Evaluation of electrical aging life of nano SiO2/PP composites

-

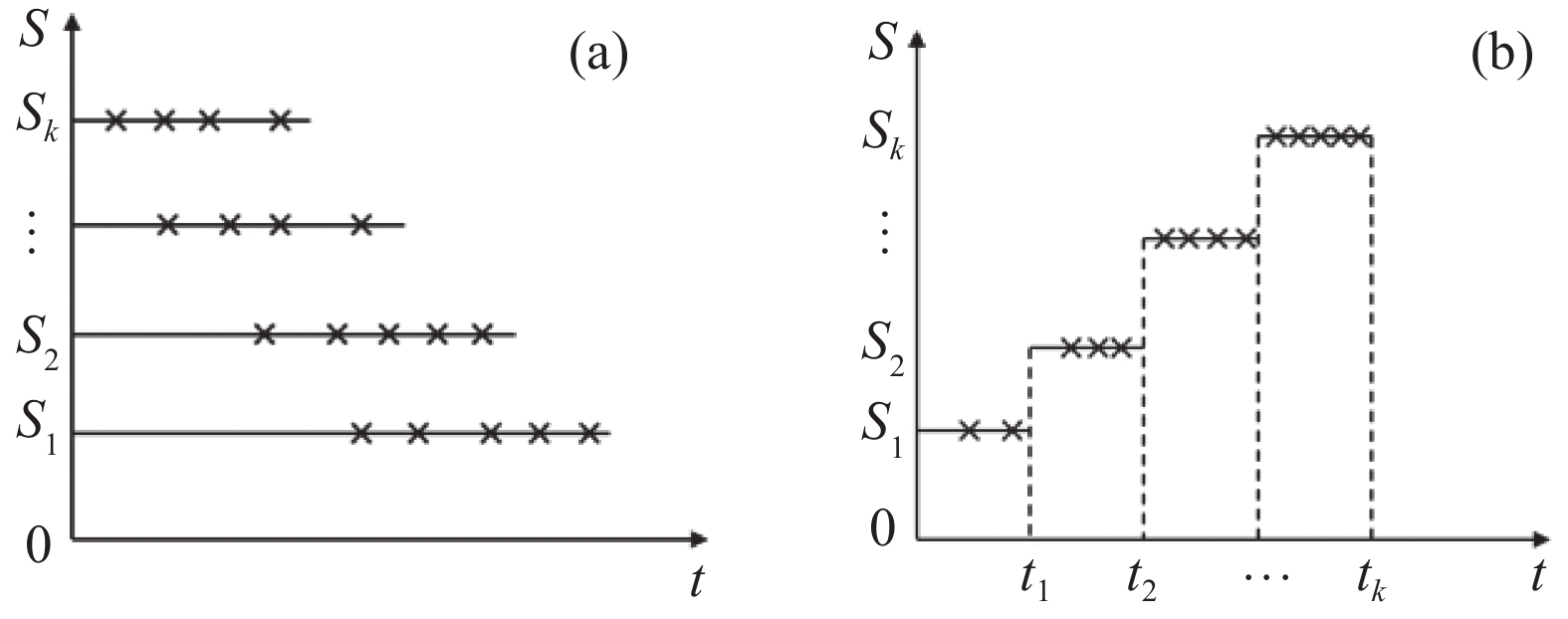

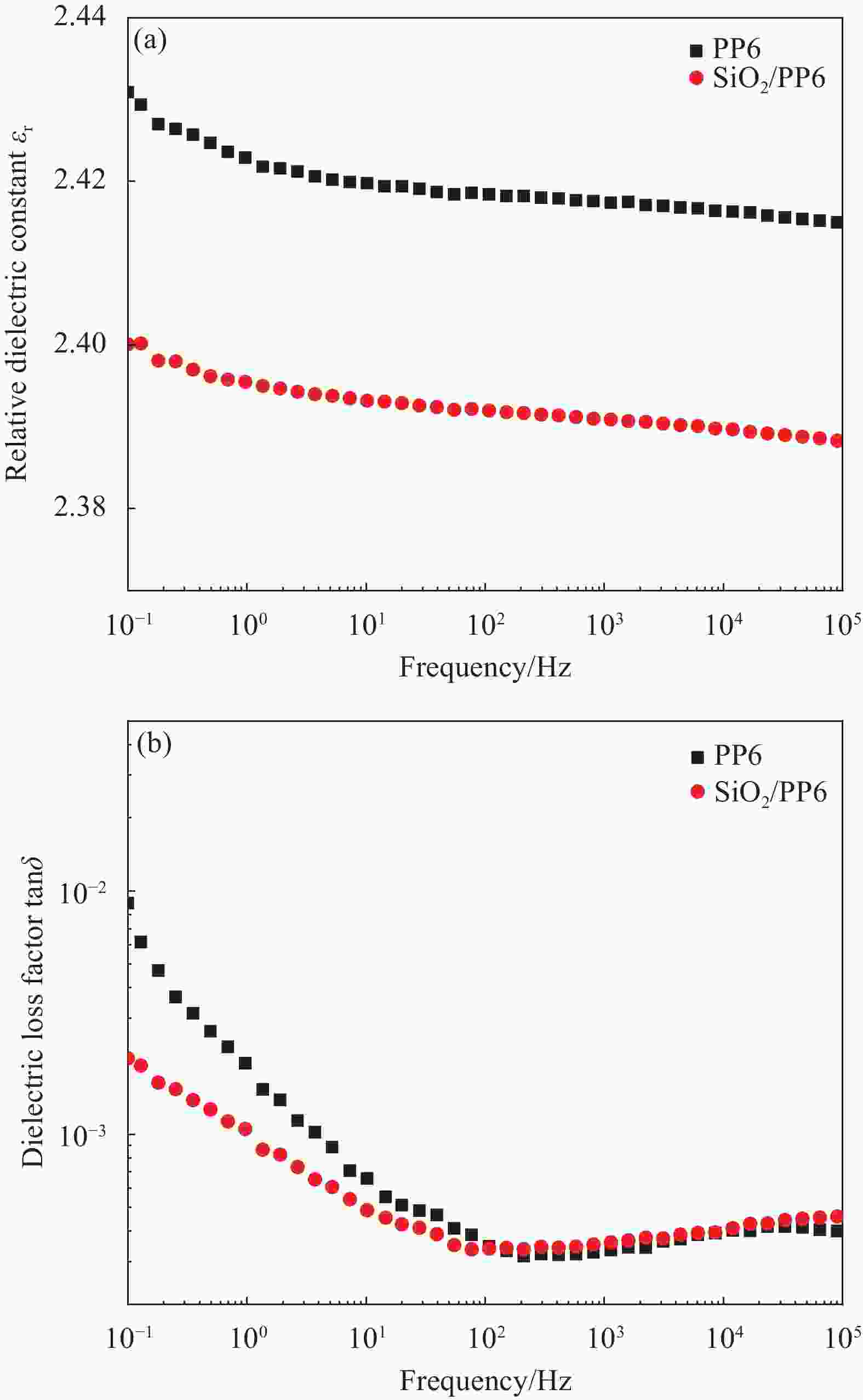

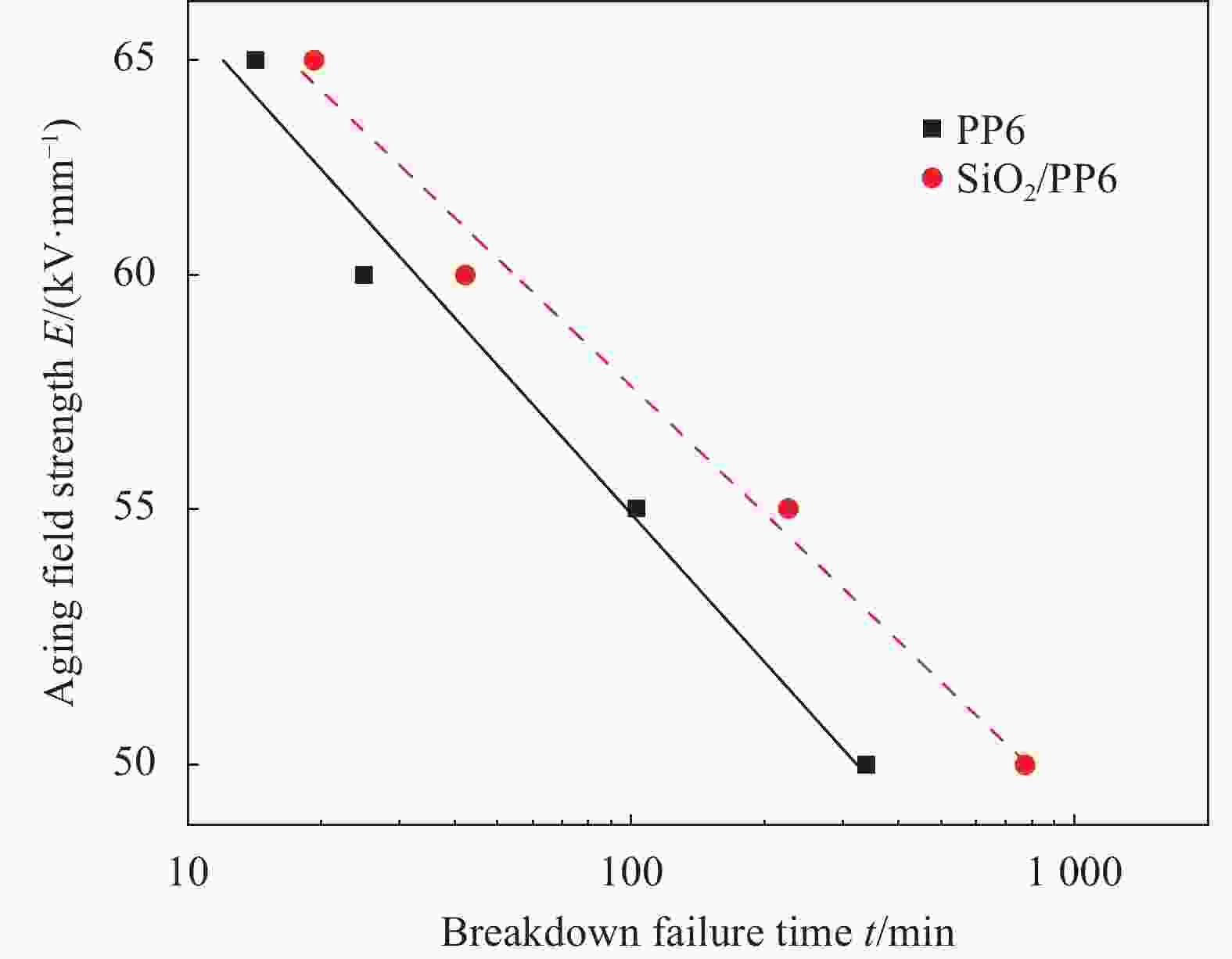

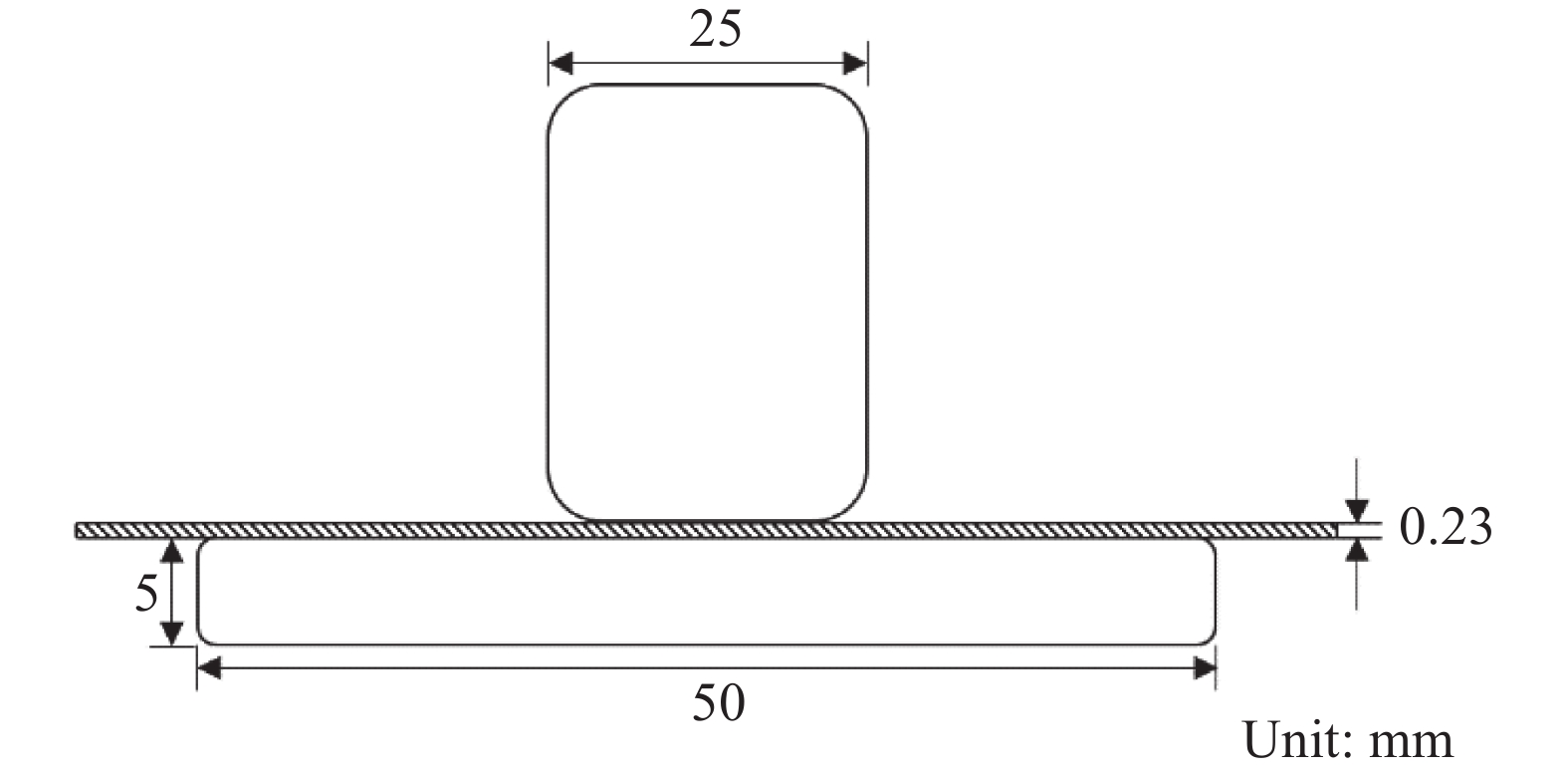

摘要: 探究新型环保材料聚丙烯(PP)绝缘和其纳米SiO2复合材料的电老化寿命,为后期PP绝缘电缆应用可靠性提供理论支撑。基于电老化寿命公式−反幂定律,通过恒压加速老化试验估算了PP绝缘和SiO2/PP复合材料的寿命模型参数,再采用逐级升压加速老化试验对寿命指数n的可靠性进行评估。并对SiO2/PP复合材料进行结构表征和性能测试。结果表明,SiO2/PP6的寿命指数n为14.61,相较PP6的12.54提升了16.51%;试验阶段发现在较低老化场强下SiO2的掺杂对PP6的失效时间提升效果明显,预测SiO2/PP6在老化场强25 kV·mm−1以下的长期电老化寿命是PP6的5倍以上。同时,掺杂纳米SiO2使PP绝缘的工频介电损耗因数和损耗峰高度降低。基于电老化空腔理论,提出了SiO2通过消耗热电子能量限制链段断裂,从而提升PP绝缘电老化寿命的观点。Abstract: The electrical aging life of polypropylene (PP) insulation, a new environmentally friendly material, and its nano-SiO2 composites were investigated to provide theoretical support for the reliability of PP-insulated cables in later applications. Based on the electric aging life formula-inverse power method, the life model parameters of PP insulation and SiO2/PP composites were estimated by constant voltage accelerated aging test, and then the reliabi-lity of life index n was evaluated by stepwise accelerated aging test. The SiO2/PP composites were also structurally characterized and performance tested. The results show that the lifetime index n of SiO2/PP6 is 14.61, which is enhanced by 16.51% compared with that of PP6 of 12.54. It is found in the experimental stage that the doping of SiO2 has a significant effect on the enhancement of PP6's time to failure at lower aging field strengths, and it is predicted that the long-term electrical aging lifetime of SiO2/PP6 is more than five times that of PP6 below the aging field strength of 25 kV·mm−1. Meanwhile, the doping of nano-SiO2 reduced the industrial frequency dielectric loss factor and lowered the loss peak height of PP insulation. Based on the electrical aging cavity theory, it is proposed that SiO2 enhances the electrical aging life of PP insulation by limiting the chain segment breakage by consuming hot electron energy.

-

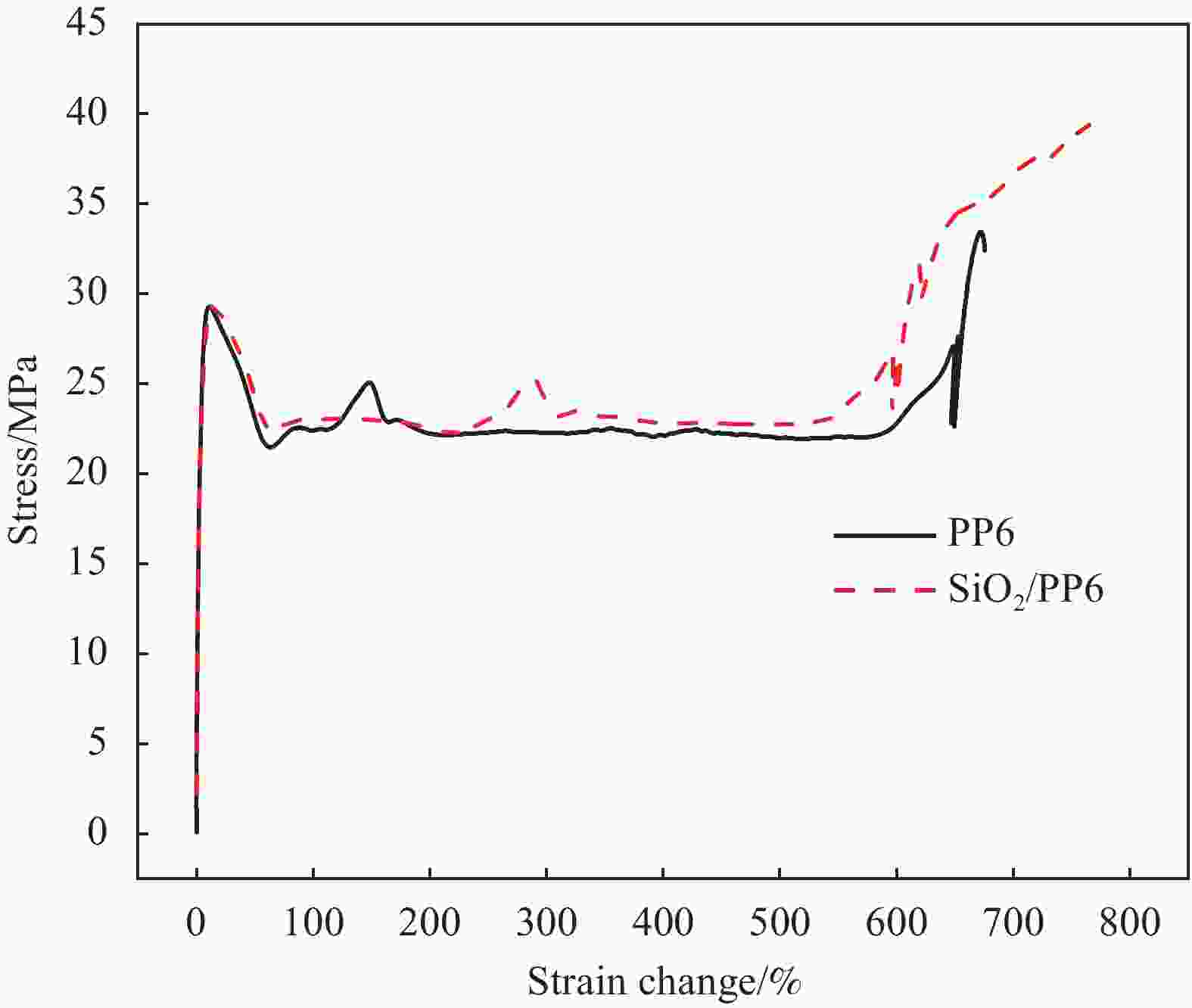

表 1 PP6和SiO2/PP6复合材料应力-应变实验参数

Table 1. Stress-strain experimental parameters of PP6 and SiO2/PP6 composites

Specimen Tensile yield stress/MPa Tensile strain at fracture/% Tensile strength/MPa PP6 29 672 33 SiO2/PP6 29 770 37 表 2 PP6和SiO2/PP6寿命模型参数最小二乘拟合估计值

Table 2. Least squares fitting estimates of the lifetime model parameters for PP6 and SiO2/PP6

Estimates of model

parametersPP6 SiO2/PP6 lnC 54.86±4.81 63.83±4.73 n 12.54±1.19 14.61±1.17 Goodness of fit 0.97 0.98 Fitted formula t=6.69×1023 E−12.54 t=5.26×1027 E−14.61 Notes: lnC—Constant related to the material itself; n—Voltage endurance coefficient; t—Electrical aging lifetime; E—Aging electric field strength. 表 3 PP6和SiO2/PP6的逐级升压加速老化试验数据参数

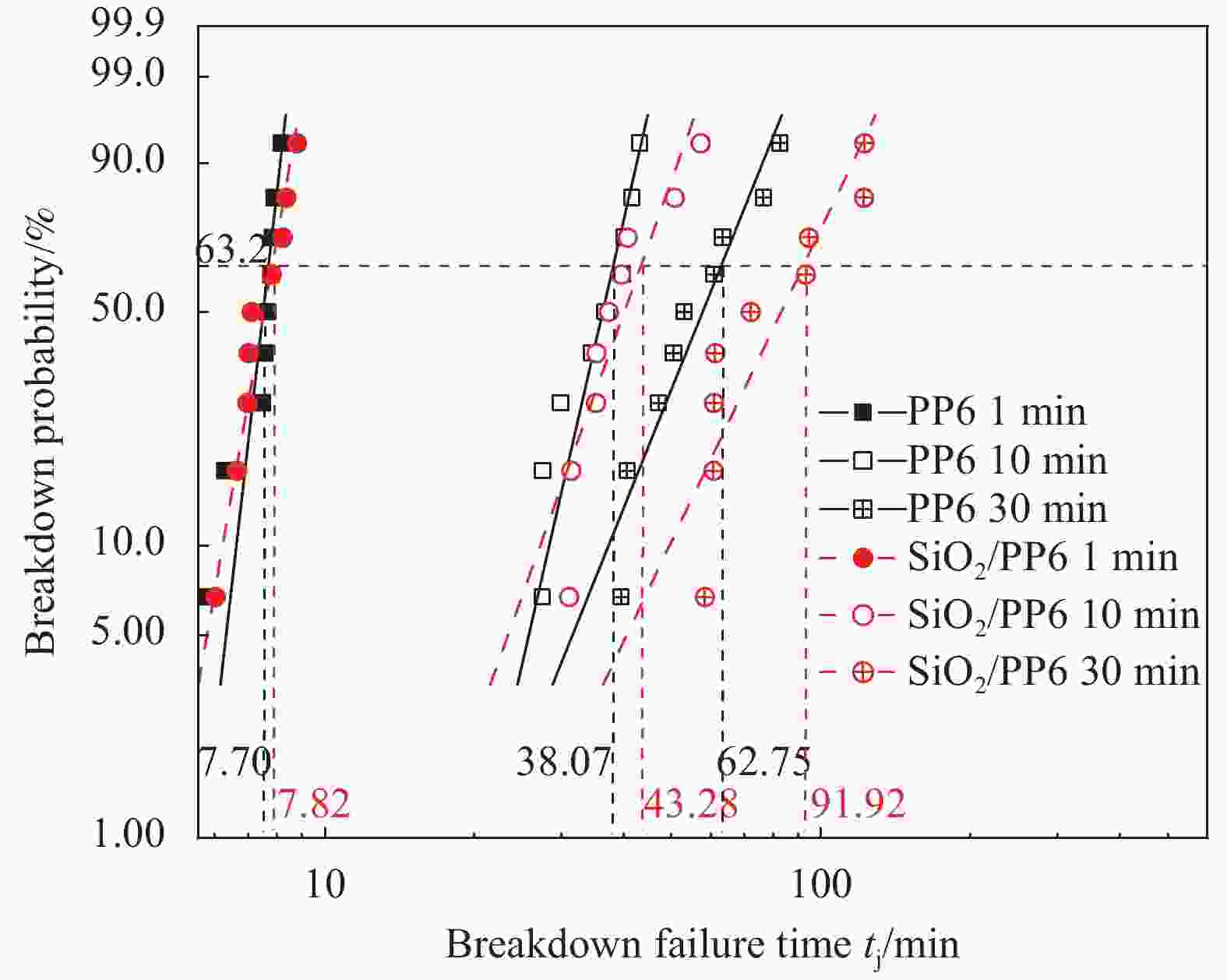

Table 3. Stepwise accelerated aging test data parameters of PP6 and SiO2/PP6

Material parameters Voltage duration per level T/min 1 min 10 min 30 min PP6 tstep 7.70 38.07 62.75 p 7.70 3.81 2.09 SiO2/PP6 tstep 7.82 43.28 91.92 p 7.82 4.33 3.06 Notes:tstep—Failure time of the Weibull distribution for the step-up test; p—Number of stages corresponding to the breakdown time: p= tstep/T. 表 4 PP6和SiO2/PP6寿命指数n值计算

Table 4. PP6 and SiO2/PP6 life index n value calculation

Material Calculation of the value of the life index n n1/10 min n10/30 min n30/1 min PP6 12.13 13.09 12.43 SiO2/PP6 13.52 17.73 14.65 表 5 PP6和SiO2/PP6的电老化寿命预测情况

Table 5. Electrical aging life prediction of PP6 and SiO2/PP6

Electric field strength E/(kV·mm−1) Estimated life/year PP6 SiO2/PP6 25 6.25 44.65 24 10.65 81.73 23 18.60 153.51 -

[1] 牟明明, 袁光明, 陈世尧. 纳米TiO2对木纤维/聚丙烯复合材料抗紫外老化性能的影响[J]. 复合材料学报, 2020, 5(6):1268-1277.MOU Mingming, YUAN Guangming, CHEN Shiyao. Effect of nano-TiO2 on anti-aging properties of wood fiber/polypropylene composites[J]. Acta Materiae Compositae Sinica,2020,5(6):1268-1277(in Chinese). [2] 胡世勋, 张雅茹, 邵清, 等. 不同改性技术路线的聚丙烯基高压直流电缆绝缘材料综合性能比较[J]. 中国电机工程学报, 2022, 42(4):1243-1252. doi: 10.13334/j.0258-8013.pcsee.212446HU Shixun, ZHANG Yaru, SHAO Qing, et al. Comprehen-sive performance comparison of polypropylene based HVDC cable insulation materials with different modification techniques[J]. Proceedings of the CSEE,2022,42(4):1243-1252(in Chinese). doi: 10.13334/j.0258-8013.pcsee.212446 [3] 黄兴溢, 张军, 江平开. 热塑性电力电缆绝缘材料: 历史与发展[J]. 高电压技术, 2018, 44(5):1377-1398.HUANG Xingyi, ZHANG Jun, JIANG Pingkai. Thermoplastic power cable insulation materials: History and development[J]. High Voltage Technology,2018,44(5):1377-1398(in Chinese). [4] YOSHINO K, DEMURA T, KAWAHIGASHI M, et al. Application of a novel polypropylene to the insulation of an electric power cable[J]. Electrical Engineering in Japan,2004,146(1):18-26. doi: 10.1002/eej.10210 [5] MIYASHITA Y, DEMURA T, UEDA A, et al. The application of novel polypropylene to the insulation of electric power cable (2)[J]. IEEJ Transactions on Fundamentals and Materials,2003,123(8):797-803. doi: 10.1541/ieejfms.123.797 [6] KURAHASHI K, MATSUDA Y, MIYASHITA Y, et al. The application of novel polypropylene to the insulation of electric power cable (3)[J]. IEEJ Transactions on Fundamentals and Materials,2004,124(4):331-336. doi: 10.1541/ieejfms.124.331 [7] BIAN H, YANG L, YAO R, et al. Method of selecting step stress test parameters for XLPE insulation DC voltage endurance coefficient[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2019,26(3):746-753. doi: 10.1109/TDEI.2019.007649 [8] 乔海霞, 顾东雅, 曾竟成. 聚合物基复合材料加速老化方法研究进展[J]. 材料导报, 2007(4):48-51. doi: 10.3321/j.issn:1005-023X.2007.04.012QIAO Haixia, GU Dongya, ZENG Jingcheng. Research progress of accelerated aging methods for polymer matrix composites[J]. Materials Review,2007(4):48-51(in Chinese). doi: 10.3321/j.issn:1005-023X.2007.04.012 [9] PREETHA P, THOMAS M J. Life estimation of electrother-mally stressed epoxy nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2014,21(3):1154-1160. doi: 10.1109/TDEI.2014.6832260 [10] 廖雁群, 冯冰, 罗潘, 等. 反幂定律应用于高压电缆寿命设计的研究进展[J]. 绝缘材料, 2016, 49(3):1-6. doi: 10.16790/j.cnki.1009-9239.im.2016.03.001LIAO Yanqun, FENG Bing, LUO Pan, et al. Research progress of inverse power law applied to life design of high voltage cable[J]. Insulation Materials,2016,49(3):1-6(in Chinese). doi: 10.16790/j.cnki.1009-9239.im.2016.03.001 [11] 刘霞, 于钦学, 钟力生, 等. 高压XLPE电缆绝缘V-t特性研究综述[J]. 南方电网技术, 2015, 9(10):57-63. doi: 10.13648/j.cnki.issn1674-0629.2015.10.010LIU Xia, YU Qinxue, ZHONG Lisheng, et al. Review on V-t characteristics of high voltage XLPE cable insulation[J]. China Southern Power Grid Technology,2015,9(10):57-63(in Chinese). doi: 10.13648/j.cnki.issn1674-0629.2015.10.010 [12] 林春耀, 欧小波, 魏新劳, 等. 温度对步进电压下油纸绝缘电老化的影响[J]. 高压电器, 2016, 52(10):194-200. doi: 10.13296/j.1001-1609.hva.2016.10.033LIN Chunyao, OU Xiaobo, WEI Xinlao, et al. Effect of temperature on electrical aging of oil paper insulation under stepping voltage[J]. High Voltage Electrical Apparatus,2016,52(10):194-200(in Chinese). doi: 10.13296/j.1001-1609.hva.2016.10.033 [13] 刘智谦, 高震, 郝建, 等. 交流500 kV交联聚乙烯海缆绝缘材料的步进工频击穿特性及寿命模型[J]. 绝缘材料, 2020, 53(2):29-35.LIU Zhiqian, GAO Zhen, HAO Jian, et al. Stepping power frequency breakdown characteristics and life model of 500 kV XLPE marine cable insulation[J]. Insulation Mate-rials,2020,53(2):29-35(in Chinese). [14] 袁端磊, 王海燕, 杨芳, 等. 固体绝缘件长时间正常工作条件下电老化寿命评估方法研究[J]. 高压电器, 2017, 53(4):31-35, 40. doi: 10.13296/j.1001-1609.hva.2017.04.006YUAN Duanlei, WANG Haiyan, YANG Fang, et al. Study on evaluation method of electric aging life of solid insulating parts under normal working conditions for long time[J]. High Voltage Electrical Equipment,2017,53(4):31-35, 40(in Chinese). doi: 10.13296/j.1001-1609.hva.2017.04.006 [15] 李艳文, 李媛媛, 田慕琴, 等. 矿用典型绝缘材料击穿特性及寿命模型的研究[J]. 高压电器, 2019, 55(2):104-109. doi: 10.13296/j.1001-1609.hva.2019.02.015LI Yanwen, LI Yuanyuan, TIAN Muqin, et al. Study on breakdown characteristics and life model of typical insula-ting materials used in mines[J]. High Voltage Electrical Equipment,2019,55(2):104-109(in Chinese). doi: 10.13296/j.1001-1609.hva.2019.02.015 [16] HUANG Y, ZHAO H, WANG Y, et al. Predicting the breakdown strength and lifetime of nanocomposites using a multi-scale modeling approach[J]. Journal of Applied Physics,2017,122(6):065101. doi: 10.1063/1.4997720 [17] TAKALA M, RANTA H, NEVALAINEN P, et al. Dielectric properties and partial discharge endurance of polypropy-lene-silica nanocomposite[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2010,17(4):1259-1267. doi: 10.1109/TDEI.2010.5539698 [18] LI W, ZHANG L, ZHANG M, et al. The effects of interfacial water and SiO2 surface wettability on the adhesion properties of SiO2 in epoxy nanocomposites[J]. Applied Surface Science,2020,502:144151. doi: 10.1016/j.apsusc.2019.144151 [19] RONG Z, ZHAO M, WANG Y. Effects of modified nano-SiO2 particles on properties of high-performance cement-based composites[J]. Materials,2020,13(3):646. doi: 10.3390/ma13030646 [20] WANG Y, XIAO K, WANG C, et al. Effect of nanoparticle surface modification and filling concentration on space charge characteristics in TiO2/XLPE nanocomposites[J]. Journal of Nanomaterials, 2016: 2840410. [21] ASHISH SHARAD P, KUMAR K S. Application of surface-modified XLPE nanocomposites for electrical insulation-partial discharge and morphological study[J]. Nanocomposites,2017,3(1):30-41. doi: 10.1080/20550324.2017.1325987 [22] ZHANG L, ZHOU Y, HUANG M, et al. Effect of nanoparticle surface modification on charge transport characteristics in XLPE/SiO2 nanocomposites[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2014,21(2):424-433. doi: 10.1109/TDEI.2013.004145 [23] ZHANG G W, GAO J G, WANG R, et al. Space charge characteristics and breakdown properties of nanostructured SiO2/PP composites[J]. Polymers,2023,15(13):2826. doi: 10.3390/polym15132826 [24] GAO J G, LIU H S, LEE T T, et al. Effect of hydrophilic/hydrophobic nanostructured TiO2 on space charge and breakdown properties of polypropylene[J]. Polymers,2022,14(14):2762. doi: 10.3390/polym14142762 [25] ROY M, NELSON J K, MACCRONE R K, et al. Polymer nanocomposite dielectrics-the role of the interface[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2005,12(4):629-643. doi: 10.1109/TDEI.2005.1511089 [26] WANG Y, LYU Z, WANG X, et al. Estimating the inverse power law aging exponent for the DC aging of XLPE and its nanocomposites at different temperatures[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2016,23(6):3504-3513. doi: 10.1109/TDEI.2016.005889 [27] 黄烜城, 王政钧, 吕泽鹏, 等. 基于Crine模型和逐步升压法的交联聚乙烯及其纳米复合材料老化寿命研究[J]. 绝缘材料, 2021, 54(12):73-79. doi: 10.16790/j.cnki.1009-9239.im.2021.12.012HUANG Xuan Cheng, WANG Zhengjun, LYU Zepeng, et al. Study on aging life of crosslinked polyethylene and its nano composites based on crine model and step-up method[J]. Insulating Materials,2021,54(12):73-79(in Chinese). doi: 10.16790/j.cnki.1009-9239.im.2021.12.012 [28] 中国国家标准化管理委员会. 塑料 拉伸性能的测定 第3部分: 薄膜和薄片的试验条件: GB/T 1040.3—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People's Republic of China. Plastics—Determination of tensile properties—Part 3: Test conditions for films and sheets: GB/T 1040.3—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [29] LIU T, LYU Z, WANG Y, et al. A new method of estimating the inverse power law ageing parameter of XLPE based on step-stress tests[C]//2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena. Shenzhen: IEEE, 2013: 69-72. [30] 敖玉辉, 周梦思, 冯芳. 不同弹性体增韧聚丙烯的研究[J]. 化工新型材料, 2014, 42(3):189-190, 193.AO Yuhui, ZHOU Mengsi, FENG Fang. Research on toughening polypropylene with different elastomers[J]. Chemical New Materials,2014,42(3):189-190, 193(in Chinese). [31] 郗晓光, 宋鹏先, 王浩鸣, 等. 无机纳米掺杂XLPE电缆绝缘的力学性能与电气强度研究[J]. 绝缘材料, 2018, 51(8):21-25, 36.XI Xiaoguang, SONG Pengxian, WANG Haoming, et al. Mechanical properties and electrical strength of inorganic nano-doped XLPE cable insulation[J]. Insulation Mate-rials,2018,51(8):21-25, 36(in Chinese). [32] 宋红艳, 黄兴溢, 张军, 等. XLPE及XLPE/MgO纳米复合材料的击穿强度与力学性能的比较研究[J]. 绝缘材料, 2014, 47(3):17-21. doi: 10.16790/j.cnki.1009-9239.im.2014.03.006SONG Hongyan, HUANG Xingyi, ZHANG Jun, et al. Comparative study of breakdown strength and mechanical properties of XLPE and XLPE/MgO nanocomposites[J]. Insulation Materials,2014,47(3):17-21(in Chinese). doi: 10.16790/j.cnki.1009-9239.im.2014.03.006 [33] 蒋佩南, 钱跃新, 王佳坤, 等. 评定挤塑电缆n值的新方法及其验证试验[J]. 电线电缆, 1983(4):26-33. doi: 10.16105/j.cnki.dxdl.1983.04.007JIANG Peinan, QIAN Yuexin, WANG Jiakun, et al. A new method for evaluating the n value of extruded cable and its verification test[J]. Wire and Cable,1983(4):26-33(in Chinese). doi: 10.16105/j.cnki.dxdl.1983.04.007 [34] MAZZANTI G, MONTANARI G C, CIVENNI F. Model of inception and growth of damage from microvoids in polyethylene-based materials for HVDC cables. 1. Theoretical approach[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2007,14(5):1242-1254. doi: 10.1109/TDEI.2007.4339485 [35] DISSADO L A, MAZZANTI G, MONTANARI G C. The role of trapped space charges in the electrical aging of insulating materials[J]. IEEE Transactions on Dielectrics and Electrical Insulation,1997,4(5):496-506. doi: 10.1109/94.625642 [36] 张杰, 赵学童, 边浩然, 等. 电荷陷阱对XLPE绝缘电老化特性的影响[J]. 高电压技术, 2021, 47(8):2991-3000. doi: 10.13336/j.1003-6520.hve.20200809ZHANG Jie, ZHAO Xuedong, BIAN Haoran, et al. Effect of charge traps on the electrical aging characteristics of XLPE insulation[J]. High Voltage Technology,2021,47(8):2991-3000(in Chinese). doi: 10.13336/j.1003-6520.hve.20200809 [37] 李晓虎, 李剑, 孙才新, 等. 植物油-纸绝缘的电老化寿命试验研究[J]. 中国电机工程学报, 2007(9):18-22. doi: 10.3321/j.issn:0258-8013.2007.09.004LI Xiaohu, LI Jian, SUN Caixin, et al. Experimental study on electric aging life of vegetable oil paper insulation[J]. Proceedings of the CSEE,2007(9):18-22(in Chinese). doi: 10.3321/j.issn:0258-8013.2007.09.004 [38] 王新生, 屠德民, 杨会中. 聚合物电老化击穿临界状态的实验验证[J]. 中国电机工程学报, 1993(S1):3-8. doi: 10.13334/j.0258-8013.pcsee.1993.s1.001WANG Xinsheng, TU Demin, YANG Huizhong. Experimental verification of critical state of breakdown in polymer electroaging[J]. Proceedings of the CSEE,1993(S1):3-8(in Chinese). doi: 10.13334/j.0258-8013.pcsee.1993.s1.001 [39] 高俊国, 赵贺, 李霞, 等. 纳米SiO2/低密度聚乙烯复合材料的陷阱特性与电击穿机制[J]. 复合材料学报, 2019, 36(4):801-810.GAO Junguo, ZHAO He, LI Xia, et al. Trap properties and electrical breakdown mechanism of nano-SiO2/low-density polyethylene composites[J]. Acta Materiae Compositae Sinica,2019,36(4):801-810(in Chinese). [40] 王猛, 成如如, 高俊国, 等. 微纳米SiO2/低密度聚乙烯复合材料的空间电荷性能[J]. 复合材料学报, 2019, 36(11):2541-2551.WANG Meng, CHENG Ruru, GAO Junguo, et al. Space charge properties of micro- and nano-SiO2/low-density polyethylene composites[J]. Acta Materiae Compositae Sinica,2019,36(11):2541-2551(in Chinese). [41] 姜洪涛, 张晓虹, 高俊国, 等. SiO2粒子的尺度因素对聚乙烯基复合材料的结晶行为及电学性能的影响[J]. 复合材料学报, 2022, 39(2):645-655.JIANG Hongtao, ZHANG Xiaohong, GAO Junguo, et al. Influence of the scale factor of SiO2 particles on the crystalli-zation behavior and electrical properties of polyethylene matrix composites[J]. Acta Materiae Compositae Sinica,2022,39(2):645-655(in Chinese). [42] 高俊国. 聚乙烯/纳米蒙脱土复合物的空间电荷特性与介电性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2013.GAO Junguo. Study on space charge and dielectric properties of polyethylene/nano-montmorillonite composites[D]. Harbin: Harbin University of Science and Technology, 2013(in Chinese). -

下载:

下载: