Optimization of broadband sound absorption performance of honeycomb sandwich sound liner

-

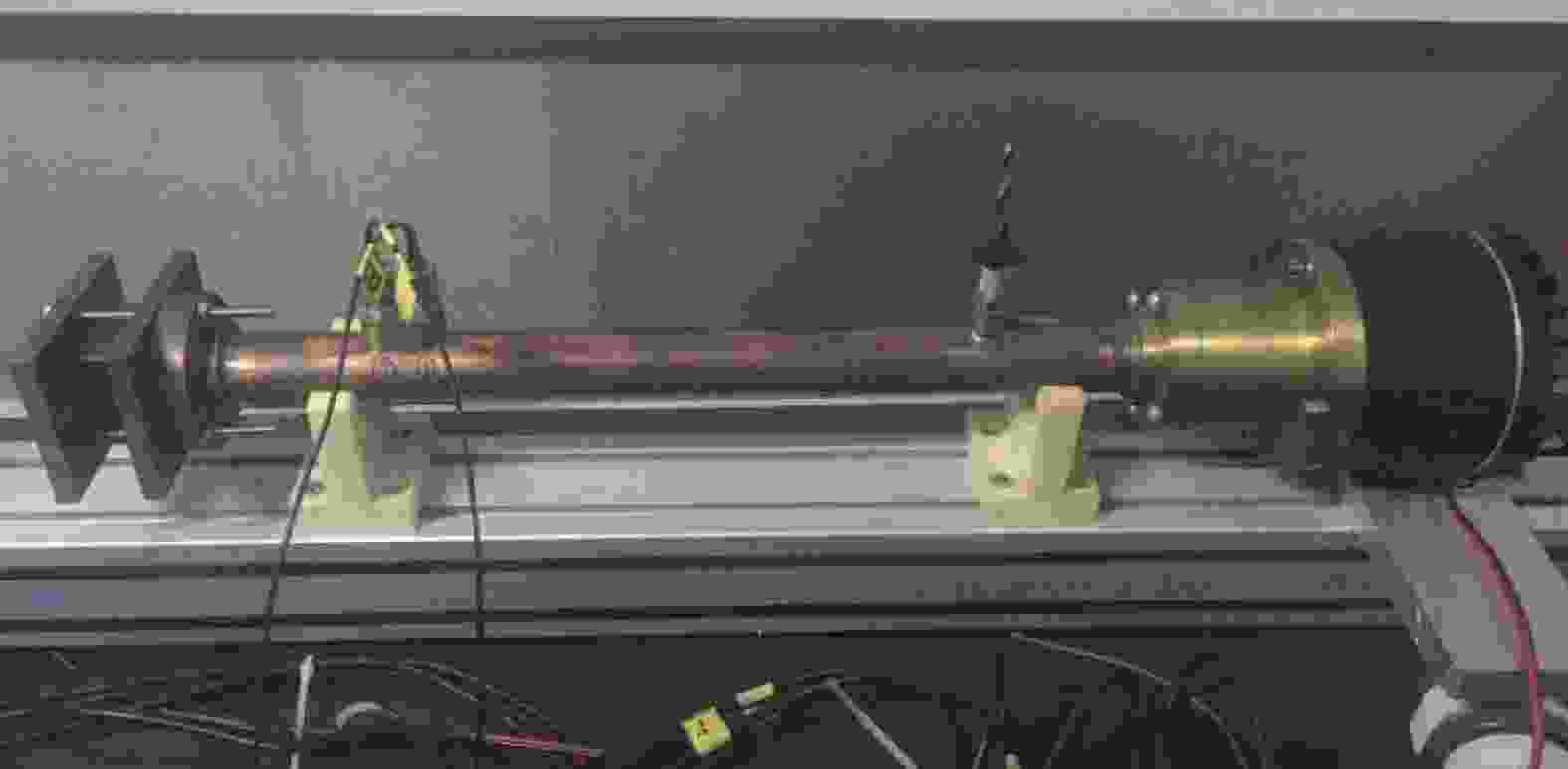

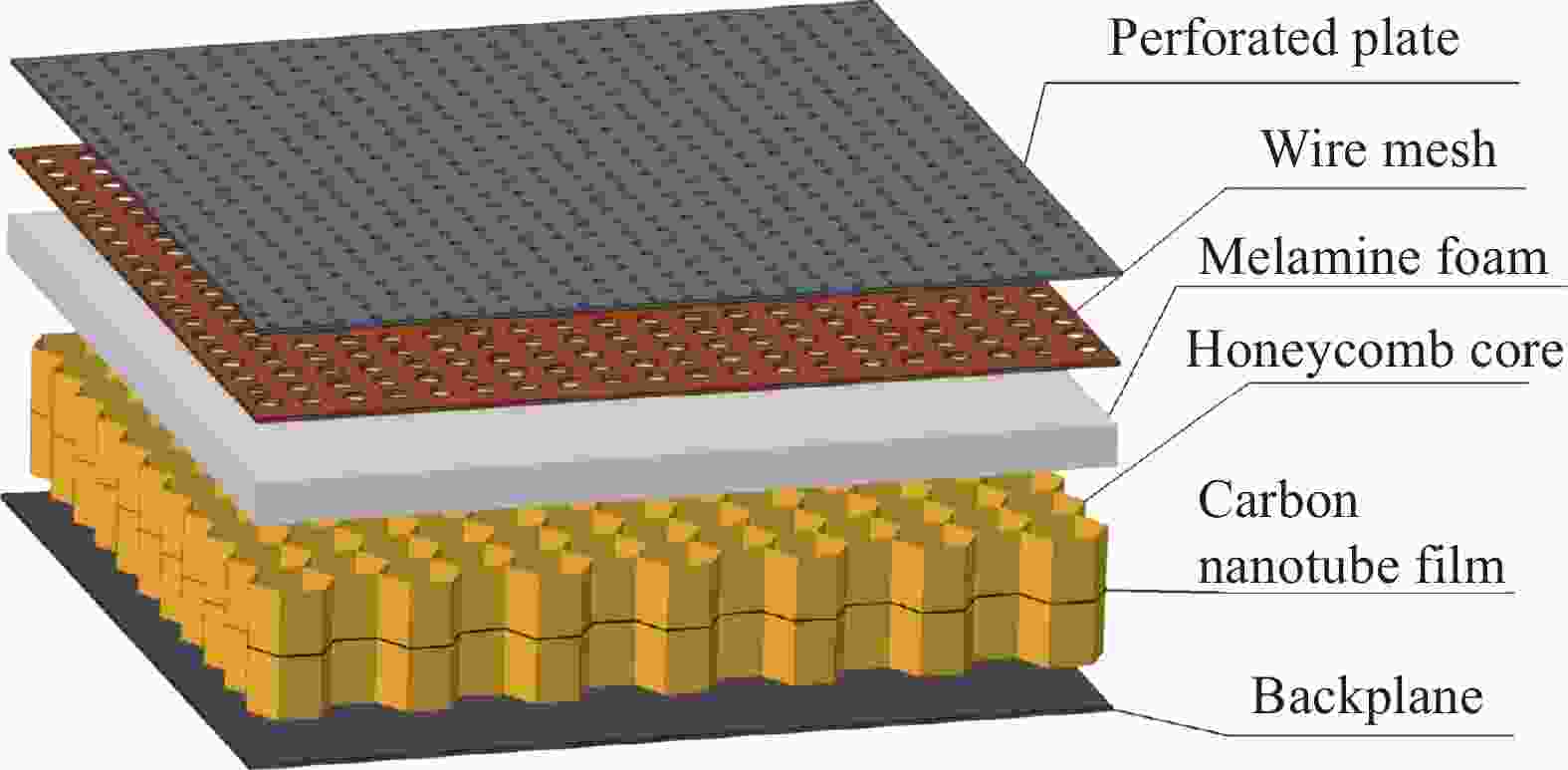

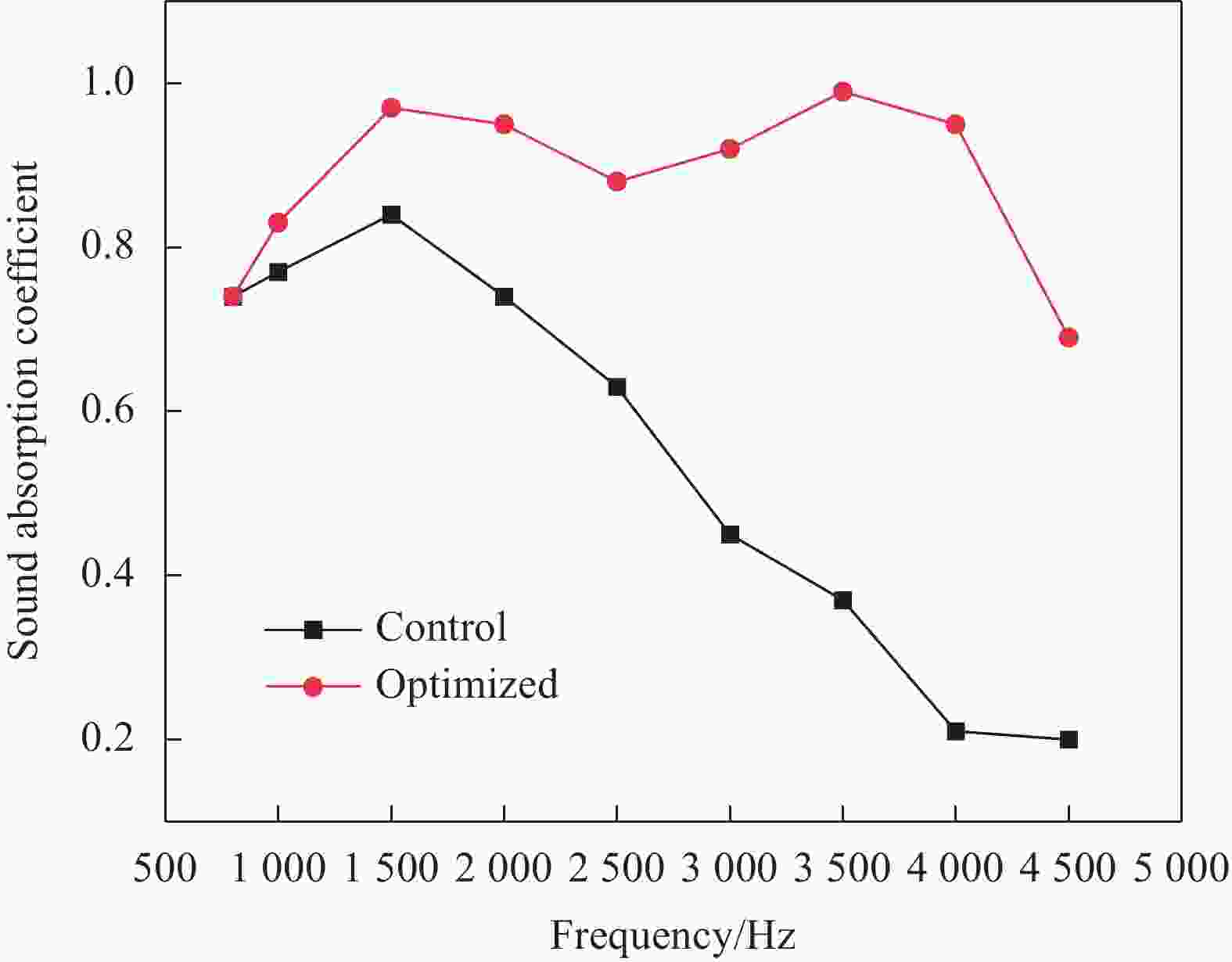

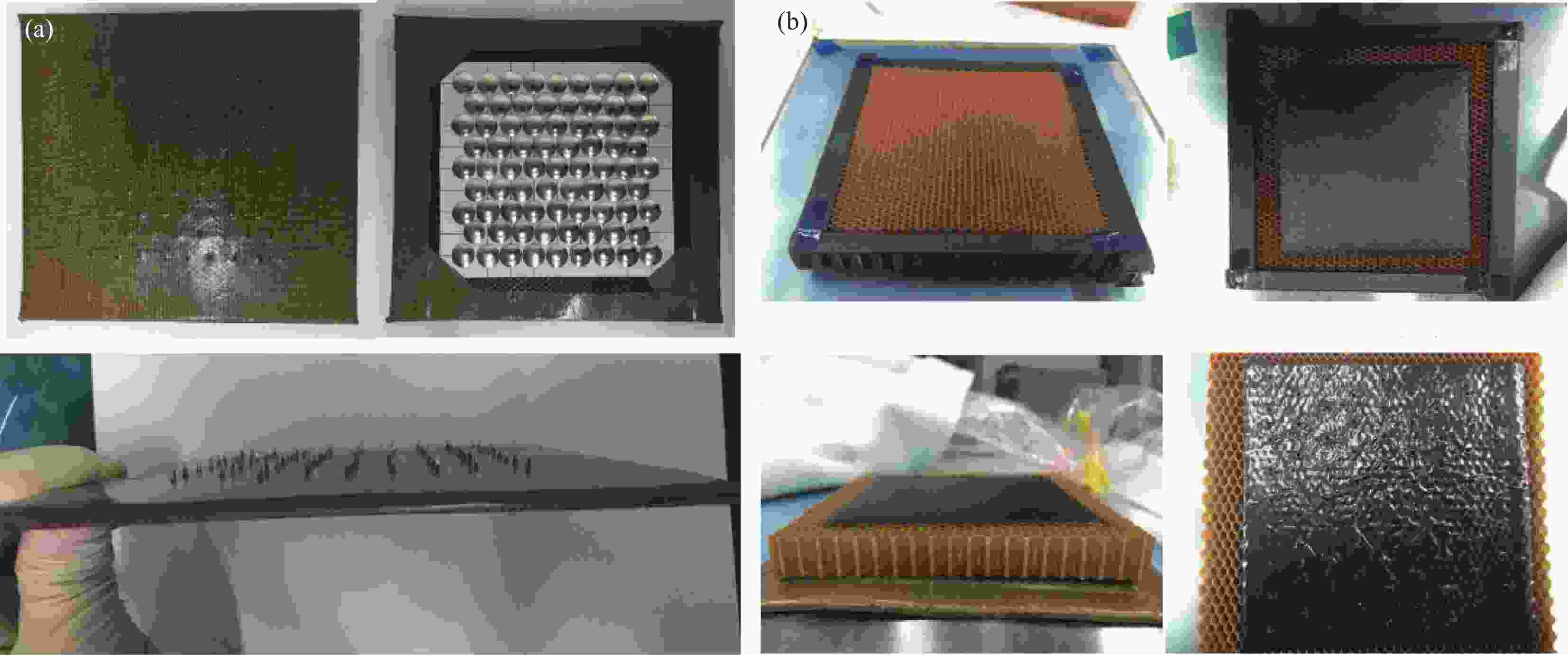

摘要: 针对目前大涵道比涡扇发动机宽频随机的噪声特点,对传统单自由度蜂窝夹层声衬材料进行了结构优化,提升其吸声性能。在保持声衬单自由度蜂窝夹层结构基本形式不变的前提下,为拓宽吸声频谱、达到两个甚至两个以上的特征频率,在单层蜂窝芯内部特定位置复合碳纳米管薄膜,同时为了提高吸声效果,通过快捷的工艺组装,在多孔板和蜂窝芯之间引入金属丝网和柔性多孔材料,并探究了引入材料的放置位置和参数对于声衬材料吸声性能的影响。实验结果显示,孔径37 μm的金属丝网置于多孔面板后、15 mm厚的三聚氰胺海绵放置在多孔面板和蜂窝之间、开孔率为2%和4%的碳纳米管薄膜放置在蜂窝夹层结构内近中间位置的吸声性能最好。基于该结果制备的声衬吸声性能优异,在800 Hz到4500 Hz范围内表现出良好的吸声性能,两个特征频率的峰值吸声系数分别达到0.98和0.99,平均吸声系数达到0.89,相比优化前提升61.8%,同时半峰宽度能够完全覆盖测试的800 Hz到4500 Hz频率范围,具有良好的宽频降噪特性。Abstract: In view of the wide frequency noise characteristics of turbofan engine with large bypass ratio at present, traditional single-degree-of-freedom honeycomb sandwich acoustic lining material was optimized to improve its sound absorption performance. Under the premise of keeping the basic form of single-degree-of-freedom honeycomb structure of sound liner unchanged, in order to broaden the sound absorption spectrum and reach two or more characteristic frequencies, carbon nanotube film was compounded at a specific position inside the single-layer honeycomb core. At the same time, in order to improve the sound absorption effect, metal wire mesh and flexible porous materials were introduced between perforated plate and honeycomb core, and they were assembled through a rapid process. The influences of placement position and parameters of the introduced material on the sound absorption performance of the sound absorption composite were also investigated. The experimental results show that the structure with the best sound absorption performance is the introduction of 37 μm hole diameter wire mesh placed behind the porous panel, the placement of 15 mm thick melamine sponge between the porous panel and the honeycomb, and the placement of carbon nanotube film with a porosity of 2% and 4% in the middle of the honeycomb sandwich structure. The sound liner prepared based on this result has excellent sound absorption performance, and shows good sound absorption performance in the range of 800 Hz to 4500 Hz. The peak sound absorption coefficients of the two characteristic frequencies reach 0.98 and 0.99, respectively, and the average sound absorption coefficient reaches 0.89, which is 61.8% higher than that before optimization. At the same time, the half-peak width can fully cover the frequency range of 800 Hz to 4500 Hz tested, which indicates good broadband noise reduction characteristics.

-

表 1 蜂窝夹层声衬材料(对照组)参数

Table 1. Parameters of honeycomb sandwich structure sound absorbing material (Control)

Thickness of

perforated plate/mmHole diameter of

perforated plate/mmPorosity of

perforated plate/%Thickness of

honeycomb core/mmSide length of

honeycomb

core cell/mm0.50 2.00 9.33 30.00 5.50 表 2 不同优化材料的参数

Table 2. Parameters for different optimized materials

Wire mesh Carbon nanotube film Flexible porous material Position Hole dia-meter/μm Depth Porosity/% Position Thickness/

mmMaterial In front of perforated plate

Behind perforated plate74

37

2010

14

202

3

4In front of honeycomb core

In honeycomb core

Behind honeycomb core5

10

15#25 polyurethane sponge

#55 polyurethane sponge

Melamine sponge

Polyester cotton

Carbon nanotube sponge

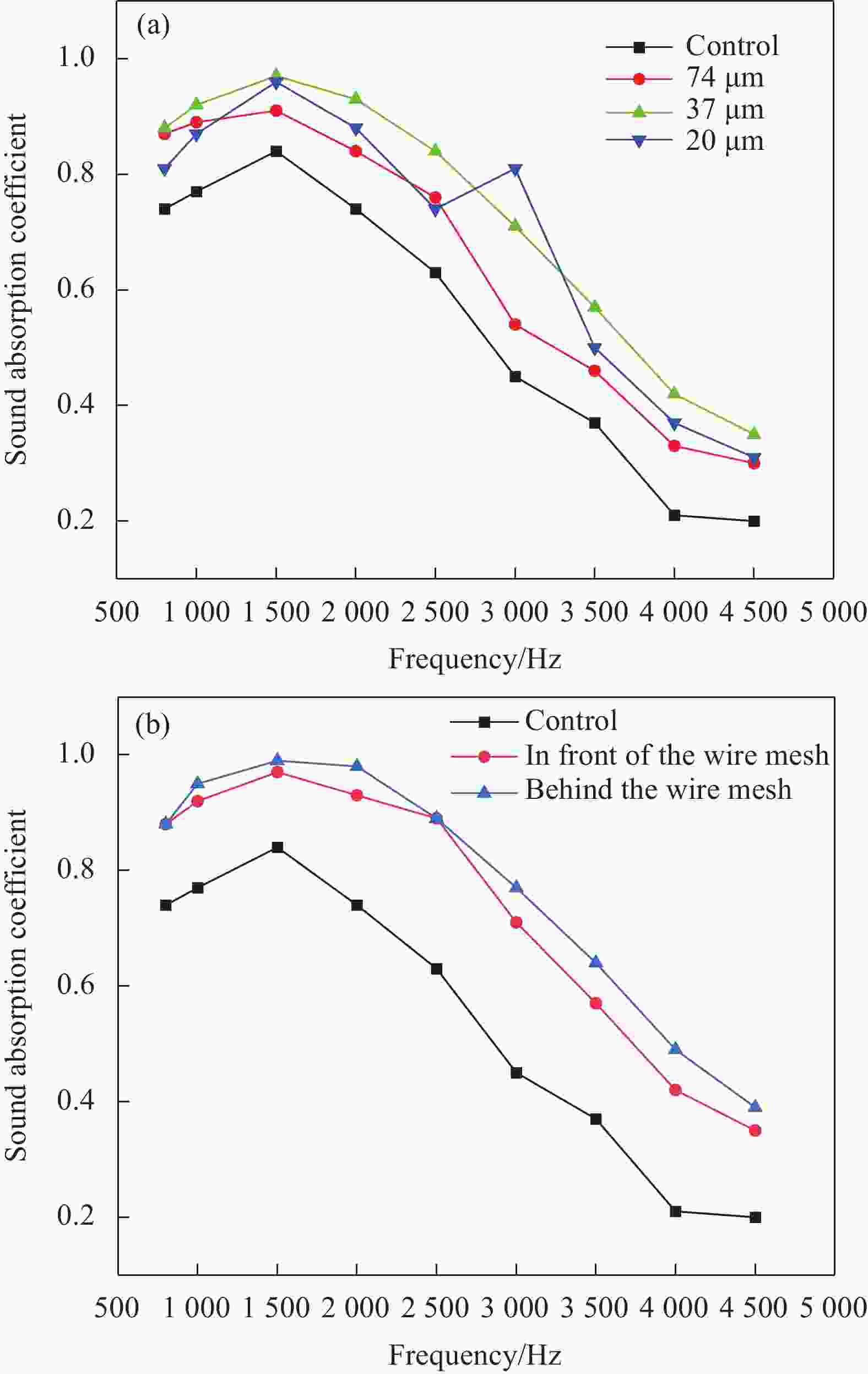

Polymethacrylimide (PMI) foam表 3 金属丝网孔径对蜂窝夹层声衬材料吸声性能的影响

Table 3. Effect of hole diameter of wire mesh on sound absorption properties of honeycomb sandwich structure

Subject Characteristic frequency/Hz Half peak width/Hz Peak absorption coefficient Average absorption coefficient Control 1500 2200 0.84 0.55 74 μm 1500 2700 0.91 0.66 37 μm 1500 3000 0.97 0.73 20 μm 1500 2800 0.96 0.69 表 4 金属丝网放置位置对蜂窝夹层声衬材料吸声性能的影响

Table 4. Effect of position of wire mesh on sound absorption performance of honeycomb sandwich structure

Subject Characteristic

frequency/HzHalf peak

width/HzPeak absorption

coefficientAverage absorption

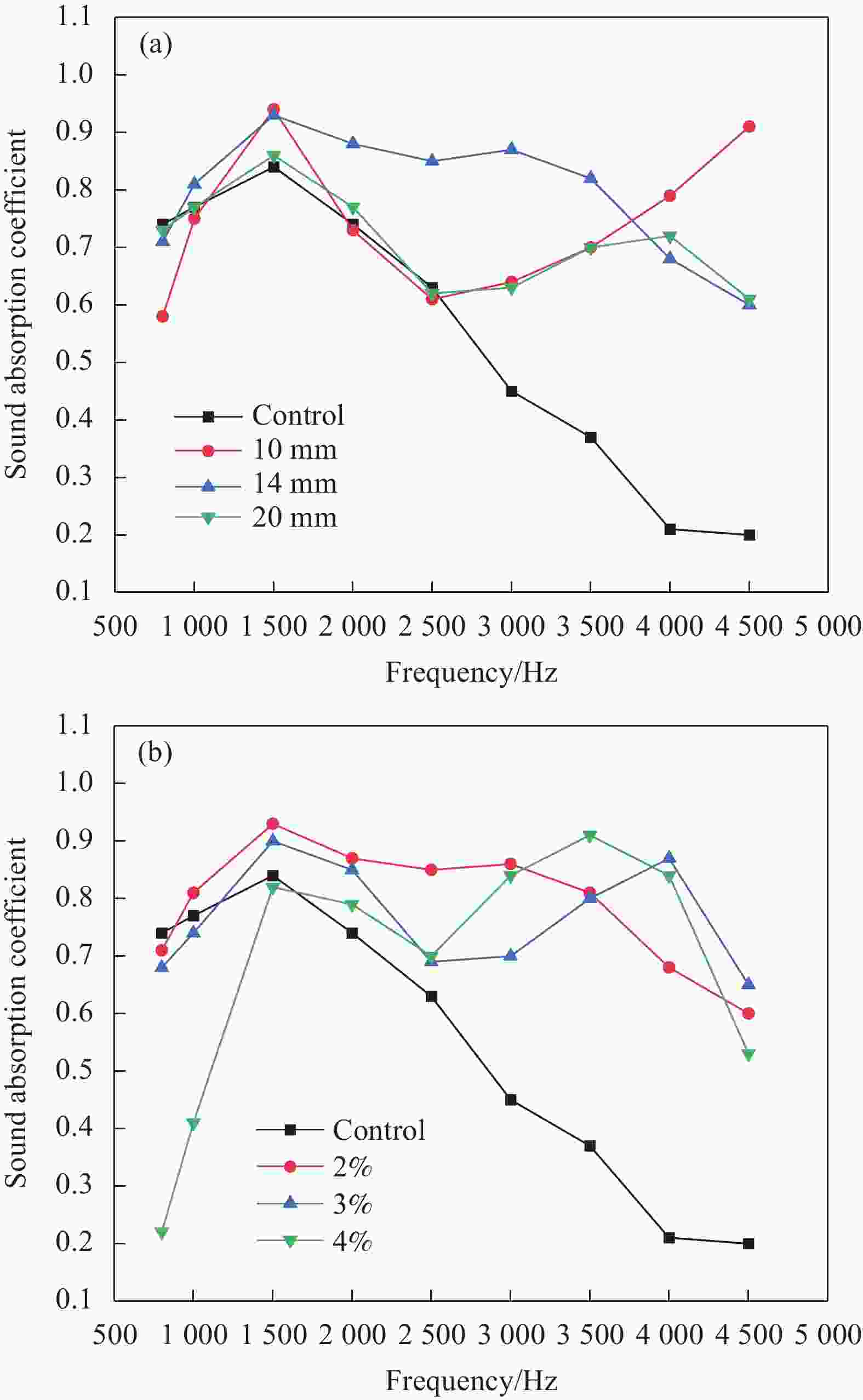

coefficientControl 1500 2200 0.84 0.55 In front of perforated plate 1500 3000 0.97 0.73 Behind perforated plate 1500 3200 0.99 0.78 表 5 碳纳米管薄膜放置深度对蜂窝夹层声衬材料吸声性能的影响

Table 5. Effect of placement depth of carbon nanotube films on sound absorption properties of honeycomb sandwich structure sound absorbing materials

Subject Characteristic frequency/Hz Half peak width/Hz Peak absorption coefficient Average absorption coefficient Control 1500 2200 0.84 0.55 10 mm — — 0.94 0.74 14 mm 1500 >3700 0.93 0.79 20 mm 1500 >3700 0.86 0.71 表 6 碳纳米管薄膜开孔率对蜂窝夹层声衬材料吸声性能的影响

Table 6. Effect of porosity of carbon nanotube films on sound absorption properties of honeycomb sandwich sound absorbing materials

Subject Characteristic frequency/Hz Half peak width/Hz Peak absorption coefficient Average absorption coefficient Control 1500 2200 0.84 0.55 2% 1500 >3700 0.93 0.79 3% — — 0.90 0.76 4% — — 0.91 0.67 表 7 #25聚氨酯海绵放置位置对蜂窝夹层声衬材料吸声性能的影响

Table 7. Influence of #25 polyurethane sponge placement on sound absorption performance of honeycombsandwich structuree

Subject Characteristic

frequency/HzHalf peak

width/HzPeak absorption

coefficientAverage absorption

coefficientControl 1500 2200 0.84 0.55 In front of honeycomb core 1500 3000 0.93 0.65 In honeycomb core 1500 2800 0.81 0.55 Behind honeycomb core 1500 2500 0.82 0.53 表 8 #25聚氨酯海绵厚度对蜂窝夹层声衬材料吸声性能的影响

Table 8. Influence of thickness of #25 polyurethane sponge on sound absorption properties of honeycomb sandwich structure

Subject Characteristic

frequency/HzHalf peak

width/HzPeak absorption

coefficientAverage absorption

coefficientControl 1500 2200 0.84 0.55 5 mm 1500 2600 0.91 0.60 10 mm 1500 3000 0.93 0.65 15 mm 1500 2900 0.95 0.69 表 9 柔性多孔材料类型对蜂窝夹层声衬材料吸声性能的影响

Table 9. Effect of type of flexible porous materials on sound absorption properties of honeycomb sandwich structure sound absorption material

Subject Characteristic frequency/Hz Half peak width/Hz Peak absorption coefficient Average absorption coefficient Control 1500 2200 0.84 0.55 #25 polyurethane sponge 1500 3000 0.93 0.65 #55 polyurethane sponge 1500 3200 0.98 0.75 Melamine foam 1500 >3700 1.00 0.81 Polyester cotton 1500 2700 0.91 0.62 Carbon nanotube sponge — — 0.57 0.45 PMI foam — — 0.98 0.50 表 10 优化的蜂窝夹层声衬复合材料结构参数

Table 10. Structural parameters of optimized honeycomb sandwich structure sound absorbing composites

Material Structural parameters Specifications Perforated plate Thickness 0.5 mm Porosity 9.33% Wire mesh Hole diameter 37 μm Melamine foam Thickness 15 mm Honeycomb core Thickness 30 mm Carbon nanotube film Thickness 0.01 mm Porosity 2%/4% Depth 14 mm Backplane Thickness 1 mm -

[1] 宋笔锋, 张彬乾, 韩忠华. 大型客机总体设计准则与概念创新[J]. 航空学报, 2008(3):583-595. doi: 10.3321/j.issn:1000-6893.2008.03.009SONG Bifeng, ZHANG Binqian, HAN Zhonghua. The study of concept design criteria for large-scale passenger aircraft with new technologies[J]. Acta Aeronautica et Astronautica Sinica,2008(3):583-595(in Chinese). doi: 10.3321/j.issn:1000-6893.2008.03.009 [2] 赵鲲, 梁俊彪, BELYAEV Ivan, 等. 民用飞机起落架噪声及其控制技术研究进展综述[J]. 航空学报, 2022(8):137-173. doi: 10.7527/j.issn.1000-6893.2022.8.hkxb202208012ZHAO Kun, LIANG Junbiao, BELYAEV Ivan, et al. Review of civil airplane landing gear noise study and its control approaches[J]. Acta Aeronautica et Astronautica Sinica,2022(8):137-173(in Chinese). doi: 10.7527/j.issn.1000-6893.2022.8.hkxb202208012 [3] 乔渭阳. 航空发动机气动声学[M]. 北京: 北京航空航天大学出版社, 2010, 10-20.QIAO Weiyang. Aeroengine aeroacoustics[M]. Beijing: Beijing University of Aeronautics and Astronautics Press, 2010, 10-20(in Chinese). [4] 乔渭阳, 王良锋, 段文华, 等. 航空发动机气动声学设计的理论、模型和方法[J]. 推进技术, 2021, 42(1):10-38.QIAO Weiyang, WANG Liangfeng, DUAN Wenhua, et al. Theory, model and method of aeroacoustic design for aero-engines[J]. Journal of Propulsion Technology,2021,42(1):10-38(in Chinese). [5] 伍赛特. 航空发动机环境污染现象及解决措施研究[J]. 能源与节能, 2021(1):80-82.WU Saite. Study on phenomenon of aero engine environmental pollution and its solutions[J]. Energy and Energy Conservation,2021(1):80-82(in Chinese). [6] 伍赛特. 航空发动机燃烧室设计研发过程研究综述[J]. 上海节能, 2019(7):584-588.WU Saite. Summary of research on aero engine combustion chamber design and development process[J]. Shanghai Energy Conservation,2019(7):584-588(in Chinese). [7] 张晨东, 唐庆如, 赵军, 等. GE90大涵道比涡扇发动机动态性能研究[J]. 西安航空学院学报, 2021, 41(1):28-33.ZHANG Chendong, TANG Qingru, ZHAO Jun, et al. Research of dynamic performance of GE90 high bypass ratio turbofan engine[J]. Journal of Xi'an Aeronautical University,2021,41(1):28-33(in Chinese). [8] 蔡常鹏, 郑前钢, 颜秋英, 等. 军用小涵道比涡扇发动机最大状态控制计划鲁棒性分析[J]. 推进技术, 2022, 43(5):315-322.CAI Changpeng, ZHENG Qiangang, YAN Qiuying, et al. Robustness analysis of maximum state control plan for mili-tary small bypass ratio turbofan engine[J]. Journal of Propulsion Technology,2022,43(5):315-322(in Chinese). [9] 赖安卿, 付尧明, 闫锋. 民航涡扇发动机高高原起动失效机制试验研究[J]. 机械设计与制造, 2020(1):101-104.LAI Anqing, FU Yaoming, YAN Feng. Experimental research on starting failure of civil aviation turbofan engine at high plateau[J]. Machinery Design & Manufacture,2020(1):101-104(in Chinese). [10] 张丹玲, 郝勇, 王德友, 等. 中国大涵道比涡扇发动机适航技术初步研究[J]. 航空发动机, 2011, 37(4):58-62.ZHANG Danling, HAO Yong, WANG Deyou, et al. Prelimi-nary investigation of airworthiness technologies for high bypass ratio turbofan engine in China[J]. Aeroengine,2011,37(4):58-62(in Chinese). [11] 陈光. 用于波音787客机的GEnx发动机设计特点[J]. 航空发动机, 2010, 36(1):1-6.CHEN Guang. Design characteristics of GEnx engine for B787[J]. Aeroengine,2010,36(1):1-6(in Chinese). [12] 陈光. 大涵道比涡扇发动机的发展[J]. 航空动力, 2019(3):56-61.CHEN Guang. The development of civil high-bypass turbofans[J]. Aerospace Power,2019(3):56-61(in Chinese). [13] 陈光. 大涵道比涡扇发动机风扇叶片的变迁[J]. 航空动力, 2018(5):26-30.CHEN Guang. Changes of fan blades of high-bypass-ratio turbofans[J]. Aerospace Power,2018(5):26-30(in Chinese). [14] 陈玲, 夏语, 纪良. 民用飞机发动机噪声辐射特性研究[J]. 噪声与振动控制, 2012, 32(4):78-82. doi: 10.3969/j.issn.1006-1355.2012.04.018CHEN Ling, XIA Yu, JI Liang. Study on characteristics noise radiation of civil aircraft engine[J]. Noise and Vibration Control,2012,32(4):78-82(in Chinese). doi: 10.3969/j.issn.1006-1355.2012.04.018 [15] 李旦望, 夏烨. 大涵道比涡扇发动机风扇转静干涉降噪研究[J]. 中国设备工程, 2019(13):61-63.LI Danwang, XIA Ye. Research on noise reduction of turbofan fan with large bypass ratio by rotor stator interfe-rence[J]. China Plant Engineering,2019(13):61-63(in Chinese). [16] 聂平. 涡扇发动机核心机静态噪声数据预测方法研究[D]. 天津: 中国民航大学, 2017.NIE Ping. Research on prediction method of static noise data of turbofan engine core engine[D]. Tianjin: Civil Aviation University of China, 2017(in Chinese). [17] AZIMI M, OMMI F, ALSSHTI N J. Using acoustic liner for fan noise reduction in modern turbofan engines[J]. International Journal of Aeronautical and Space Sciences,2014,15(1):97-101. doi: 10.5139/IJASS.2014.15.1.97 [18] 段翠云, 崔光, 刘培生. 多孔吸声材料的研究现状与展望[J]. 金属功能材料, 2011, 18(1):60-65.DUAN Cuiyun, CUI Guang, LIU Peisheng. Present research and prospect of porous absorption materials[J]. Metallic Functional Materials,2011,18(1):60-65(in Chinese). [19] BECK B S, SCHILLER N H, JONES M G. Impedance assessment of a dual-resonance acoustic liner[J]. Applied Acoustics,2015,93:15-22. doi: 10.1016/j.apacoust.2015.01.011 [20] 龚情, 何志平, 黄建萍, 等. 吸声蜂窝结构材料及其在直升机上的应用展望[J]. 高科技纤维与应用, 2020, 45(5):1-7.GONG Qing, HE Zhiping, HUANG Jianping, et al. Review of sound-absorbing honeycomb material and the application on helicopter[J]. Hi-Tech Fiber and Application,2020,45(5):1-7(in Chinese). [21] 李文智, 陈忱, 黄建萍, 等. 内嵌式多自由度吸声蜂窝结构降噪性能影响因素研究[J]. 高科技纤维与应用, 2022, 47(3):24-29. doi: 10.3969/j.issn.1007-9815.2022.03.003LI Wenzhi, CHEN Chen, HUANG Jianping, et al. Study on the influence factors of noise reduction performance of embedded multi degree of freedom acoustic honeycomb structure[J]. Hi-Tech Fiber and Application,2022,47(3):24-29(in Chinese). doi: 10.3969/j.issn.1007-9815.2022.03.003 [22] 纪双英, 郝巍, 史湘宁, 等. 内嵌式多自由度共振吸声结构研究[J]. 纤维复合材料, 2018, 35(3):38-41. doi: 10.3969/j.issn.1003-6423.2018.03.008JI Shuangying, HAO Wei, SHI Xiangning, et al. Study on sound absorptionstructure of embedded multi degree of freedom resonance[J]. Fiber Composites,2018,35(3):38-41(in Chinese). doi: 10.3969/j.issn.1003-6423.2018.03.008 [23] MA X Q, SU Z T. Development of acoustic liner in aero engine: A review[J]. Science China Technological Sciences,2020,63(12):2491-2504. doi: 10.1007/s11431-019-1501-3 [24] 杨嘉丰, 薛东文, 李卓瀚, 等. 切向流条件下短舱单/双自由度声衬实验[J]. 航空学报, 2020, 41(11):337-347.YANG Jiafeng, XUE Dongwen, LI Zhuohan, et al. Single and double degree-of-freedom acoustic liners under grazing flow: Experiment[J]. Acta Aeronautica et Astronautica Sinica,2020,41(11):337-347(in Chinese). [25] DANNEMANN M, KUCHER M, KUNZE E, et al. Experimental study of advanced helmholtz resonator liners with increased acoustic performance by utilising material damping effects[J]. Applied Sciences,2018,8(10):1923. doi: 10.3390/app8101923 [26] SUN G H, ZHANG J H, ZHANG H, et al. Research on acoustic absorption properties of aramid honeycomb composite material reinforced by polyimide foam[J]. Advanced Engineering Materials,2022,24(3):2101158. doi: 10.1002/adem.202101158 [27] KWAN H W, YU J, ABEYSINGHE A. A review of acoustic treatment design for aircraft engine noise reduction[C]//35th International Congress and Exposition on Noise Control Engineering, INTER-NOISE 2006. Washington: Institute of Noise Control Engineering, 2006, 2: 990-999. -

下载:

下载: