Evolution model of thermal expansion coefficient for 2D-C/SiC composites

-

摘要: 热膨胀系数是耐高温复合材料的重要热力学参数。针对复合材料在服役条件下存在基体开裂和界面脱粘而影响其热膨胀变形的现象,通过理论模拟和实验测试,研究了含损伤2D-C/SiC复合材料热膨胀系数随环境温度的演变行为。首先,基于Mini复合材料模型给出了组分材料的三维热失配应力计算模型;其次,引入基体开裂和界面脱粘损伤,并考虑组分材料热膨胀性能差异、纤维的横观各向同性以及泊松效应的影响,推导了Mini复合材料轴向和径向热膨胀系数的解析表达式;再次,基于[0/90]正交层压板模型和宏观应变的一致性假设,建立了2D-C/SiC复合材料含损伤表观热膨胀系数的分析预测模型;最后,将本模型与经典Schapery模型及实验值进行对比,分析了热膨胀系数的主要影响因素。参数分析表明:基体裂纹间距、界面脱粘率、孔隙率、组分材料的弹性模量及热膨胀系数等均会影响复合材料的表观热膨胀系数,其中基体膨胀系数的影响尤为显著;验证结果表明:本模型具有合理性与正确性,其预测值与经典模型及实验曲线均吻合良好。

-

关键词:

- 热膨胀系数 /

- Mini复合材料模型 /

- 2D-C/SiC /

- 热失配应力 /

- Schapery 模型

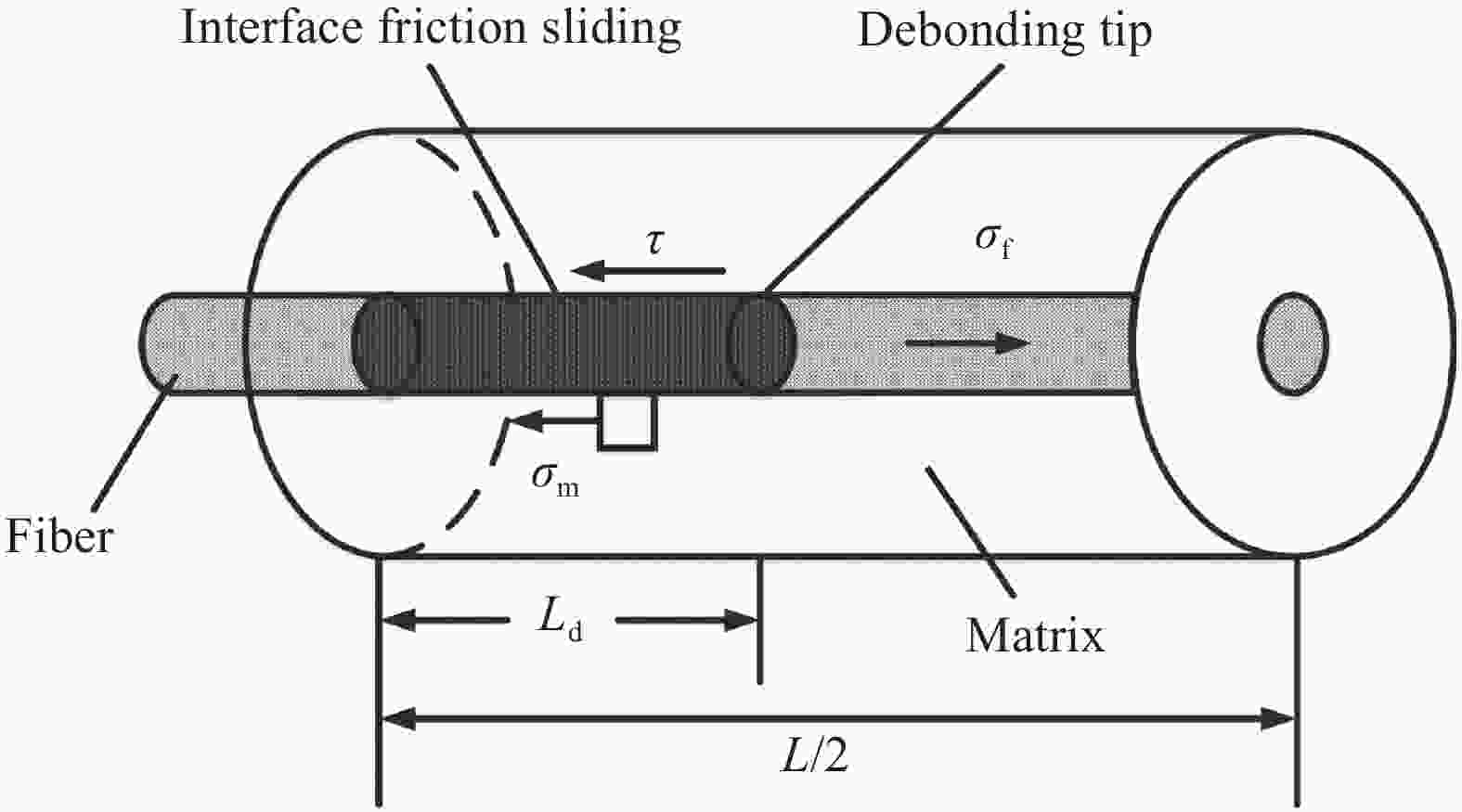

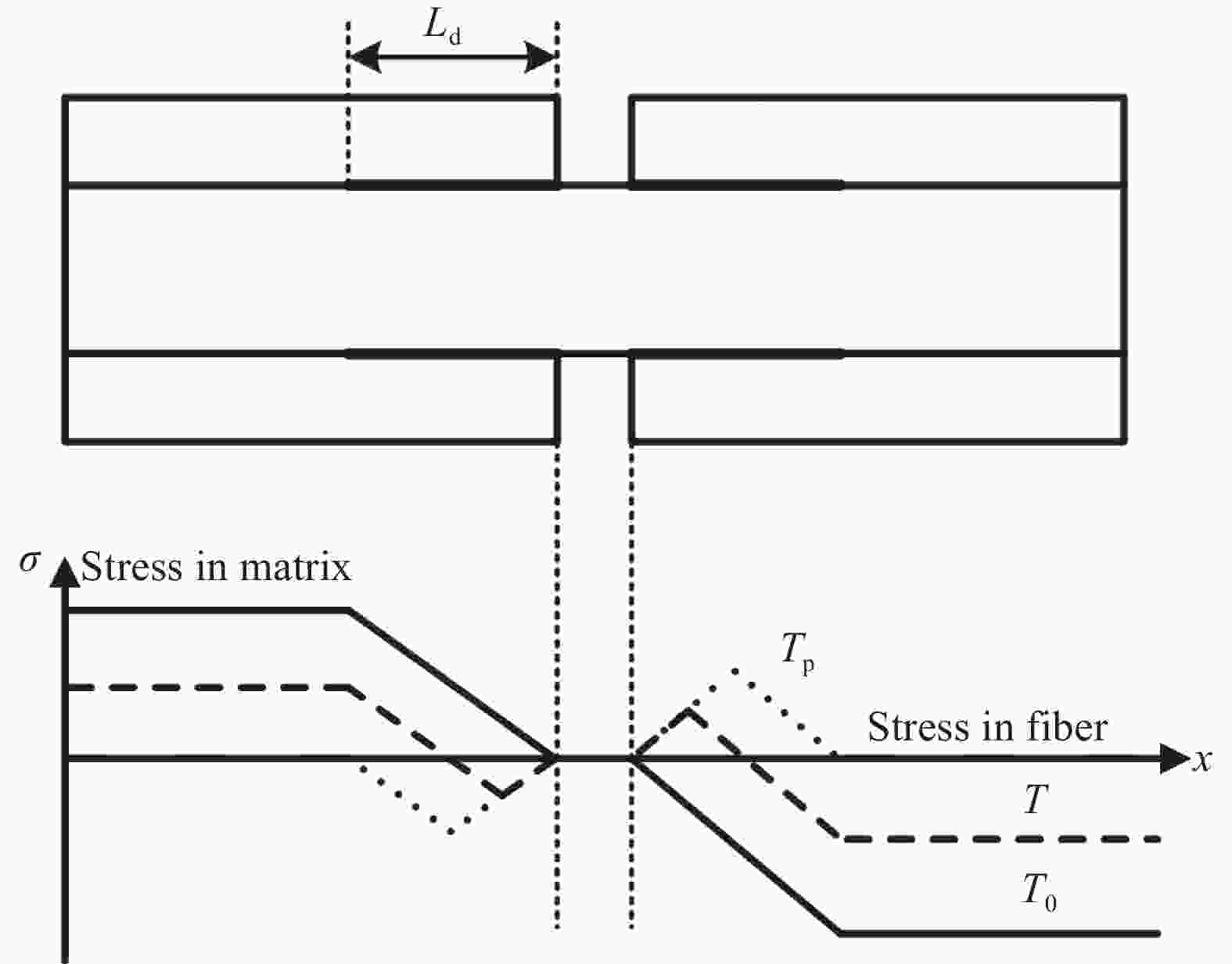

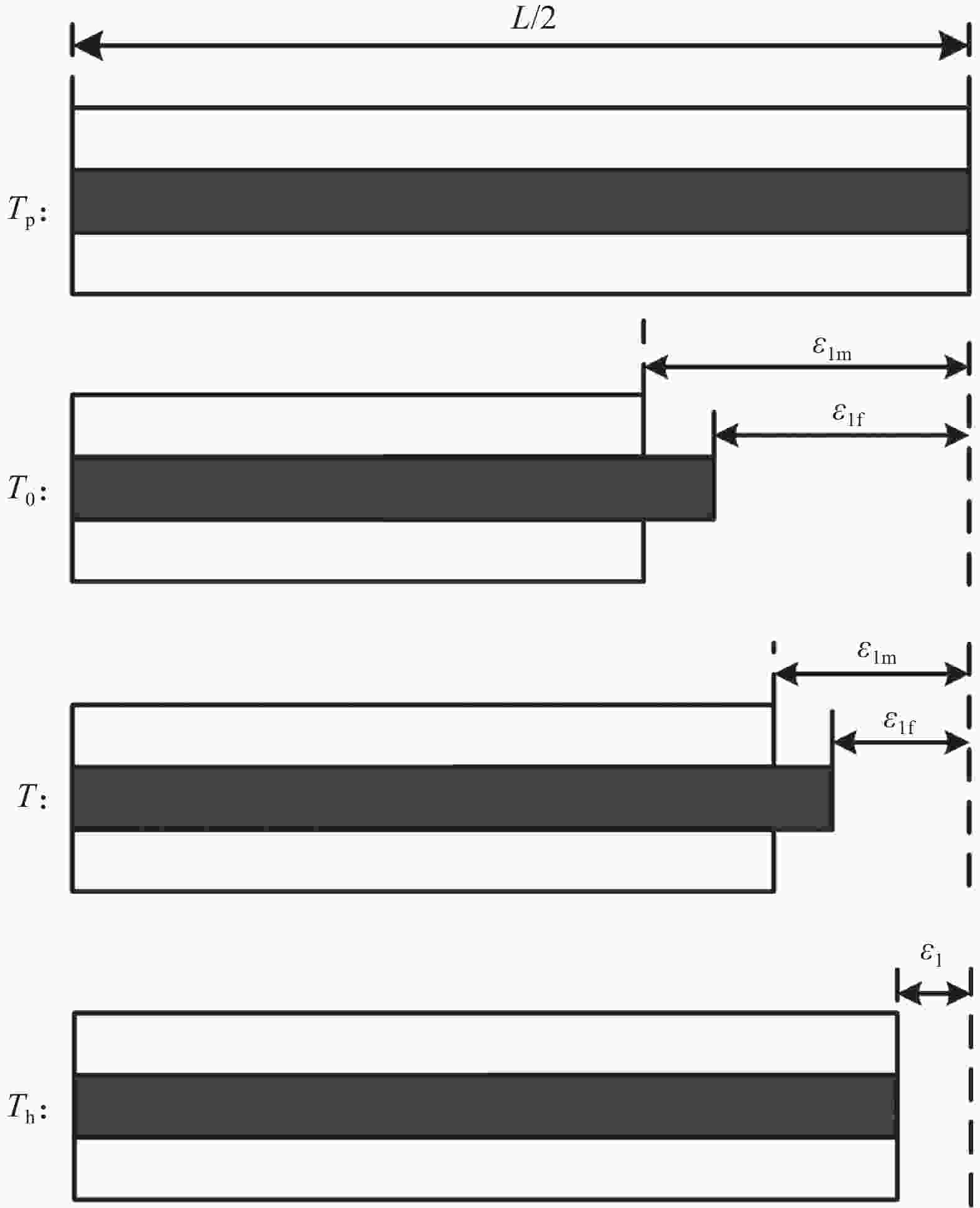

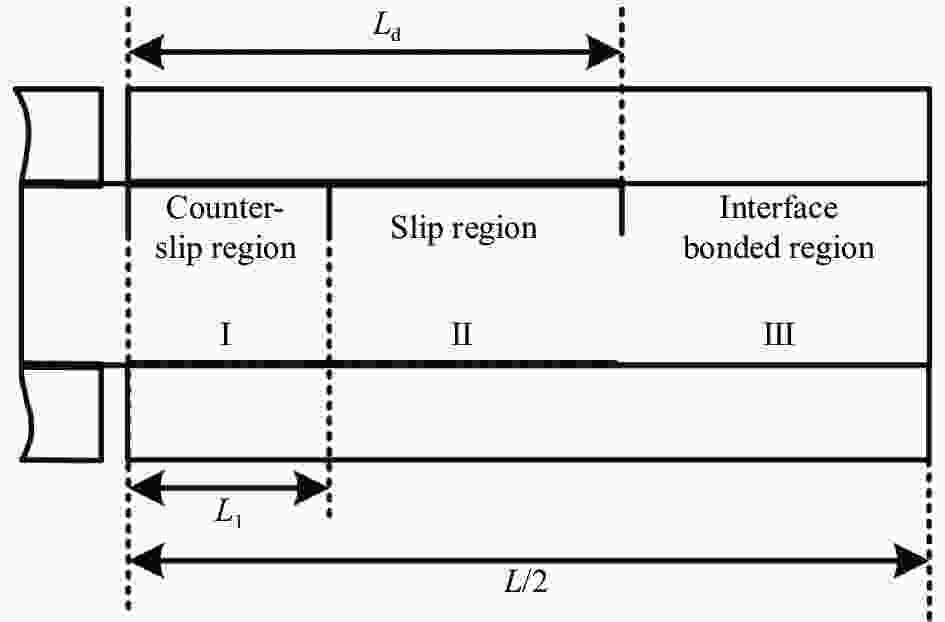

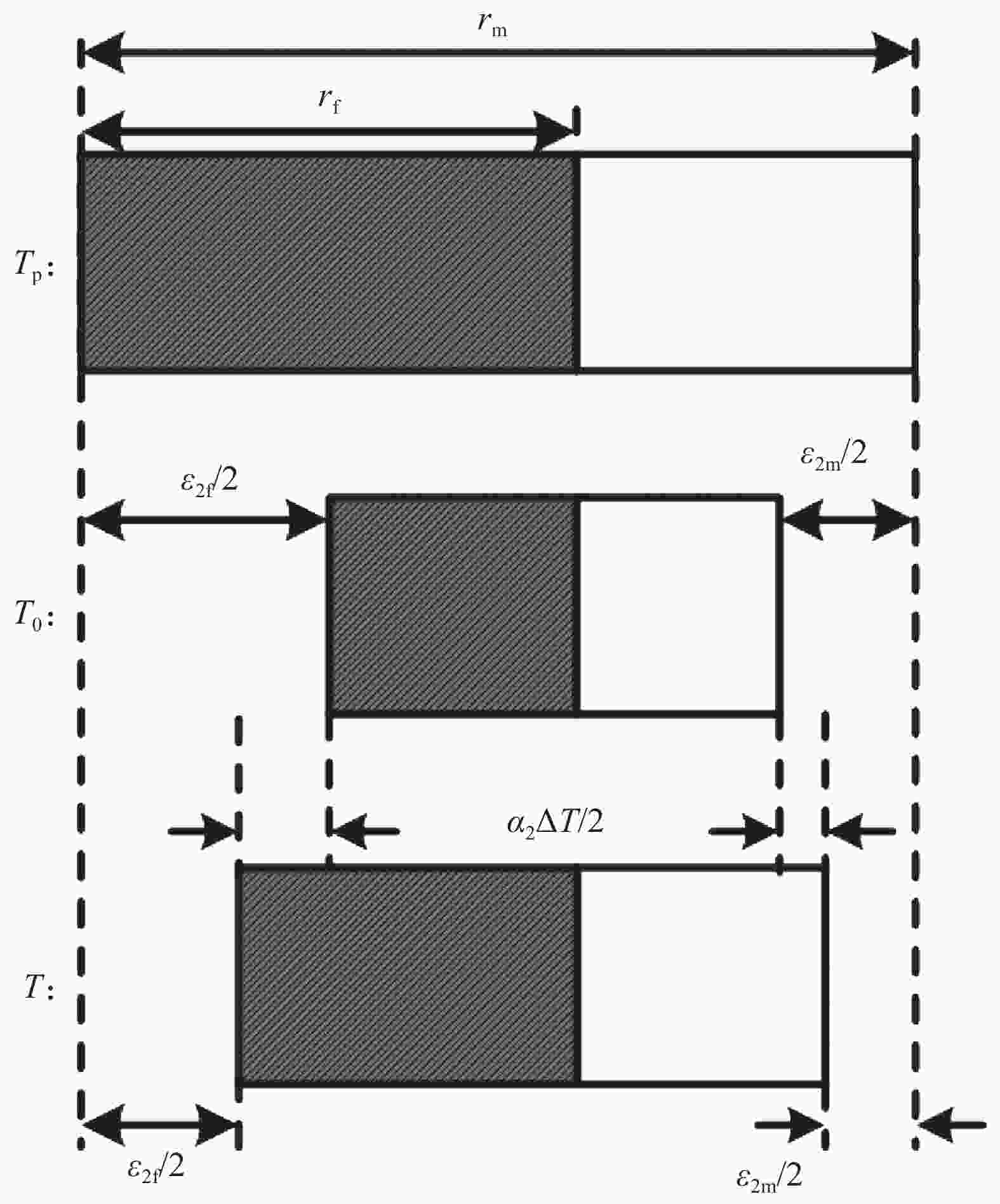

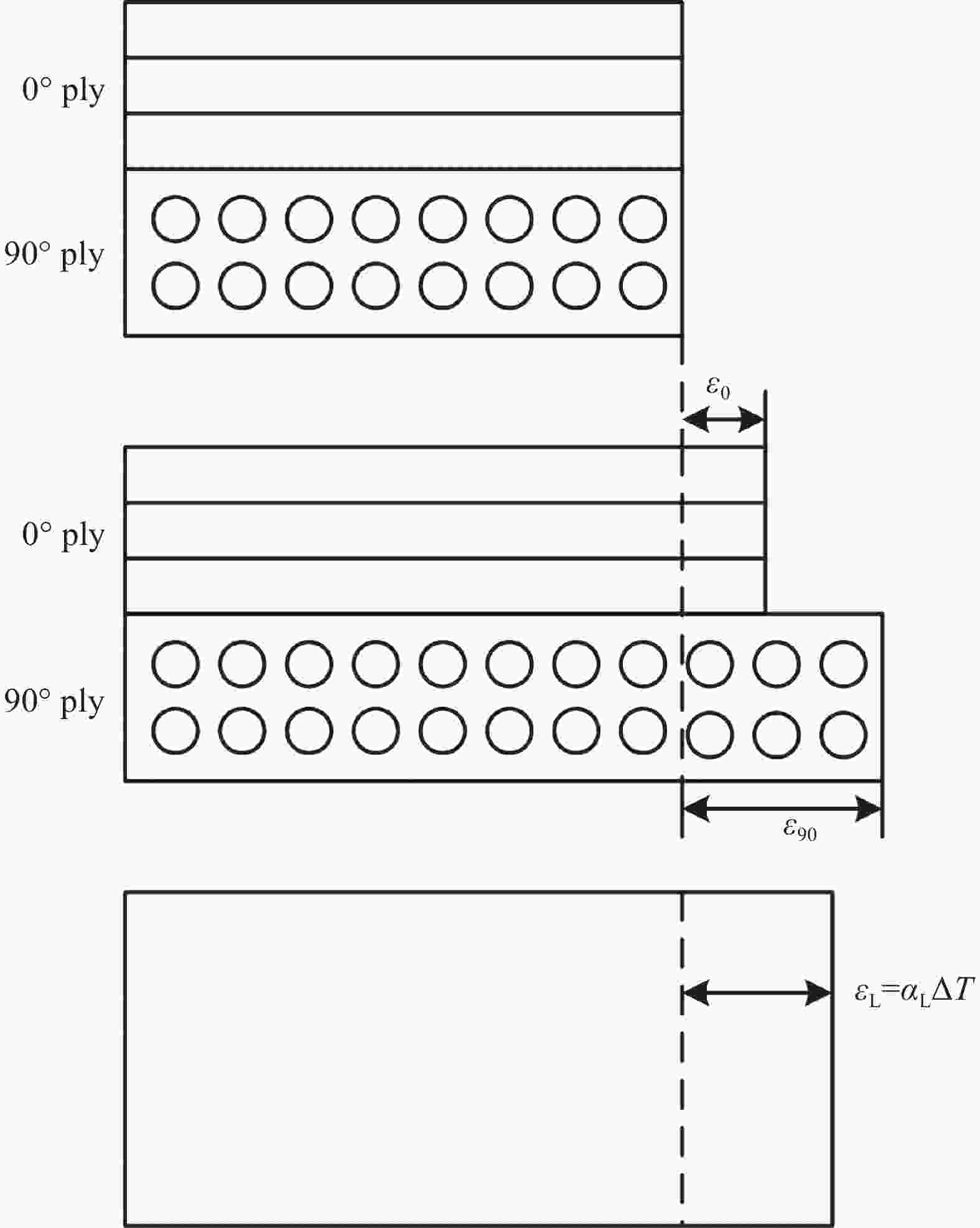

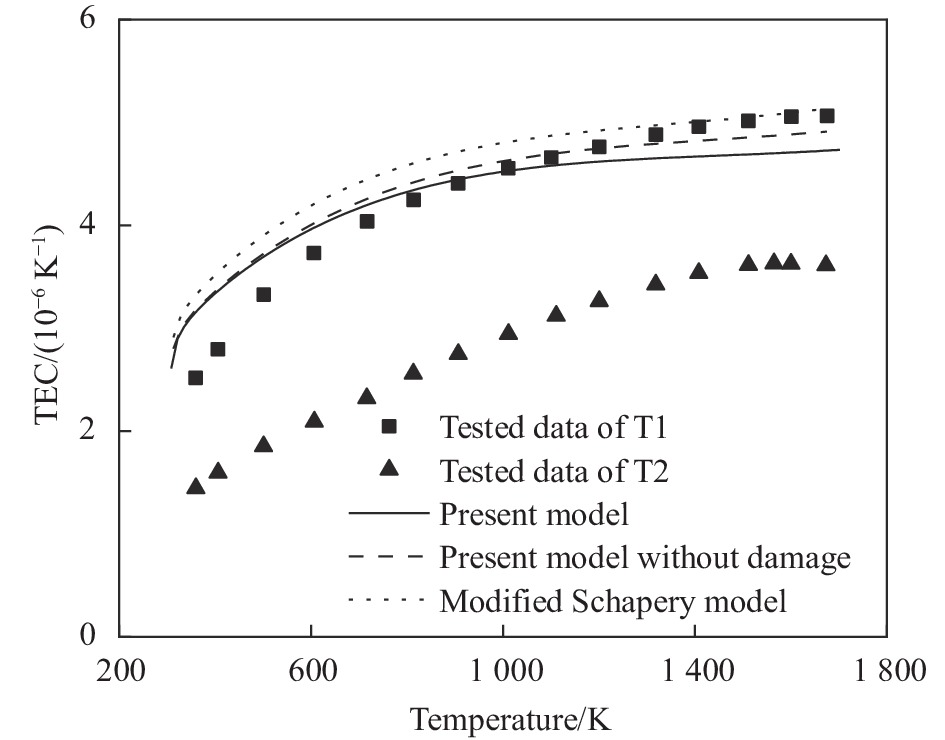

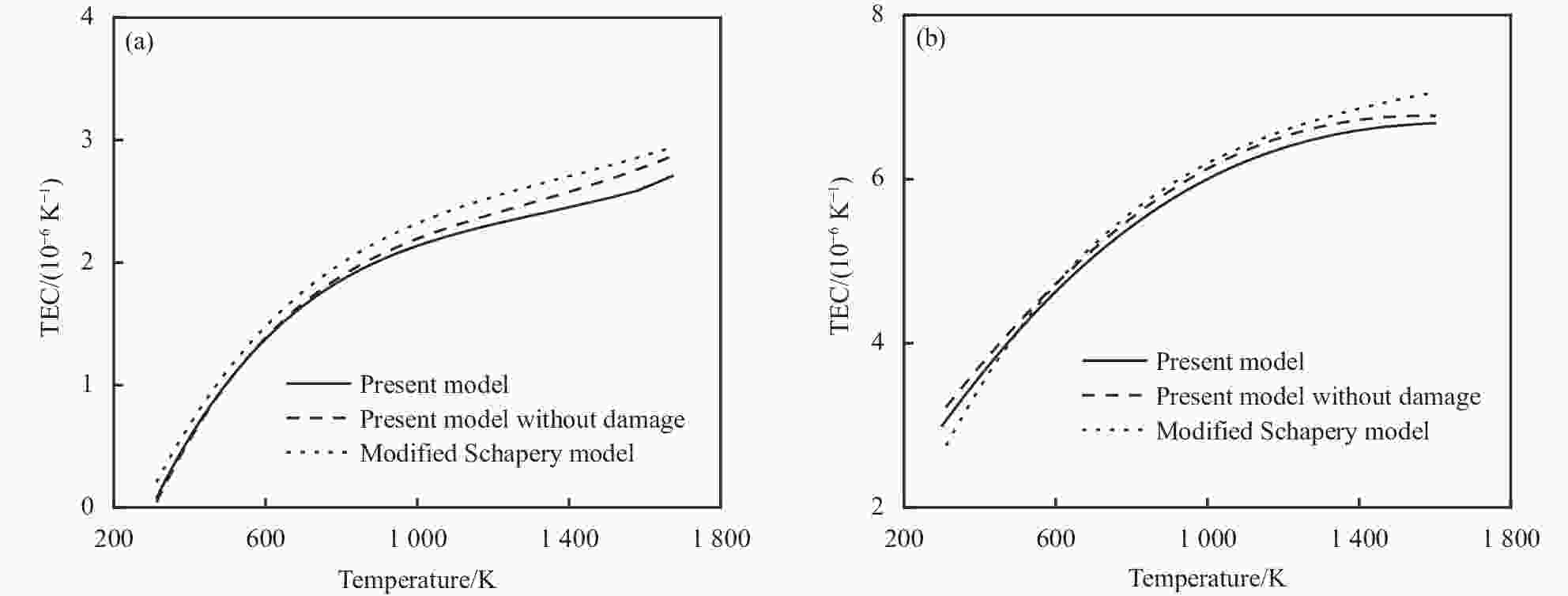

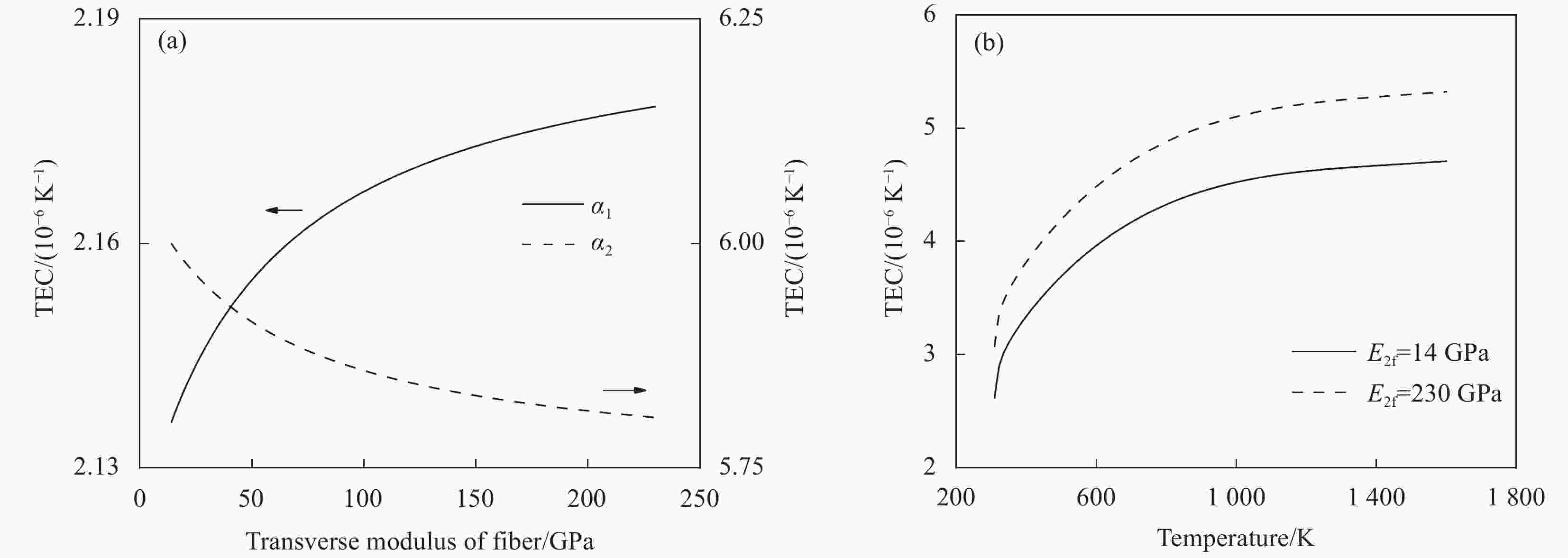

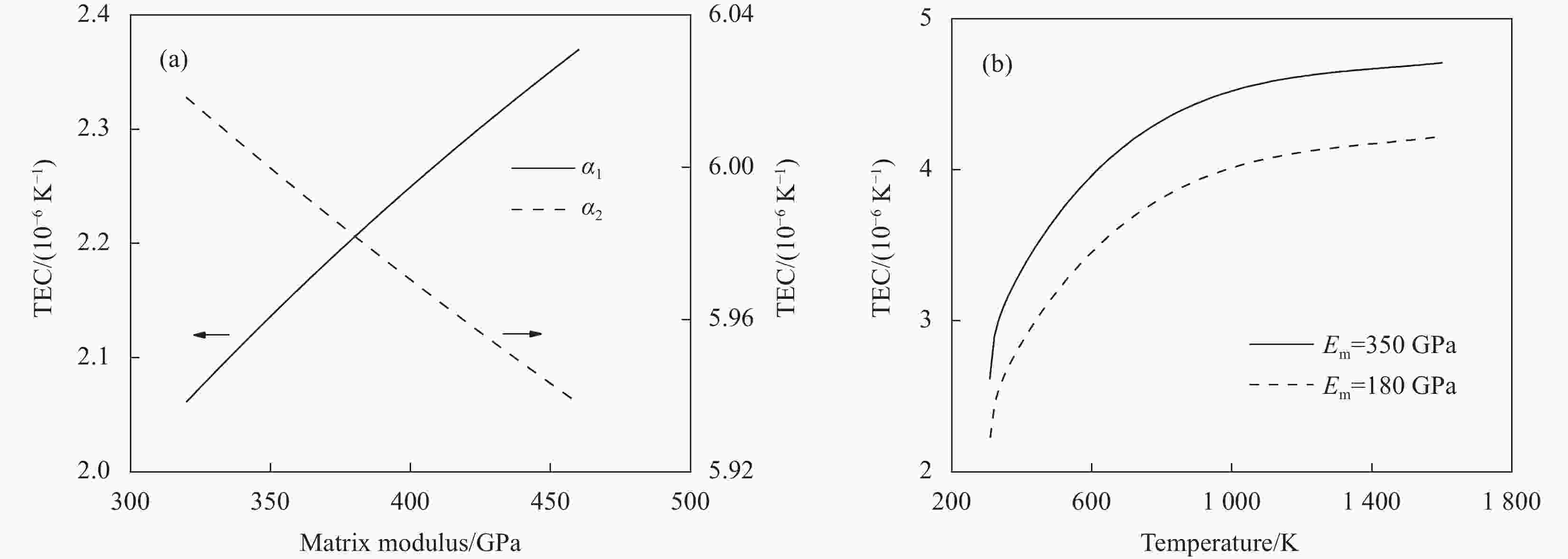

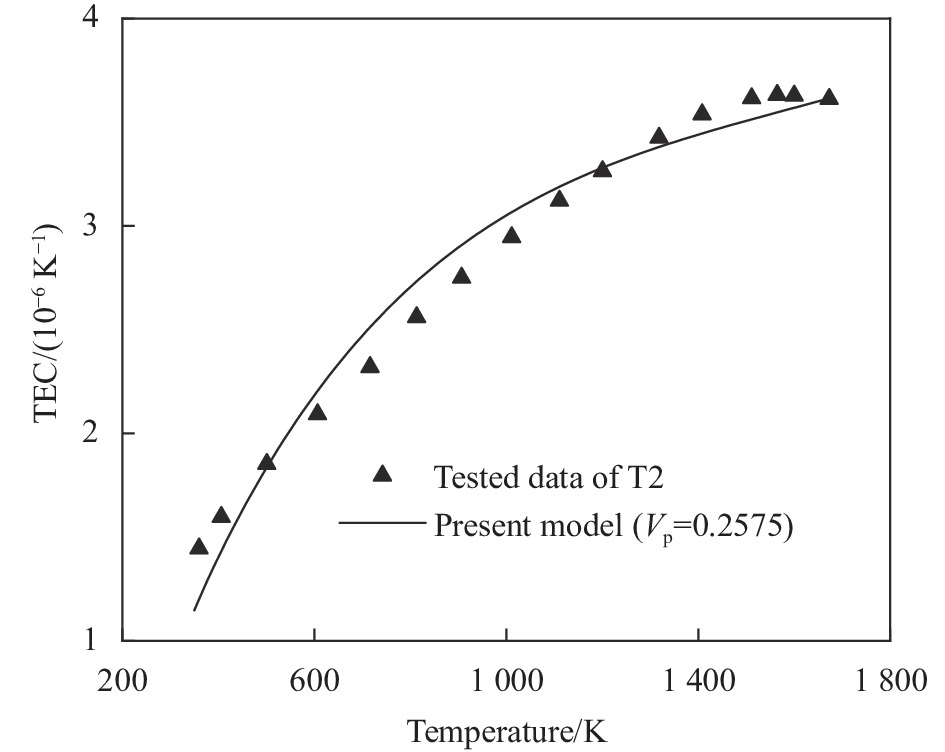

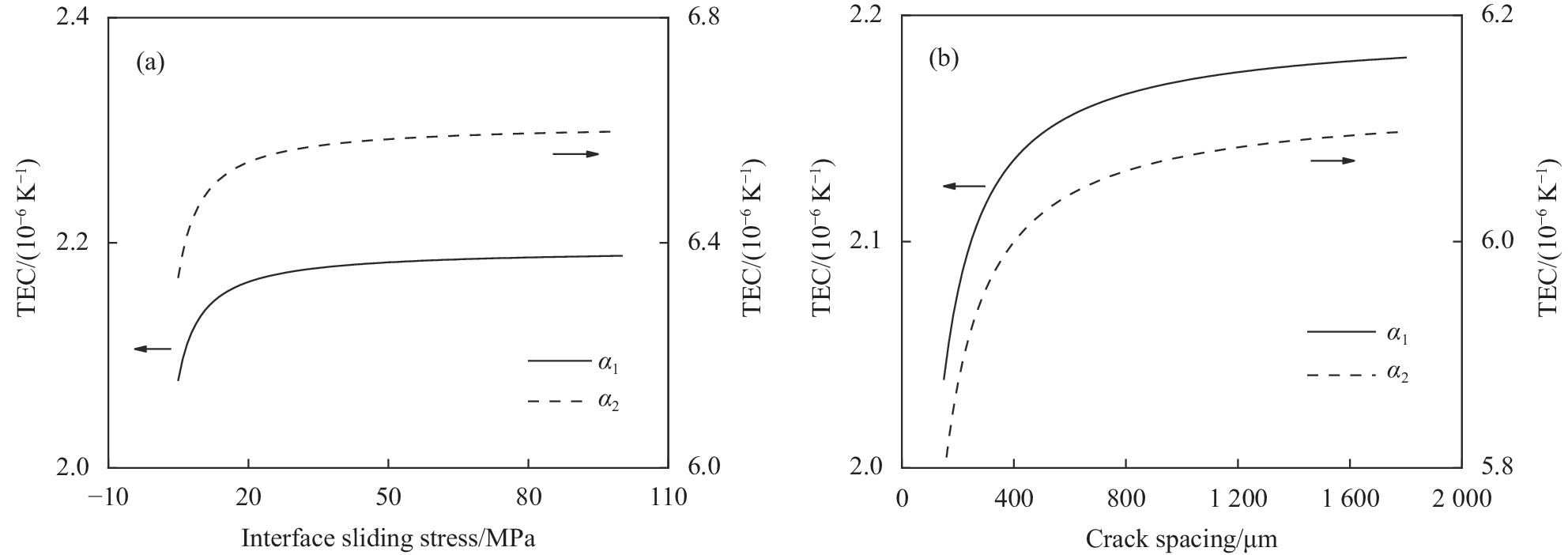

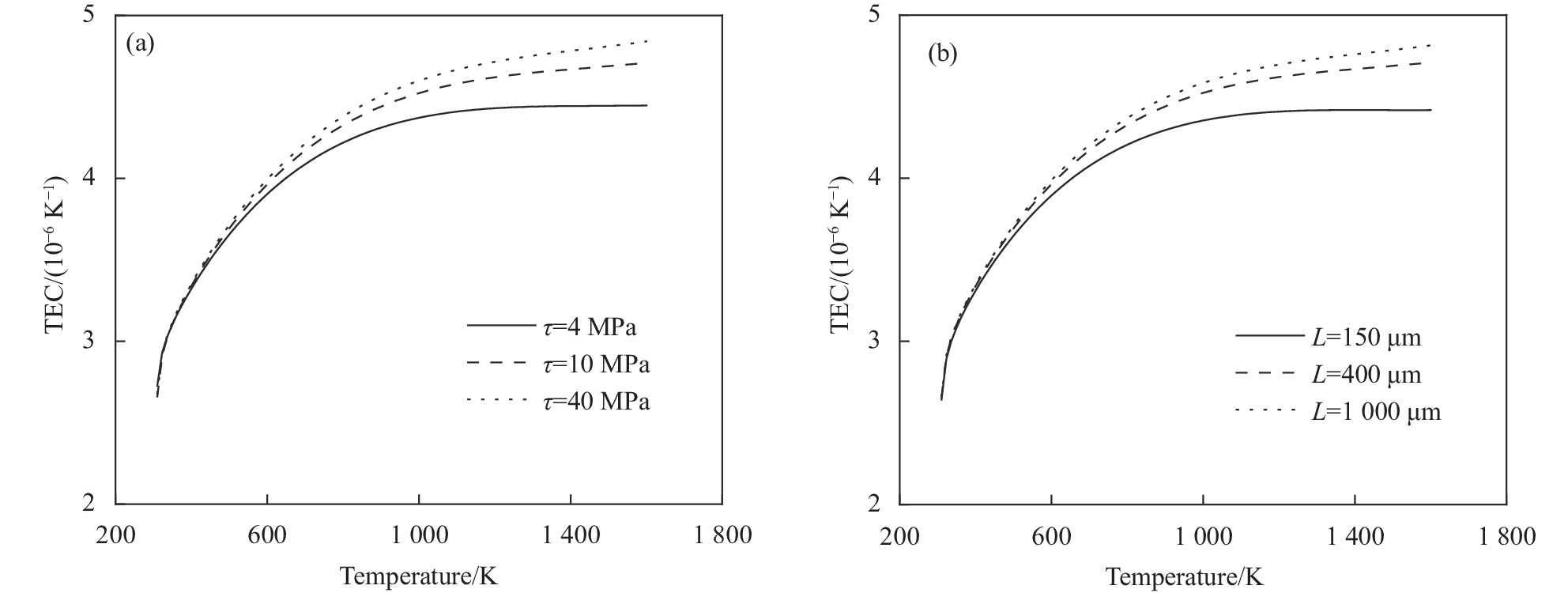

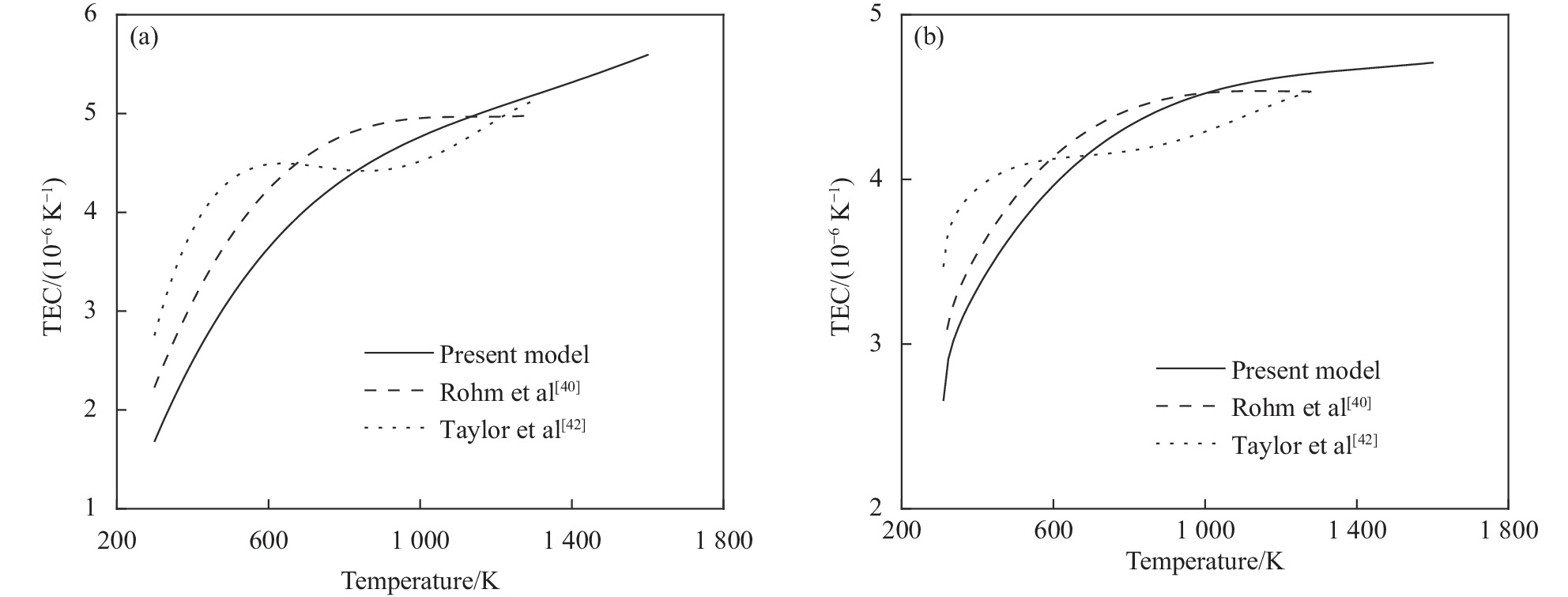

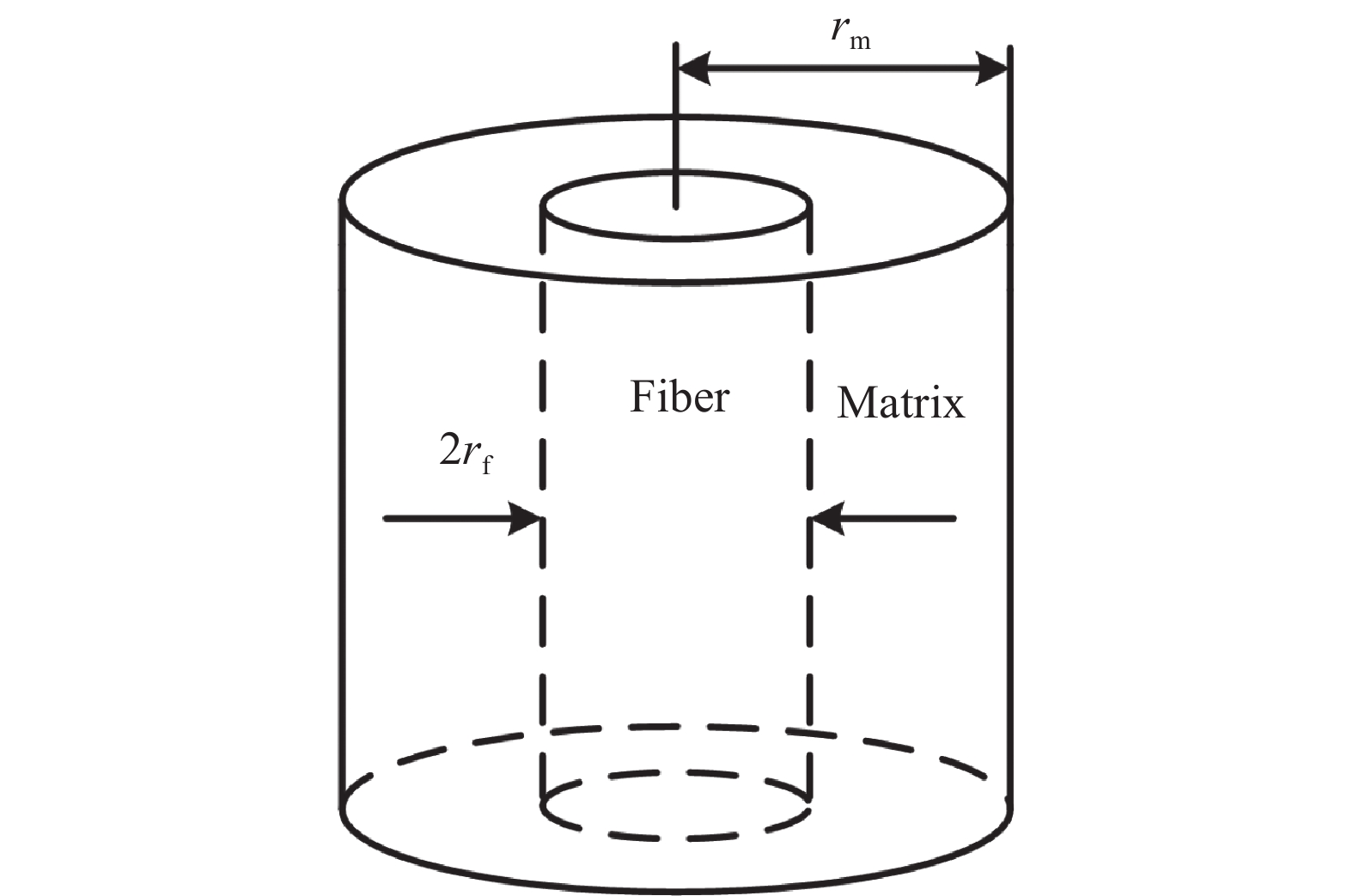

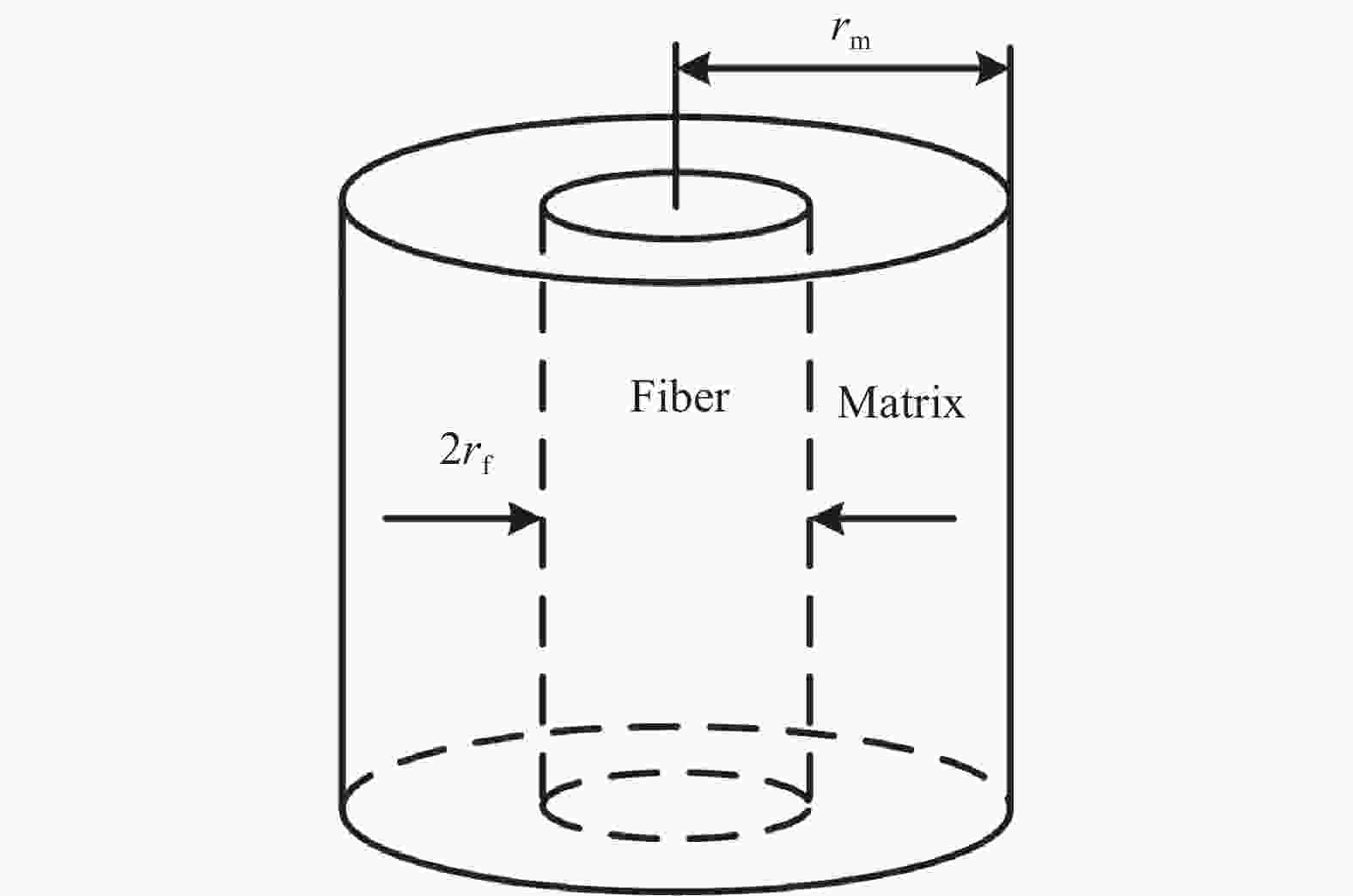

Abstract: Thermal expansion coefficient (TEC) is an important thermodynamic parameter of high-temperature resistant composites. The evolution behavior of the TEC of damaged 2D-C/SiC composites with ambient temperature was studied by theoretical model and experimental tests for the phenomenon of matrix cracking and interface debonding, which affects the thermal expansion deformation of the material under service condition. Firstly, the three-dimensional thermal mismatch stress calculation model of constituents was given based on minicomposite model. Secondly, matrix cracking and interface debonding were introduced, and the analytical expressions for axial and radial TECs of minicomposite were derived by considering thermal expansion difference between the fibers and matrix, transverse isotropy of fibers and the Poisson's effect. Thirdly, based on the [0/90] cross-ply laminate model and the macro-strain consistency assumption, a predictive model was established towards the apparent TEC of damaged 2D-C/SiC composites. Finally, the present model was compared with the classical Schapery model and experimental data, and the main influencing factors of TEC were analyzed. Parameter analysis indicate that the apparent TEC of the material is affected by matrix crack spacing, interface debonding ratio, porosity, elastic modulus and TEC of the constituents, among which the influence of the matrix expansion coefficient is particularly significant. The verification results show that the proposed model is reasonable and correct, and the predicted results are in good agreement with the classical model and experimental curve.-

Key words:

- TEC /

- minicomposite model /

- 2D-C/SiC /

- thermal mismatch stress /

- Schapery model

-

表 1 2D-C/SiC复合材料模型基本参数

Table 1. Basic parameters of 2D-C/SiC composites model

Parameter Value Longitudinal modulus of fiber $ {E}_{1\mathrm{f}} $/GPa 230 Transverse modulus of fiber $ {E}_{2\mathrm{f}} $/GPa 14 Matrix modulus $ {E}_{\mathrm{m}} $/GPa 350 Fiber volume fraction $ {V}_{\mathrm{f}} $/vol% 40 Matrix volume fraction $ {V}_{\mathrm{m}} $/vol% 60 Fiber volume fraction in bundle $ {V}_{\mathrm{f}\mathrm{b}} $/vol% 70 Matrix volume fraction in bundle $ {V}_{\mathrm{m}\mathrm{b}} $/vol% 30 Axial Poisson's ratio of fiber $ {\nu }_{1\mathrm{f}} $ 0.2 Transverse Poisson's ratio of fiber $ {\nu }_{2\mathrm{f}} $ 0.07 Matrix Poisson's ratio $ {\nu }_{\mathrm{m}} $ 0.2 Interface sliding stress $ \tau $/MPa 10 Crack spacing L/μm 400 -

[1] 黄亿洲, 王志瑾, 刘格菲. 碳纤维增强复合材料在航空航天领域的应用[J]. 西安航空学院学报, 2021, 39(5):44-51. doi: 10.3969/j.issn.1008-9233.2021.05.009HUANG Yizhou, WANG Zhijin, LIU Gefei. Application of carbon fiber reinforced composite in aerospace[J]. Journal of Xi'an Aeronautical University,2021,39(5):44-51(in Chinese). doi: 10.3969/j.issn.1008-9233.2021.05.009 [2] 段国晨, 赵景丽, 赵伟超. 先进复合材料在无人机结构的应用[J]. 纤维复合材料, 2022, 39(2):105-114. doi: 10.3969/j.issn.1003-6423.2022.02.020DUAN Guochen, ZHAO Jingli, ZHAO Weichao. Application of advanced composite materials in UAV at home and abroad[J]. Fiber Composites,2022,39(2):105-114(in Chinese). doi: 10.3969/j.issn.1003-6423.2022.02.020 [3] 高铁, 洪智亮, 杨娟. 商用航空发动机陶瓷基复合材料部件的研发应用及展望[J]. 航空制造技术, 2014, 57(6):14-21.GAO Tie, HONG Zhiliang, YANG Juan. Application and prospect of ceramic matrix composite components for commercial aircraft engine[J]. Aeronautical Manufacturing Technology,2014,57(6):14-21(in Chinese). [4] CRAMER C L, YOON B, LANCE M J, et al. Additive manufacturing of C/C-SiC ceramic matrix composites by automated fiber placement of continuous fiber tow in polymer with pyrolysis and reactive silicon melt infiltration[J]. Journal of Composites Science,2022,6(12):359. doi: 10.3390/jcs6120359 [5] TIAN W L, CHAO X J, FU M W, et al. New numerical algorithm for the periodic boundary condition for predicting the coefficients of thermal expansion of composites[J]. Mechanics of Materials,2021,154:103737. doi: 10.1016/j.mechmat.2020.103737 [6] TROFIMOV A, LE-PAVIC J, THERRIAULT D, et al. An efficient multi-scale computation of the macroscopic coefficient of thermal expansion: Application to the resin transfer molding manufactured 3D woven composites[J]. International Journal of Solids and Structures,2021,210-211:162-169. doi: 10.1016/j.ijsolstr.2020.11.012 [7] 万佩, 夏辉, 刘晨, 等. 基于多尺度数值模型的复合材料各向异性热膨胀系数预测[J]. 复合材料学报, 2023, 40(2):1208-1217.WAN Pei, XIA Hui, LIU Chen, et al. Prediction of anisotropic coefficient of thermal expansion for laminated composite using multiscale numerical models[J]. Acta Materiae Compositae Sinica,2023,40(2):1208-1217(in Chinese). [8] 吴欣歌, 何智海, 赵思宇, 等. 可调热膨胀系数的复合材料层合结构预测与设计[J]. 应用力学学报, 2023, 40(3):636-642.WU Xinge, HE Zhihai, ZHAO Siyu, et al. Prediction and design of composite laminate with adjustable thermal expansion coefficient[J]. Chinese Journal of Applied Mechanics,2023,40(3):636-642(in Chinese). [9] AVELLANEDA R, RODRÍGUEZ-ALEMÁN S, OTERO J A. Semi-analytical method for computing effective thermoelastic properties in fiber-reinforced composite materials[J]. Applied Sciences,2021,11(12):5354. doi: 10.3390/app11125354 [10] TURNER P S. Thermal-expansion stresses in reinforced plastics[J]. Journal of Research of the National Bureau of Standards,1946,37(4):239-250. doi: 10.6028/jres.037.015 [11] BOWLES D E, TOMPKINS S S. Prediction of coefficients of thermal expansion for unidirectional composites[J]. Journal of Composite Materials,1989,23(4):370-388. doi: 10.1177/002199838902300405 [12] SCHAPERY R A. Thermal expansion coefficients of composite materials based on energy principles[J]. Journal of Composite Materials,1968,2(3):380-404. doi: 10.1177/002199836800200308 [13] 宋美慧, 武高辉, 王宁, 等. Cf/Mg复合材料热膨胀系数及其计算[J]. 稀有金属材料与工程, 2009, 38(6):1043-1047. doi: 10.3321/j.issn:1002-185X.2009.06.023SONG Meihui, WU Gaohui, WANG Ning, et al. Coefficient of thermal expansion and compute of carbon fibre reinforced magnesium composites[J]. Rare Metal Materials and Engineering,2009,38(6):1043-1047(in Chinese). doi: 10.3321/j.issn:1002-185X.2009.06.023 [14] 刘兵山, 燕瑛, 田金梅. 纤维增强对称层合复合材料的宏观热膨胀系数研究[J]. 强度与环境, 2008, 35(5):17-24.LIU Bingshan, YAN Ying, TIAN Jinmei. Study on the macro thermal expansion coefficients of fiber-reinforced symmetric laminates[J]. Structure and Environment Engineering,2008,35(5):17-24(in Chinese). [15] ZAHID M, SHARMA R, BHAGAT A R. Realistic microstructure-based two-scale finite element analysis of 3D C/C composite for effective thermal expansion coefficient [J]. International Journal of Advances in Engineering Sciences and Applied Mathematics, 2020, 12(3): 81-93. [16] LIU X D, GUAN Z D, WANG X D, et al. Improved semi-analytical and numerical methods on prediction of in-plane coefficients of thermal expansion of woven ceramic matrix composite considering defects[J]. Journal of the European Ceramic Society,2021,41(3):1795-1809. [17] DU Z H, YANG R X, WU M A. Effect of defect distribution on thermal expansion coefficient of eutectic composite ceramics[J]. Vibroengineering Procedia, 2022, 40: 100-106. [18] 梁军, 杜善义, 许兴利, 等. 含缺陷纤维增强复合材料热膨胀系数预报[J]. 哈尔滨工业大学学报, 1997, 29(3): 36-39.LIANG Jun, DU Shanyi, XU Xingli, et al. Thermal expansion coefficients of fiber composite materials containing matrix microcracks [J]. Journal of Harbin Institute of Technology, 1997, 29(3): 36-39(in Chinese). [19] 何乾强, 周储伟, 周灿. 纤维增强复合材料考虑损伤的温度胀缩细观力学模型[J]. 复合材料学报, 2014, 31(4): 1077-1083.HE Qianqiang, ZHOU Chuwei, ZHOU Can. Micro-mechanical model of thermal expansion/contraction for damaged fiber reinforced composites [J]. Acta Materiae Compositae Sinica, 2014, 31(4): 1077-1083(in Chinese). [20] JO H S, LEE G W. Thermal expansion coefficient and Young's modulus of silica-reinforced epoxy composite[J]. International Scholarly and Scientific Research and Innovation,2014,8(11):1063-1066. [21] 朱龙基, 曹先启, 张洪楠, 等. 颗粒增强复合材料热膨胀系数预测模型的研究现状[J]. 化学与黏合, 2015, 37(4):298-302.ZHU Longji, CAO Xianqi, ZHANG Hongnan, et al. Progress in prediction model of thermal expansion coefficient of particle reinforced composites[J]. Chemistry and Adhesion,2015,37(4):298-302(in Chinese). [22] 李开元, 徐永东, 张立同, 等. 纤维编织结构对碳纤维增强碳化硅复合材料热膨胀和热扩散系数的影响[J]. 硅酸盐学报, 2008, 36(11):1564-1569, 1576.LI Kaiyuan, XU Yongdong, ZHANG Litong, et al. Effects of fabric architectures on the thermal expansion coefficient and the thermal diffusivity of carbon fiber reinforced silicon carbide composites[J]. Journal of the Chinese Ceramic Society,2008,36(11):1564-1569, 1576(in Chinese). [23] 邱雪琼, 陈琳. 碳纤维增强复合材料层压板的热膨胀系数测量及理论计算方法[J]. 复合材料科学与工程, 2021, 330(7):28-32, 104.QIU Xueqiong, CHEN Lin. Test and theoretical method for coefficients of thermal expansion of carbon fiber reinforced composite laminate[J]. Composites Science and Engineering,2021,330(7):28-32, 104(in Chinese). [24] ZHANG Q, CHENG L F, ZHANG L T, et al. Thermal expansion behavior of carbon fiber reinforced chemical-vapor-infiltrated silicon carbide composites from room temperature to 1400℃[J]. Materials Letters,2006,60(27):3245-3247. doi: 10.1016/j.matlet.2006.02.088 [25] SUN Z, SHAN Z D, SHAO T M, et al. A multiscale modeling for predicting the thermal expansion behaviors of 3D C/SiC composites considering porosity and fiber volume fraction[J]. Ceramics International,2021,47(6):7925-7936. doi: 10.1016/j.ceramint.2020.11.142 [26] 薛玉冬, 胡建宝, 杨金山, 等. 不同应力水平下SiCf/SiC复合材料的损伤行为和机制研究[J]. 材料科学与工艺, 2020, 28(3): 89-97.XUE Yudong, HU Jianbao, YANG Jinshan, et al. Study on damage behavior and mechanism of SiCf/SiC composites subjected to different stress levels [J]. Materials Science and Technology, 2020, 28(3): 89-97(in Chinese). [27] KASTRITSEAS C, SMITH P A, YEOMANS J A. Thermal shock fracture in cross-ply fibre-reinforced ceramic-matrix composites[J]. Philosophical Magazine,2010,90(31-32):4209-4226. doi: 10.1080/14786431003785621 [28] 白国栋, 童小燕, 姚磊江. 材料初始缺陷对平纹编织C/SiC复合材料热残余应力的影响研究[J]. 航空工程进展, 2020, 11(3):332-337.BAI Guodong, TONG Xiaoyan, YAO Leijiang. Study on the influence of initial defects on thermal residual stress of plain weave C/SiC composites[J]. Advances in Aeronautical Science and Engineering,2020,11(3):332-337(in Chinese). [29] 郑茹悦, 杨成鹏, 乔成成, 等. 2D-C/SiC复合材料的主泊松比演化行为[J]. 复合材料学报, 2023, 40(6):3683-3694.ZHENG Ruyue, YANG Chengpeng, QIAO Chengcheng, et al. Evolution behavior of major Poisson's ratio of 2D-C/SiC composites[J]. Acta Materiae Compositae Sinica,2023,40(6):3683-3694(in Chinese). [30] JAMES J D, SPITTLE J A, BROWN S R, et al. A review of measurement techniques for the thermal expansion coefficient of metals and alloys at elevated temperatures[J]. Measurement Science and Technology,2001,12(3):R1-R15. doi: 10.1088/0957-0233/12/3/201 [31] LU T J, HUTCHINSON J W. Effect of matrix cracking and interface sliding on the thermal expansion of fibre-reinforced composites[J]. Composites,1995,26(6):403-414. doi: 10.1016/0010-4361(95)90913-K [32] YANG C P, ZHANG L, WANG B, et al. Tensile behavior of 2D-C/SiC composites at elevated temperatures: Experiment and modeling[J]. Journal of the European Ceramic Society,2017,37(4):1281-1290. doi: 10.1016/j.jeurceramsoc.2016.11.011 [33] COX H L. The elasticity and strength of paper and other fibrous materials[J]. British Journal of Applied Physics,1952,3(3):72-79. doi: 10.1088/0508-3443/3/3/302 [34] 李龙彪. 基于迟滞耗散能的纤维增强陶瓷基复合材料疲劳寿命预测方法[J]. 复合材料学报, 2016, 33(4):841-851. doi: 10.13801/j.cnki.fhclxb.20151010.002LI Longbiao. Fatigue life prediction approach of fiber-reinforced ceramic-matrix composites based on hysteresis dissipated energy[J]. Acta Materiae Compositae Sinica,2016,33(4):841-851(in Chinese). doi: 10.13801/j.cnki.fhclxb.20151010.002 [35] RAN Z G, YAN Y, LI J F, et al. Determination of thermal expansion coefficients for unidirectional fiber-reinforced composites[J]. Chinese Journal of Aeronautics,2014,27(5):1180-1187. doi: 10.1016/j.cja.2014.03.010 [36] 陶永强, 李晶, 矫桂琼, 等. 双向等轴拉伸载荷下二维编织陶瓷基复合材料的应力-应变行为预测[J]. 材料科学与工程学报, 2016, 34(1):75-79, 67. doi: 10.14136/j.cnki.issn1673-2812.2016.01.014TAO Yongqiang, LI Jing, JIAO Guiqiong, et al. Prediction of stress-strain behavior in 2D weave ceramic matrix composite under 1:1 planar biaxial tensile loading[J]. Journal of Materials Science and Engineering,2016,34(1):75-79, 67(in Chinese). doi: 10.14136/j.cnki.issn1673-2812.2016.01.014 [37] 杨成鹏, 矫桂琼, 王波. 2D-C/SiC复合材料的单轴拉伸力学行为及其强度[J]. 力学学报, 2011, 43(2):330-337. doi: 10.6052/0459-1879-2011-2-lxxb2009-717YANG Chengpeng, JIAO Guiqiong, WANG Bo. Uniaxial tensile stress-strain behavior and strength of plain woven C/SiC composite[J]. Chinese Journal of Theoretical and Applied Mechanics,2011,43(2):330-337(in Chinese). doi: 10.6052/0459-1879-2011-2-lxxb2009-717 [38] MUNRO R G. Material properties of a sintered α-SiC[J]. Journal of Physical and Chemical Reference Data,1997,26(5):1195-1203. doi: 10.1063/1.556000 [39] PRADERE C, SAUDER C. Transverse and longitudinal coefficient of thermal expansion of carbon fibers at high temperatures (300-2500 K)[J]. Carbon,2008,46(14):1874-1884. doi: 10.1016/j.carbon.2008.07.035 [40] SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling[J]. Journal of Nuclear Materials,2007,371(1-3):329-377. doi: 10.1016/j.jnucmat.2007.05.016 [41] 牛宏伟, 文敏, 张帅. 考虑界面层和孔隙的SiCf/SiCm复合材料热膨胀性能研究[J]. 功能材料, 2020, 51(4):4101-4108.NIU Hongwei, WEN Min, ZHANG Shuai. Investigation on thermal expansion properties of a braided SiCf/SiCm composite considering fiber-matrix interface and porosity[J]. Journal of Functional Materials,2020,51(4):4101-4108(in Chinese). [42] LI Z, BRADT R C. Thermal expansion of the cubic (3C) polytype of SiC[J]. Journal of Materials Science,1986,21(12):4366-4368. doi: 10.1007/BF01106557 -

下载:

下载: