Effect of vulcanization system on thermal aging property of silicone rubber

-

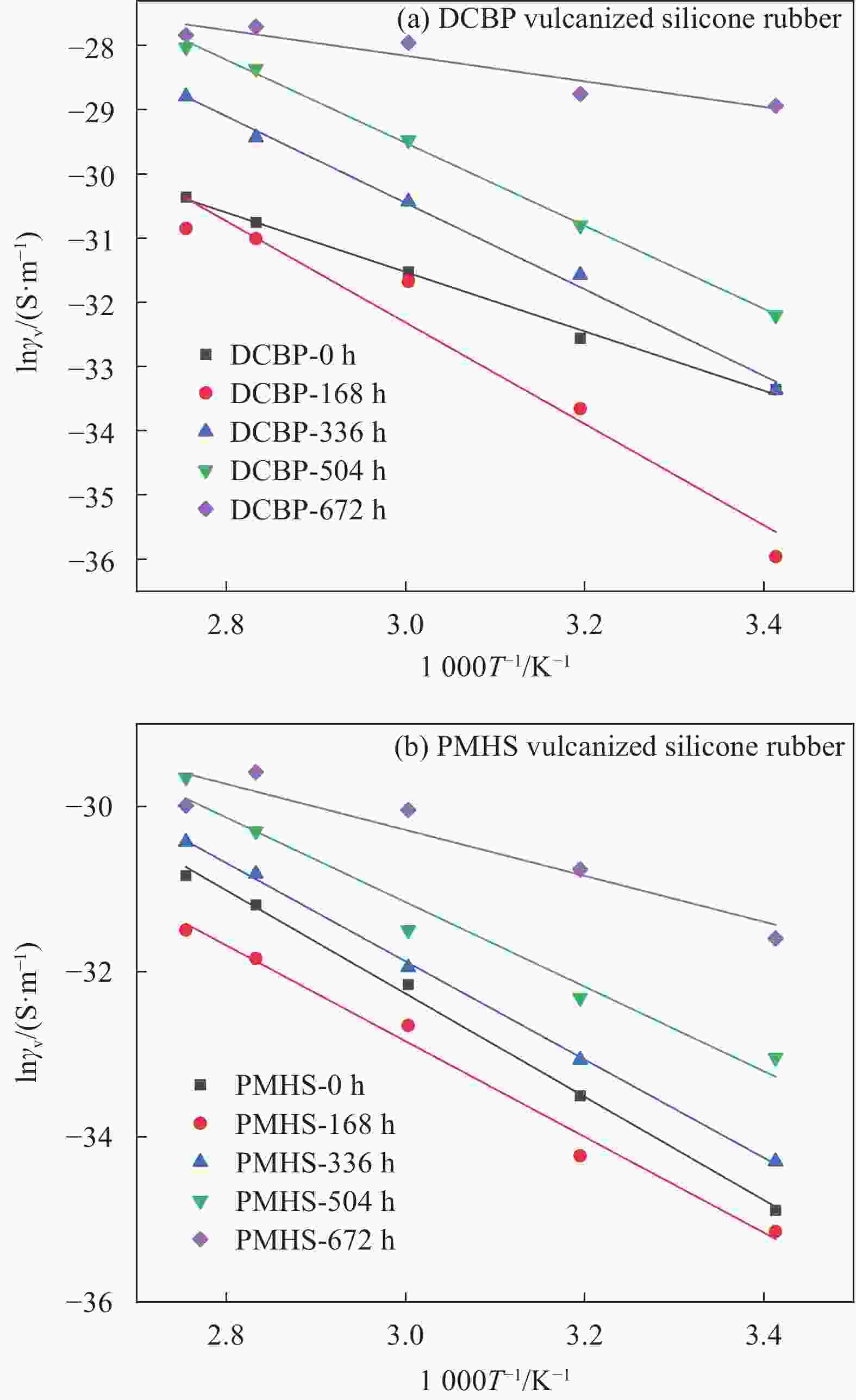

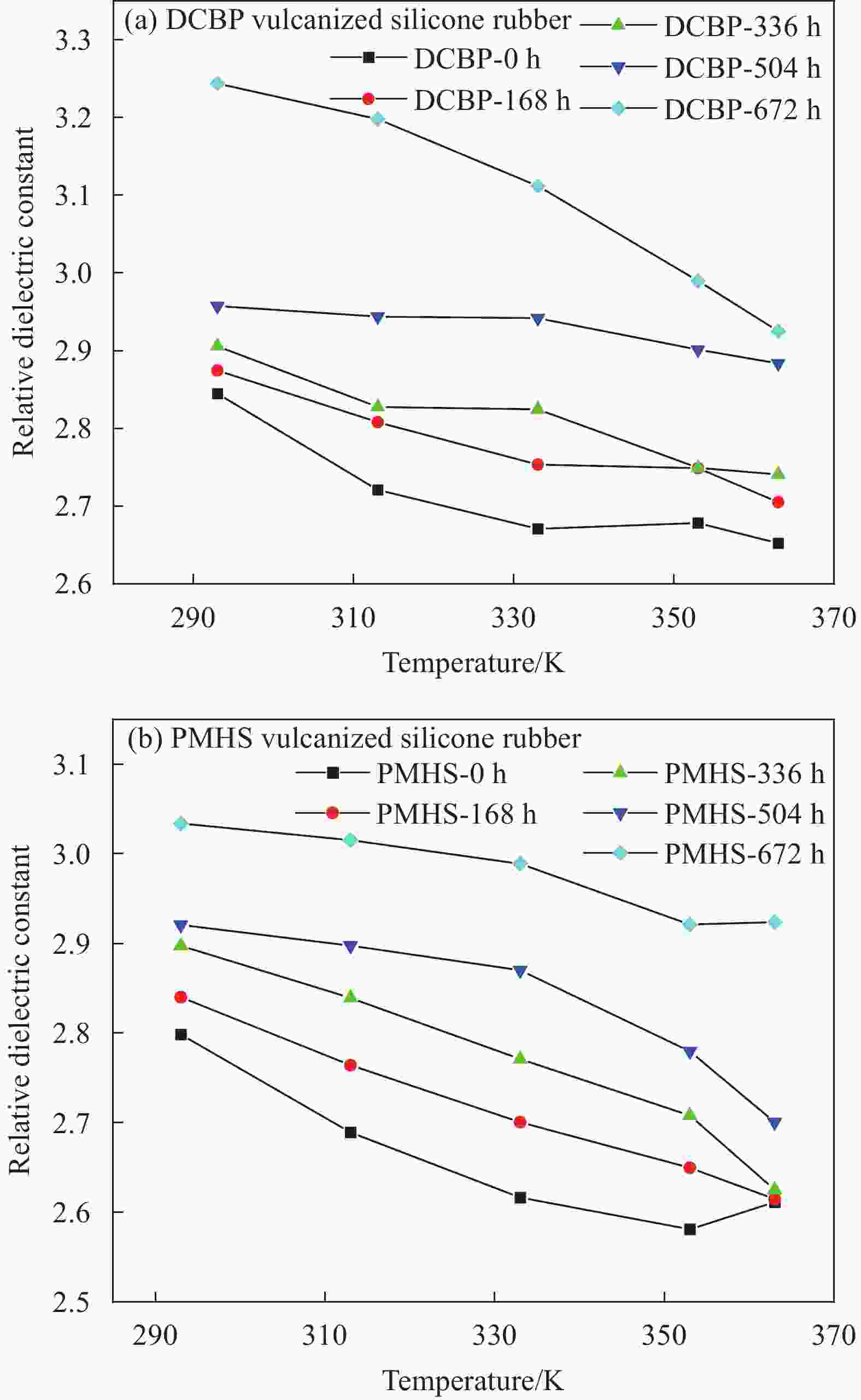

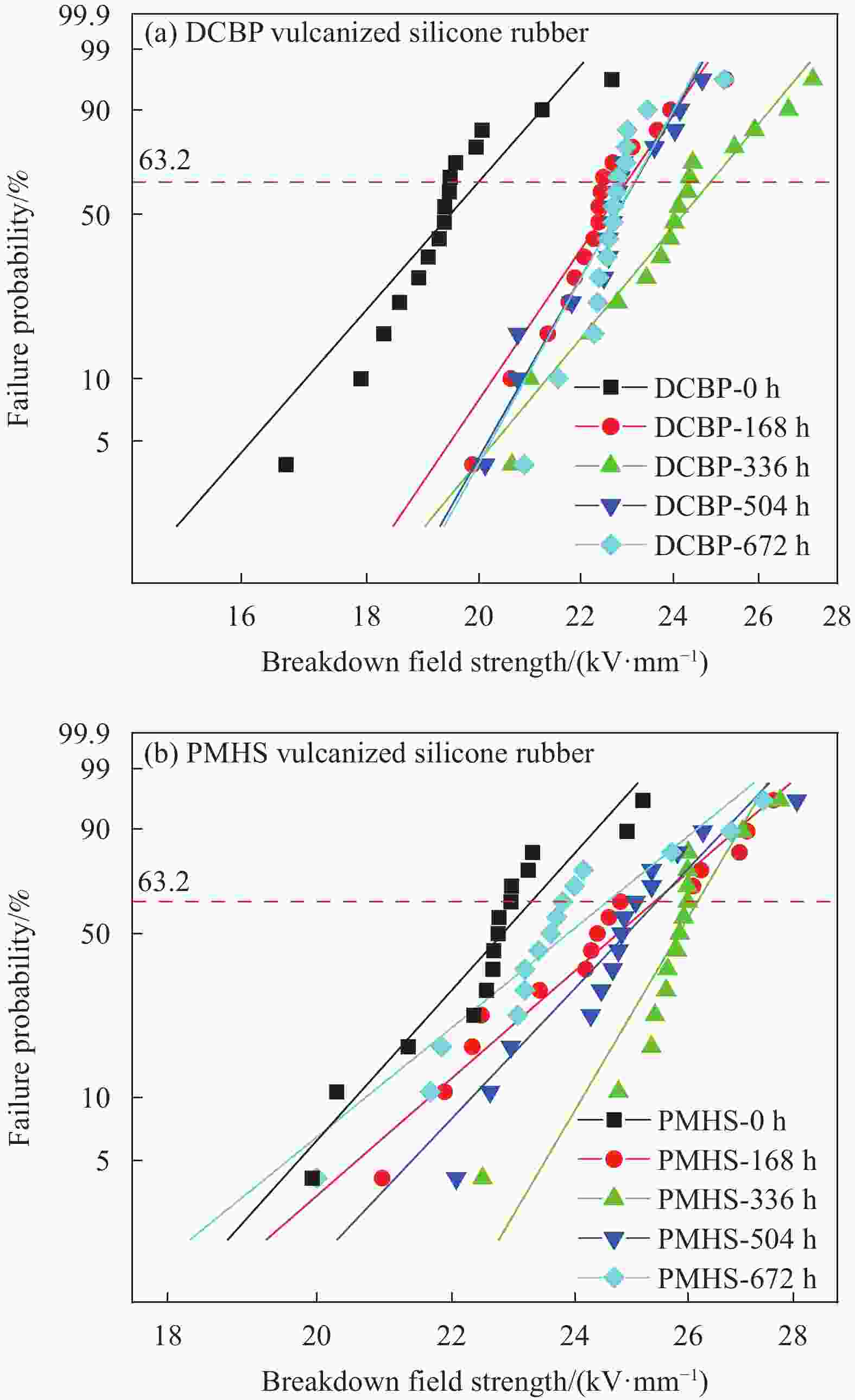

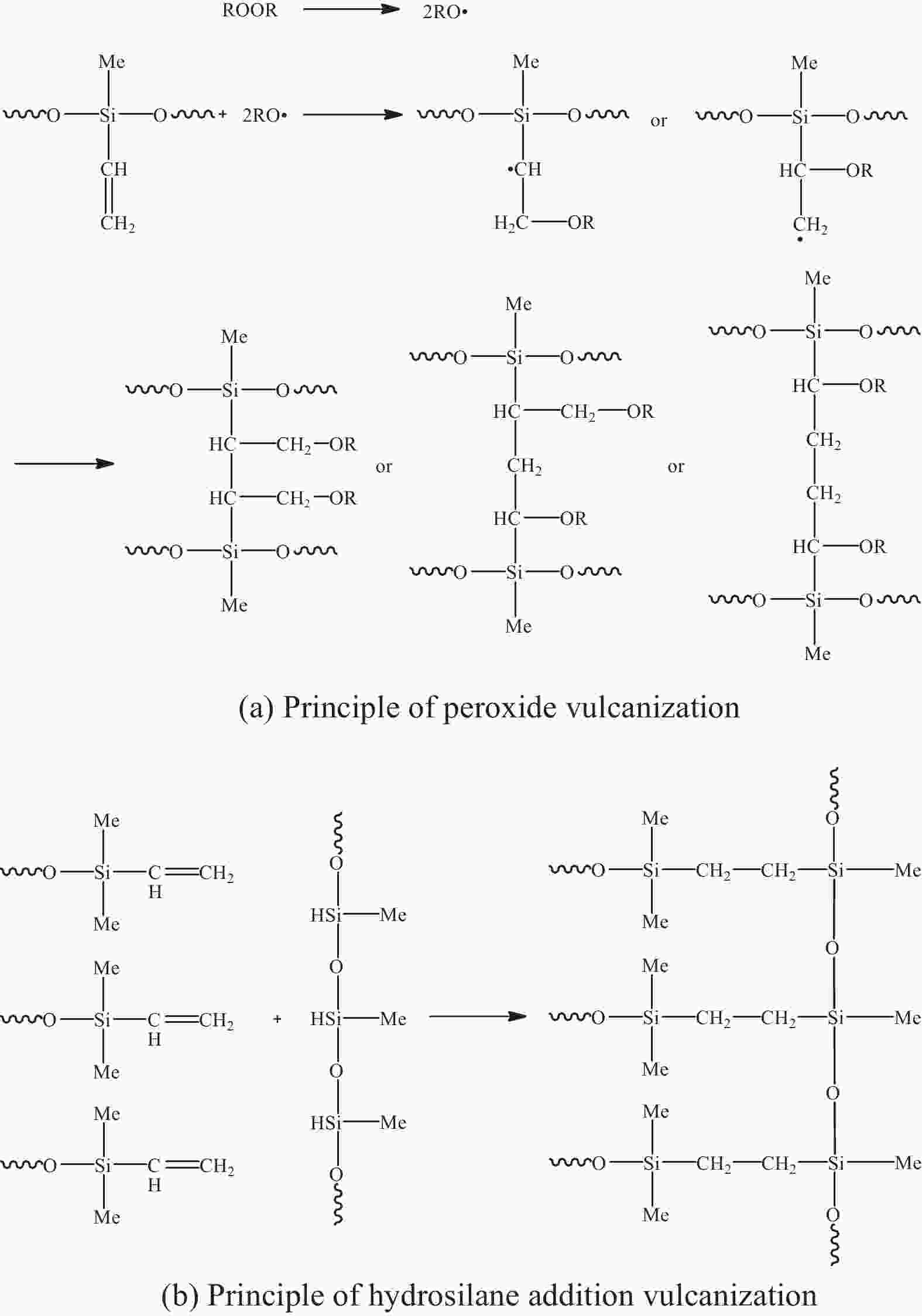

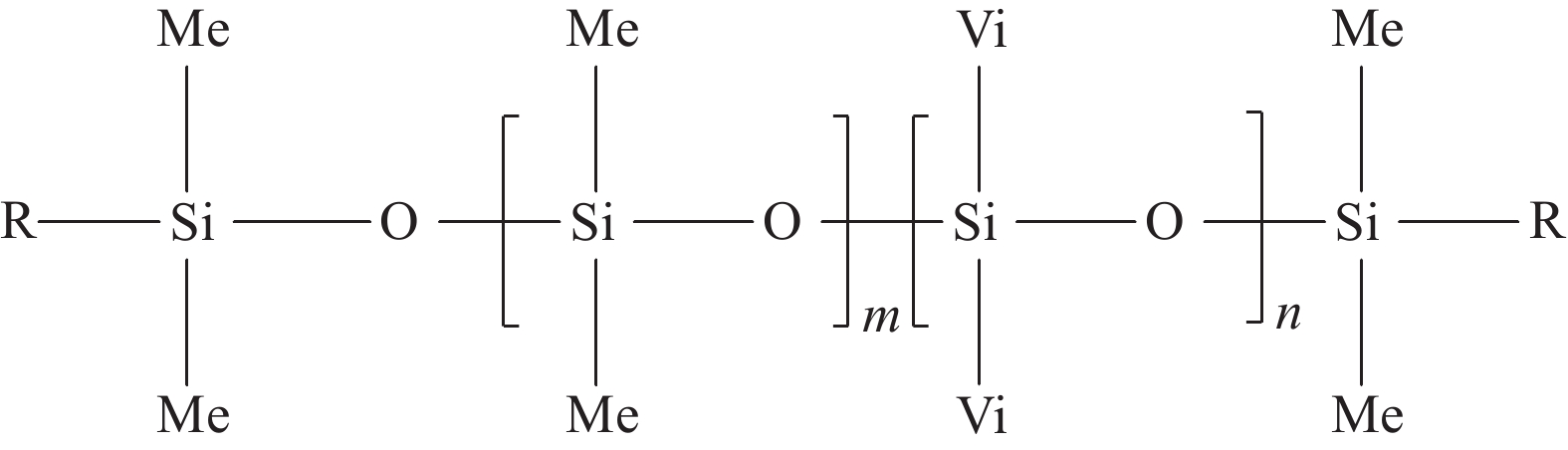

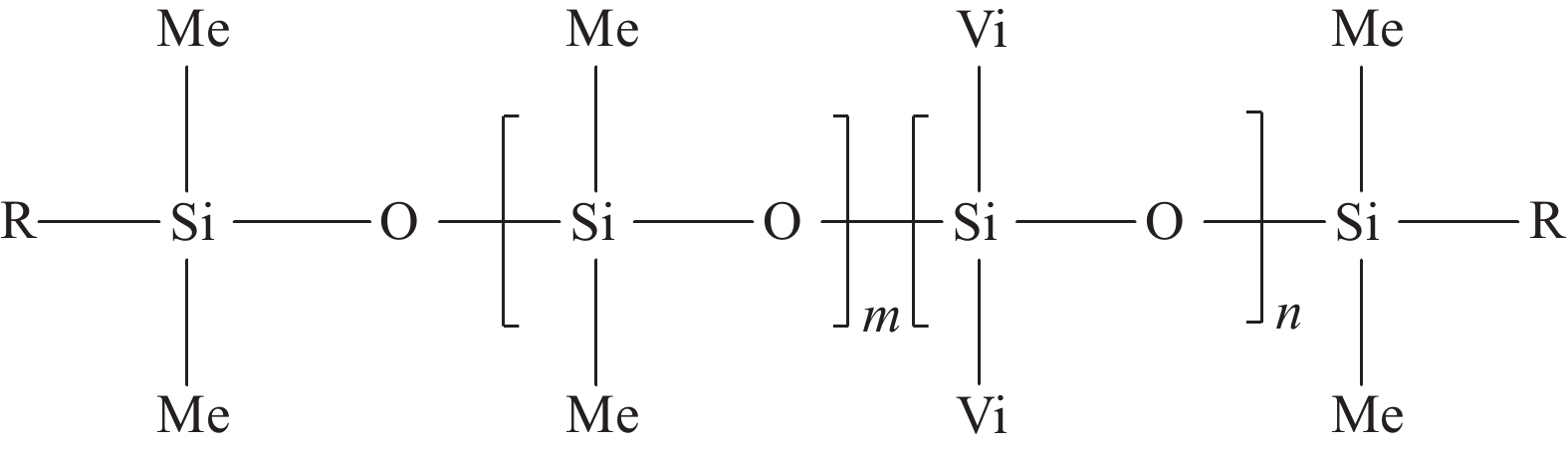

摘要: 为了探究不同硫化体系对电缆附件增强绝缘用硅橡胶热老化性能的影响,本文以35 kV电缆附件增强绝缘用硅橡胶为研究对象,利用过氧化物、硅氢加成两种硫化体系分别制作硫化硅橡胶试样并开展热老化试验,对比分析其力学性能和电气性能的变化特征。在热老化前期,两种硫化体系下硅橡胶均发生分子侧链的氧化交联反应和分子链间的再交联反应,交联度增大;热老化后期,交联体系结构和分子链被破坏,交联度变小。研究与测试结果表明:随着热老化时间的增加,硅橡胶试样拉伸强度和断裂伸长率逐渐减小,电导率先减小后增大、随温度升高而增大,相对介电常数逐渐增大、随温度升高而减小,介质损耗角正切逐渐增大、随温度升高而增大,击穿场强呈现先增后降趋势。硅氢加成硫化体系下的硅橡胶一直保持高交联度,在热老化后具备更优的力学性能和电气性能,而过氧化物硫化体系下的硅橡胶在硫化过程中产生强酸性副产物,在热老化后产生强极性基团,致使硅橡胶的热老化性能劣化。Abstract: In order to explore the effects of different vulcanization systems on the thermal aging properties of sili-cone rubber used for enhanced insulation of cable accessories, silicone rubber was used for enhanced insulation of 35 kV cable accessories as the research object, and peroxide and hydrosilane addition vulcanization systems were used to produce vulcanized silicone rubber samples and carry out thermal aging tests to compare and analyze the mechanical and electrical properties of the rubber. In the early stage of thermal aging, the oxidative cross-linking reaction of molecular side chains and the re-cross-linking reaction between molecular chains occurred in both sili-cone rubber vulcanization systems, and the cross-linking degree increased. In the later stage of thermal aging, the cross-linking system structure and molecular chain were destroyed, and the cross-linking degree decreased. The research and test results show that the tensile strength and elongation at break of silicone rubber samples gradually decrease with the increase of thermal aging time, the conductivity decreases first and then increases with the increase of temperature, the relative dielectric constant increases gradually and decreases with the increase of temperature, the tangent of dielectric loss angle increases gradually and increases with the increase of temperature, and the breakdown field strength increases first and then decreases. The silicone rubber under the hydrosilane addition vulcanization system has always maintained high crosslinking degree and has better mechanical and electrical properties after thermal aging, while the silicone rubber under the peroxide vulcanization system produces strong acidic by-products during vulcanization and produces strong polar groups after thermal aging, resulting in the deterioration of the thermal aging performance of the silicone rubber.

-

表 1 各试样的主要成分及质量分数

Table 1. Main components and mass fraction of each sample

Material Mass fraction/wt% DCBP PMHS Silicone rubber 100 100 Silica 30 30 Structured control agents 5 5 2,4-dichlorobenzoyl peroxide (DCBP) 1.2 0 Platinum catalyst 0 0.7 Polymethyl hydro siloxane (PMHS) 0 0.6 表 2 不同热老化时间硅橡胶试样的热延伸性能

Table 2. Thermal elongation properties of silicone rubber samples at different thermal aging time

Vulcanization

systemThermal

aging time/

hThermal

elongation/

%Permanent

deformation

rate/%DCBP vulcanized

silicone rubber0 83.0 4.0 168 31.0 0.5 336 16.5 1.5 504 21.0 1.0 672 28.0 1.0 PMHS vulcanized

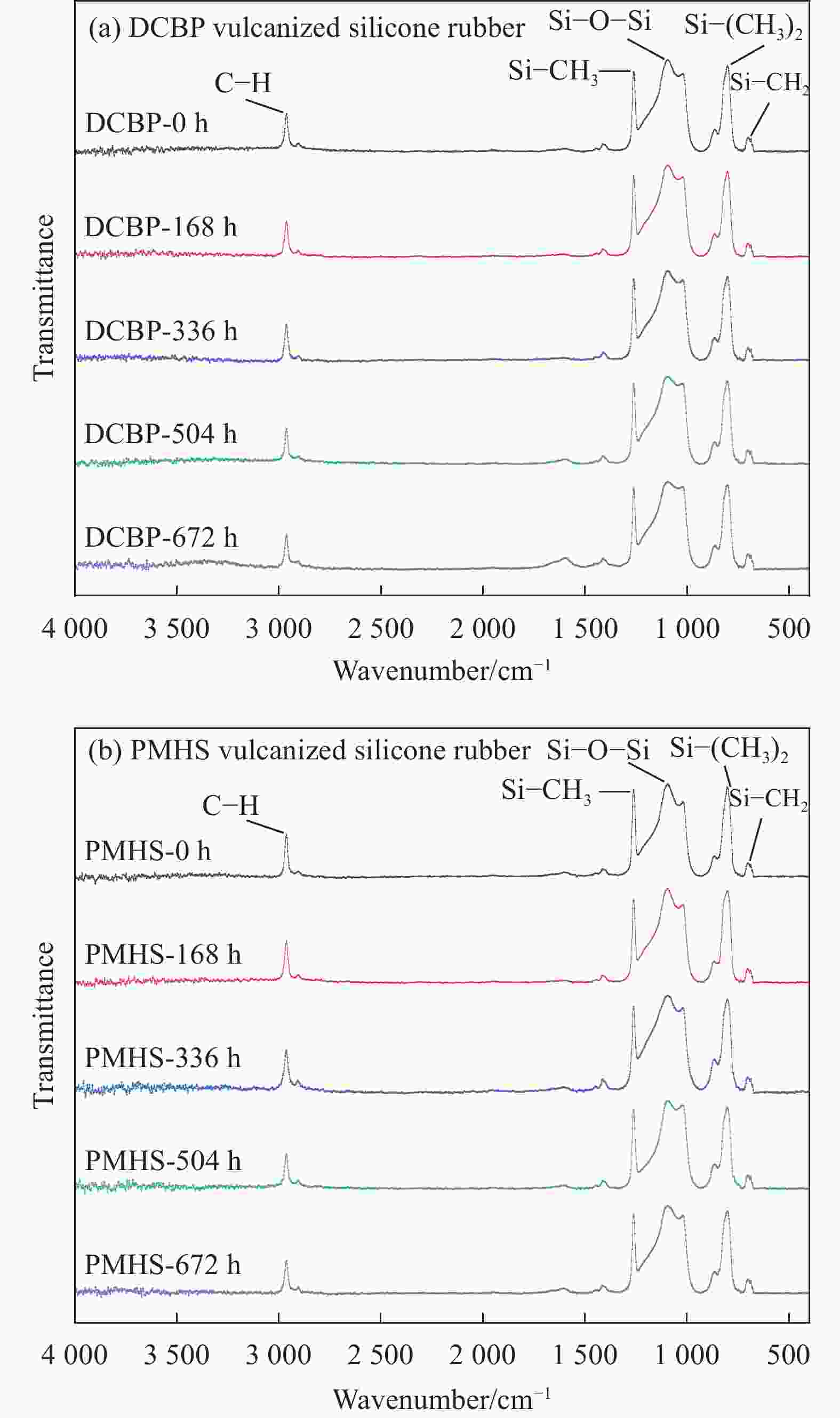

silicone rubber0 18.5 1.0 168 15.0 0.5 336 16.0 0.0 504 17.5 0.5 672 19.0 0.5 表 3 硅橡胶试样的各官能团指数

Table 3. Functional group index of each functional group of silicone rubber samples

Vulcanization

systemThermal

aging time/hFunctional group index Si—(CH3)2 Si—O—Si Si—CH3 C—H DCBP

vulcanized

silicone

rubber0 8.35 3.29 0.48 1.90 168 8.85 4.59 0.49 2.26 336 8.89 4.44 0.50 2.21 504 8.63 4.69 0.47 1.82 672 8.80 3.76 0.47 1.87 PMHS

vulcanized

silicone

rubber0 7.33 6.23 0.47 1.99 168 8.02 5.52 0.50 2.04 336 8.65 6.71 0.62 3.22 504 7.52 6.42 0.61 2.34 672 6.91 6.43 0.49 1.97 -

[1] 胡丽斌, 张传升, 谭 笑, 等. 退役电缆附件微观结构与电荷特性研究[J]. 中国电机工程学报, 2021, 41(2):770-781. doi: 10.13334/j.0258-8013.pcsee.200492HU Libin, ZHANG Chuansheng, TAN Xiao, et al. Study on micro-structure and charge characteristics of retired cable accessories[J]. Proceedings of the CSEE,2021,41(2):770-781(in Chinese). doi: 10.13334/j.0258-8013.pcsee.200492 [2] 尚南强, 陈庆国, 秦君. 纳米TiO2/液体硅橡胶直流电缆附件绝缘复合材料的介电性能[J]. 复合材料学报, 2019, 36(1):104-113.SHANG Nanqiang, CHEN Qingguo, QIN Jun. Dielectric properties of nano-TiO2/liquid silicone rubber DC cable accessories insulating composites[J]. Acta Materiae Compositae Sinica,2019,36(1):104-113(in Chinese). [3] 邵满智, 赵洪, 李春阳, 等. 紫外光交联低压三元乙丙橡胶电缆绝缘材料配方与性能[J]. 复合材料学报, 2022, 39(12):5922-5933. doi: 10.13801/j.cnki.fhclxb.20211217.003SHAO Manzhi, ZHAO Hong, LI Chunyang, et al. Formulation and properties of ultraviolet-crosslinked low voltage EPDM cable insulation materials[J]. Acta Materiae Compositae Sinica,2022,39(12):5922-5933(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211217.003 [4] 陈杰, 吴世林, 胡丽斌, 等. 退役高压电缆附件绝缘状态及理化性能分析[J]. 电工技术学报, 2021, 36(12):2650-2658. doi: 10.19595/j.cnki.1000-6753.tces.200367CHEN Jie, WU Shilin, HU Libin, et al. Analysis on insulation status and physicochemical properties of decommissioned high-voltage cable accessories[J]. Transactions of China Electrotechnical Society,2021,36(12):2650-2658(in Chinese). doi: 10.19595/j.cnki.1000-6753.tces.200367 [5] ZHU B, JIA Z, HU H, et al. Relationship between the interfacial ramped DC breakdown voltage and the morphology of the XLPE/SiR interface[J]. IEEE Transactions on Dielectrics and Electrical Insulation,2019,26(3):689-697. doi: 10.1109/TDEI.2018.007600 [6] 陈庆国, 尚南强, 魏昕喆. 热老化对液体硅橡胶材料介电性能及力学特性的影响研究[J]. 电机与控制学报, 2020, 24(4):141-148. doi: 10.15938/j.emc.2020.04.016CHEN Qingguo, SHANG Nanqiang, WEI Xinzhe. Effect of thermal aging on dielectric properties and mechanical properties of liquid silicone rubber materials[J]. Electric Machines and Control,2020,24(4):141-148(in Chinese). doi: 10.15938/j.emc.2020.04.016 [7] 迟庆国, 李振, 张天栋, 等. 钛酸铜钙纳米纤维/液体硅橡胶复合介质非线性电导性能[J]. 复合材料学报, 2019, 36(10):2247-2258. doi: 10.13801/j.cnki.fhclxb.20181119.004CHI Qingguo, LI Zhen, ZHANG Tiandong, et al. Nonlinear conductivity of copper calcium titanate nanofiber/liquid silicone rubber composite Media[J]. Acta Materiae Compositae Sinica,2019,36(10):2247-2258(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181119.004 [8] 王若丞, 贺云逸, 康洪玮, 等. 电缆接头绝缘用硅橡胶热老化及超声特性[J]. 高电压技术, 2021, 47(9):3181-3188. doi: 10.13336/j.1003-6520.hve.20201160WANG Ruocheng, HE Yunyi, KANG Hongwei, et al. Thermal aging and ultrasonic characteristics of silicone rubber for cable joint insulation[J]. High Voltage Technology,2021,47(9):3181-3188(in Chinese). doi: 10.13336/j.1003-6520.hve.20201160 [9] 王明英, 王健, 杜思辰, 等. 硅橡胶硫化体系研究进展[J]. 合成橡胶工业, 2022, 45(3):244-252. doi: 10.19908/j.cnki.ISSN1000-1255.2022.03.0244WANG Mingying, WANG Jian, DU Sichen, et al. Research progress of vulcanization system of silicone rubber[J]. Synthetic Rubber Industry,2022,45(3):244-252(in Chinese). doi: 10.19908/j.cnki.ISSN1000-1255.2022.03.0244 [10] 李浩. 变形翼硅橡胶柔性蒙皮材料的制备及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2021.LI Hao. Study on the preparation and properties of sili-cone rubber flexible skin material for deformed wing[D]. Harbin: Harbin Institute of Technology, 2021. [11] ULLAH R, AKBAR M. Lifetime estimation based on surface degradation and characterization of HTV silicone-rubber based composites for HVAC and HVDC transmission[J]. CSEE Journal of Power and Energy Systems, 2023, 9(2): 751-758. [12] 崔永岩, 朱晓蒙, 杨翰, 等. 丙烯腈-丁二烯-苯乙烯/甲基乙烯基硅橡胶共混体系的动态硫化及性能[J]. 高分子材料科学与工程, 2018, 34(11):74-78, 85. doi: 10.16865/j.cnki.1000-7555.2018.11.013CUI Yongyan, ZHU Xiaomeng, YANG Han, et al. Dynamic vulcanization and properties of acryloni-trile-butadiene-styrene/methylvinyl silicone rubber blends[J]. Polymer Materials Science and Engineering,2018,34(11):74-78, 85(in Chinese). doi: 10.16865/j.cnki.1000-7555.2018.11.013 [13] 王凯, 范襄, 陈萌炯. 白炭黑增强型硅橡胶的组成及抗原子氧性能分析[J]. 高等学校化学学报, 2020, 41(3):548-555. doi: 10.7503/cjcu20190517WANG Kai, FAN Xiang, CHEN Mengjiong. Analysis on the composition and atomic oxygen resistance of silica reinforced silicone rubber[J]. Chemical Journal of Chinese Universities,2020,41(3):548-555(in Chinese). doi: 10.7503/cjcu20190517 [14] 张天萍, 甄卫军, 赵玲. 配方对有机硅橡胶非等温硫化动力学的影响[J]. 高校化学工程学报, 2020, 34(1):222-229. doi: 10.3969/j.issn.1003-9015.2020.01.028ZHANG Tianping, ZHEN Weijun, ZHAO Ling. Effect of formulation on non-isothermal vulcanization kinetics of sili-cone rubber[J]. Journal of Chemical Engineering in Chinese Universities,2020,34(1):222-229(in Chinese). doi: 10.3969/j.issn.1003-9015.2020.01.028 [15] 周远翔, 张征辉, 张云霄, 等. 热-力联合老化对硅橡胶交联网络及力学和耐电特性的影响[J]. 电工技术学报, 2022, 37(17):4474-4486.ZHOU Yuanxiang, ZHANG Zhenghui, ZHANG Yunxiao, et al. Effects of combined thermal and mechanical aging on mechanical and electrical resistance of silicon rubber crosslinked networks[J]. Transactions of China Electrotechnical Society,2022,37(17):4474-4486(in Chinese). [16] 王成江, 范正阳, 赵宁, 等. 硅烷偶联剂修饰下SiO2-甲基乙烯基硅橡胶分子界面的粘结性[J]. 复合材料学报, 2019, 37(12):3079-3090.WANG Chengjiang, FAN Zhengyang, ZHAO Ning, et al. Adhesion of molecular interface of SiO2-methylvinylsilicone rubber modified by silane coupling agent[J]. Acta Materiae Compositae Sinica,2019,37(12):3079-3090(in Chinese). [17] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶热空气加速老化和耐热试验: GB/T 3512—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People's Republic of China. Hot air accelerated aging and heat resistance test of vulcanized rubber or thermoplastic rubber: GB/T 3512—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [18] International Organization for Standardization. Rubber, vulcanized or thermoplastic—Estimation of life-time and maximum temperature of use: ISO 11346—2014[S]. Geneva: ISO, 2023. [19] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Determination of tensile stress-strain properties of vulcanized or thermoplastic rubber: GB/T 528—2009[S]. Beijing: Standards Press of China, 2009(in Chinese). [20] 中国国家标准化管理委员会. 电缆和光缆绝缘和护套材料通用试验方法: GB/T 2951.21—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. General test method for insulation and sheathing materials of cables and optical cables: GB/T 2951.21—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [21] 中国国家标准化管理委员会. 绝缘材料电气强度试验方法: GB/T 1408.1—2016[S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People's Republic of China. Test method for electrical strength of insulating materials: GB/T 1408.1—2016[S]. Beijing: Standards Press of China, 2016(in Chinese). [22] 吕鸿, 马佳炜, 杨贤, 等. 热老化对220 kV硅橡胶电缆接头绝缘材料介电性能的影响[J]. 绝缘材料, 2019, 52(2):47-51.LYU Hong, MA Jiawei, YANG Xian, et al. Effect of thermal aging on dielectric properties of 220 kV silicone rubber cable joint insulation materials[J]. Journal of Insulation Materials,2019,52(2):47-51(in Chinese). [23] 邵光磊, 秦福宁, 赵金辉, 等. 电缆中间接头硅橡胶绝缘的电气特性研究[J]. 绝缘材料, 2020, 53(10):38-43. doi: 10.16790/j.cnki.1009-9239.im.2020.10.006SHAO Guanglei, QIN Funing, ZHAO Jinhui, et al. Research on electrical characteristics of silicone rubber insulation of cable intermediate joint[J]. Journal of Insulating Mate-rials,2020,53(10):38-43(in Chinese). doi: 10.16790/j.cnki.1009-9239.im.2020.10.006 -

下载:

下载: