Preparation and properties of double crosslinked waste corrugated paper-based aerogel buffer materials

-

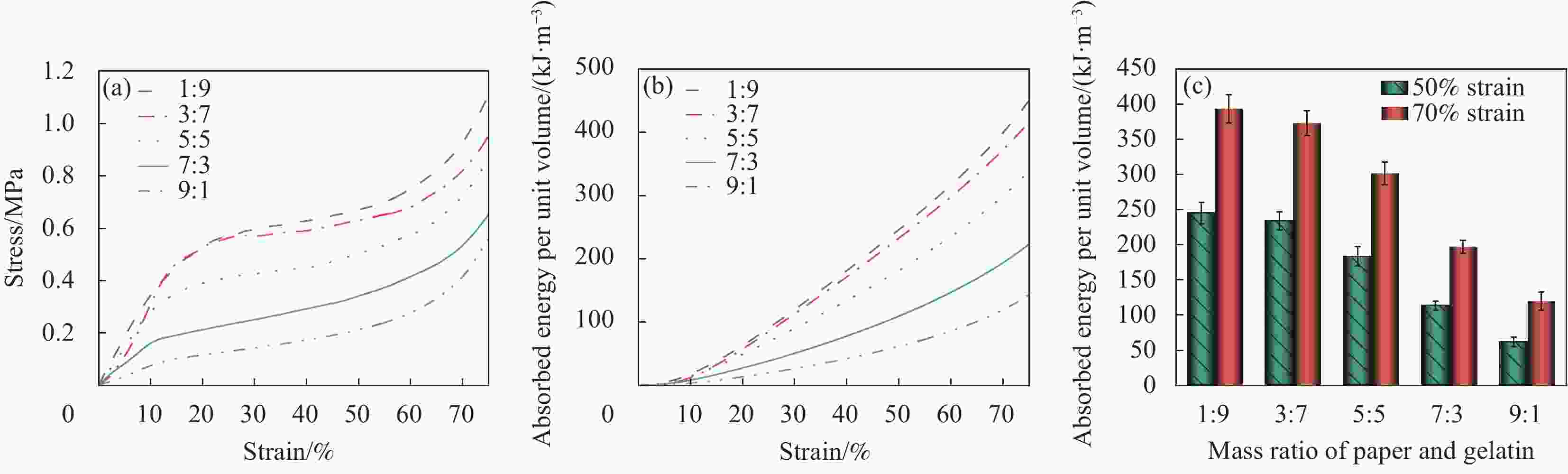

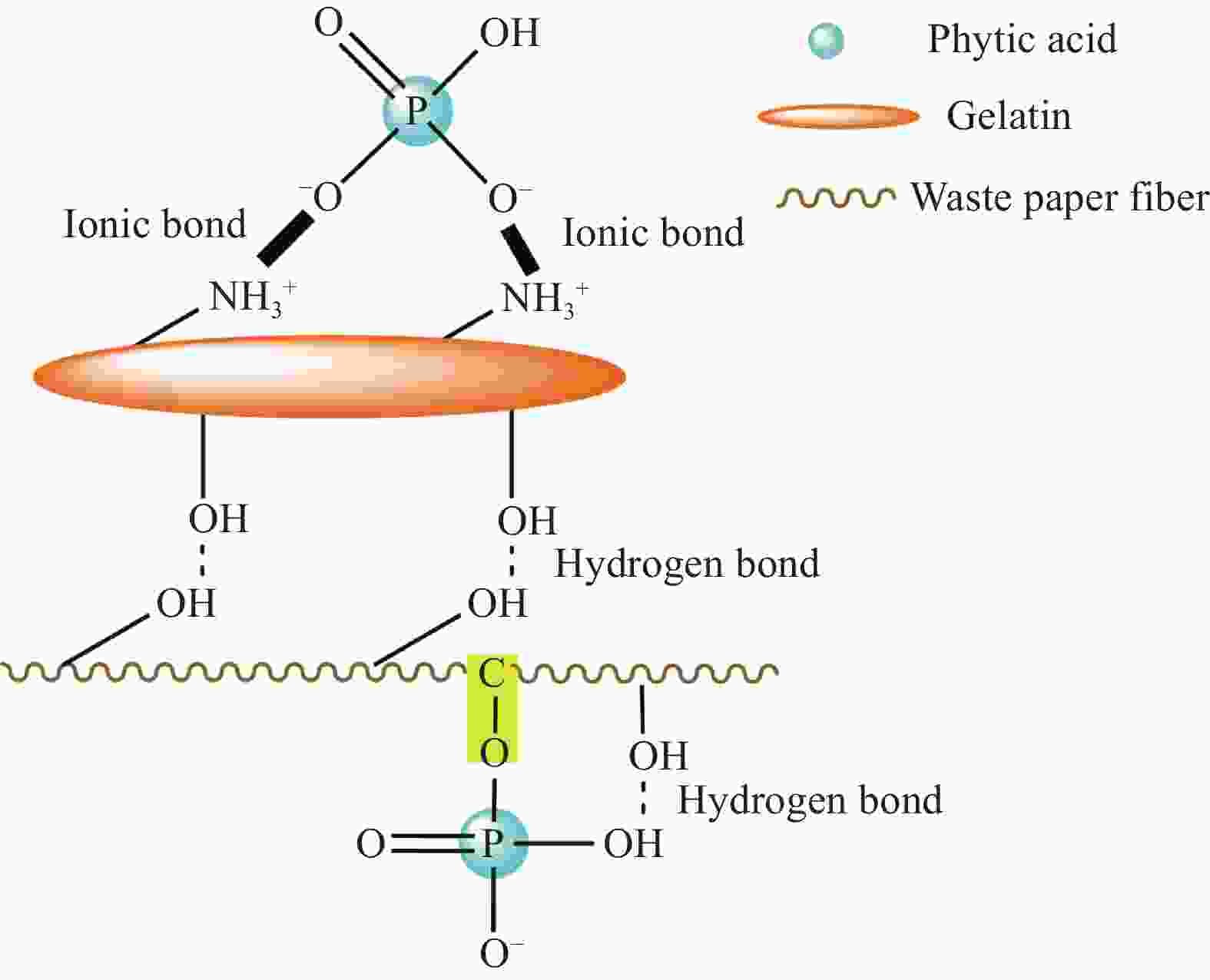

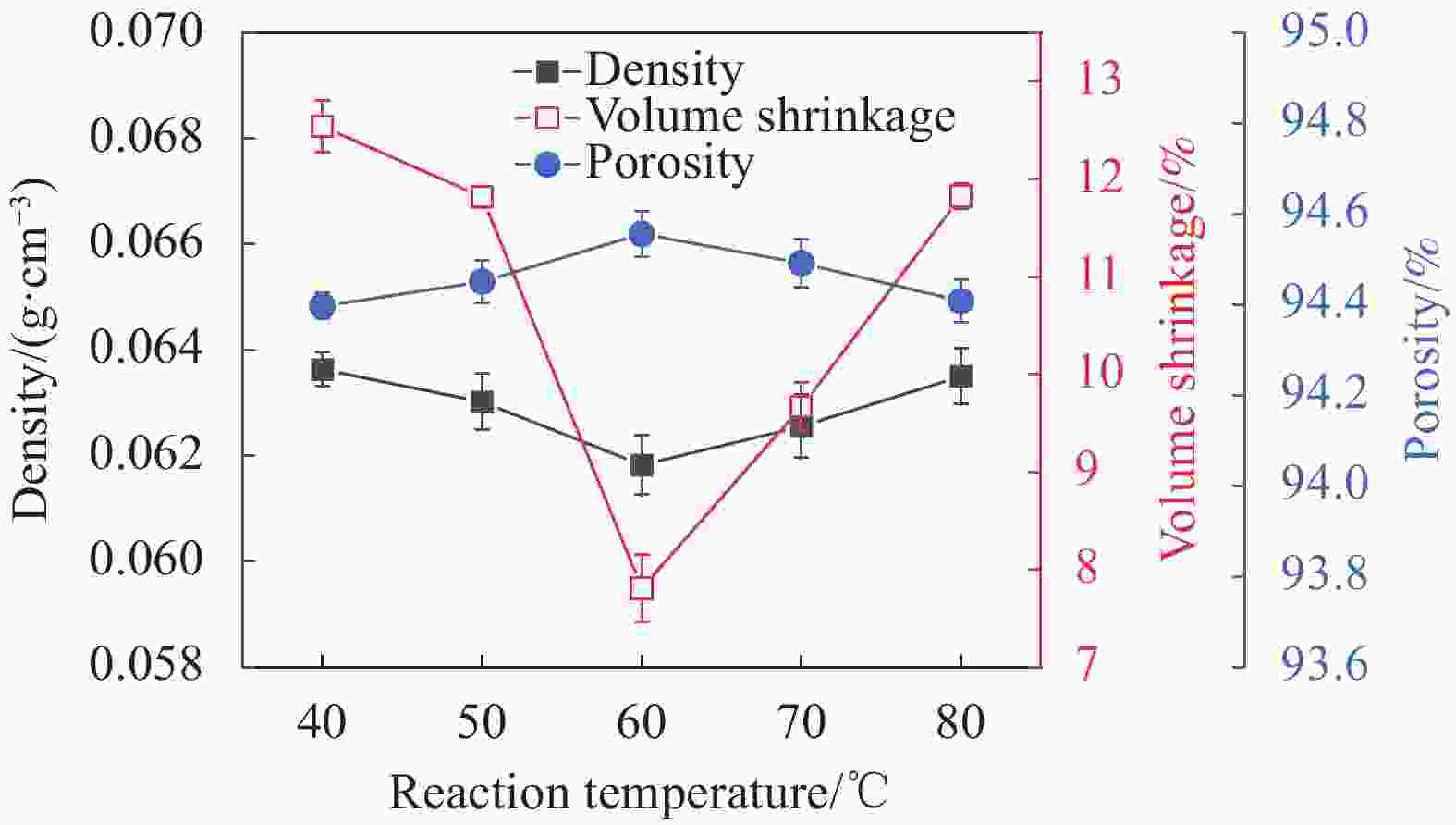

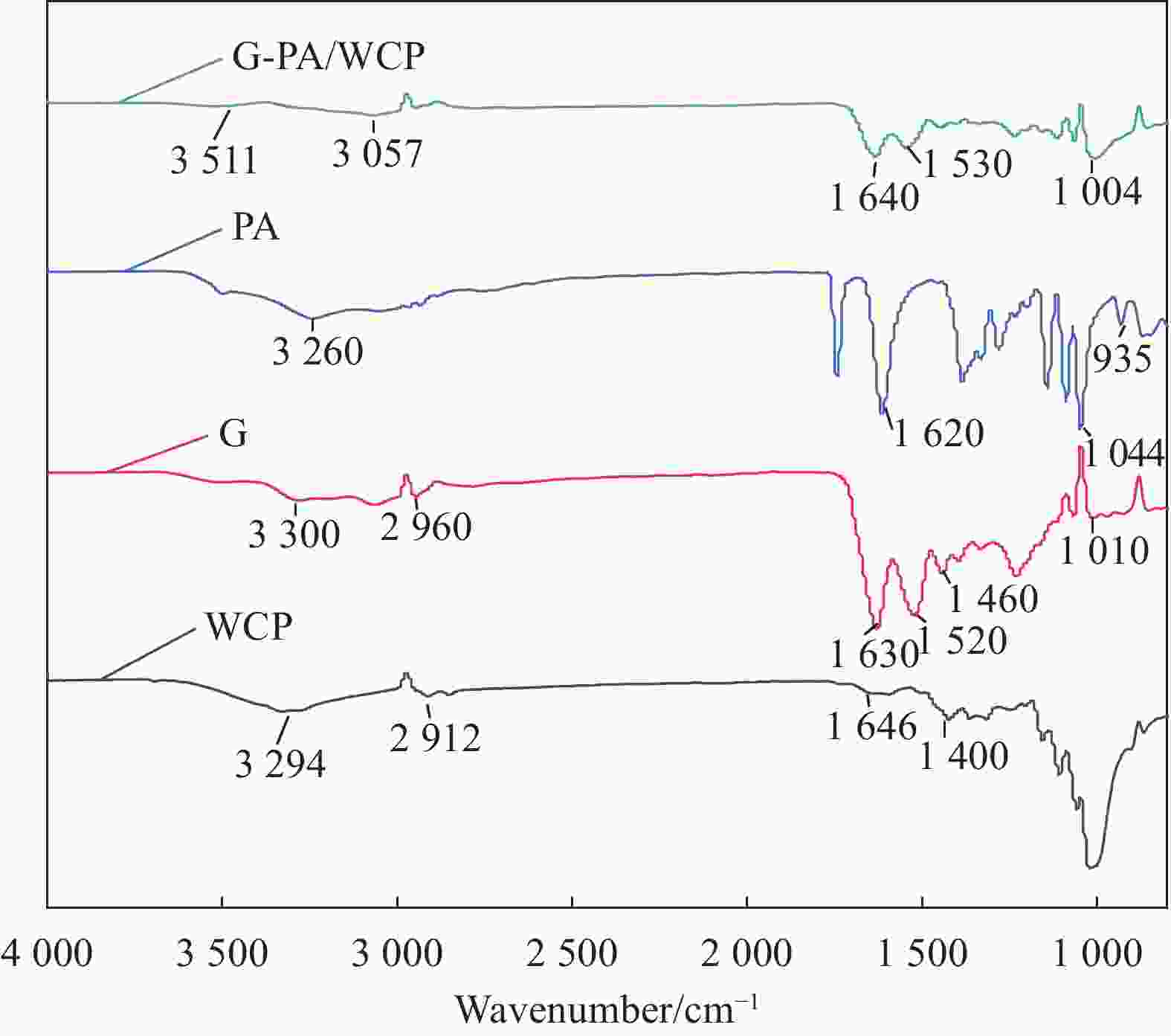

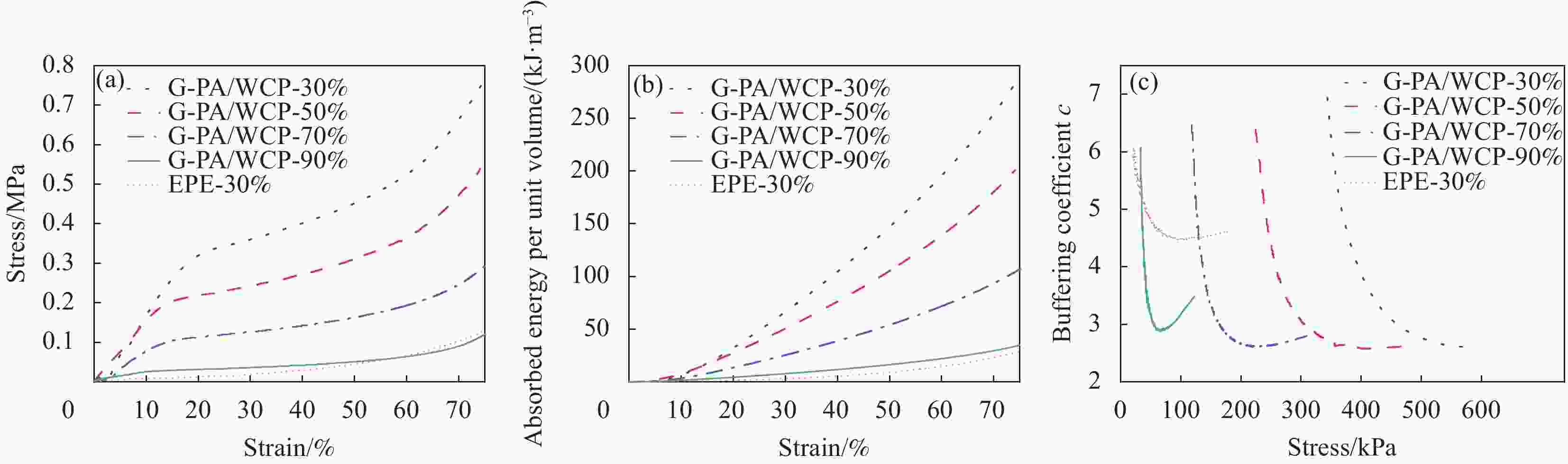

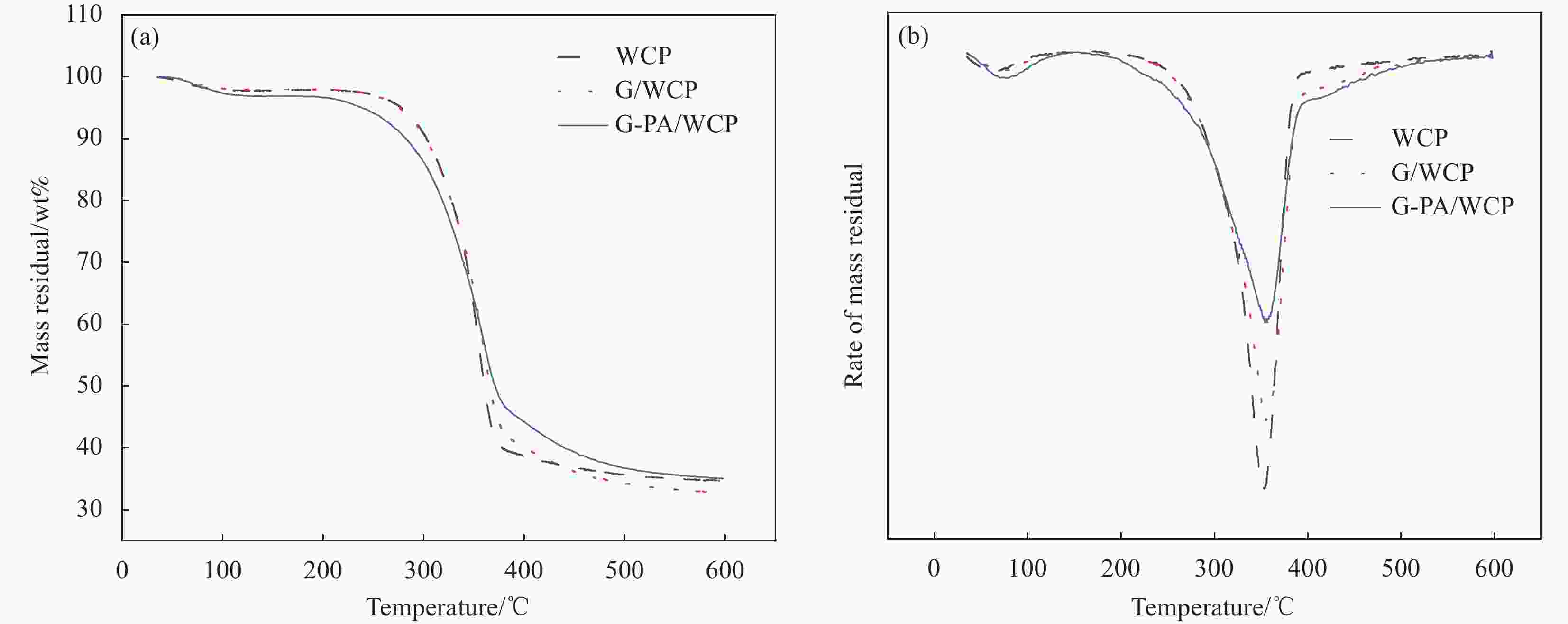

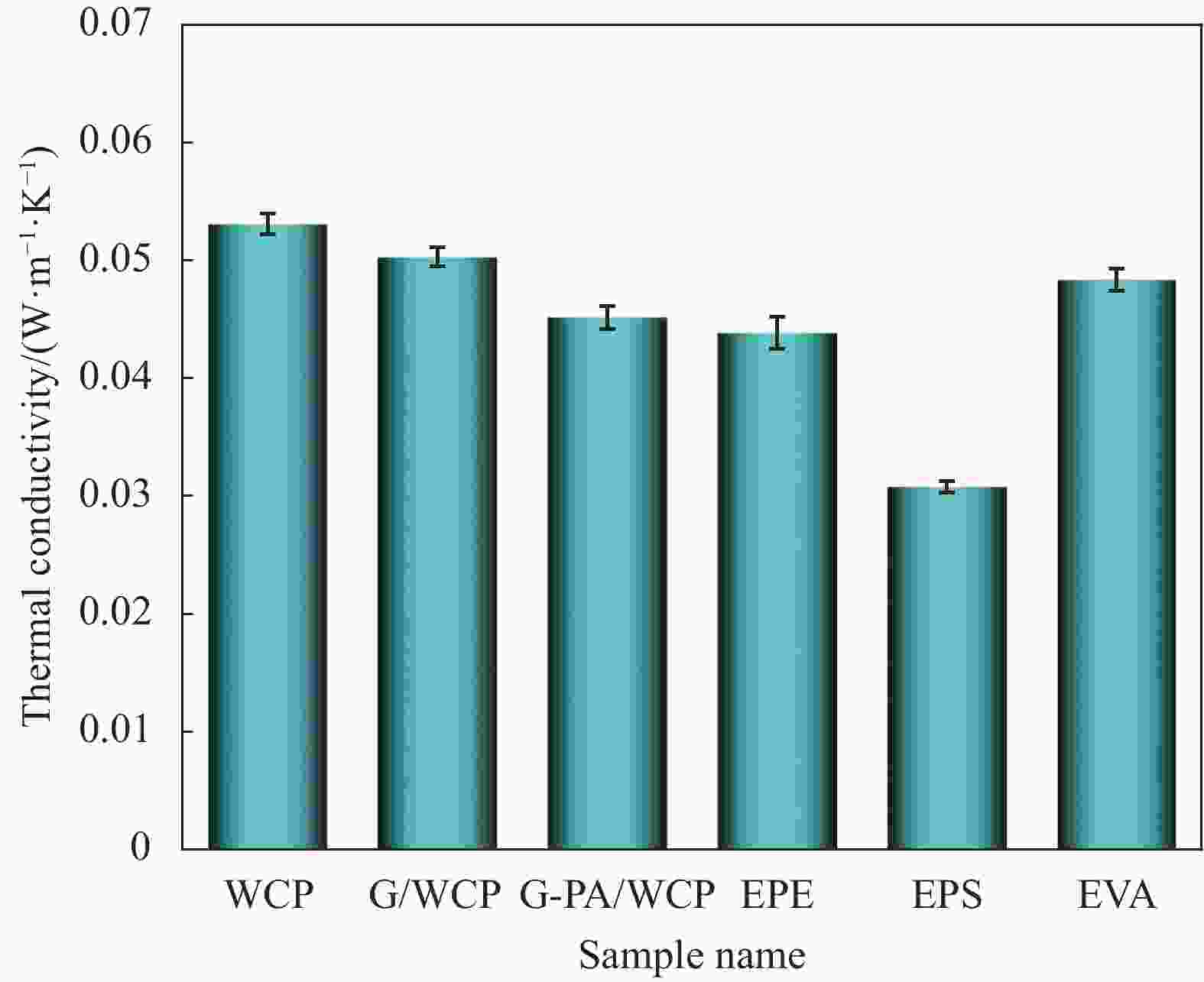

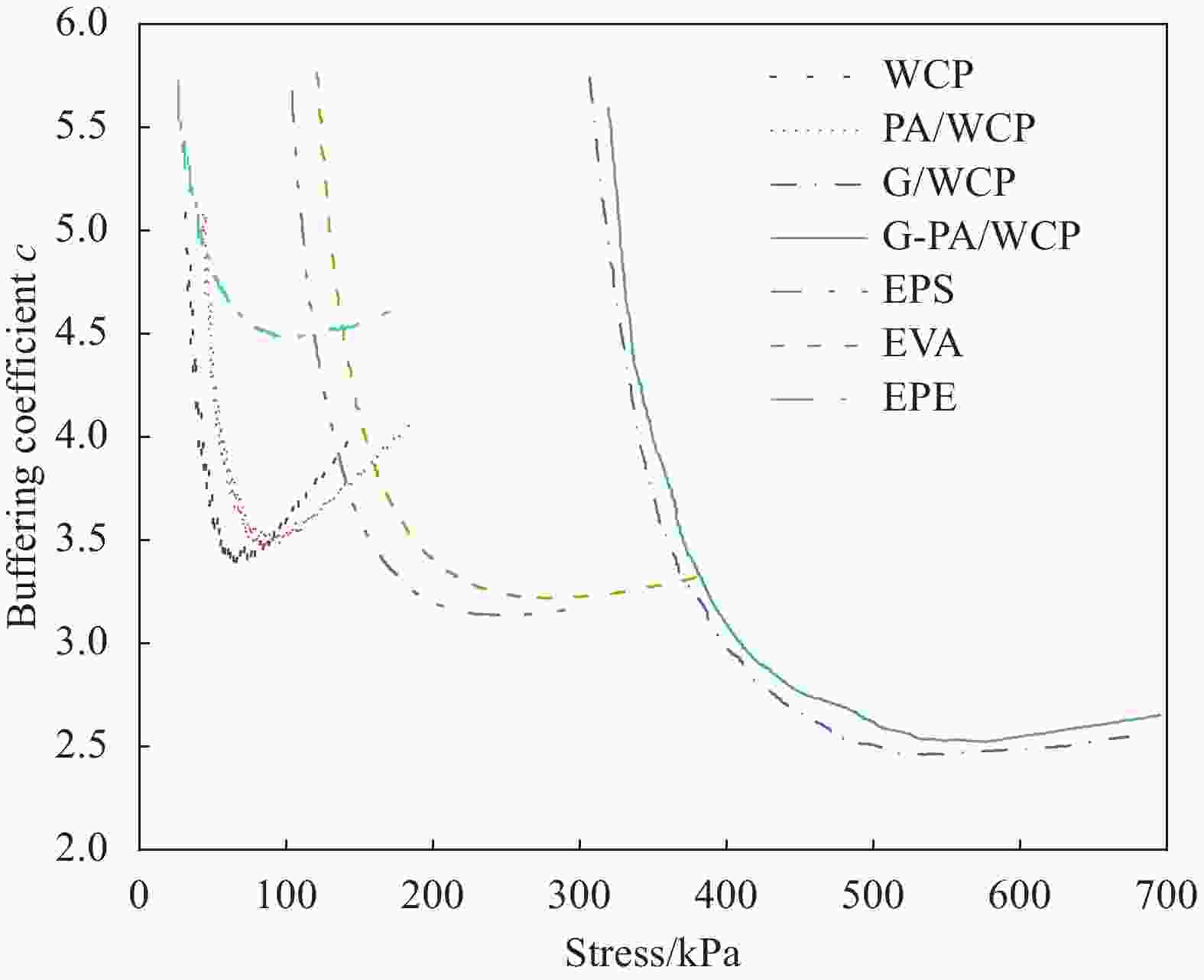

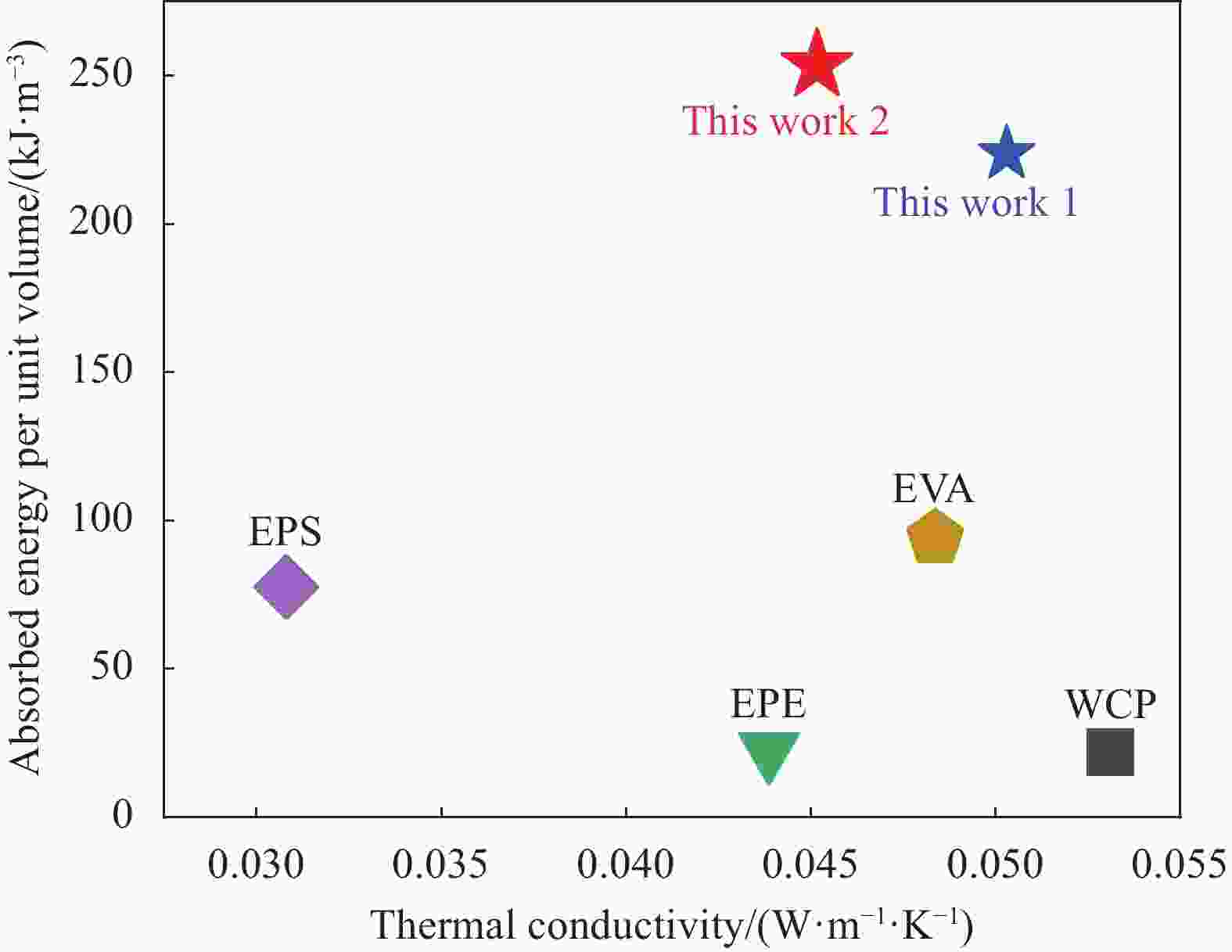

摘要: 以废弃瓦楞纸(WCP)为原料,明胶(G)和植酸(PA)为改性剂,采用溶胶-凝胶法制备高吸能气凝胶。对明胶用量、植酸用量和反应温度对双交联改性废纸基气凝胶力学性能的影响进行了研究,并通过SEM、FTIR、XRD和TGA表征了明胶单一改性和明胶-植酸双交联改性前后气凝胶的结构与性能变化。结果表明:改性单体成功交联到废纸纤维上,双交联改性后的废纸基气凝胶呈现三维网状结构,相较于未改性和单一改性废纸基气凝胶具有较高的热稳定性、优异的隔热性能(0.045 W·m−1·K−1)和超强的吸能性(应变70%时,单位体积吸收能为253.45 kJ/m3),吸能性分别为珍珠棉(EPE)和乙烯-醋酸乙烯酯共聚物(EVA)的11.26和2.7倍。作为包装运输过程中的一种绿色缓冲材料,具有广阔的应用前景。Abstract: Waste corrugated paper (WCP) was used as raw material, gelatin (G) and phytic acid (PA) were used as modifiers, and high energy absorption aerogel was prepared by sol-gel method. The effects of G dosage, PA dosage, and reaction temperature on the mechanical properties of dual-crosslinked modified waste paper-based aerogels were investigated. The structural and performance changes of aerogels before and after single modification with G and dual modification with G and PA were characterized by SEM, FTIR, XRD and TGA. The results show that the modified monomer is successfully crosslinked onto the waste paper fiber, and the double crosslinked waste paper based aerogel presents a three-dimensional network structure. Compared with the unmodified and single modified waste paper based aerogel, it has higher thermal stability, excellent thermal insulation (0.045 W·m−1·K−1) and super energy absorption (Absorption energy per unit volume is 253.45 kJ/m3 at 70% strain). The energy absorption capacity is 11.26 and 2.7 times higher than that of expanded polyethylene (EPE) and ethylene vinyl acetate (EVA), respectively. As a green cushioning material in the packaging and transportation process, it has broad application prospects.

-

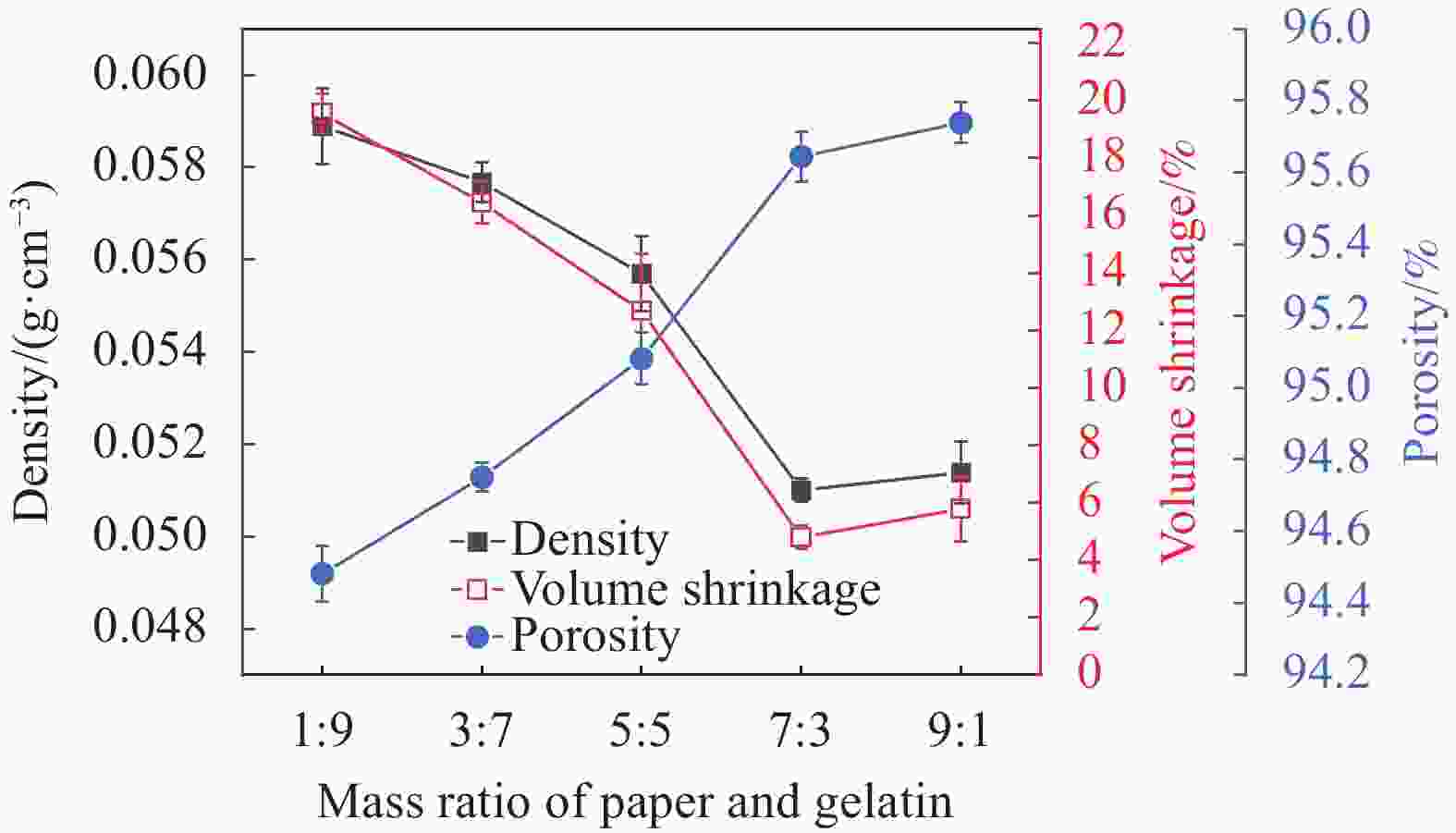

图 4 废纸和明胶不同质量比下:(a) G-PA/WCP气凝胶的压缩应力-应变曲线;(b) G-PA/WCP气凝胶的吸能曲线;(c) G-PA/WCP气凝胶在压缩应变为50%和70%处的单位体积吸能值

Figure 4. Different mass ratios of waste paper and gelatin: (a) Compression stress-strain curves of G-PA/WCP aerogel; (b) Energy absorption curves of G-PA/WCP aerogel; (c) Unit volume energy absorption values of G-PA/WCP aerogel at 50% and 70% compression strain

图 7 不同植酸添加量下:(a) G-PA/WCP气凝胶的压缩应力-应变曲线;(b) G-PA/WCP气凝胶的吸能曲线;(c) G-PA/WCP气凝胶在压缩应变为50%和70%处的单位体积吸能值

Figure 7. Different phytic acid contents: (a) Compressive stress-strain curves of G-PA/WCP aerogel; (b) Energy absorption curves of G-PA/WCP aerogel; (c) Energy absorption per unit volume of G-PA/WCP aerogel at compression strain of 50% and 70%

图 10 不同反应温度下:(a) G-PA/WCP气凝胶的压缩应力-应变曲线;(b) G-PA/WCP气凝胶的吸能曲线;(c) G-PA/WCP气凝胶在压缩应变为50%和70%处的单位体积吸能值

Figure 10. At different reaction temperatures: (a) Compressive stress-strain curves of G-PA/WCP aerogel; (b) Energy absorption curves of G-PA/WCP aerogel; (c) Energy absorption per unit volume of G-PA/WCP aerogel at 50% and 70% compression strain

图 13 不同湿度条件下:(a) G-PA/WCP气凝胶的压缩应力-应变曲线;(b) G-PA/WCP气凝胶的吸能曲线;(c) G-PA/WCP气凝胶的缓冲系数

Figure 13. Under different humidity conditions: (a) Compression stress-strain curves of G-PA/WCP aerogels; (b) Energy absorption curves of G-PA/WCP aerogels; (c) Buffering coefficient of G-PA/WCP aerogels

EPE—Expanded polyethylene

-

[1] 张乾. 新型缓冲包装材料的发展走向[J]. 上海包装, 2013(12):49-51. doi: 10.19446/j.cnki.1005-9423.2013.12.017ZHANG Qian. The development trend of new cushioning packaging materials[J]. Shanghai Packaging,2013(12):49-51(in Chinese). doi: 10.19446/j.cnki.1005-9423.2013.12.017 [2] 程琳, 王伟. 常见缓冲包装材料的应用现状[J]. 上海包装, 2014(6):53-54. doi: 10.19446/j.cnki.1005-9423.2014.06.025CHENG Lin, WANG Wei. The current application status of common cushioning packaging materials[J]. Shanghai Packaging,2014(6):53-54(in Chinese). doi: 10.19446/j.cnki.1005-9423.2014.06.025 [3] 章婷, 赵春林, 乐弦, 等. 气凝胶研究进展[J]. 现代技术陶瓷, 2018, 39(1):1-39. doi: 10.16253/j.cnki.37-1226/tq.2017.12.001ZHANG Ting, ZHAO Chunlin, LE Xian, et al. Research progress of aerogel[J]. Modern Technology Ceramics,2018,39(1):1-39(in Chinese). doi: 10.16253/j.cnki.37-1226/tq.2017.12.001 [4] 段一凡, 张光磊, 史新月, 等. 纤维素气凝胶的制备与应用研究进展[J]. 陶瓷学报, 2021, 42(1):36-43. doi: 10.13957/j.cnki.tcxb.2021.01.003DUAN Yifan, ZHANG Guanglei, SHI Xinyue, et al. Research progress in preparation and application of cellulose aerogel[J]. Journal of Ceramics,2021,42(1):36-43(in Chinese). doi: 10.13957/j.cnki.tcxb.2021.01.003 [5] 张潇, 胡豪, 侯庆喜, 等. 纤维素基气凝胶在保温隔热领域中的研究进展[J]. 中国造纸, 2023, 42(2):86-93.ZHANG Xiao, HU Hao, HOU Qingxi, et al. Research progress of cellulose based aerogel in the field of thermal insulation[J]. China Paper,2023,42(2):86-93(in Chinese). [6] 狄莹莹, 任鹏刚, 李贞. 废弃物基纤维素气凝胶的研究进展[J]. 合成材料老化与应用, 2018, 47(5):114-121. doi: 10.16584/j.cnki.issn1671-5381.2018.05.025DI Yingying, REN Penggang, LI Zhen. Research progress of waste based cellulose aerogel[J]. Aging and Application of Synthetic Materials,2018,47(5):114-121(in Chinese). doi: 10.16584/j.cnki.issn1671-5381.2018.05.025 [7] NGUYEN S T, FENG J, LE N T, et al. Cellulose aerogel from paper waste for crude oil spill cleaning[J]. Industrial & Engineering Chemistry Research,2013,52(51):18386-18391. [8] JIN C, HAN S, LI J, et al. Fabrication of cellulose-based aerogels from waste newspaper without any pretreatment and their use for absorbents[J]. Carbohydrate Polymers,2015,123:150-156. doi: 10.1016/j.carbpol.2015.01.056 [9] 陈琪, 杨浩, 马新华, 等. 废纸浆气凝胶的制备及性能研究[J]. 化工新型材料, 2020, 48(6):261-265. doi: 10.19817/j.cnki.issn1006-3536.2020.06.057CHEN Qi, YANG Hao, MA Xinhua, et al. Study on preparation and properties of waste paper pulp aerogel[J]. New Chemical Materials,2020,48(6):261-265(in Chinese). doi: 10.19817/j.cnki.issn1006-3536.2020.06.057 [10] CHEN Y W, LEE H V. Revalorization of selected municipal solid wastes as new precursors of "green" nanocellulose via a novel one-pot isolation system: A source perspective[J]. International Journal of Biological Macromolecules,2018,107:78-92. doi: 10.1016/j.ijbiomac.2017.08.143 [11] ZHU Y, ZHU J, YU Z, et al. Air drying scalable production of hydrophobic, mechanically stable, and thermally insulating lignocellulosic foam[J]. Chemical Engineering Journal,2022,450:138300. doi: 10.1016/j.cej.2022.138300 [12] MALEKZADEH H, MD ZAID N S B, BELE E. Characterization and structural properties of bamboo fibre solid foams[J]. Cellulose,2021,28(2):703-714. doi: 10.1007/s10570-020-03565-0 [13] LIU Y, LU P, XIAO H, et al. Novel aqueous spongy foams made of three-dimensionally dispersed wood-fiber: Entrapment and stabilization with NFC/MFC within capillary foams[J]. Cellulose,2017,24(1):241-251. doi: 10.1007/s10570-016-1103-y [14] ZHANG T, XU J, ZHANG Y, et al. Gelatins as emulsifiers for oil-in-water emulsions: Extraction, chemical composition, molecular structure, and molecular modification[J]. Trends in Food Science & Technology,2020,106:113-131. [15] 王学川, 赵文莹, 张慧洁. 明胶的改性及其在胶黏剂中的应用研究进展[J]. 陕西科技大学学报, 2022, 40(4):100-108, 120. doi: 10.3969/j.issn.1000-5811.2022.04.015WANG Xuechuan, ZHAO Wenying, ZHANG Huijie. Research progress on the modification of gelatin and its application in adhesives[J]. Journal of Shaanxi University of Science and Technology,2022,40(4):100-108, 120(in Chinese). doi: 10.3969/j.issn.1000-5811.2022.04.015 [16] 吴文娟, 钟建. 多酚改性明胶复合物的制备及乳液应用[D]. 上海: 上海海洋大学, 2022.WU Wenjuan, ZHONG Jian. Preparation of polyphenol modified gelatin complex and application of lotion[D]. Shanghai: Shanghai Ocean University, 2022(in Chinese). [17] 唐杰斌, 赵传山. 明胶及其改性物作为造纸增强剂的应用[J]. 黑龙江造纸, 2008(130):47-49, 52.TANG Jiebin, ZHAO Chuanshan. The application of gelatin and its modifications as reinforcement agents for paper making[J]. Heilongjiang Paper,2008(130):47-49, 52(in Chinese). [18] 郭浩麒, 罗文翰, 肖乃玉, 等. 半纤维素/壳聚糖/明胶绿色抗菌包装膜的制备与表征[J]. 仲恺农业工程学院学报, 2021, 34(2):17-22, 30. doi: 10.3969/j.issn.1674-5663.2021.02.004GUO Haoqi, LUO Wenhan, XIAO Naiyu, et al. Preparation and characterization of hemicellulose/chitosan/gelatin green antibacterial packaging film[J]. Journal of Zhongkai Agricultural Engineering College,2021,34(2):17-22, 30(in Chinese). doi: 10.3969/j.issn.1674-5663.2021.02.004 [19] 李建, 吴伟兵. 纳米纤维素基凝胶材料的结构功能设计及应用[D]. 南京: 南京林业大学, 2018.LI Jian, WU Weibing. Structure function design and application of nano cellulose based gel materials[D]. Nanjing: Nanjing Forestry University, 2018(in Chinese). [20] 金浩, 刘杏, 林咏梅. 植酸改性的明胶复合膜制备及其结构与性能分析[J]. 化工进展, 2021, 40(7):3847-3853.JIN Hao, LIU Xing, LIN Yongmei. Preparation and structure and performance analysis of phytic acid modified gelatin composite film[J]. Chemical Progress,2021,40(7):3847-3853(in Chinese). [21] LI J, LI Y, SONG Y, et al. Ultrasonic-assisted synthesis of polyvinyl alcohol/phytic acid polymer film and its thermal stability, mechanical properties and surface resistivity[J]. Ultrasonics Sonochemistry,2017,39:853-862. doi: 10.1016/j.ultsonch.2017.06.017 [22] CAO M, LIU B W, ZHANG L, et al. Fully biomass-based aerogels with ultrahigh mechanical modulus, enhanced flame retardancy, and great thermal insulation applications[J]. Composites Part B: Engineering,2021,225:109309. doi: 10.1016/j.compositesb.2021.109309 [23] WANG H, CAO M, ZHAO H B, et al. Double-cross-linked aerogels towards ultrahigh mechanical properties and thermal insulation at extreme environment[J]. Chemical Engineering Journal,2020,399:125698. doi: 10.1016/j.cej.2020.125698 [24] 刘燕飞. 明胶-二氧化硅复合气凝胶的制备、改性及其性能研究[D]. 天津: 天津大学, 2016.LIU Yanfei. Preparation, modification and properties of gelatin silica composite aerogel[D]. Tianjin: Tianjin University, 2016(in Chinese). [25] 中华人民共和国国家质量监督检验检疫总局. 包装 运输包装件基本试验 第2部分: 温湿度调节处理: GB/T 4857.2—2005[S]. 北京: 中国标准出版社, 2005.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Packaging, transportation, basic testing of packaging components—Part 2: Temperature and humidity adjustment treatment: GB/T 4857.2—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [26] 闫慧敏, 杨光, 杨波, 等. 明胶/海藻酸钠/沙蒿胶复合水凝胶的制备及表征[J]. 工业微生物, 2022, 52(1):24-33.YAN Huimin, YANG Guang, YANG Bo, et al. Preparation and characterization of gelatin/sodium alginate/artemisia sphaerocephala gum composite hydrogel[J]. Industrial Microbiology,2022,52(1):24-33(in Chinese). [27] 付丽红, 张铭让, 齐永钦, 等. 胶原蛋白和植物纤维结合机理的研究[J]. 中国造纸学报, 2002(1):71-74. doi: 10.3321/j.issn:1000-6842.2002.01.016FU Lihong, ZHANG Mingrang, QI Yongqin, et al. A study on the binding mechanism between collagen and plant fibers[J]. Chinese Journal of Paper Industry,2002(1):71-74(in Chinese). doi: 10.3321/j.issn:1000-6842.2002.01.016 -

下载:

下载: