Direct-write 3D printing of polyimide-silica aerogel composites

-

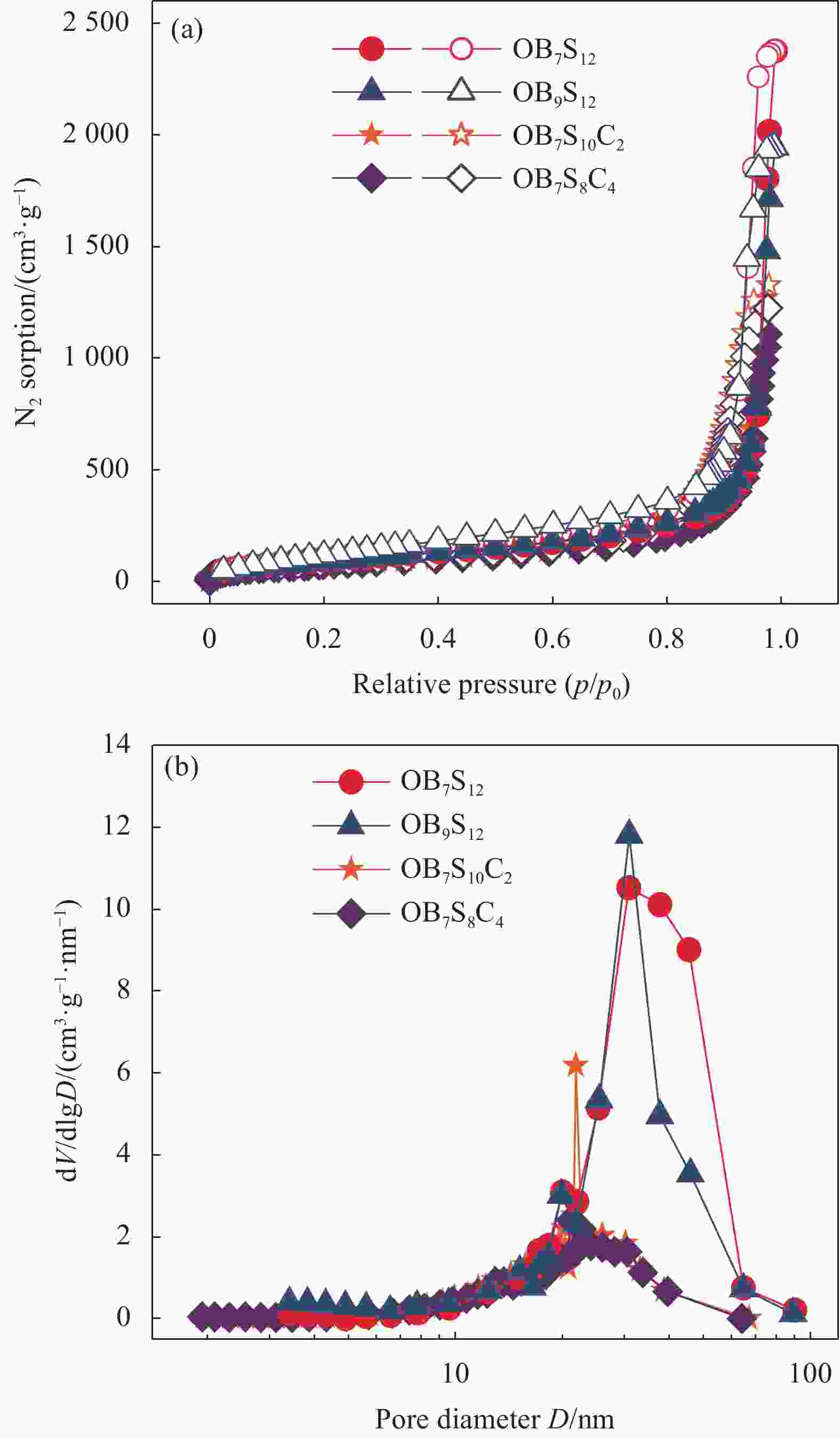

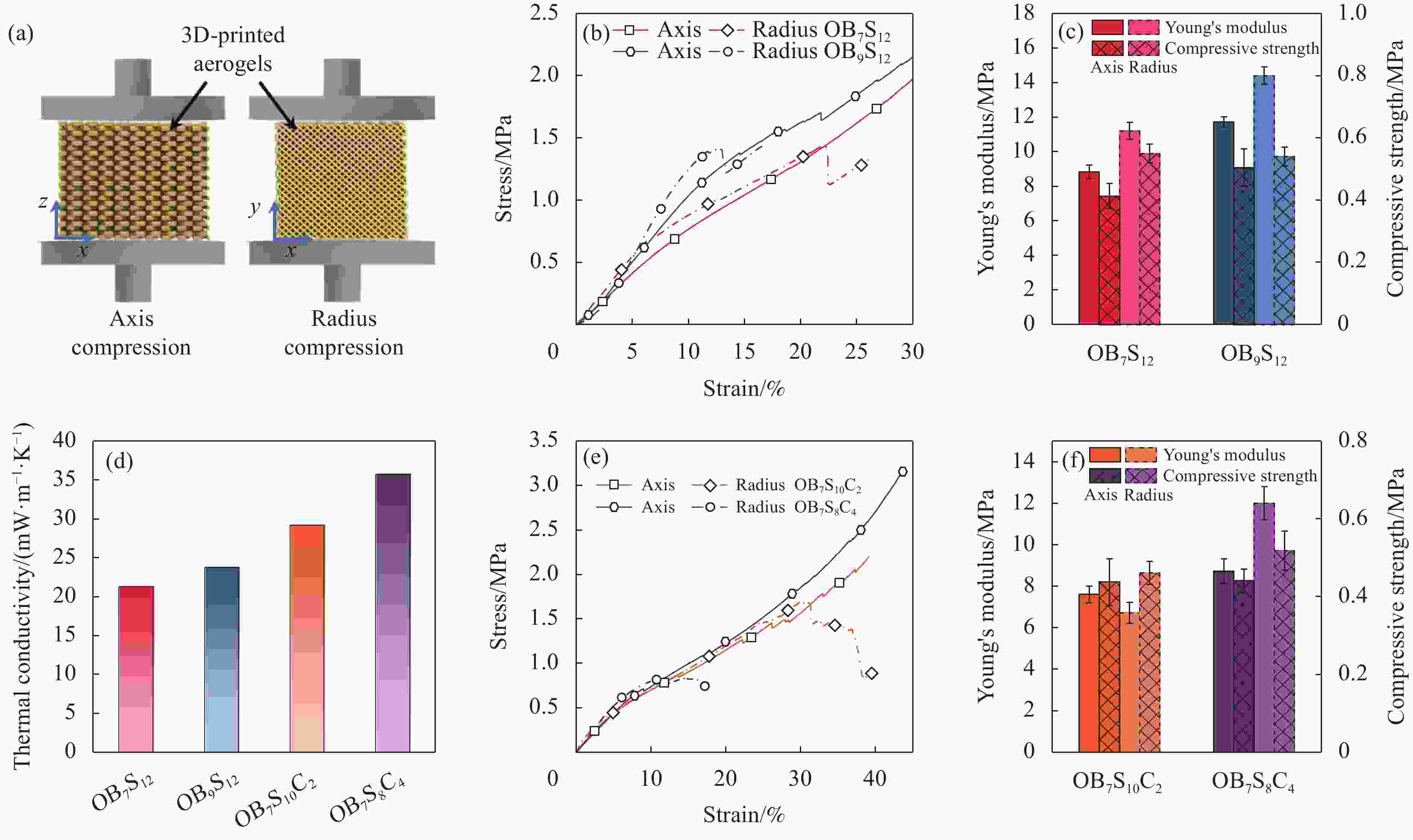

摘要: 特定几何体结构对实际应用场景中高效发挥气凝胶材料功能效应有着至关重要的影响。然而,受限于气凝胶的脆性、耗时制造周期和较差模具设计性,传统制造技术在气凝胶定制成型方面仍存在着挑战。直写3D打印技术可实现气凝胶按需塑型,并赋予气凝胶兼容材料组成和功能特性。本文提出了一种基于双通道互混挤出方式的直写3D打印策略,用于制备聚酰亚胺-氧化硅(OBS)气凝胶复合材料。受益于挤出过程中墨水与催化剂之间的流体扩散混合效应,化学酰亚胺化固化得以顺利实现,3D打印OBS气凝胶复合材料呈现出高结构完整性和高形状保真度。借助直写3D打印技术的空间组装优势,OBS气凝胶复合材料形成毫米、微米、纳米多尺度形貌,其中,微米尺度复合结构使3D打印OBS气凝胶复合材料表现出良好力学性能(杨氏模量高达14.4 MPa);纳米尺度多孔结构特征,如低密度(0.208 g·cm−3)、高表面积(373 m2·g−1)和集中孔径分布(20~30 nm),赋予3D打印OBS气凝胶复合材料优异隔热性能(热导率低至21.25 mW·m−1·K−1)。尽管本文仅关注于3D打印OBS气凝胶复合材料,但该3D打印策略的成功实施将为增材制造其他种类气凝胶复合材料提供了经验借鉴。Abstract: The specific geometry has a crucial impact on the function of aerogel materials in application scenarios. However, conventional manufacturing technology remains challenging in the customized shaping of aerogels due to the fragility of aerogels, time-consuming manufacturing cycles, and poor designability of molds. Direct-write 3D printing technology has been applied to achieve the on-demand shaping of aerogels, imparting aerogels with compatible material composition and functional characteristics. In this work, a direct-write 3D printing strategy based on dual-channel intermixing extrusion was proposed to prepare polyimide-silica (OBS) aerogel composites. Benefiting from the efficient fluid diffusion intermixing between inks and catalysts during extrusion processes, chemical imidization solidification can be successfully achieved, and 3D-printed OBS aerogel composites show high structural integrity and high shape fidelity. Depending on the advantages of the spatial assembly of direct-write 3D printing technology, OBS aerogel composites have formed multi-scale morphologies of millimeters, micrometers, and nanometers. In micron scale, the composite structure enables 3D-printed OBS aerogel composites to display excellent mechanical properties (Young's modulus up to 14.4 MPa). Meanwhile, nanoscale pore structure features, such as low density (0.208 g·cm−3), high surface area (373 m2·g−1), and concentrated poren diameter distribution (20-30 nm), impart 3D-printed OBS aerogel composites with excellent thermal insulation performance (thermal conductivity as low as 21.25 mW·m−1·K−1). Although our work only focuses on OBS aerogel composites, the successful implementation of this 3D printing strategy would provide guidelines for additive manufacturing of other aerogel composites.

-

Key words:

- 3D printing /

- silica /

- polyimide /

- aerogel /

- composite

-

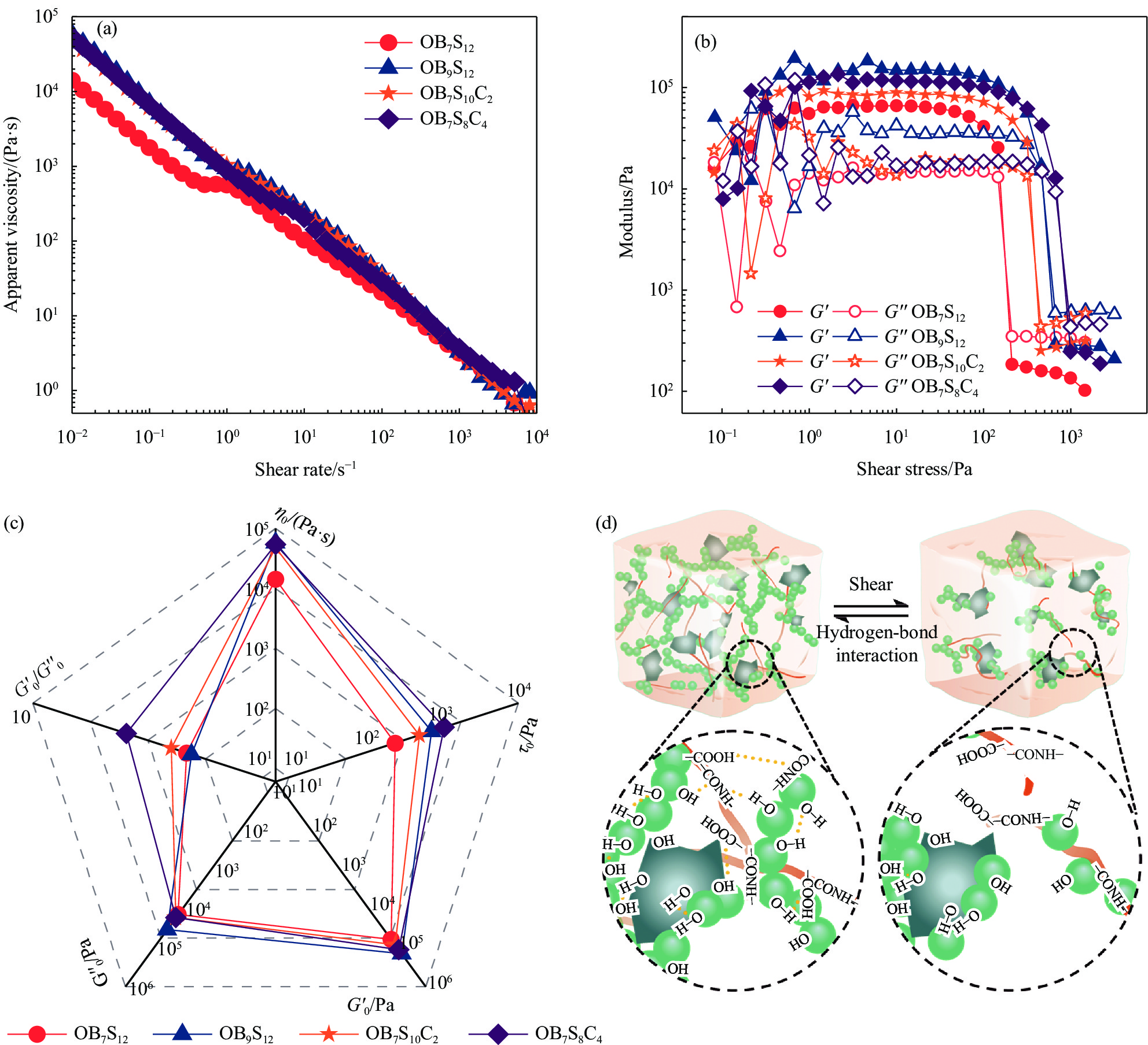

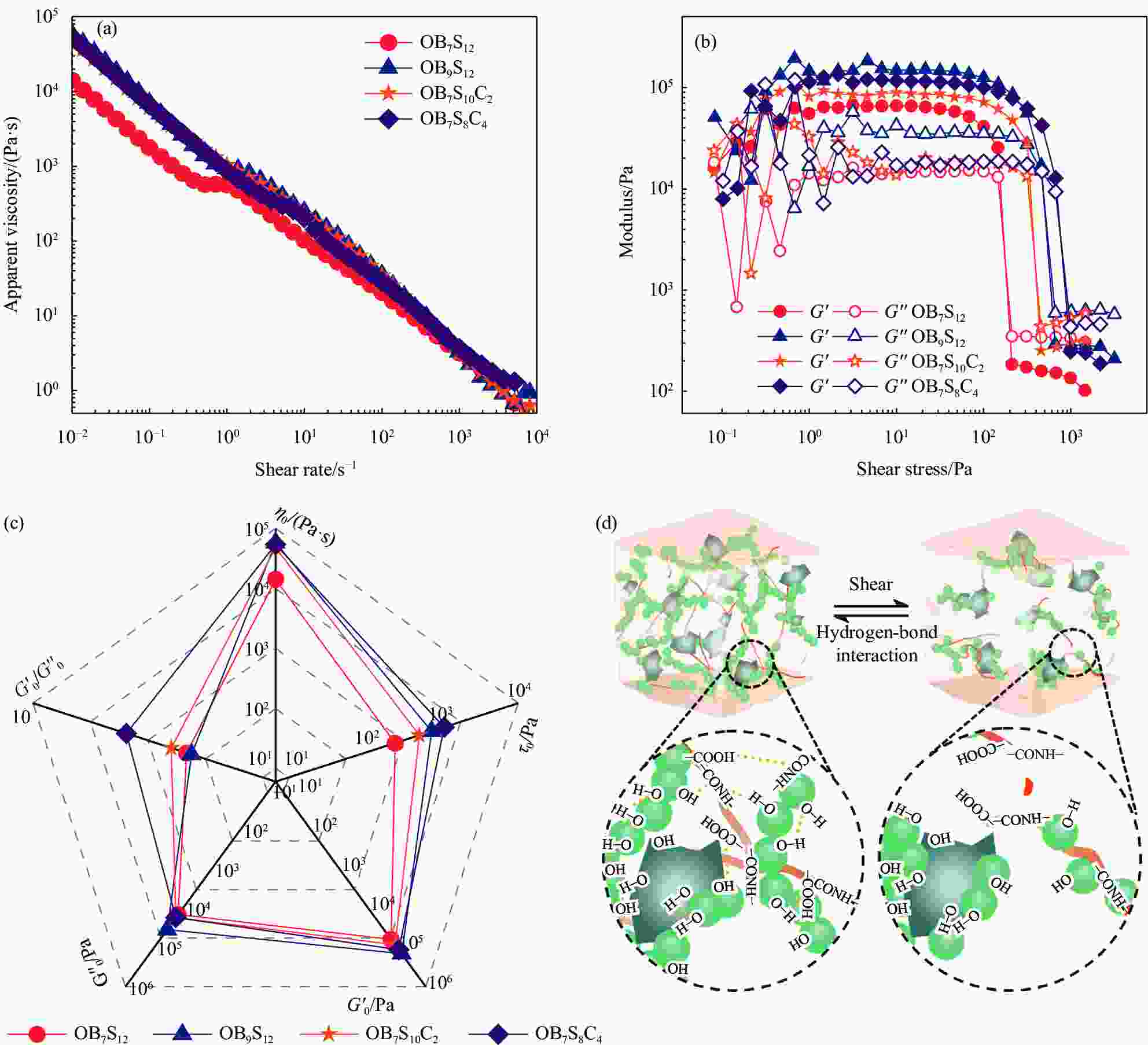

图 1 墨水的流变性能:(a) 黏度与剪切速率之间对数坐标关系图;(b) 储能模量(G')、损耗模量(G'')与剪切应力之间对数坐标关系图;(c) 墨水的流变性能参数对比图;(d) 可逆氢键交联结构示意图

Figure 1. Rheological properties of inks: (a) Log-log plots of apparent viscosity versus the shear rate; (b) Log-log plots of storage modulus (G') and loss modulus (G'') versus the shear stress; (c) Comparison of rheological performance index of different inks; (d) Schematic illustration of reversible hydrogen-bond crosslinking structure

η0—Initial apparent viscosity; τ0—Yield stress

图 2 基于双通道混合挤出方式的直写3D打印技术:(a) Z字形结构中墨水与催化剂发生流体扩散混合的示意图;(b) 直写3D打印OB7S12气凝胶复合材料(b1)和OB7S10C2气凝胶复合材料(b2)的过程照片

Figure 2. Direct-write 3D printing technology based on the specific methodology of two-channel intermixing extrusion: (a) Schematic illustration of the fluid diffusion intermixing of inks and catalysts in a zig-zag structure; (b) Optical photographs of direct-write 3D printing processes of OB7S12 aerogel composites (b1) and OB7S10C2 aerogel composites (b2)

Sc—Supercritical; TEA—Triethylamine

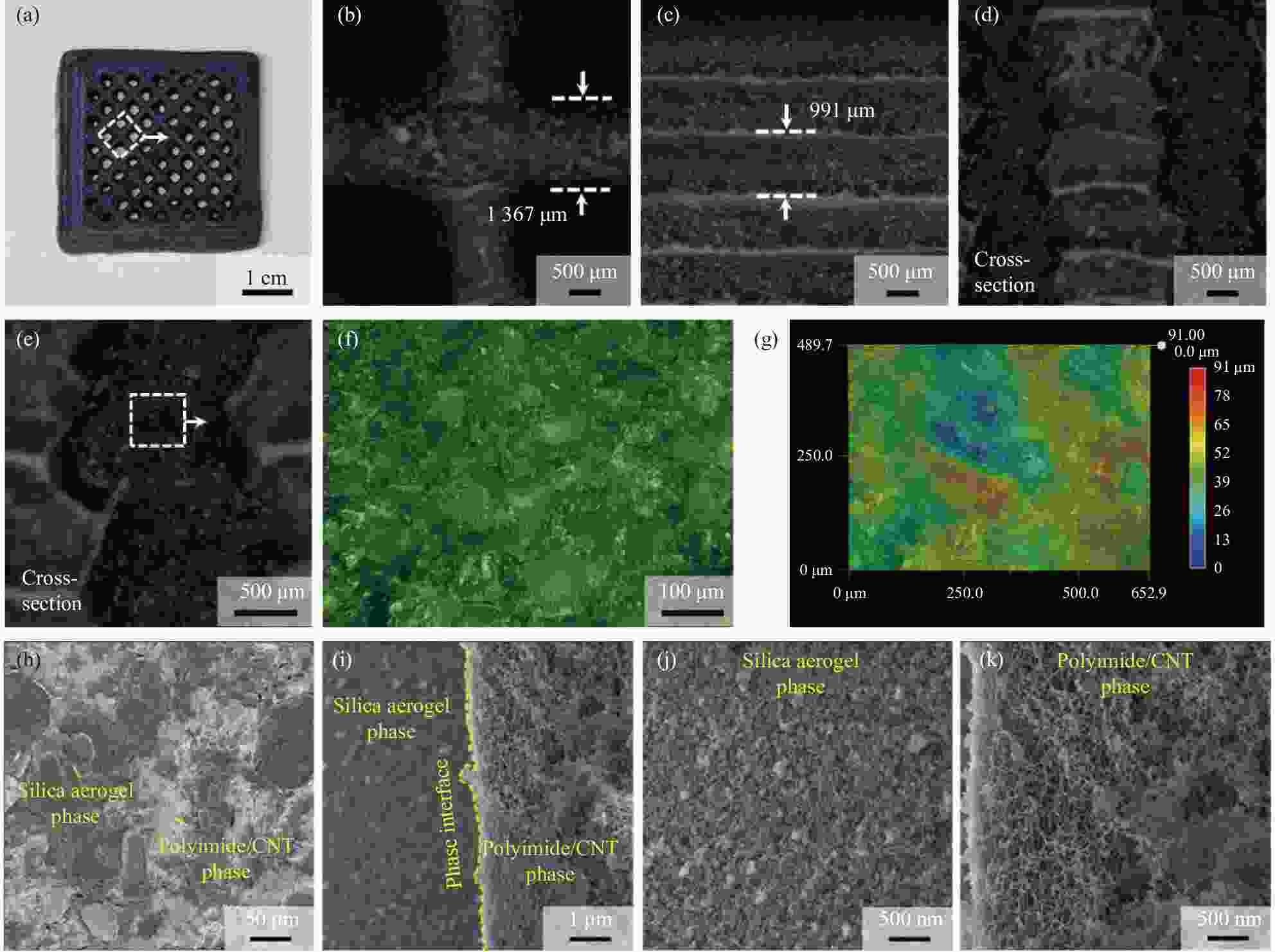

图 3 3D打印OB7S10C2气凝胶格栅的多尺度形貌:(a) 采用1.35 mm喷嘴打印的气凝胶格栅结构的光学照片;((b)~(f)) 格栅精细结构的超景深显微镜照片;(g) 格栅横截面的表面粗糙度;((h)~(k)) OB7S10C2气凝胶复合材料的SEM图像

Figure 3. Multi-scale morphologies of 3D-printed OB7S10C2 aerogel grids: (a) Optical photographs of aerogel grids printed with nozzles with a diameter of 1.35 mm; ((b)-(f)) Ultra-depth three-dimensional microscopic images of fine structures in grids; (g) Surface profile of cross-sectional structure in grids; ((h)-(k)) SEM images of OB7S10C2 aerogel composites

CNT—Carbon nanotube

图 6 3D打印OBS气凝胶复合材料的力学与隔热性能:(a) 轴向和径向压缩示意图;((b), (e)) 压缩应力-应变曲线;((c), (f)) 杨氏模量和5%应变处压缩强度;(d) 3D打印OBS气凝胶的热导率

Figure 6. Mechanical and thermal performances of 3D-printed OBS aerogel composites: (a) Schematic illustration of mechanical compression in axis and radius directions; ((b), (e)) Compression stress-strain curves; ((c), (f)) Young's moduli and compressive strength at 5% strain; (d) Thermal conductivity of 3D-printed OBS aerogels

表 1 3D打印聚酰亚胺-氧化硅(OBS)气凝胶及其复合材料的墨水配方

Table 1. Ink formula of 3D printing polyimide-silica (OBS) aerogels and their composites

Sample name

abbreviationODA-BPDA/

wt%Silica/

wt%Carbon

nanotube/wt%Solvent/

wt%OB7S12 7.0 12.0 0.0 81.0 OB9S12 9.0 12.0 0.0 79.0 OB7S10C2 7.0 10.0 2.0 81.0 OB7S8C4 7.0 8.0 4.0 81.0 Note: ODA—4, 4-diaminodiphenyl ether; BPDA—3, 3', 4, 4'-bi-phenyltetracarboxylic dianhydride. 表 2 3D打印OBS气凝胶复合材料的孔结构数据

Table 2. Pore structure data of OBS aerogels and their composites

Sample Density/(g·cm−3) Shrinkage/% Specific surface

areaa/(m2·g−1)Mean pore

diameterb/nmPore volumec/

(cm3·g−1)OB7S12 0.208 0.74 370 30.8 3.69 OB9S12 0.234 1.36 373 30.8 2.99 OB7S10C2 0.223 3.29 285 21.7 2.19 OB7S8C4 0.224 1.37 279 20.9 2.00 Notes: a—Specific surface area obtained by the BET theory; b and c—Mean pore diameter and pore volume obtained by the BJH method; BET—Brunauer-Emmett-Teller; BJH—Barrett-Joyner-Halenda. -

[1] GURAV J L, JUNG I K, PARK H H, et al. Silica aerogel: Synthesis and applications[J]. Journal of Nanomaterials,2010,2010:409310. doi: 10.1155/2010/409310 [2] KISTLER S S. Coherent expanded aerogels and jellies[J]. Nature,1931,127(3211):741. doi: 10.1038/127741a0 [3] SOLEIMANI DORCHEH A, ABBASI M H. Silica aerogel: Synthesis, properties and characterization[J]. Journal of Materials Processing Technology,2008,199(1-3):10-26. doi: 10.1016/j.jmatprotec.2007.10.060 [4] LINHARES T, PESSOA DE AMORIM M T, DURÃES L. Silica aerogel composites with embedded fibres: A review on their preparation, properties and applications[J]. Journal of Materials Chemistry A,2019,7(40):22768-22802. doi: 10.1039/C9TA04811A [5] LI C D, CHEN Z F, DONG W F, et al. A review of silicon-based aerogel thermal insulation materials: Performance optimization through composition and microstructure[J]. Journal of Non-Crystalline Solids,2021,553:120517. doi: 10.1016/j.jnoncrysol.2020.120517 [6] 张明. 增强改性SiO2气凝胶复合材料的研究进展[J]. 复合材料学报, 2020, 37(11):2674-2683.ZHANG Ming. Research progress of reinforced SiO2 aerogel composites[J]. Acta Materiae Compositae Sinica,2020,37(11):2674-2683(in Chinese). [7] HASAN M A, SANGASHETTY R, ESTHER A M, et al. Prospect of thermal insulation by silica aerogel: A brief review[J]. Journal of the Institution of Engineers (India): Series D,2017,98(2):297-304. doi: 10.1007/s40033-017-0136-1 [8] GRONAUER M, FRICKE J. Acoustic properties of microporous SiO2 aerogel[J]. Acta Acustica United with Acustica,1986,59(3):177-181. [9] DÍAZ D D, KÜHBECK D, KOOPMANS R J. Stimuli-responsive gels as reaction vessels and reusable catalysts[J]. Chemical Society Reviews,2011,40(1):427-448. doi: 10.1039/C005401C [10] TABATA M, ADACHI I, KAWAI H, et al. Recent progress in silica aerogel Cherenkov radiator[J]. Physics Procedia,2012,37:642-649. doi: 10.1016/j.phpro.2012.02.410 [11] AYERS M R, HUNT A J. Visibly photoluminescent silica aerogels[J]. Journal of Non-Crystalline Solids,1997,217(2-3):229-235. doi: 10.1016/S0022-3093(97)00126-9 [12] JI X F, DU Y, ZHANG X T. Elaborate size-tuning of silica aerogel building blocks enables laser-driven lighting[J]. Advanced Materials,2022,34(6):2107168. doi: 10.1002/adma.202107168 [13] BASKARAN S, LIU J, DOMANSKY K, et al. Low dielectric constant mesoporous silica films through molecularly templated synthesis[J]. Advanced Materials,2000,12(4):291-294. doi: 10.1002/(SICI)1521-4095(200002)12:4<291::AID-ADMA291>3.0.CO;2-P [14] MALEKI H, DURÃES L, PORTUGAL A. An overview on silica aerogels synthesis and different mechanical reinforcing strategies[J]. Journal of Non-Crystalline Solids, 2014, 385: 55-74. [15] ISWAR S, MALFAIT W J, BALOG S, et al. Effect of aging on silica aerogel properties[J]. Microporous and Mesoporous Materials,2017,241:293-302. doi: 10.1016/j.micromeso.2016.11.037 [16] 王鲁凯. 双交联聚有机硅氧烷气凝胶的制备及其性能研究[D]. 长沙: 国防科技大学, 2019.WANG Lukai. Synthesis and properties of doubly cross-linked polyorganosiloxane aerogels[D]. Changsha: National University of Defense Technology, 2019(in Chinese). [17] AKHTER F, SOOMRO S A, INGLEZAKIS V J. Silica aerogels: A review of synthesis, applications and fabrication of hybrid composites[J]. Journal of Porous Materials,2021,28(5):1387-1400. doi: 10.1007/s10934-021-01091-3 [18] ŚLOSARCZYK A. Recent advances in research on the synthetic fiber based silica aerogel nanocomposites[J]. Nanomaterials,2017,7(2):44. doi: 10.3390/nano7020044 [19] WANG L K, FENG J Z, JIANG Y G, et al. Elastic methyltrimethoxysilane based silica aerogels reinforced with polyvinylmethyldimethoxysilane[J]. RSC Advances,2019,9(19):10948-10957. doi: 10.1039/C9RA00970A [20] MALEKI H, DURÃES L, PORTUGAL A. Synthesis of lightweight polymer-reinforced silica aerogels with improved mechanical and thermal insulation properties for space applications[J]. Microporous and Mesoporous Materials,2014,197:116-129. doi: 10.1016/j.micromeso.2014.06.003 [21] LEE K Y, MAHADIK D B, PARALE V G, et al. Composites of silica aerogels with organics: A review of synthesis and mechanical properties[J]. Journal of the Korean Ceramic Society,2020,57(1):1-23. doi: 10.1007/s43207-019-00002-2 [22] 王鲁凯, 冯军宗, 李良军, 等. 疏水改性聚酰亚胺的研究进展[J]. 材料导报, 2018, 32(S2):264-269.WANG Lukai, FENG Junzong, LI Liangjun, et al. Research progress on hydrophobic modification of polyimide[J]. Materials Reports,2018,32(S2):264-269(in Chinese). [23] LIAW D J, WANG K L, HUANG Y C, et al. Advanced polyimide materials: Syntheses, physical properties and applications[J]. Progress in Polymer Science,2012,37(7):907-974. doi: 10.1016/j.progpolymsci.2012.02.005 [24] 罗伟, 王林生, 陈裕欣, 等. 有机-无机复合气凝胶的制备及其阻燃性能研究进展[J]. 复合材料学报, 2021, 38(7):2056-2069. doi: 10.13801/j.cnki.fhclxb.20210324.002LUO Wei, WANG Linsheng, CHEN Yuxin, et al. Research progress on preparation and flame retardant properties of organic-inorganic composite aerogel[J]. Acta Materiae Compositae Sinica,2021,38(7):2056-2069(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210324.002 [25] 费志方, 杨自春, 李昆锋, 等. 疏水性聚酰亚胺增强SiO2气凝胶复合材料的制备与表征[J]. 复合材料学报, 2018, 35(9):2566-2572.FEI Zhifang, YANG Zichun, LI Kunfeng, et al. Preparation and characterization of hydrophobic polyimide reinforced SiO2 aerogel composites[J]. Acta Materiae Compositae Sinica,2018,35(9):2566-2572(in Chinese). [26] KANTOR Z, WU T T, ZENG Z H, et al. Heterogeneous silica-polyimide aerogel-in-aerogel nanocomposites[J]. Chemical Engineering Journal,2022,443:136401. doi: 10.1016/j.cej.2022.136401 [27] 王鲁凯, 冯军宗, 姜勇刚, 等. 直写3D打印陶瓷基多孔结构的研究进展[J]. 无机材料学报, 2023, 38(10): 1133-1148.WANG Lukai, FENG Junzong, JIANG Yonggang, et al. Direct-ink-writing 3D printing of ceramic-based porous structures: A review[J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148(in Chinese). [28] WAN X E, LUO L, LIU Y J, et al. Direct ink writing based 4D printing of materials and their applications[J]. Advanced Science,2020,7(16):2001000. doi: 10.1002/advs.202001000 [29] SAADI M A S R, MAGUIRE A, POTTACKAL N T, et al. Direct ink writing: A 3D printing technology for diverse materials[J]. Advanced Materials,2022,34(28):2108855. doi: 10.1002/adma.202108855 [30] FENG J Z, SU B L, XIA H S, et al. Printed aerogels: Chemistry, processing, and applications[J]. Chemical Society Reviews,2021,50(6):3842-3888. doi: 10.1039/C9CS00757A [31] WANG L K, FENG J Z, LUO Y, et al. Versatile thermal-solidifying direct-write assembly towards heat-resistant 3D-printed ceramic aerogels for thermal insulation[J]. Small Methods, 2022, 6(5): 2200045. [32] WANG L K, FENG J Z, JIANG Y G, et al. Ultraviolet-assisted direct-write printing strategy towards polyorganosiloxane-based aerogels with freeform geometry and outstanding thermal insulation performance[J]. Chemical Engineering Journal, 2023, 455: 140818. [33] WANG L K, FENG J Z, LUO Y, et al. Three-dimensional-printed silica aerogels for thermal insulation by directly writing temperature-induced solidifiable inks[J]. ACS Applied Materials & Interfaces,2021,13(34):40964-40975. [34] YUN S, LUO H J, GAO Y F. Ambient-pressure drying synthesis of large resorcinol-formaldehyde-reinforced silica aerogels with enhanced mechanical strength and superhydrophobicity[J]. Journal of Materials Chemistry A,2014,2(35):14542-14549. doi: 10.1039/C4TA02195A [35] NOTARIO B, PINTO J, SOLORZANO E, et al. Experimental validation of the Knudsen effect in nanocellular polymeric foams[J]. Polymer,2015,56:57-67. doi: 10.1016/j.polymer.2014.10.006 [36] ZU G Q, KANAMORI K, SHIMIZU T, et al. Versatile double-cross-linking approach to transparent, machinable, supercompressible, highly bendable aerogel thermal superinsulators[J]. Chemistry of Materials,2018,30(8):2759-2770. doi: 10.1021/acs.chemmater.8b00563 [37] KIM J, KWON J, KIM M, et al. Low-dielectric-constant polyimide aerogel composite films with low water uptake[J]. Polymer Journal,2016,48(7):829-834. doi: 10.1038/pj.2016.37 [38] GUO H Q, MEADOR M A B, MCCORKLE L, et al. Tailoring properties of cross-linked polyimide aerogels for better moisture resistance, flexibility, and strength[J]. ACS Applied Materials & Interfaces,2012,4(10):5422-5429. [39] TAFRESHI O A, SAADATNIA Z, GHAFFARI-MOSANENZADEH S, et al. Flexible and shape-configurable PI composite aerogel films with tunable dielectric properties[J]. Composites Communications,2022,34:101274. doi: 10.1016/j.coco.2022.101274 -

下载:

下载: