Mechanical and electrical response of silicon rubber intelligent composite materials reinforced by dual carbon structure

-

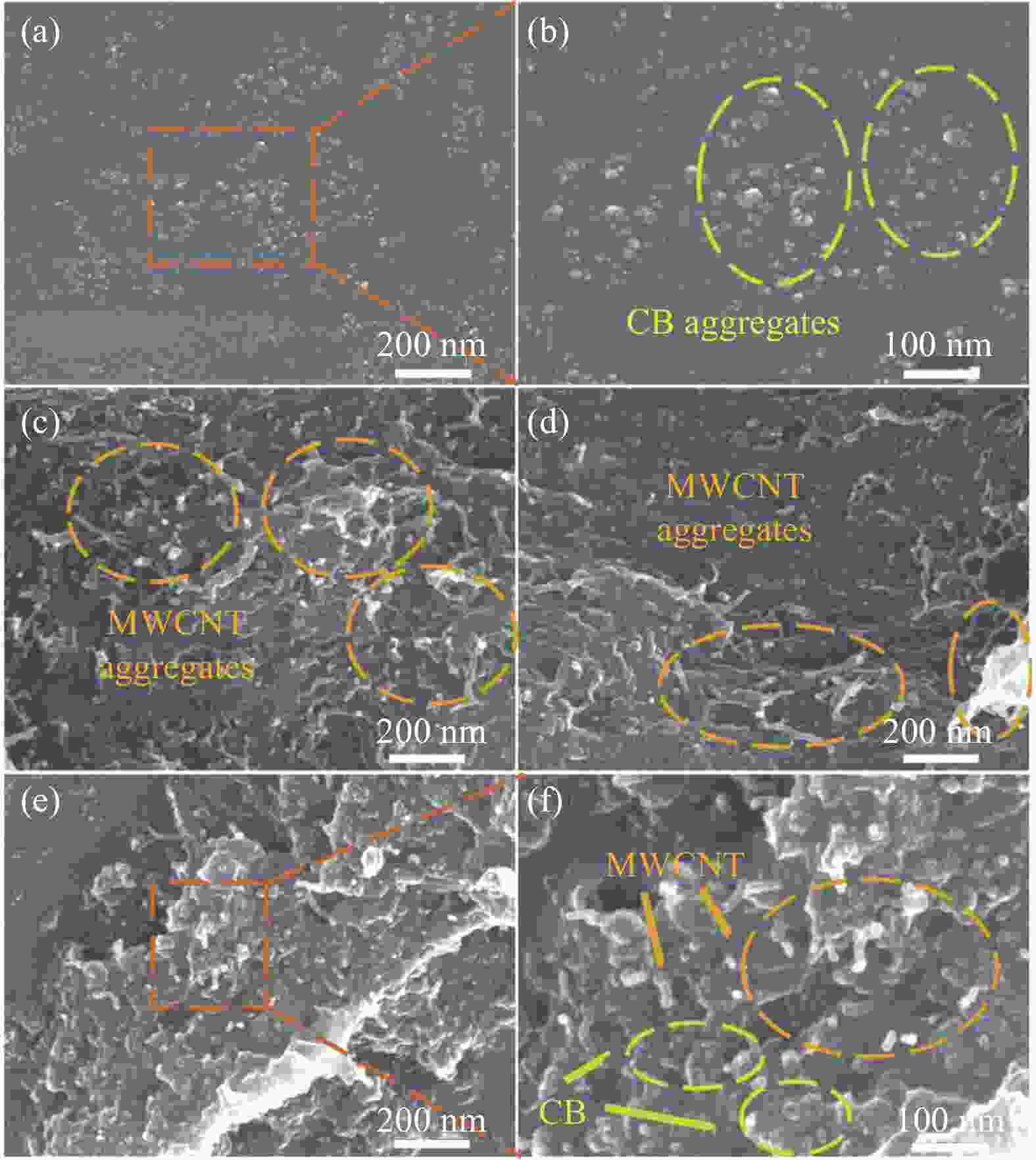

摘要: 可拉伸应变传感器在减隔震领域具有广阔的应用前景,然而,研发低成本和高稳定性可拉伸应变传感器仍然是一个巨大挑战。本文采用开炼法制备出多壁碳纳米管(MWCNT)-导电炭黑(CB)/甲基乙烯基硅橡胶(VMQ)导电纳米复合材料。研究MWCNT与CB之间的协同效应对复合材料分散性能、导电性能、力学性能及电阻-应变响应性能影响。结果表明:添加CB后复合材料力学性能提升,具有较低的渗流阈值(1.24wt%),5000次循环加载-卸载过程中表现出优异的电阻-应变响应稳定性。此外,MWCNT-CB/VMQ复合材料相比于MWCNT/VMQ、CB/VMQ复合材料在电阻-应变响应性能中没有出现肩峰现象,同时解释了肩峰现象机制。通过SEM发现复合材料中MWCNT和CB均匀分布及形成的协同效应是低阈值和稳定电阻-应变响应性能的重要原因。通过隧道效应理论模型解释了电阻-应变响应机制。该复合材料对减隔震结构应变监测具有巨大潜力。Abstract: Stretchable strain sensors have broad application prospects in the field of vibration reduction and isolation, however, developing low-cost and high stability stretchable strain sensors remains a huge challenge. This article used the open melt method to prepare multi-walled carbon nanotubes (MWCNT)-conductive carbon black (CB)/methyl vinyl silicone rubber (VMQ) conductive nanocomposites. The effects of the synergistic effect between MWCNT and CB on the dispersion, conductivity, mechanical properties and resistance-strain response of the composites were investigated.The results show that the mechanical properties of the composite material are improved after adding CB, with a lower percolation threshold (1.24wt%), and excellent resistance strain response stability is demonstrated during 5000 cycles of loading-unloading. In addition, compared to MWCNT/VMQ and CB/VMQ composites, the MWCNT-CB/VMQ composite did not exhibit shoulder peak phenomenon in the resistance-strain response performance, and explained the mechanism of shoulder peak phenomenon. Through SEM, it is found that the uniform distribution and synergistic effect of MWCNT and CB in the composite material are important reasons for the low threshold and stable resistance-strain response performance. The mechanism of resistance-strain response was explained through the tunnel effect theory model. This composite material has great potential for strain monitoring of seismic isolation structures.

-

图 1 (a) 导电硅橡胶复合材料制备流程;(b) 复合材料在原始、拉伸、弯曲、扭转下的图像;(c) 测试装置

Figure 1. (a) Preparation process of conductive silicone rubber composite; (b) Photos of composite material under original, stretching, bending and torsion; (c) Test diagram

MWCNT—Multi-walled carbon nanotubes; CB—Carbon black; VMQ—Methyl vinyl silicone rubber; HPMS—Hydroxyl silicone oil; DBPMH—2, 5-dimethyl-2, 5-bis(tert-butyl peroxy)hexane; LMBG—Two-stage vulcanization

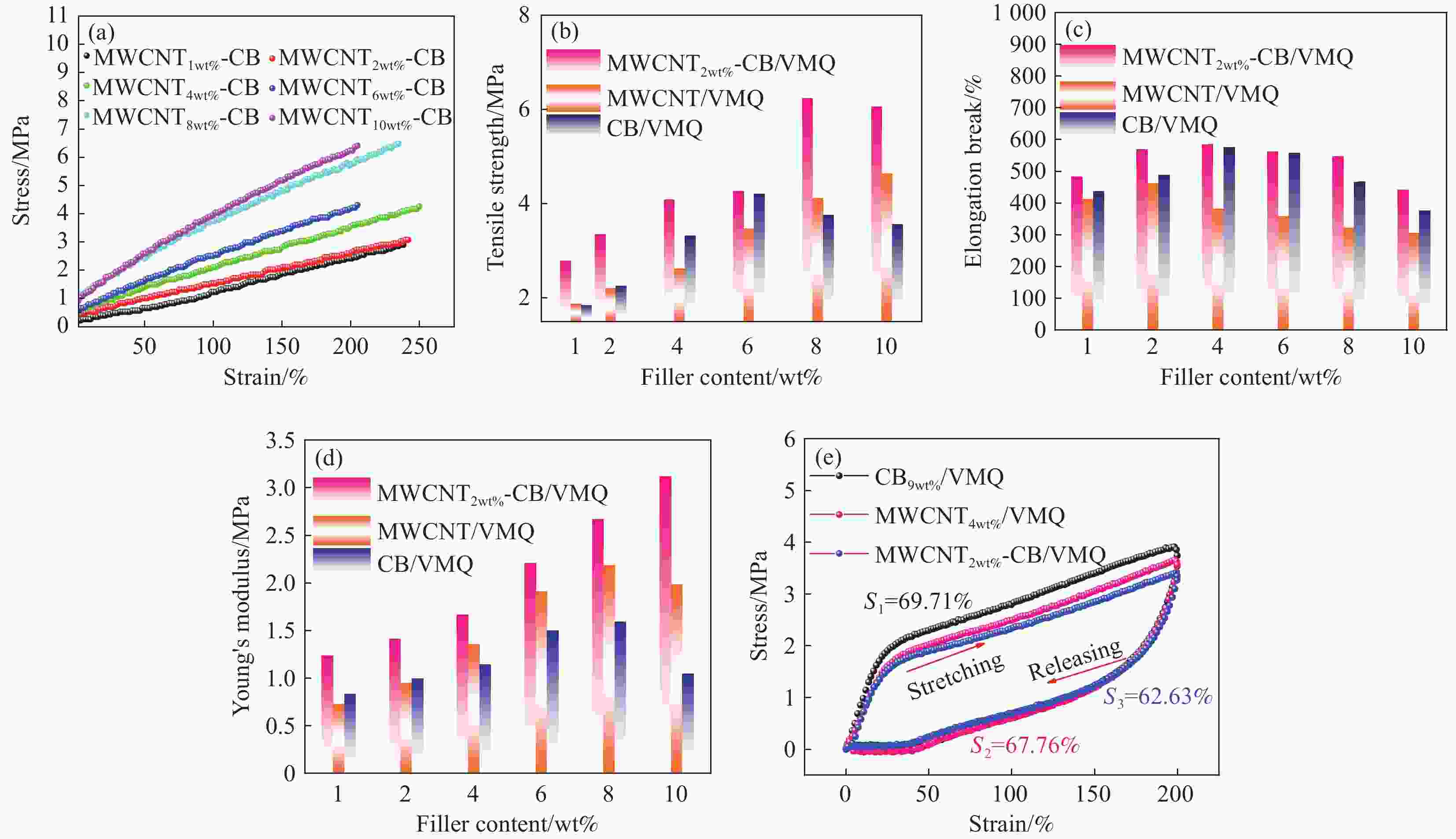

图 2 (a) 多壁碳纳米管(MWCNT)-导电炭黑(CB)/甲基乙烯基硅橡胶(VMQ)复合材料在不同MWCNT含量下的应力-应变曲线;((b)~(d)) MWCNT2wt%-CB/VMQ、MWCNT/VMQ、CB/VMQ复合材料的拉伸强度、断裂伸长率、杨氏模量;(e) 3种复合材料在应变为200%下的循环应力-应变曲线

Figure 2. (a) Stress-strain curves of multi-walled carbon nanotubes (MWCNT)-conductive carbon black (CB)/methyl vinyl silicone rubber (VMQ) composites with different MWCNT contents; ((b)-(d)) Tensile strength, elongation at break, and Young's modulus of MWCNT2wt%-CB/VMQ、MWCNT/VMQ and CB/VMQ composites; (e) Cycle stress-strain curves of three composites under 200% strain

S1, S2, S3—Area of hysteretic curves

图 3 (a) 3种复合材料的体积电导率σ;(b) 3种复合材料渗流阈值拟合曲线;(c) 3种复合材料在应变为150%下的电阻-应变响应曲线和变形灵敏度(GF)值;(d) MWCNT2wt%-CB/VMQ复合材料和其他先前报道的应变传感器在最大应变下的最高GF的比较

Figure 3. (a) Volume conductivity σ of three composites; (b) Fitting curves of seepage threshold of three composites; (c) Resistance-strain response curves and GF values of the three composites at 150% strain; (d) Comparison of the maximum GF at maximum strain of MWCNT2wt%-CB/VMQ composites with other previously reported strain sensors

w—Conductive filler content; φ—Percolation threshold; GF—Sensitivity; ΔR/R0—Resistance; ε—Strain

图 5 CB9wt%/VMQ (a)、MWCNT4wt%/VMQ (b)、MWCNT2wt%-CB/VMQ (c)复合材料在应变为30%下电阻-应变响应第7次循环加载-卸载

Figure 5. CB9wt%/VMQ (a), MWCNT4wt%/VMQ (b), MWCNT2wt%-CB/VMQ (c) composites respond to the 7th cyclic loading-unloading under the strain of 30%

IH1, IH2, IH3—Shoulder peak phenomenon area of CB9wt%/VMQ, MWCNT4wt%/VMQ, and MWCNT2wt%-CB/VMQ, respectively

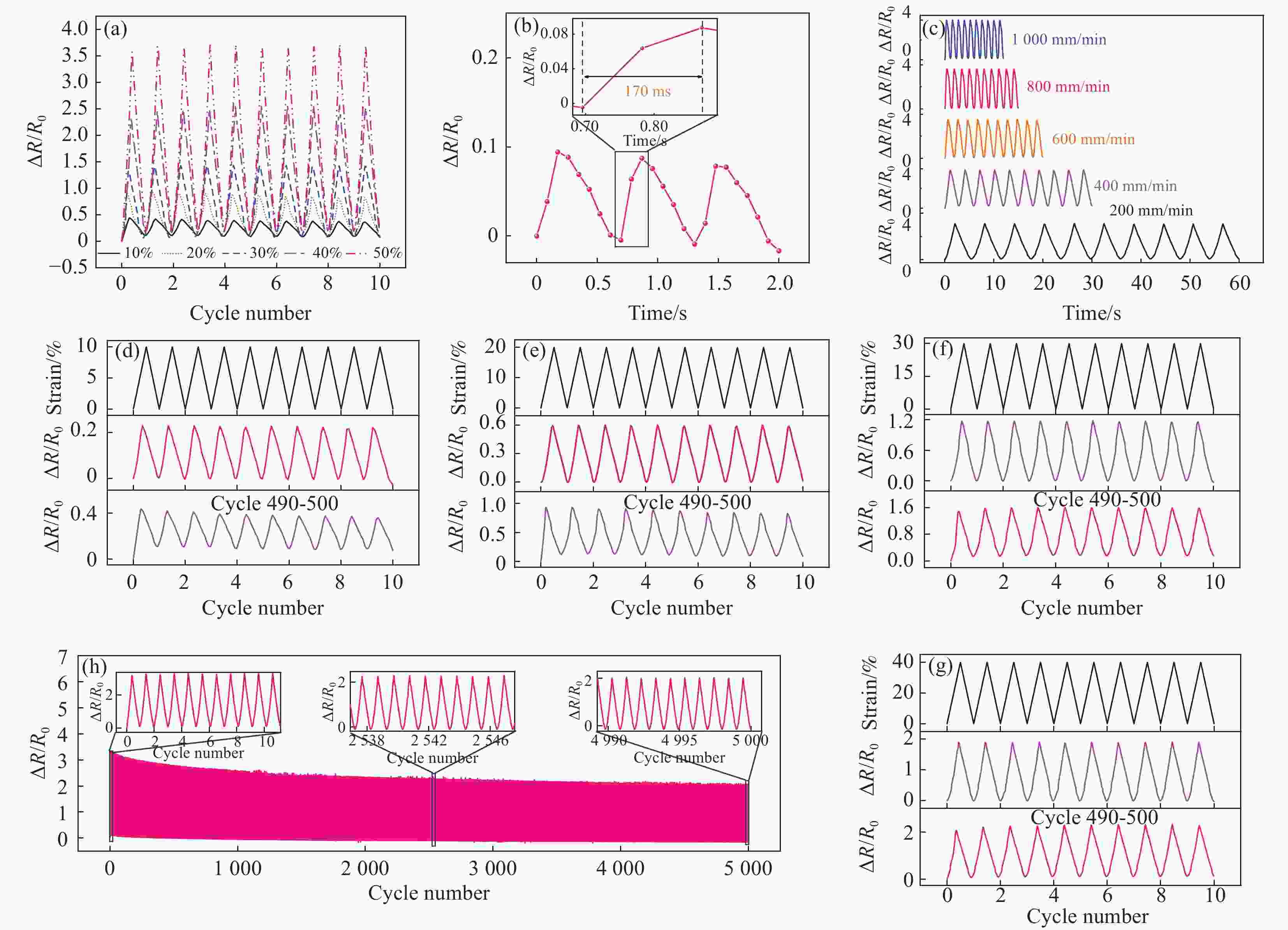

图 6 (a) MWCNT2wt%-CB/VMQ复合材料在不同应变下的电阻响应;(b) MWCNT2wt%-CB/VMQ复合材料在应变为5%、速率1000 mm/min−1下的响应时间;(c) MWCNT2wt%-CB/VMQ复合材料在不同速率下的电阻响应;((d)~(g)) MWCNT2wt%-CB/VMQ复合材料在应变为10%、20%、30%、40%下500次电阻响应;(h) MWCNT2wt%-CB/VMQ复合材料在应变为50%下的5000次电阻响应

Figure 6. (a) Resistance responses of MWCNT2wt%-CB/VMQ composites under different strains; (b) Response time of MWCNT2wt%-CB/VMQ composites at a strain of 5% and a rate of 1000 mm/min−1; (c) Resistance responses of MWCNT2wt%-CB/VMQ composites at different rates; ((d)-(g)) MWCNT2wt%-CB/VMQ composites have 500 times resistance responses at strain of 10%, 20%, 30% and 40%; (h) 5000 times resistance responses of MWCNT2wt%-CB/VMQ composites at 50% strain

图 8 ((a)~(d)) MWCNT-CB/VMQ复合材料的导电网络在拉伸过程的演化机制;MWCNT2wt%-CB/VMQ (e)、CB9wt%/VMQ (f)、MWCNT4wt%/VMQ (g)复合材料在拉伸过程实验结果与理论结果的电阻

Figure 8. ((a)-(d)) Evolution mechanism of the conductive network of the MWCNT-CB/VMQ composites during the tensile process; Experimental and theoretical resistance of MWCNT2wt%-CB/VMQ (e), CB9wt%/VMQ (f), MWCNT4wt%/VMQ (g) composites

表 1 不同导电填料含量的ΔR/R0-应变曲线拟合后的参数

Table 1. Parameters of resistance ΔR/R0-strain curves fitting for different conductive filler contents

Filler content $ {m} $ $ {{ \varepsilon }}_{\text{c}} $ $ {{n}}_{\text{s}} $ MWCNT4wt%

MWCNT2wt%-CB

CB9wt%2.55

14.56

7.083.92

6.55

4.96−1.81

−3.62

−3.48Notes: m—Aconstant related to the fractal structure of the network; εc—Constant which can be interpreted as the yield strain; ns—Scaling exponent. -

[1] ARIA M, AKBARI R. Inspection, condition evaluation and replacement of elastomeric bearings in road bridges[J]. Structure and Infrastructure Engineering,2013,9(9):918-934. doi: 10.1080/15732479.2011.638171 [2] SUN L, SHANG Z, XIA Y, et al. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection[J]. Journal of Structural Engineering,2020,146(5):04020073. doi: 10.1061/(ASCE)ST.1943-541X.0002535 [3] SIRINGORINGO D M, FUJINO Y, SUZUKI M. Long-term continuous seismic monitoring of multi-span highway bridge and evaluation of bearing condition by wireless sensor network[J]. Engineering Structures,2023,276:115372. doi: 10.1016/j.engstruct.2022.115372 [4] MENG X, NGUYEN D T, XIE Y, et al. Design and implementation of a new system for large bridge monitoring—GeoSHM[J]. Sensors,2018,18(3):775. doi: 10.3390/s18030775 [5] YANG H, YAO X, ZHENG Z, et al. Highly sensitive and stretchable graphene-silicone rubber composites for strain sensing[J]. Composites Science and Technology,2018,167:371-378. doi: 10.1016/j.compscitech.2018.08.022 [6] XU Y, XIE X, HUANG H, et al. Encapsulated core-sheath carbon nanotube-graphene/polyurethane composite fiber for highly stable, stretchable, and sensitive strain sensor[J]. Journal of Materials Science,2020,56(3):2296-2310. [7] LIU X, REN Z, LIU F, et al. Multifunctional self-healing dual network hydrogels constructed via host-guest interaction and dynamic covalent bond as wearable strain sensors for monitoring human and organ motions[J]. ACS Applied Materials & Interfaces,2021,13(12):14612-14622. [8] LIU L, GAO Y, LIU Y, et al. Biomimetic metal-organic framework-derived porous carbon welded carbon nanotube networks for strain sensors with high sensitivity and wide sensing range[J]. Applied Surface Science,2022,593:153417. doi: 10.1016/j.apsusc.2022.153417 [9] OH S, KIM J, CHANG S T. Highly sensitive metal-grid strain sensors via water-based solution processing[J]. RSC Advances,2018,8(73):42153-42159. doi: 10.1039/C8RA08721K [10] CHRIST J F, ALIHEIDARI N, AMELI A, et al. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites[J]. Materials & Design,2017,131:394-401. [11] YAN J, MALAKOOTI M H, LU Z, et al. Solution processable liquid metal nanodroplets by surface-initiated atom transfer radical polymerization[J]. Nature Nanotechnology,2019,14(7):684-690. doi: 10.1038/s41565-019-0454-6 [12] MIN S H, LEE G Y, AHN S H. Direct printing of highly sensitive, stretchable, and durable strain sensor based on silver nanoparticles/multi-walled carbon nanotubes composites[J]. Composites Part B: Engineering,2019,161:395-401. doi: 10.1016/j.compositesb.2018.12.107 [13] BORAYEK R, FOROUGHI F, XIN X, et al. Near-zero hysteresis ionic conductive elastomers with long-term stability for sensing applications[J]. ACS Applied Materials & Interfaces,2022,14(9):11727-11738. doi: 10.1021/acsami.1c24784 [14] LIU X, GUO R, LIN Z, et al. Resistance-strain sensitive rubber composites filled by multiwalled carbon nanotubes for structural deformation monitoring[J]. Nanomaterials and Nanotechnology,2021,11:1-13. [15] KURIAN A S, MOHAN V B, BHATTACHARYYA D. Embedded large strain sensors with graphene-carbon black-silicone rubber composites[J]. Sensors and Actuators A: Physical,2018,282:206-214. doi: 10.1016/j.sna.2018.09.017 [16] XU X, YUAN Y, ZHANG T, et al. A silanized MCNT/TPU-based flexible strain sensor with high stretchability for deformation monitoring of elastomeric isolators for bridges[J]. Construction and Building Materials,2022,338:127664. doi: 10.1016/j.conbuildmat.2022.127664 [17] REN H, LI H, WANG H, et al. Biodegradation of tetrahydrofuran by the newly isolated filamentous fungus Pseudallescheria boydii ZM01[J]. Microorganisms,2020,8(8):1190. doi: 10.3390/microorganisms8081190 [18] WAN B, YANG Y, GUO R, et al. Effect of vulcanization on the electro-mechanical sensing characteristics of multi-walled carbon nanotube/silicone rubber composites[J]. Polymers,2023,15(6):1412. doi: 10.3390/polym15061412 [19] ZHU S, SUN H, LU Y, et al. Inherently conductive poly(dimethylsiloxane) elastomers synergistically mediated by nanocellulose/carbon nanotube nanohybrids toward highly sensitive, stretchable, and durable strain sensors[J]. ACS Applied Materials & Interfaces,2021,13(49):59142-59153. doi: 10.1021/acsami.1c19482 [20] YANG H, GONG L H, ZHENG Z, et al. Highly stretchable and sensitive conductive rubber composites with tunable piezoresistivity for motion detection and flexible electrodes[J]. Carbon,2020,158:893-903. doi: 10.1016/j.carbon.2019.11.079 [21] GEORGOUSIS G, ROUMPOS K, KONTOU E, et al. Strain and damage monitoring in SBR nanocomposites under cyclic loading[J]. Composites Part B: Engineering,2017,131:50-61. doi: 10.1016/j.compositesb.2017.08.006 [22] YANG H, YAO X, YUAN L, et al. Strain-sensitive electrical conductivity of carbon nanotube-graphene-filled rubber composites under cyclic loading[J]. Nanoscale,2019,11(2):578-586. doi: 10.1039/C8NR07737A [23] YANG H, YUAN L, YAO X, et al. Monotonic strain sensing behavior of self-assembled carbon nanotubes/graphene silicone rubber composites under cyclic loading[J]. Composites Science and Technology,2020,200:108474. doi: 10.1016/j.compscitech.2020.108474 [24] SHEN L, WANG F Q, YANG H, et al. The combined effects of carbon black and carbon fiber on the electrical properties of composites based on polyethylene or polyethylene/polypropylene blend[J]. Polymer Testing,2011,30(4):442-448. doi: 10.1016/j.polymertesting.2011.03.007 [25] CUI X, JIANG Y, XU Z, et al. Stretchable strain sensors with dentate groove structure for enhanced sensing recoverability[J]. Composites Part B: Engineering,2021,211:108641. doi: 10.1016/j.compositesb.2021.108641 [26] LU Y, WU H, LIU J, et al. Electrical percolation of silicone rubber filled by carbon black and carbon nanotubes researched by the Monte Carlo simulation[J]. Journal of Applied Polymer Science,2019,136(46):48222. doi: 10.1002/app.48222 [27] HUANG J C. Carbon black filled conducting polymers and polymer blends[J]. Advances in Polymer Technology,2002,21(4):299-313. doi: 10.1002/adv.10025 [28] DENG H, LIN L, JI M, et al. Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials[J]. Progress in Polymer Science,2014,39(4):627-655. doi: 10.1016/j.progpolymsci.2013.07.007 [29] SURVE M, PRYAMITSYN V, GANESAN V. Universality in structure and elasticity of polymer-nanoparticle gels[J]. Physical Review Letters,2006,96(17):177805. doi: 10.1103/PhysRevLett.96.177805 [30] FAN Z, GUO R, YANG Z, et al. The effect of the co-blending process on the sensing characteristics of conductive chloroprene rubber/natural rubber composites[J]. Polymers,2022,14(16):3326. doi: 10.3390/polym14163326 [31] LI Z, QI X, XU L, et al. Self-repairing, large linear working range shape memory carbon nanotubes/ethylene vinyl acetate fiber strain sensor for human movement monitoring[J]. ACS Applied Materials & Interfaces,2020,12(37):42179-42192. doi: 10.1021/acsami.0c12425 [32] ZHOU B, LIU Z, LI C, et al. Fabrication of ultrasensitive and flexible strain sensor based on multi-wall carbon nanotubes coated electrospun styrene-ethylene-butylene-styrene block copolymer fibrous tubes[J]. European Polymer Journal,2022,178:111501. doi: 10.1016/j.eurpolymj.2022.111501 [33] ZHAO S, LI Y, WU F, et al. Humidity response of single carbon nanocoil and its temperature sensor independent of humidity and strain[J]. Applied Surface Science,2022,605:154745. doi: 10.1016/j.apsusc.2022.154745 [34] WEN N, GUAN X, FAN Z, et al. A highly stretchable and breathable self-powered dual-parameter sensor for decoupled temperature and strain sensing[J]. Organic Electronics,2023,113:106723. doi: 10.1016/j.orgel.2022.106723 [35] WANG H, HE X, HUANG X, et al. Vapor-based fabrication of PEDOT coating for wearable strain sensors with excellent sensitivity and self-cleaning capability[J]. Materials Today Chemistry,2023,28:101361. doi: 10.1016/j.mtchem.2022.101361 [36] KIM S, YOO B, MILLER M, et al. EGaIn-silicone-based highly stretchable and flexible strain sensor for real-time two joint robotic motion monitoring[J]. Sensors and Actuators A: Physical,2022,342:113659. doi: 10.1016/j.sna.2022.113659 [37] WANG H, YANG L, ZHANG X, et al. Effect of different prestretching index and preloading on actuation behaviors of dielectric elastomer actuator[J]. Journal of Materials Research and Technology,2021,15:4064-4073. doi: 10.1016/j.jmrt.2021.10.029 [38] YANG H, YAO X, ZHENG Z, et al. Highly sensitive and stretchable graphene-silicone rubber composites for strain sensing[J]. Composites Science and Technology, 2018, 167: 371-378. [39] HEINRICH G, KLÜPPEL M. Recent advances in the theory of filler networking in elastomers[J]. Filled Elastomers Drug Delivery Systems,2002,160:1-44. -

下载:

下载: