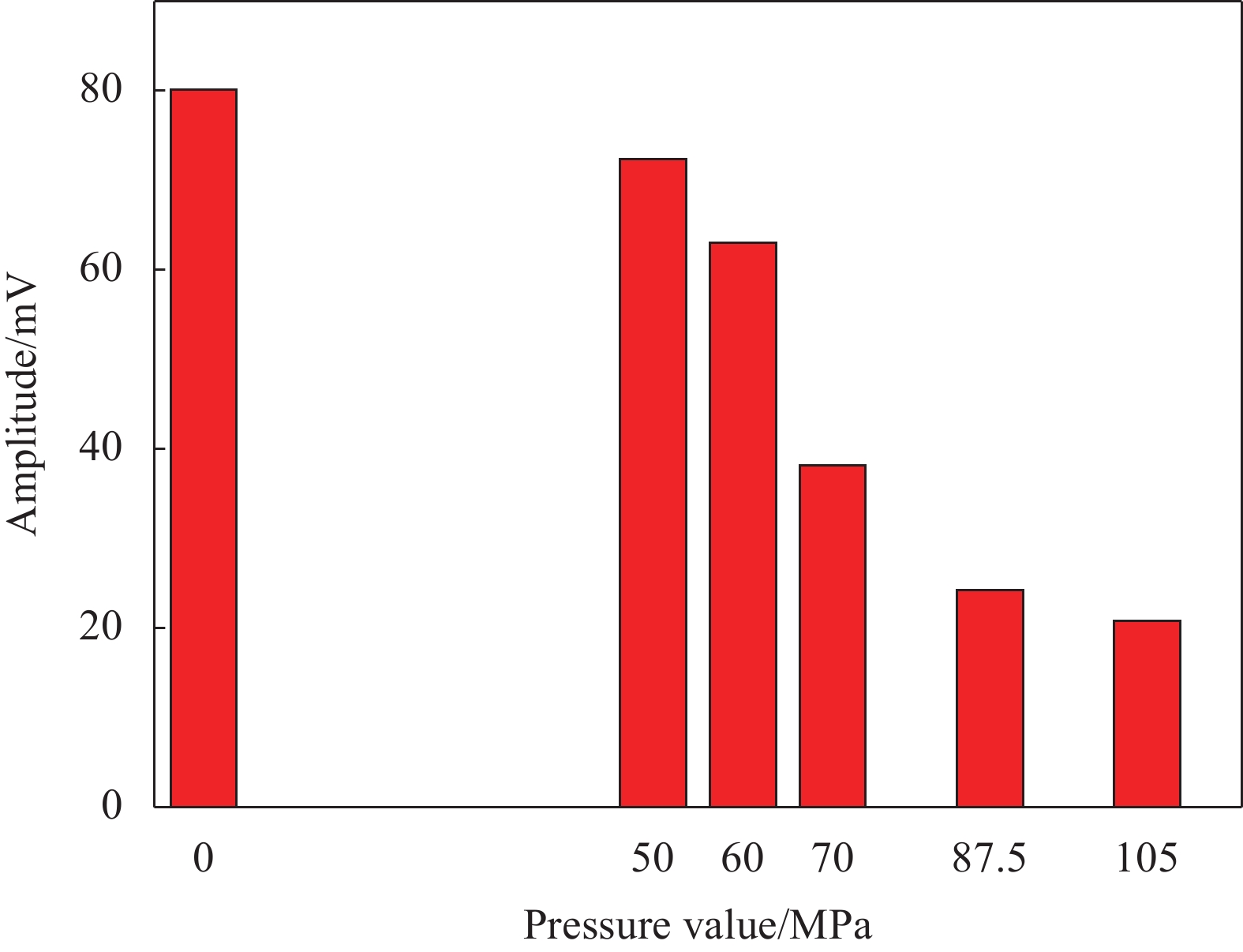

摘要: 氢能具有来源广泛、清洁无碳等优点,随着氢能源的广泛应用,氢能储运逐渐成为研究热点。目前,国家大力发展的碳纤维增强树脂基复合材料气瓶已被广泛应用于氢能储运领域,然而气瓶在使用和运输过程中,容易出现纤维断裂、划伤,严重影响使用安全,故亟需发展碳纤维增强树脂基复合材料气瓶在线监测技术。针对复合材料气瓶的纤维断裂、划伤缺陷在长期、多次充放气过程中发生扩展的问题,采用电磁超声换能器(Electromagnetic acoustic transducer,EMAT)在线监测方法,并结合90TJ3-140 MPa水压疲劳系统,分别采用超声导波反射式和透射式方法,分析了纤维损伤对导波幅值的影响,并研究了含纤维损伤的气瓶在不同疲劳状态下的导波信号特征的变化规律。结果表明:纤维损伤会降低透射波幅值,且幅值减少量由纤维损伤程度决定;随着气瓶内压的增加,超声导波的声速和中心频率逐渐减小;长20 mm、宽0.5 mm和深1 mm的裂纹对应的缺陷波幅值呈先增大后减小的趋势,经过110 MPa、80次循环后,缺陷波幅值由19.33 mV减小至8.02 mV,声速减小了6.6%,中心频率从0.24 MHz减小至0.17 MHz,纤维完全分层;针对长20 mm、宽0.5 mm和深0.5 mm的裂纹,当气瓶内压由0 MPa增加至105 MPa时,直达波幅值由80.17 mV减小至20.08 mV,降低了75%;采用的电磁超声技术能够很好地解决碳纤维增强树脂基复合材料气瓶在线监测技术难题。Abstract: Hydrogen energy has the advantages of wide source, clean and carbon-free. With the wide application of hydrogen energy, hydrogen energy storage and transportation has gradually become a research hotspot. At present, the carbon fiber reinforced resin matrix composite material gas cylinder vigorously developed by the country has been widely used in the field of hydrogen energy storage and transportation, but the gas cylinder is prone to fiber breakage and scratches during use and transportation, which seriously affects the safety of use, so it is urgent to develop the carbon fiber reinforced resin matrix composite material gas cylinder online monitoring technology. In order to solve the problem that fiber fracture and scratch defects of composite material gas cylinders will expand during long-term and multiple filling and venting, an online monitoring method using electromagnetic acoustic transducer (EMAT) was adopted. Combined with the 90TJ3-140 MPa hydraulic pressure fatigue system, the influence of fiber damage on the amplitude of guided wave was analyzed by ultrasonic guided wave reflection method and ultrasonic guided wave transmission method, and the variation of guided wave signal characteristics of gas cylinders with fiber damage under different fatigue conditions was studied. The results show that fiber damage can reduce the amplitude of transmission wave, and the amplitude reduction is determined by the degree of fiber damage. With the increase of the pressure inside the cylinder, the sound velocity and center frequency of ultrasonic guided wave decrease gradually. For cracks with length 20 mm, width 0.5 mm and depth 1 mm, the amplitude of the defect wave increases first and then decreases. After 110 MPa and 80 cycles, the amplitude of the defect wave decreases from 19.33 mV to 8.02 mV, the sound velocity decreases by 6.6%, and the center frequency decreases from 0.24 MHz to 0.17 MHz, the fibers are completely layered. For cracks with a length of 20 mm, a width of 0.5 mm and a depth of 0.5 mm, when the internal pressure of the cylinder increases from 0 MPa to 105 MPa, the direct wave amplitude decreases from 80.17 mV to 20.08 mV, which decreases by 75%. The electromagnetic ultrasonic technology can effectively solve the difficult problem of on-line monitoring of carbon fiber reinforced resin matrix composite material gas cylinder.

-

图 15 碳纤维增强树脂基复合材料高压气瓶不同疲劳状态下的纤维分层情况:(a) 0 MPa;(b) 50 MPa;(c) 60 MPa;(d) 70 MPa;(e) 87.5 MPa;(f) 105 MPa

Figure 15. Fiber delamination of carbon fiber reinforced resin matrix composite high pressure gas cylinder under different fatigue conditions: (a) 0 MPa; (b) 50 MPa; (c) 60 MPa; (d) 70 MPa; (e) 87.5 MPa; (f) 105 MPa

表 1 水压疲劳试验参数

Table 1. Hydraulic fatigue test parameters

Parameter Value High pressure holding deviation setting/MPa 4 High pressure holding time setting/s 2 Low pressure holding deviation setting/MPa 1 Low pressure holding time setting/s 2 Unloading proportional valve close setting 80.0 Pressure relief proportional valve close setting 80.0 Pressure relief proportional valve close minimum 0.2 Pressure relief proportional valve close extreme

dead zone value0.2 Step-down time increment setting/s 1 表 2 不同损伤状态下的碳纤维增强树脂基复合材料声速

Table 2. Sound velocity of carbon fiber reinforced resin matrix composites under different damage states

Fatigue state Velocity of sound/(m·s−1) 0 MPa 1833.07 20 MPa-15 cycles 1828.60 30 MPa-15 cycles 1827.49 40 MPa-15 cycles 1827.15 50 MPa-15 cycles 1767.83 60 MPa-15 cycles 1718.21 70 MPa-15 cycles 1713.31 80 MPa-15 cycles 1713.30 90 MPa-15 cycles 1718.21 100 MPa-30 cycles 1718.21 110 MPa-30 cycles 1711.74 110 MPa-80 cycles 1711.74 -

[1] CHEN S, WANG Y, LANG X, et al. Rapid and high hydrogen storage in epoxycyclopentane hydrate at moderate pressure[J]. Energy, 2023, 286: 126638. [2] 吕洪, 黄港淇, 沈亚皓, 等. 燃料电池汽车车载高压IV型储氢瓶耐火烧性能仿真[J]. 中南大学学报(自然科学版), 2022, 53(12):4637-4647.LYU Hong, HUANG Gangqi, SHEN Yahao, et al. Numerical simulation of fire resistance performance of high-pressure type IV hydrogen storage tank for fuel cell vehicle[J]. Journal of Central South University (Science and Technology),2022,53(12):4637-4647(in Chinese). [3] 刘培启, 杨帆, 黄强华, 等. T700碳纤维增强树脂复合材料气瓶封头非测地线缠绕强度[J]. 复合材料学报, 2019, 36(12):2772-2778.LIU Peiqi, YANG Fan, HUANG Qianghua, et al. Non-geodetic winding strength of T700 carbon fiber reinforced resin composite cylinder head[J]. Acta Materiae Compositae Sinica,2019,36(12):2772-2778(in Chinese). [4] 李玉峰, 靳庆臣, 刘志栋. 复合材料高压气瓶的碳纤维缠绕设计和ANSYS分析技术[J]. 推进技术, 2013, 34(7):968-976.LI Yufeng, JIN Qingchen, LIU Zhidong. Filament-wound design and ANSYS analysis for composite material high-pressure vessel[J]. Journal of Propulsion Technology,2013,34(7):968-976(in Chinese). [5] DENG G, WANG H, JIA G, et al. Effect of outer surface defects on large capacity composite cylinders for tube trailers[C]//ASME 2019 Pressure Vessels & Piping Conference. San Antonio: Pressure Vessels and Piping Division, 2019, 58943: V003T03A065. [6] DAVIS P, BROCKHURST J. Subsea pipeline infrastructure monitoring: A framework for technology review and selection[J]. Ocean Engineering,2015,104:540-548. doi: 10.1016/j.oceaneng.2015.04.025 [7] EYBPOOSH M, BERGES M, NOH H Y. An energy-based sparse representation of ultrasonic guided-waves for online damage detection of pipelines under varying environmental and operational conditions[J]. Mechanical Systems and Signal Processing,2017,82:260-278. doi: 10.1016/j.ymssp.2016.05.022 [8] BIE H, LI X, LIU P, et al. Fatigue life evaluation of high pressure hydrogen storage vessel[J]. International Journal of Hydrogen Energy,2010,35(7):2633-2636. doi: 10.1016/j.ijhydene.2009.04.037 [9] HO J K M, CHAU J P C, CHEUNG N M C. Effectiveness of emergency nurses' use of the Ottawa Ankle Rules to initiate radiographic tests on improving healthcare outcomes for patients with ankle injuries: A systematic review[J]. International Journal of Nursing Studies,2016,63:37-47. doi: 10.1016/j.ijnurstu.2016.08.016 [10] TOKURA S, HARA M, KAWAGUCHI N, et al. Contactless magnetic manipulation of magnetic particles in a fluid[J]. Journal of Magnetism and Magnetic Materials,2016,411:68-78. doi: 10.1016/j.jmmm.2016.03.021 [11] SCHRÖDER M, BIEDERMANN C, VILBRANDT R. On the applicability of dye penetrant tests on vacuum components: Allowed or forbidden[J]. Fusion Engineering and Design,2013,88(9-10):1947-1950. doi: 10.1016/j.fusengdes.2012.11.019 [12] DAVID N, VON SCHILLING K, WILD P M, et al. In situ measurement of relative humidity in a PEM fuel cell using fibre Bragg grating sensors[J]. International Journal of Hydrogen Energy,2014,39(31):17638-17644. doi: 10.1016/j.ijhydene.2014.08.010 [13] WESTERWAAL R J, ROOIJMANS J S A, LECLERCQ L, et al. Nanostructured Pd-Au based fiber optic sensors for probing hydrogen concentrations in gas mixtures[J]. International Journal of Hydrogen Energy,2013,38(10):4201-4212. doi: 10.1016/j.ijhydene.2012.12.146 [14] LIU T, WANG W, QIANG W, et al. Mechanical properties and eddy current testing of thermally aged Z3CN20.09M cast duplex stainless steel[J]. Journal of Nuclear Materials,2018,501:1-7. doi: 10.1016/j.jnucmat.2018.01.028 [15] YANG B, XIANG Y, XUAN F Z, et al. Damage localization in hydrogen storage vessel by guided waves based on a real-time monitoring system[J]. International Journal of Hydrogen Energy,2019,44(40):22740-22751. doi: 10.1016/j.ijhydene.2019.01.009 [16] 骆辉, 李桐, 黄强华, 等. 基于声发射技术的大容积玻璃纤维缠绕气瓶冲击损伤评定[J]. 振动与冲击, 2023, 42(5):143-149.LUO Hui, LI Tong, HUANG Qianghua, et al. Impact damage evaluation of large volume glass fiber wrapped gas cylinder based on AE technology[J]. Journal of Vibration and Shock,2023,42(5):143-149(in Chinese). [17] CHOU H Y, MOURITZ A P, BANNISTER M K, et al. Acoustic emission analysis of composite pressure vessels under constant and cyclic pressure[J]. Composites Part A: Applied Science and Manufacturing,2015,70:111-120. doi: 10.1016/j.compositesa.2014.11.027 [18] LIAO B B, WANG D L, HAMDI M, et al. Acoustic emission-based damage characterization of 70 MPa type IV hydrogen composite pressure vessels during hydraulic tests[J]. International Journal of Hydrogen Energy,2019,44(40):22494-22506. doi: 10.1016/j.ijhydene.2019.02.217 [19] BO K, LIU S, CHENG L, et al. Experiment research on acoustic emission of impact-damaged fully-wrapped composite gas cylinder with non-metallic liner[C]//Advances in Acoustic Emission Technology: Proceedings of the World Conference on Acoustic Emission. Singapore: Springer Proceedings in Physics, 2021: 383-391. [20] 杨斌, 胡超杰, 轩福贞, 等. 基于超声导波的压力容器健康监测I: 波传导行为及损伤定位[J]. 机械工程学报, 2020, 56(4):1-10. doi: 10.3901/JME.2020.04.001YANG Bin, HU Chaojie, XUAN Fuzhen, et al. Structural health monitoring of pressure vessel based on guided wave technology. Part I: Wave propagating and damage localization[J]. Journal of Mechanical Engineering,2020,56(4):1-10(in Chinese). doi: 10.3901/JME.2020.04.001 [21] 杨斌, 胡超杰, 轩福贞, 等. 基于超声导波的压力容器健康监测II: 定位精度的影响因素[J]. 机械工程学报, 2020, 56(8):133-140. doi: 10.3901/JME.2020.08.133YANG Bin, HU Chaojie, XUAN Fuzhen, et al. Structural health monitoring of pressure vessel based on guided wave technology. Part II: Damage localization accuracy influencing factors[J]. Journal of Mechanical Engineering,2020,56(8):133-140(in Chinese). doi: 10.3901/JME.2020.08.133 [22] 杨斌, 胡超杰, 轩福贞, 等. 基于超声导波的压力容器健康监测III: 纤维缠绕压力容器的在线监测[J]. 机械工程学报, 2020, 56(10):19-26. doi: 10.3901/JME.2020.10.019YANG Bin, HU Chaojie, XUAN Fuzhen, et al. Structural health monitoring of pressure vessel based on guided wave technology. Part III: Online monitoring of filament wound pressure vessel[J]. Journal of Mechanical Engineering,2020,56(10):19-26(in Chinese). doi: 10.3901/JME.2020.10.019 [23] RIBICHINI R, CEGLA F, NAGY P B, et al. Study and comparison of different EMAT configurations for SH wave inspection[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control,2011,58(12):2571-2581. doi: 10.1109/TUFFC.2011.2120 [24] 吴锐, 石文泽, 卢超, 等. 航空不锈钢薄板电磁超声SH导波检测定量分析方法[J]. 航空学报, 2022, 43(9):735-748.WU Rui, SHI Wenze, LU Chao, et al. Quantitative analysis method for electromagnetic ultrasonic SH guided wave detection of aerospace stainless steel sheet[J]. Aeronautica et Astronautice Sinica,2022,43(9):735-748(in Chinese). [25] 石文泽, 程进杰, 胡硕臻, 等. 脉冲压缩在铝薄板电磁超声导波检测中的应用[J]. 航空学报, 2022, 43(3):517-528.SHI Wenze, CHENG Jinjie, HU Shuozhen, et al. Application of pulse compression in electromagnetic ultrasonic guided wave detection of aluminum sheet[J]. Acta Aeronautica et Astronautice Sinica,2022,43(3):517-528(in Chinese). [26] 詹合林, 朱冰冰, 岳增柱, 等. 车用70 MPa压缩氢气铝内胆碳纤维全缠绕气瓶的应力分析[J]. 现代制造工程, 2018(12):114-118.ZHAN Helin, ZHU Bingbing, YUE Zengzhu, et al. The stress analysis of the fully-wrapped carbon fiber reinforced cylinders with an aluminum liner for the on-board storage of compressed hydrogen as a fuel for land vehicle with nominal working pressure of 70 MPa[J]. Modern Manufacturing Engineering,2018(12):114-118(in Chinese). [27] 李伟, 李建增, 周海林, 等. 多层碳纤维布复合材料超声检测的有限元模拟[J]. 纤维复合材料, 2011, 28(3):17-21.LI Wei, LI Jianzeng, ZHOU Hailin, et al. Finite element simulation of ultrasonic inspection in multi-layers carbon fiber composite[J]. Fiber Composites,2011,28(3):17-21(in Chinese). [28] 周正干, 朱甜甜, 马腾飞, 等. 先进树脂基复合材料纤维褶皱缺陷阵列超声全聚焦成像[J]. 复合材料学报, 2022, 39(9):4384-4392.ZHOU Zhenggan, ZHU Tiantian, MA Tengfei, et al. Array ultrasonic total-focus imaging for advanced resin matrix composite fiber wrinkle defect arrays[J]. Acta Materiae Compositae Sinica,2022,39(9):4384-4392(in Chinese). [29] 肖飚, 杨斌, 胡超杰, 等. 基于埋入式应变片的纤维缠绕压力容器的健康监测[J]. 高压物理学报, 2019, 33(4):56-62.XIAO Biao, YANG Bin, HU Chaojie, et al. Structural health monitoring of filament wound pressure vessel by embedded strain gauges[J]. Chinese Journal of High Pressure Physics,2019,33(4):56-62(in Chinese). [30] KIM Y S, KIM L H, PARK J S. The effect of composite damage on fatigue life of the high pressure vessel for natural gas vehicles[J]. Composite Structures,2011,93(11):2963-2968. doi: 10.1016/j.compstruct.2011.05.007 -

下载:

下载: