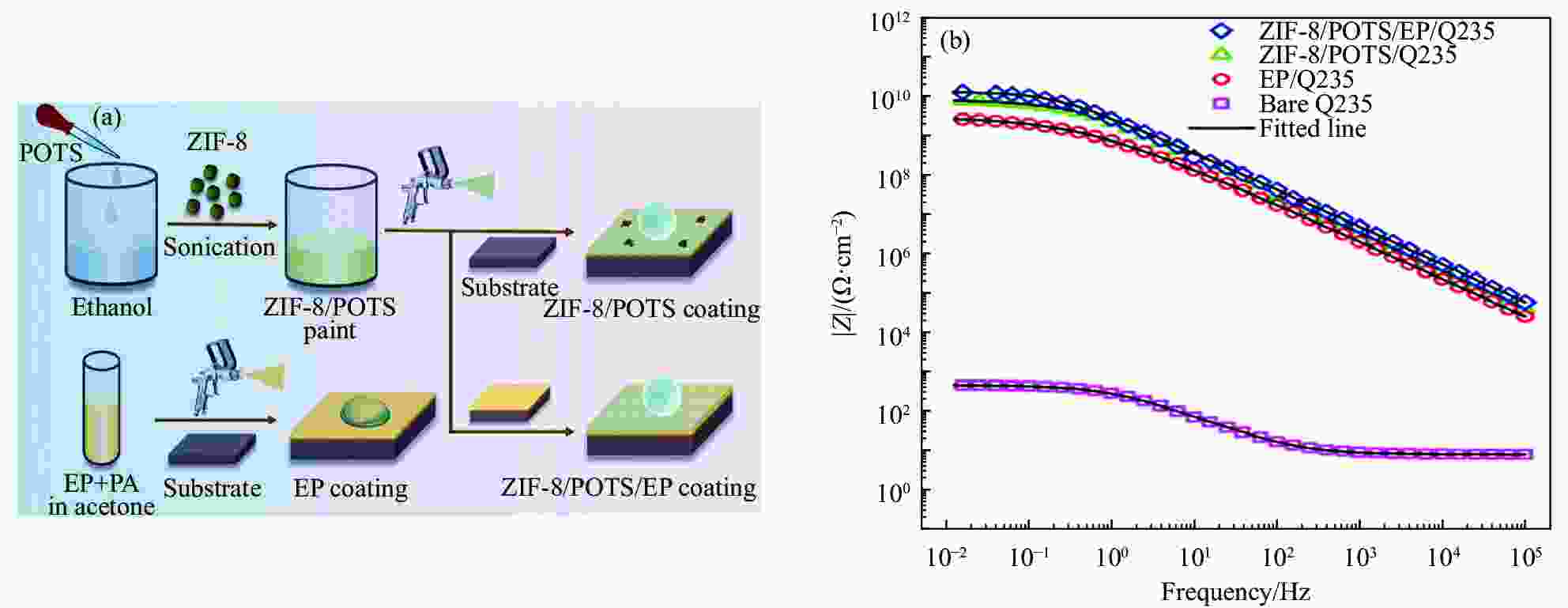

Research progress on coating application and mechanism based on MOF materials

-

摘要: 金属有机骨架(MOF)作为一种新型多孔晶体材料,因其具有高孔隙率、结构多样、化学结构可控等特点可被作为纳米粒子和载体使用。基于MOF材料的涂层可兼具MOF本身的优点,但基于MOF材料的涂层应用和机制研究的综述性论文不多。本文针对基于MOF材料的涂层国内外研究现状进行了介绍,重点阐述了基于MOF材料的涂层防/除冰应用(超疏水表面和光滑液体注入多孔表面(SLIPS))、防腐应用(MOF材料作为纳米粒子和载体)和抗菌应用(基于金属离子释放、基于光动力(PDT)和基于光热(PTT)),并归纳出不同涂层的防/除冰机制(降低水的凝固温度和减少冰的黏附)、防腐机制(直接物理阻隔或生成化合物而达到阻隔效果)和抗菌机制(对真核细胞具有弱毒性的金属离子达到抗菌效果、活性氧(ROS)在光照射下激活达到抑菌效果和通过吸收外界光产生热量,随温度升高而达到抗菌效果)。并对基于MOF材料的涂层面临的关键挑战、潜在应用和发展前景进行了展望。Abstract: Metal-organic framework (MOF), as a new type of porous crystal material, can be used as nanoparticle and carrier because of its high porosity, diverse structure and controllable chemical structure. Functional coatings prepared based on MOF materials can combine the advantages of MOF and have a wide range of applications, but there are not many papers on the application and mechanism of coatings based on MOF materials. The research status of MOF-based coatings at home and abroad was introduced, focusing on the anti-icing/de-icing applications of MOF-based coatings (superhydrophobic surfaces and smooth liquid-injected porous surfaces (SLIPS)), anti-corrosion applications (MOF materials as nanoparticles and carriers) and antibacterial applications (based on metal ion release, photodynamic therapy (PDT) and photothermal therapy (PTT)), and the anti-icing mechanisms of different coatings (reducing the solidification temperature of water and reducing ice adhesion) were summarized. Antiseptic mechanism (direct physical barrier or formation of compounds to achieve the barrier effect) and antibacterial mechanism (metal ions with weak toxicity to eukaryotic cells achieve antibacterial effect, reactive oxygen species (ROS) are activated under light irradiation to achieve antibacterial effect, and heat is generated by absorbing external light, and antibacterial effect is achieved with increasing temperature). The key challenges, potential applications and development prospects of MOF-based coatings are prospected.

-

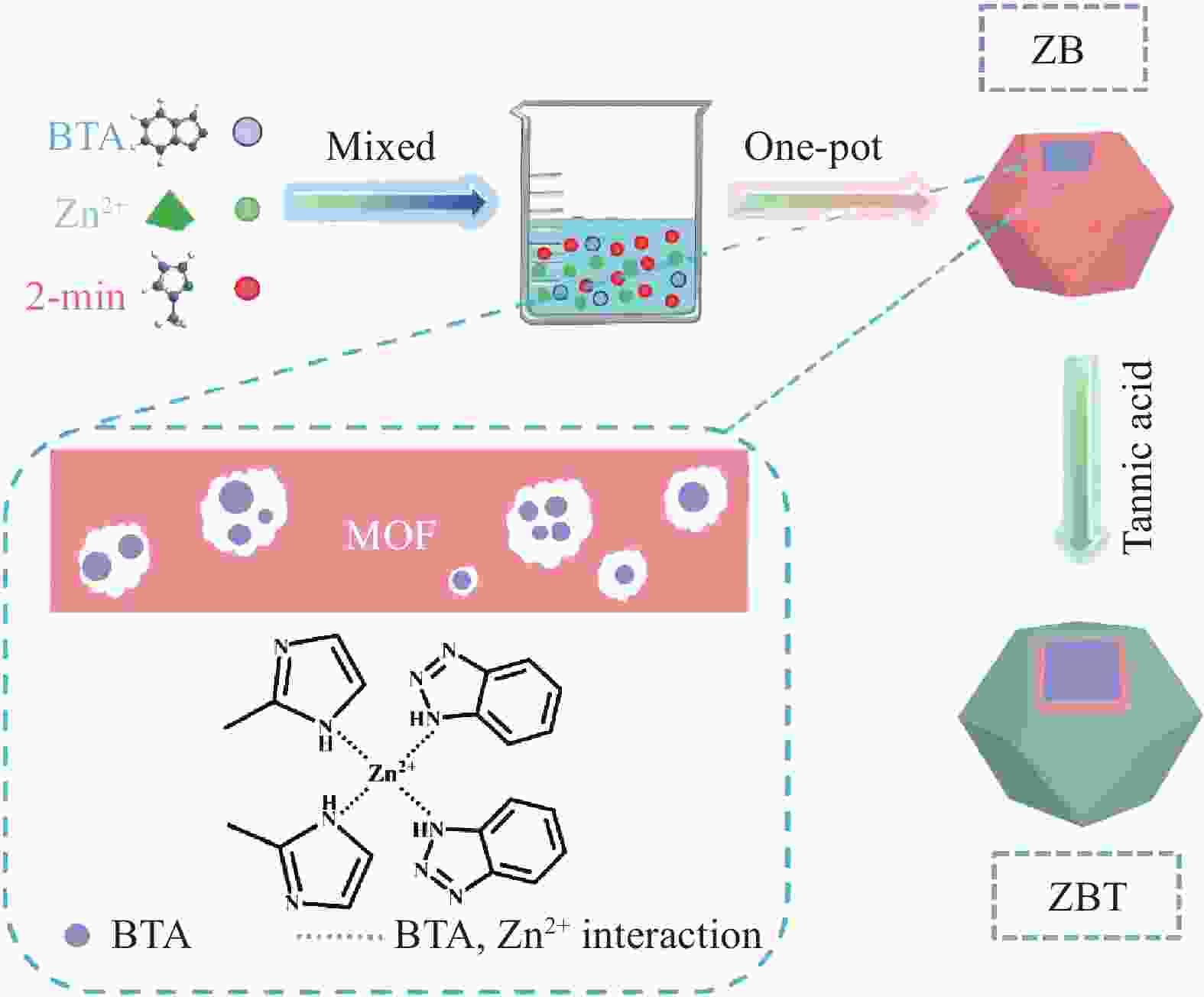

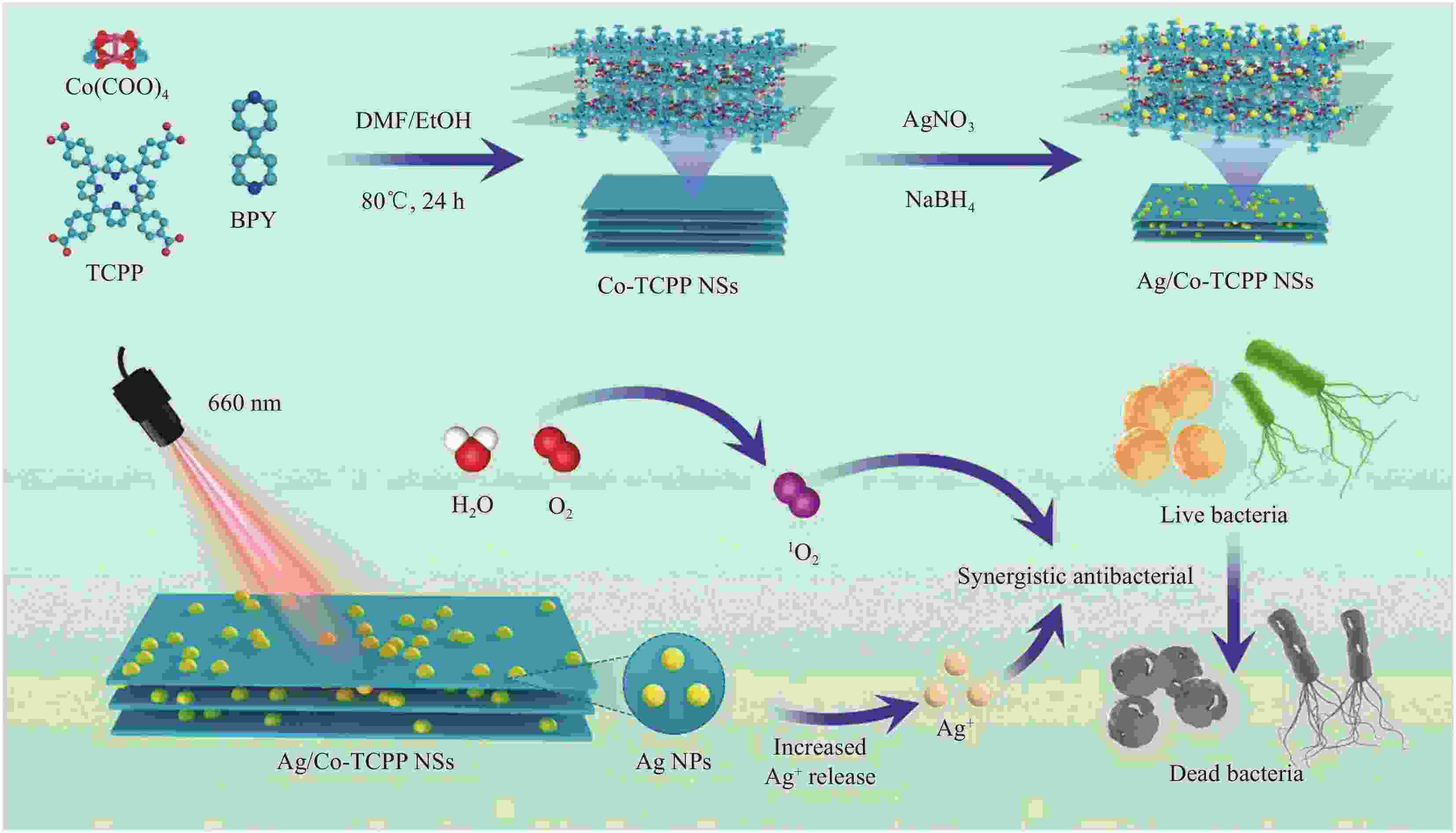

图 1 (a)超疏水复合涂层制备过程;(b)不同基体的阻抗模量|Z|与频率关系的Bode图[19]

POTS—1H, 1H, 2H, 2H-perfluoroalkyltriethoxysilanes; EP—Epoxy epoxide; PA—Polyamide; ZIF—Zeolitic imidazolate framework

Figure 1. (a) Superhydrophobic composite coating preparation process; (b) Bode plots of different matrix's relationship between impedance modulus |Z| and frequency[19]

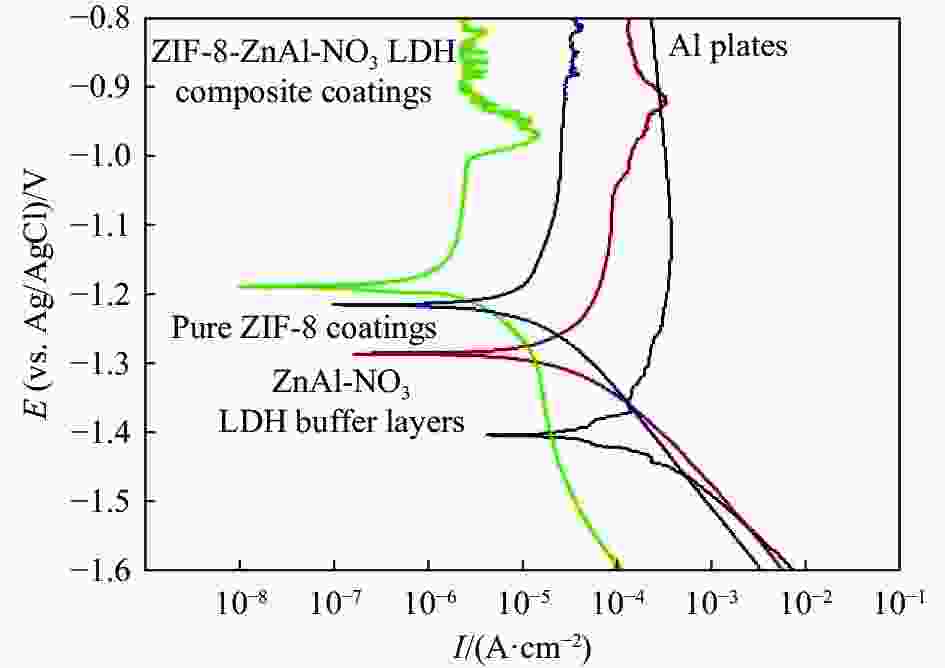

图 6 裸Al板、原位水热生长制备的ZnAl-NO3层状双氢氧化合物(LDH)缓冲层、纯ZIF-8涂层和ZIF-8-ZnAl-NO3 LDH复合涂层的DC极化曲线[48]

E—Electrode potential; I—Current density

Figure 6. DC polarization curves for bare Al plates, ZnAl-NO3 layered double hydroxides (LDH) buffer layers prepared by in situ hydrothermal growth , pure ZIF-8 coatings and ZIF-8-ZnAl-NO3 LDH composite coatings[48]

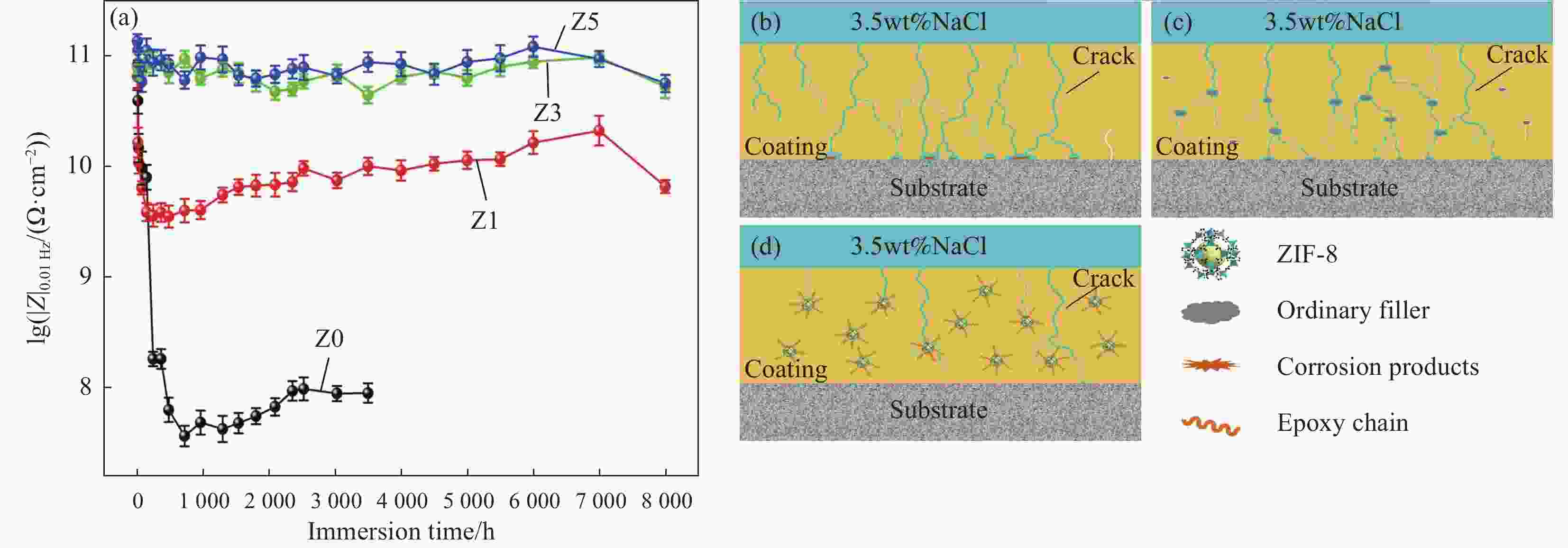

图 9 (a)不同涂层在3.5wt%NaCl溶液中的|Z|0.01 Hz的值;不同涂层的防腐机制:(b) EP涂层;(c)普通填料涂层;(d) ZIF-8涂层[54]

Z0, Z1, Z3, Z5—Mass fraction of ZIF-8 in epoxy resin is 0wt%, 1wt%, 3wt%, 5wt%

Figure 9. (a) |Z|0.01 Hz value of different coatings in 3.5wt%NaCl solution; Anti-corrosion mechanism of different coatings: (b) EP coating; (c) Ordinary filler coating; (d) ZIF-8 coating[54]

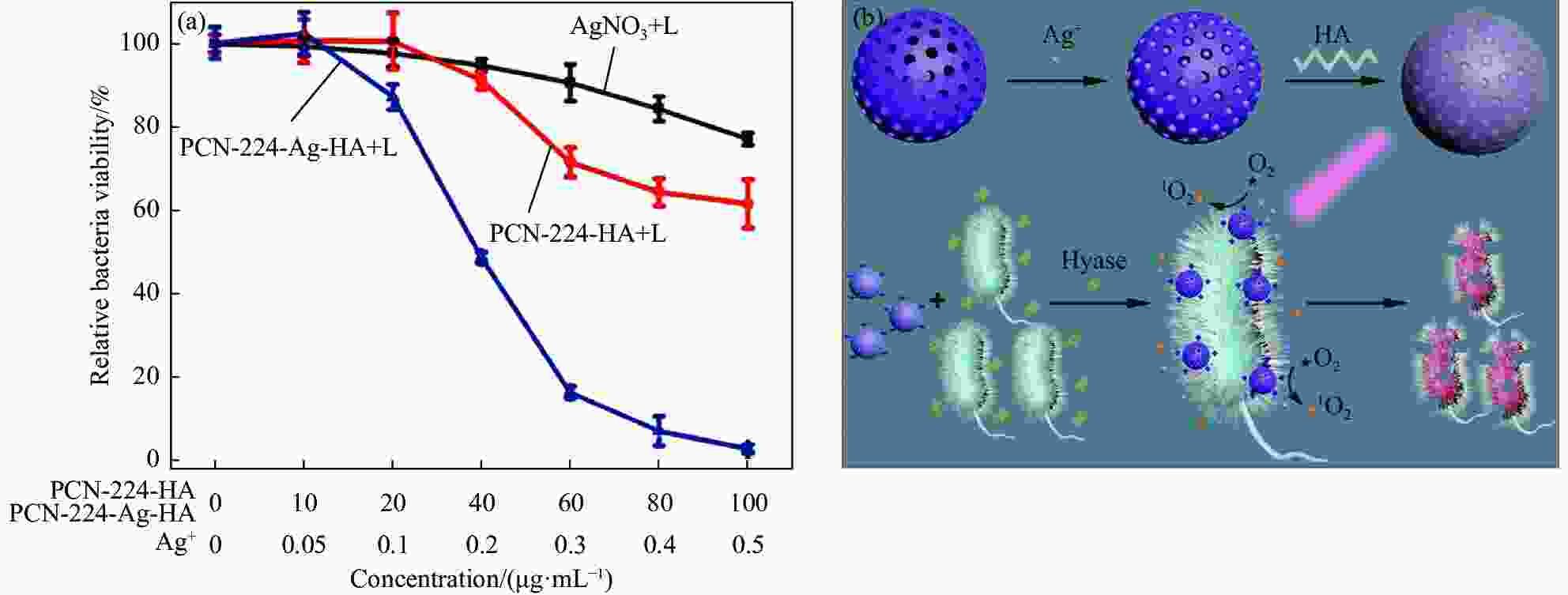

图 17 (a)不同浓度AgNO3、PCN-224-透明质酸(HA)和PCN-224-Ag-HA在光照射下MRSA菌株的存活率;(b) PCN-224-Ag-HA纳米剂的制备及其抗菌机制示意图[81]

L—Light; PCN—Porous coordination network

Figure 17. (a) Survival rates of MRSA strain at different concentrations of AgNO3, PCN-224-hyaluronic acid (HA) and PCN-224-Ag-HA under light irradiation; (b) Preparation of PCN-224-Ag-HA nanoagen and schematic diagram of antibacterial mechanism[81]

-

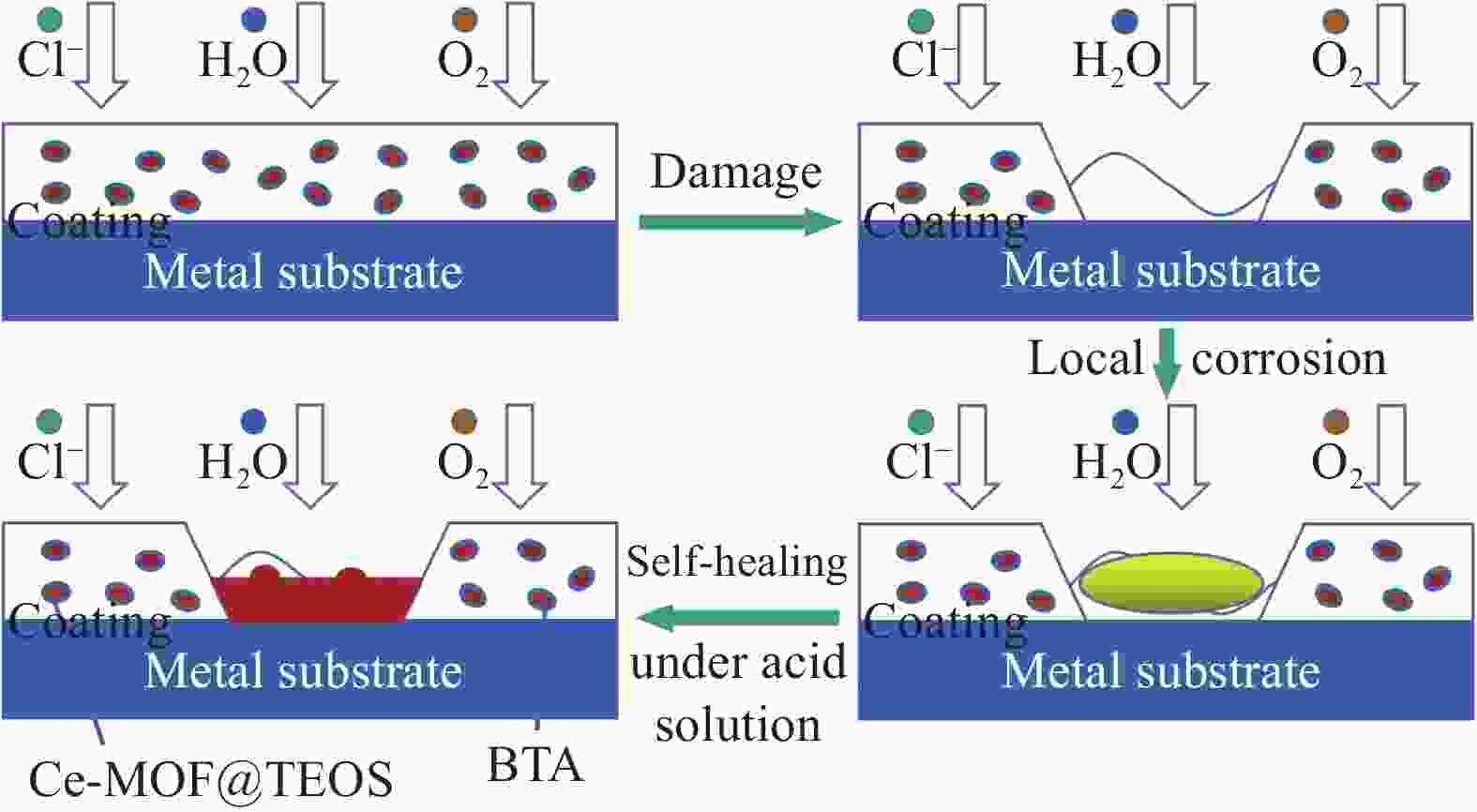

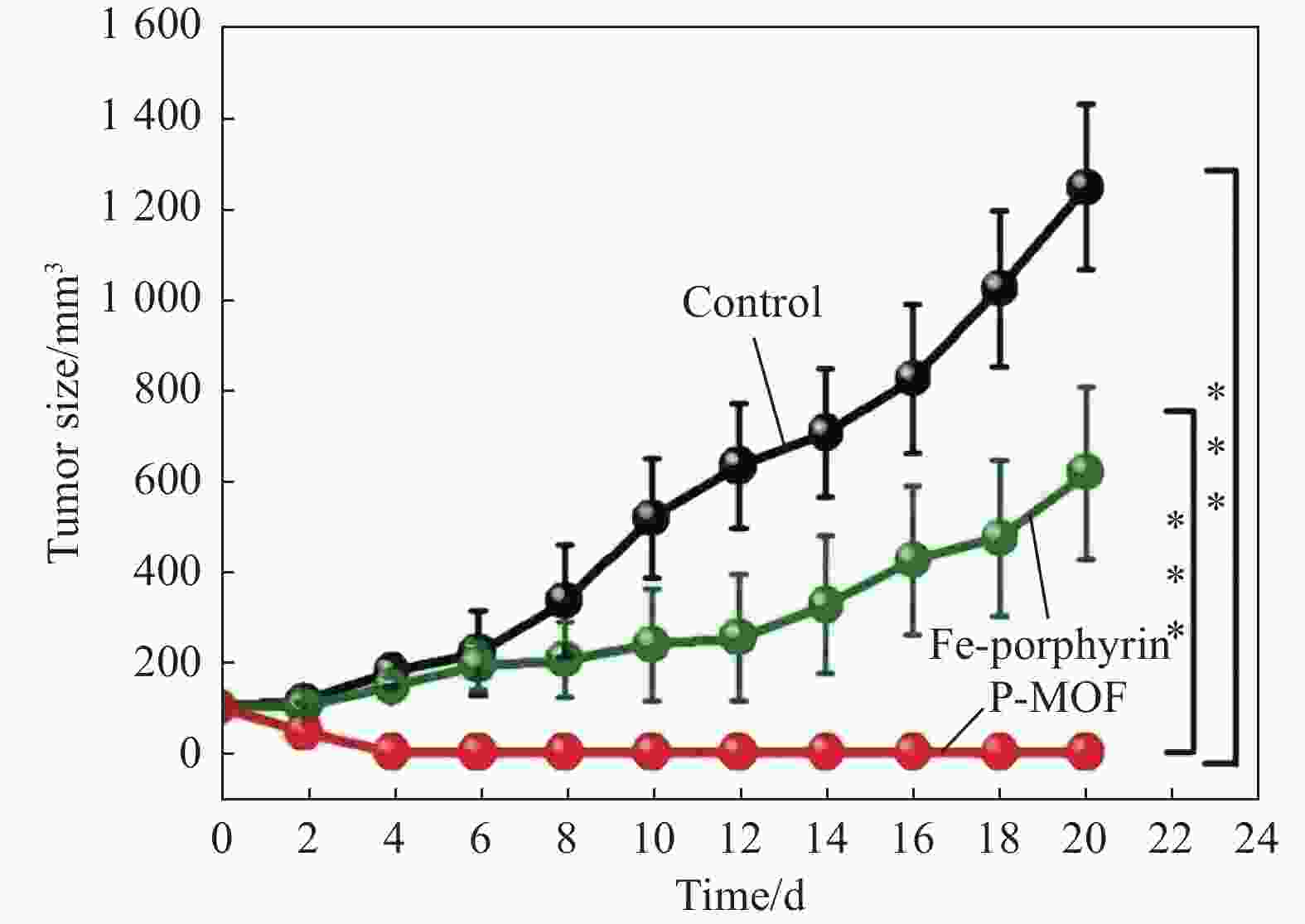

[1] JIANG C, CAO Y, XIAO G, et al. A review on the application of inorganic nanoparticles in chemical surface coatings on metallic substrates[J]. RSC Advances,2017,7(13):7531-7539. doi: 10.1039/C6RA25841G [2] WANG S, MCGUIRK C M, D'AQUINO A, et al. Metal-organic framework nanoparticles[J]. Advanced Materials,2018,30(37):1800202. doi: 10.1002/adma.201800202 [3] PRAVEEN B M, VENKATESHA T V, NAIK Y A, et al. Corrosion studies of carbon nanotubes-Zn composite coating[J]. Surface and Coatings Technology,2007,201(12):5836-5842. doi: 10.1016/j.surfcoat.2006.10.034 [4] DING R, LI W, WANG X, et al. A brief review of corrosion protective films and coatings based on graphene and graphene oxide[J]. Journal of Alloys and Compounds,2018,764:1039-1055. doi: 10.1016/j.jallcom.2018.06.133 [5] MATIN E, ATTAR M M, RAMEZANZADEH B. Investigation of corrosion protection properties of an epoxy nanocomposite loaded with polysiloxane surface modified nanosilica particles on the steel substrate[J]. Progress in Organic Coatings,2015,78:395-403. doi: 10.1016/j.porgcoat.2014.07.004 [6] CAI G, YAN P, ZHANG L, et al. Metal-organic framework-based hierarchically porous materials: Synthesis and applications[J]. Chemical Reviews,2021,121(20):12278-12326. doi: 10.1021/acs.chemrev.1c00243 [7] KITAGAWA S. Metal-organic frameworks (MOFs)[J]. Chemical Society Reviews,2014,43(16):5415-5418. doi: 10.1039/C4CS90059F [8] FARHA O K, ERYAZICI I, JEONG N C, et al. Metal-organic framework materials with ultrahigh surface areas: Is the sky the limit?[J]. Journal of the American Chemical Society,2012,134(36):15016-15021. doi: 10.1021/ja3055639 [9] CAO K, YU Z, YIN D, et al. Fabrication of BTA-MOF-TEOS-GO nanocomposite to endow coating systems with active inhibition and durable anticorrosion performances[J]. Progress in Organic Coatings,2020,143:105629. doi: 10.1016/j.porgcoat.2020.105629 [10] MENG J, LIU X, NIU C, et al. Advances in metal-organic framework coatings: Versatile synthesis and broad applications[J]. Chemical Society Reviews,2020,49(10):3142-3186. doi: 10.1039/C9CS00806C [11] SEIDI F, JOUYANDEH M, TAGHIZADEH M, et al. Metal-organic framework (MOF)/epoxy coatings: A review[J]. Materials,2020,13(12):2881. doi: 10.3390/ma13122881 [12] HOSKINS B F, ROBSON R. Infinite polymeric frameworks consisting of three dimensionally linked rod-like segments[J]. Journal of the American Chemical Society,1989,111(15):5962-5964. doi: 10.1021/ja00197a079 [13] FUJITA M, KWON Y J, WASHIZU S, et al. Preparation, clathrationability, and catalysis of a two-dimensional square network material composed of cadmium (II) and 4, 4'-bipyridine[J]. Journal of the American Chemical Society,1994,116(3):1151-1152. doi: 10.1021/ja00082a055 [14] KONDO M, YOSHITOMI T, MATSUZAKA H, et al. Three-dimensional framework with channeling cavities for small molecules: {[M2(4, 4′-bpy)3(NO3)4]·xH2O}n(M=Co, Ni, Zn)[J]. Angewandte Chemie International Edition in English,1997,36(16):1725-1727. doi: 10.1002/anie.199717251 [15] ROSI N L, ECKERT J, EDDAOUDI M, et al. Hydrogen storage in microporous metal-organic frameworks[J]. Science, 2003, 300(5622) : 1127-1129. [16] KUPPLER R J, TIMMONS D J, FANG Q R, et al. Potential applications of metal-organic frame works[J]. Coordination Chemistry Reviews,2009,253(23-24):3042-3066. doi: 10.1016/j.ccr.2009.05.019 [17] WANG Z, COHEN S M. Postsynthetic covalent modification of a neutral metal-organic framework[J]. Journal of the American Chemical Society,2007,129(41):12368-12369. doi: 10.1021/ja074366o [18] LIANG K, RICHARDSON J J, CUI J, et al. Metal-organic framework coatings as cytoprotective exoskeletons for living cells[J]. Advanced Materials,2016,28(36):7910-7914. doi: 10.1002/adma.201602335 [19] CHEN H, WANG F, FAN H, et al. Construction of MOF-based superhydrophobic composite coating with excellent abrasion resistance and durability for self-cleaning, corrosion resistance, anti-icing, and loading-increasing research[J]. Chemical Engineering Journal,2021,408:127343. doi: 10.1016/j.cej.2020.127343 [20] 裴震, 郭建栋, 张倩, 等. 金属-有机骨架抗菌复合材料与纤维的研究进展及应用[J]. 复合材料学报, 2021, 38(8):2396-2403. doi: 10.13801/j.cnki.fhclxb.20210507.001PEI Zhen, GUO Jiandong, ZHANG Qian, et al. Research progress and application of metal-organic frameworks antibacterial composite materials and fibers[J]. Acta Materiae Compositae Sinica,2021,38(8):2396-2403(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210507.001 [21] 陈芬, 杜春慧, 胡锦泰, 等. MOF原位生长改性聚对氯甲基苯乙烯-聚偏氟乙烯正渗透复合膜及其对乳化油废水的抗污染性[J]. 复合材料学报, 2023, 40(4):2075-2084. doi: 10.13801/j.cnki.fhclxb.20220606.002CHEN Fen, DU Chunhui, HU Jintai, et al. MOF in-situ growth modified poly(p-chloromethyl styrene)-polyvinylidene fluoride forward osmosis composite membrane and its anti-fouling performance for emulsified oil wastewater[J]. Acta Materiae Compositae Sinica,2023,40(4):2075-2084(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220606.002 [22] 陈柏瑜, 胡天丁, 陕绍云, 等. MOF基的光解水制氢催化剂研究进展[J]. 复合材料学报, 2022, 39(5):2073-2088. doi: 10.13801/j.cnki.fhclxb.20211011.001CHEN Boyu, HU Tianding, SHAN Shaoyun, et al. Research advances of MOF-based catalyst for photohydrolysis for hydrogen production[J]. Acta Materiae Compositae Sinica,2022,39(5):2073-2088(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211011.001 [23] LYU J, SONG Y, JIANG L, et al. Bio-inspired strategies for anti-icing[J]. ACS Nano,2014,8(4):3152-3169. doi: 10.1021/nn406522n [24] BROEREN A P, LEE S, CLARK C. Aerodynamic effects of anti-icing fluids on a thin high-performance wing section[J]. Journal of Aircraft,2016,53(2):451-462. doi: 10.2514/1.C033384 [25] FIKKE S M, KRISTJÁNSSON J E, KRINGLEBOTN NYGA ARD B E. Modern meteorology and atmospheric icing[J]. Atmospheric Icing of Power Networks, 2008: 1-29. [26] VAZIRINASAB E, JAFARI R, MOMEN G. Application of superhydrophobic coatings as a corrosion barrier: A review[J]. Surface and Coatings Technology,2018,341:40-56. doi: 10.1016/j.surfcoat.2017.11.053 [27] CAO L, JONES A K, SIKKA V K, et al. Anti- icing superhydrophobic coatings[J]. Langmuir,2009,25(21):12444-12448. doi: 10.1021/la902882b [28] NGUYEN-TRI P, TRAN H N, PLAMONDON C O, et al. Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: A review[J]. Progress in Organic Coatings,2019,132:235-256. doi: 10.1016/j.porgcoat.2019.03.042 [29] SIMPSON J T, HUNTER S R, AYTUG T. Superhydrophobic materials and coatings: A review[J]. Reports on Progress in Physics,2015,78(8):086501. doi: 10.1088/0034-4885/78/8/086501 [30] YE Y, LIU Z, LIU W, et al. Superhydrophobic oligoaniline-containing electroactive silica coating as pre-process coating for corrosion protection of carbon steel[J]. Chemical Engineering Journal,2018,348:940-951. doi: 10.1016/j.cej.2018.02.053 [31] ZHU G, SU J, YIN C, et al. Constructing a robust ZIF-7 based superhydrophobic coating with the excellent performance in self-cleaning, anti-icing, anti-biofouling and anti-corrosion[J]. Applied Surface Science,2023,622:156907. doi: 10.1016/j.apsusc.2023.156907 [32] ZHANG Y, GUO H, GAO J, et al. Self-lubricated anti-icing MOF coating with long-term durability[J]. Progress in Organic Coatings,2021,151:106089. [33] FANG X, LIU Y, LEI S. Slippery liquid-infused porous surface based on MOFs with excellent stability[J]. Chemical Physics Letters,2021,771:138470. doi: 10.1016/j.cplett.2021.138470 [34] YU Y, WEI Y, LI B, et al. Bioinspired metal-organic framework-based liquid-infused surface (MOF-LIS) with corrosion and biofouling prohibition properties[J]. Surfaces and Interfaces,2022,34:102363. [35] FANG X, LIU Y, LEI S, et al. Novel SLIPS based on the photo-thermal MOFs with enhanced anti-icing/de-icing properties[J]. RSC Advances,2022,12(22):13792-13796. [36] WU B, CUI X, JIANG H, et al. A superhydrophobic coating harvesting mechanical robustness, passive anti-icing and active de-icing performances[J]. Journal of Colloid and Interface Science,2021,590:301-310. doi: 10.1016/j.jcis.2021.01.054 [37] SINGH V, MEN X, TIWARI M K. Transparent and robust amphiphobic surfaces exploiting nanohierarchical surface-grown metal-organic frameworks[J]. Nano Letters, 2021, 21(8): 3480-3486. [38] LIN Y, CHEN H, WANG G, et al. Recent progress in preparation and anti-icing applications of superhydrophobic coatings[J]. Coatings,2018,8(6):208. doi: 10.3390/coatings8060208 [39] WU X J, LI Q X, HUANG J, et al. Theoretical study on the electron transport properties of single molecular bridge[J]. Acta Physico-Chimica Sinica,2004,20:995-1002. [40] HEYDARIAN S, JAFARI R, MOMEN G. Recent progress in the anti-icing performance of slippery liquid-infused surfaces[J]. Progress in Organic Coatings,2021,151:106096. doi: 10.1016/j.porgcoat.2020.106096 [41] GAO J, ZHANG Y, WEI W, et al. Liquid-infused micro-nanostructured MOF coatings (LIMNSMCs) with high anti-icing performance[J]. ACS Applied Materials & Interfaces,2019,11(50):47545-47552. [42] LONG Y, YIN X, MU P, et al. Slippery liquid-infused porous surface (SLIPS) with superior liquid repellency, anti-corrosion, anti-icing and intensified durability for protecting substrates[J]. Chemical Engineering Journal,2020,401:126137. doi: 10.1016/j.cej.2020.126137 [43] MA L, ZHANG Z, LIU Y, et al. An experimental study on the durability of icephobic slippery liquid-infused porous surfaces (SLIPS) pertinent to aircraft anti-/de-icing[C]. 2018 Atmospheric and Space Environments Conference. Atlanta. 2018: 3654. [44] ADIBZADEH E, MIRABEDINI S M, BEHZA DNASAB M, et al. A novel two-component self-healing coating comprising vinylester resin-filled microcapsules with prolonged anticorrosion performance[J]. Progress in Organic Coatings,2021,154:106220. doi: 10.1016/j.porgcoat.2021.106220 [45] MUSARURWA H, TAVENGWA N T. Smart metal-organic framework (MOF) composites and their applications in environmental remediation[J]. Materials Today Communications, 2022, 33: 104823. [46] SANCHEZ C, JULIÁN B, BELLEVILLE P, et al. Applications of hybrid organic-inorganic nanocomposites[J]. Journal of Materials Chemistry,2005,15(35-36):3559-3592. doi: 10.1039/b509097k [47] JIANG L, DONG Y, YUAN Y, et al. Recent advances of metal-organic frameworks in corrosion protection: From synthesis to applications[J]. Chemical Engineering Journal,2022,430:132823. doi: 10.1016/j.cej.2021.132823 [48] ZHANG M, LIU Y. Enhancing the anti-corrosion performance of ZIF-8-based coatings via microstructural optimization[J]. New Journal of Chemistry,2020,44(7):2941-2946. doi: 10.1039/C9NJ05998A [49] TARZANAGH Y J, SEIFZADEH D, RAJABA LIZADEH Z, et al. Sol-gel/MOF nanocomposite for effective protection of 2024 aluminum alloy against corrosion[J]. Surface and Coatings Technology,2019,380:125038. doi: 10.1016/j.surfcoat.2019.125038 [50] SHAHINI M H, TAHERI N, MOHAMMADLOO H E, et al. A comprehensive overview of nano and micro carriers aiming at curtailing corrosion progression[J]. Journal of the Taiwan Institute of Chemical Engineers,2021,126:252-269. doi: 10.1016/j.jtice.2021.06.053 [51] TIAN H, LI W, LIU A, et al. Controlled delivery of multi-substituted triazole by metal-organic framework for efficient inhibition of mild steel corrosion in neutral chloride solution[J]. Corrosion Science,2018,131:1-16. doi: 10.1016/j.corsci.2017.11.010 [52] ZHENG Q, LI J, YUAN W, et al. Metal-organic frameworks incorporated polycaprolactone film for enhanced corrosion resistance and biocompatibility of Mg alloy[J]. ACS Sustainable Chemistry & Engineering,2019,7(21):18114-18124. [53] YANG C, XU W, MENG X, et al. A pH-responsive hydrophilic controlled release system based on ZIF-8 for self-healing anticorrosion application[J]. Chemical Engineering Journal,2021,415:128985. doi: 10.1016/j.cej.2021.128985 [54] DUAN S, DOU B, LIN X, et al. Influence of active nanofiller ZIF-8 metal-organic framework (MOF) by microemulsion method on anticorrosion of epoxy coatings[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2021,624:126836. doi: 10.1016/j.colsurfa.2021.126836 [55] KESHMIRI N, NAJMI P, RAMEZANZADEH M, et al. Designing an eco-friendly lanthanide-based metal organic framework (MOF) assembled graphene-oxide with superior active anti-corrosion performance in epoxy composite[J]. Journal of Cleaner Production,2021,319:128732. doi: 10.1016/j.jclepro.2021.128732 [56] CAO J, GUO C, GUO X, et al. Inhibition behavior of synthesized ZIF-8 derivative for copper in sodium chloride solution[J]. Journal of Molecular Liquids,2020,311:113277. doi: 10.1016/j.molliq.2020.113277 [57] HE Z, LIN H, ZHANG X, et al. Self-healing epoxy compo-site coating based on polypyrrole@MOF nanoparticles for the long-efficiency corrosion protection on steels[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2023,657:130601. doi: 10.1016/j.colsurfa.2022.130601 [58] CAO K, YU Z, YIN D. Preparation of Ce-MOF@TEOS to enhance the anti-corrosion properties of epoxy coatings[J]. Progress in Organic Coatings,2019,135:613-621. doi: 10.1016/j.porgcoat.2019.06.015 [59] XIONG L, LIU J, YU M, et al. Improving the corrosion protection properties of PVB coating by using salicylaldehyde@ ZIF-8/graphene oxide two-dimensional nanocomposites[J]. Corrosion Science,2019,146:70-79. doi: 10.1016/j.corsci.2018.10.016 [60] MOHAMMADPOUR Z, ZARE H R. Fabricati on of a pH-sensitive epoxy nanocom posite coating based on a Zn-BTC metal-organic framework containing benzotriazole as a smart corrosion inhibitor[J]. Crystal Growth & Design,2021,21(7):3954-3966. [61] DEHGHANI A, SANAEI Z, FEDEL M, et al. Fabrication of an intelligent anti-corrosion silane film using a MoO42− loaded micro/mesoporous ZIF-67-MOF/multi-walled-CNT/APTES core-shell nano-container[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2023,656:130511. doi: 10.1016/j.colsurfa.2022.130511 [62] LIU Y, ZHOU L, DONG Y, et al. Recent developments on MOF-based platforms for antibacterial therapy[J]. RSC Medicinal Chemistry,2021,12(6):915-928. doi: 10.1039/D0MD00416B [63] SUN C Y, QIN C, WANG X L, et al. Metal-organic frameworks as potential drug delivery systems[J]. Expert Opinion on Drug Delivery,2013,10(1):89-101. doi: 10.1517/17425247.2013.741583 [64] SHEN M, FORGHANI F, KONG X, et al. Antibacterial applications of metal-organic frameworks and their compo-sites[J]. Comprehensive Reviews in Food Science and Food Safety,2020,19(4):1397-1419. doi: 10.1111/1541-4337.12515 [65] TAHERI M, ASHOK D, SEN T, et al. Stability of ZIF-8 nanopowders in bacterial culture media and its implication for antibacterial properties[J]. Chemical Engineering Journal,2021,413:127511. doi: 10.1016/j.cej.2020.127511 [66] AGUADO S, QUIRÓS J, CANIVET J, et al. Antimicrobial activity of cobalt imidazolate metal-organic frameworks[J]. Chemosphere, 2014, 113: 188-192. [67] CHAKRABORTY D, MUSIB D, SAHA R, et al. Highly stable tetradentate phosphonate-based green fluorescent Cu-MOF for anticancer therapy and antibacterial activity[J]. Materials Today Chemistry,2022,24:100882. doi: 10.1016/j.mtchem.2022.100882 [68] ARYANEJAD S, BAGHERZADE G, MOUDI M. Design and development of novel Co-MOF nanostructures as an excellent catalyst for alcohol oxidation and henry reaction, with a potential antibacterial activity[J]. Applied Organometallic Chemistry,2019,33(6):e4820. doi: 10.1002/aoc.4820 [69] HU X, ZHANG H, WANG Y, et al. Synergistic antibacterial strategy based on photodynamic therapy: Progress and perspectives[J]. Chemical Engineering Journal, 2022, 450(3): 138129. [70] PERNI S, PROKOPOVICH P, PRATTEN J, et al. Nanoparticles: Their potential use in antibacterial photodynamic therapy[J]. Photochemical & Photobiological Sciences,2011,10:712-720. [71] CHEN L J, LIU Y Y, ZHAO X, et al. Vancomycin-functionalized porphyrinic metal-organic framework PCN-224 with enhanced antibacterial activity against staphylococcus aureus[J]. Chemistry–An Asian Journal,2021,16(15):2022-2026. doi: 10.1002/asia.202100546 [72] LIU J, YANG Y, ZHU W, et al. Nanoscale metal-organic frameworks for combined photodynamic & radiation therapy in cancer treatment[J]. Biomaterials,2016,97:1-9. doi: 10.1016/j.biomaterials.2016.04.034 [73] LIANG Z, LI X, CHEN X, et al. Fe/MOF based platform for NIR laser induced efficient PDT/PTT of cancer[J]. Frontiers in Bioengineering and Biotechnology,2023,11:1156079. doi: 10.3389/fbioe.2023.1156079 [74] ZHONG Y, ZHENG X T, LI Q, et al. Antibody conjugated Au/Ir@Cu/Zn-MOF probe for bacterial lateral flow immunoassay and precise synergistic antibacterial treatment[J]. Biosensors and Bioelectronics,2023,224:115033. doi: 10.1016/j.bios.2022.115033 [75] JIANG W, ZHANG H, WU J, et al. CuS@MOF-based well-designed quercetin delivery system for chemo-photothermal therapy[J]. ACS Applied Materials & Interfaces, 2018, 10(40): 34513-34523. [76] WANG L, QU X, ZHAO Y, et al. Exploiting single atom iron centers in a porphyrin-like MOF for efficient cancer phototherapy[J]. ACS Applied Materials & Interfaces, 2019, 11(38): 35228-35237. [77] KIM D, PARK K W, PARK J T, et al. Photoactive MOF-derived bimetallic silver and cobalt nanocomposite with enhanced antibacterial activity[J]. ACS Applied Materials & Interfaces, 2023, 15(19): 22903-22914. [78] LI X, ZHAO X, CHU D, et al. Silver nanoparticle-decorated 2D Co-TCPP MOF nano sheets for synergistic photodynamic and silver ion antibacterial[J]. Surfaces and Interfaces,2022,33:102247. doi: 10.1016/j.surfin.2022.102247 [79] YOUGBARÉ S, MUTALIK C, OKORO G, et al. Emerging trends in nanomaterials for antibacterial applications[J]. International Journal of Nanomedicine,2021,16:5831. doi: 10.2147/IJN.S328767 [80] WU Y, DENG G, JIANG K, et al. Photothermally triggered nitric oxide nanogenerator targeting type IV pilifor precise therapy of bacterial infections[J]. Biomaterials,2021,268:120588. doi: 10.1016/j.biomaterials.2020.120588 [81] ZHANG Y, SUN P, ZHANG L, et al. Silver-infused porphyrinic metal-organic framework: Surface-adaptive, on-demand nanoplatform for synergistic bacteria killing and wound disinfection[J]. Advanced Functional Materials,2019,29(11):1808594. doi: 10.1002/adfm.201808594 [82] HUANG K, LI F, YUAN K, et al. A MOF-armored zinc-peroxide nanotheranostic platform for eradicating drug resistant bacteria via image-guided and in situ activated photodynamic therapy[J]. Applied Materials Today,2022,28:101513. doi: 10.1016/j.apmt.2022.101513 [83] CHEN M, LONG Z, DONG R, et al. Titanium Incorporation into Zr-porphyrinic metal-organic frameworks with enhanced antibacterial activity against multidrug-resistant pathogens[J]. Small,2020,16(7):1906240. doi: 10.1002/smll.201906240 [84] ZHOU C, PENG C, SHI C, et al. Mitochondria-specific aggregation-induced emission luminogens for selective photodynamic killing of fungi and efficacious treatment of keratitis[J]. ACS Nano,2021,15(7):12129-12139. doi: 10.1021/acsnano.1c03508 [85] BAI X, YANG Y, ZHENG W, et al. Synergistic photothermal antibacterial therapy enabled by multifunctional nanomaterials: Progress and perspectives[J]. Materials Chemistry Frontiers,2023,7:355-380. doi: 10.1039/D2QM01141G [86] YANG Y, DENG Y, HUANG J, et al. Size-transformable metal-organic framework-derived nanocarbons for localized chemo-photot hermal bacterial ablation and wound disinfection[J]. Advanced Functional Materials,2019,29(33):1900143. doi: 10.1002/adfm.201900143 [87] XIAO Y, XU M, LYU N, et al. Dual stimuli-responsive metal-organic framework-based nanosystem for synergistic photothermal/pharmacological antibacterial therapy[J]. Acta Biomaterialia,2021,122:291-305. doi: 10.1016/j.actbio.2020.12.045 [88] ZHAO X, HE X, HOU A, et al. Growth of Cu2O nanoparticles on two-dimensional Zr-ferrocene-metal-organic framework nanosheets for photothermally enhanced chemodynamic antibacterial therapy[J]. Inorganic Che-mistry,2022,61(24):9328-9338. doi: 10.1021/acs.inorgchem.2c01091 [89] YAO J, LIU Y, WANG J, et al. On-demand CO release for amplification of chemotherapy by MOF functionalized magnetic carbon nanoparticles with NIR irradiation[J]. Biomaterials,2019,195:51-62. doi: 10.1016/j.biomaterials.2018.12.029 [90] WANG Q, JI Y, SHI J, et al. NIR-driven water splitting H2 production nanoplatform for H2-mediated cascade-amplifying synergetic cancer therapy[J]. ACS Applied Materials & Interfaces,2020,12(21):23677-23688. [91] YOUGBARÉ S, MUTALIK C, KRISNAWATI D I, et al. Nanomaterials for the photothermal killing of bacteria[J]. Nanomaterials,2020,10(6):1123. doi: 10.3390/nano10061123 -

下载:

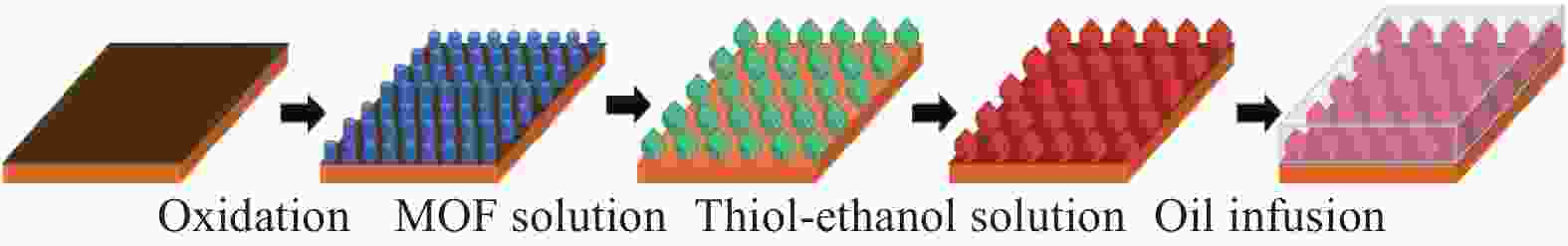

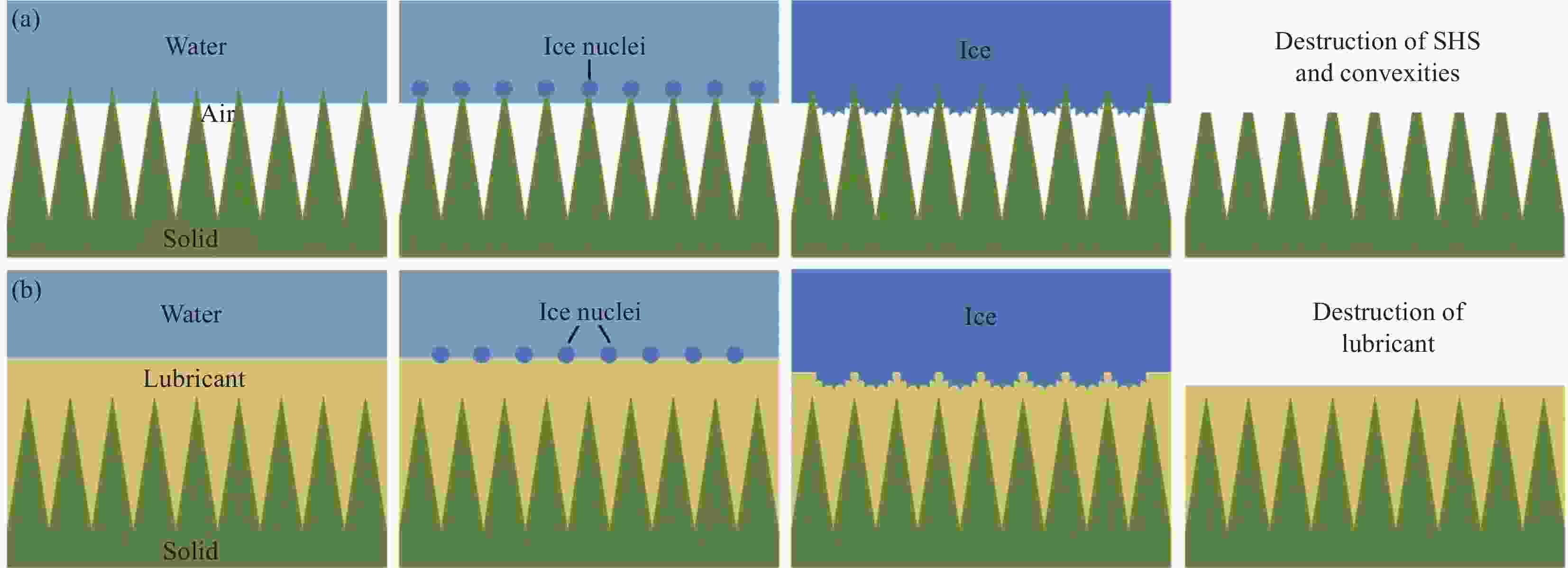

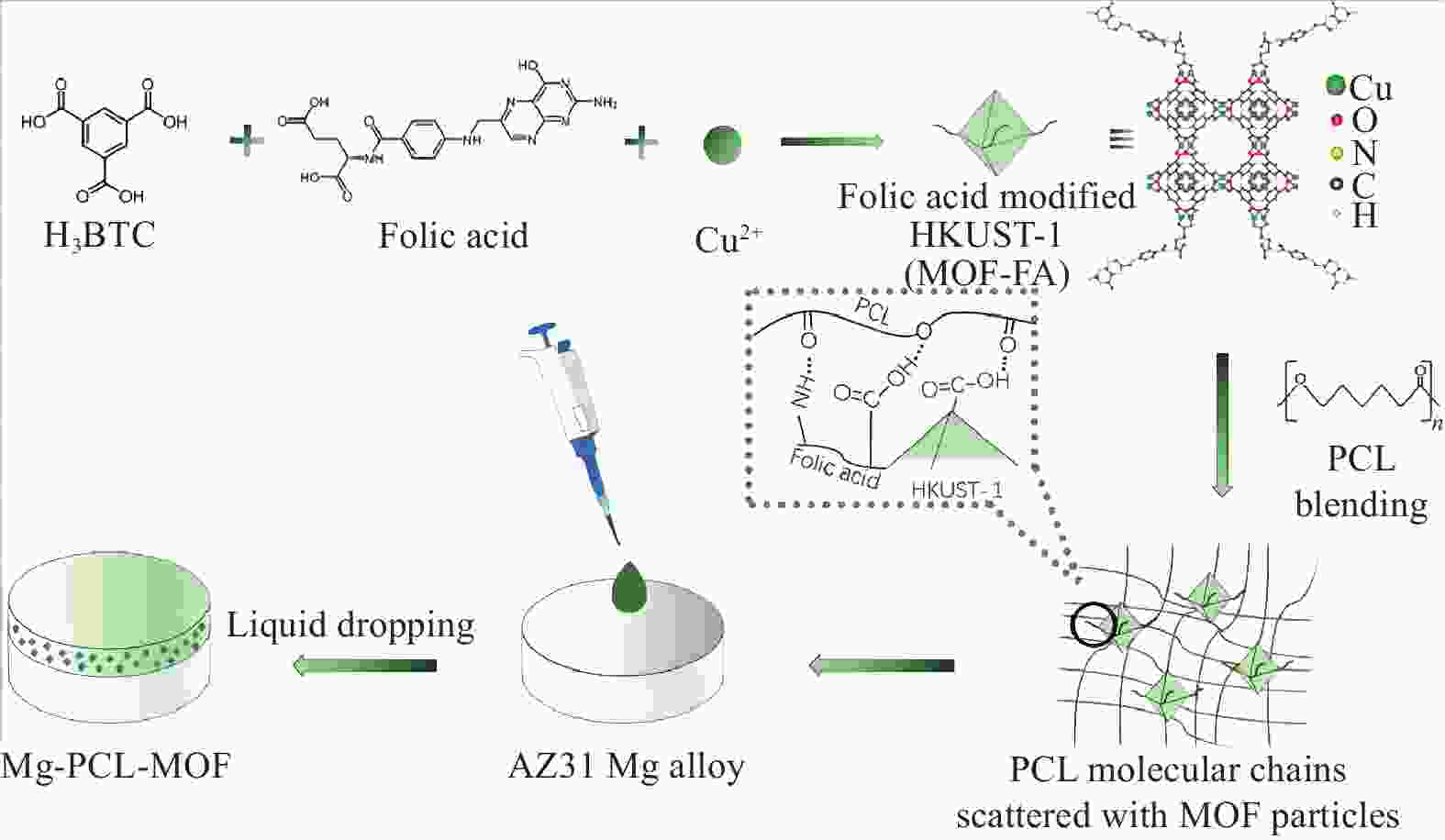

下载: