Preparation and flame retardancy of thermoplastic polyester elastomer composites

-

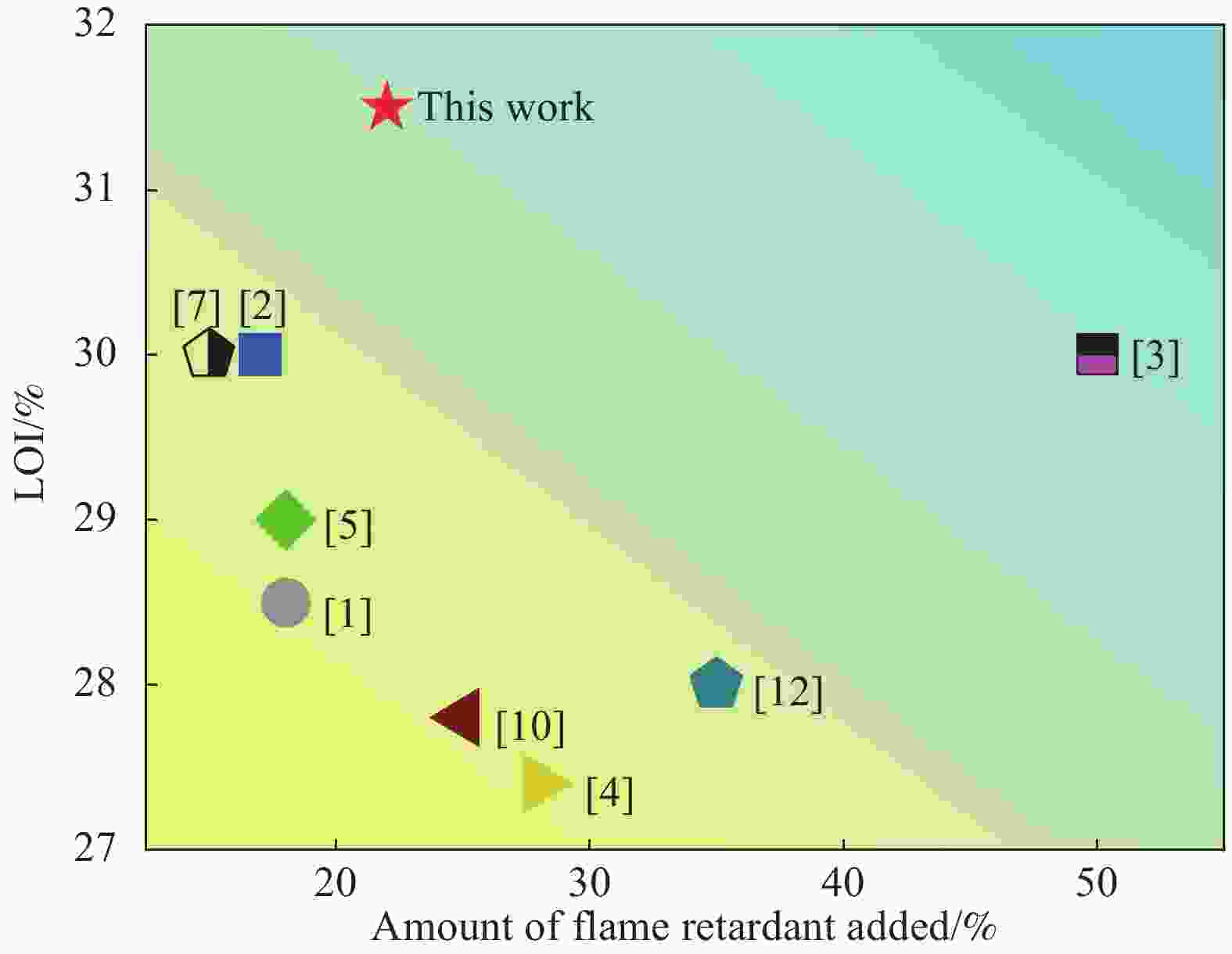

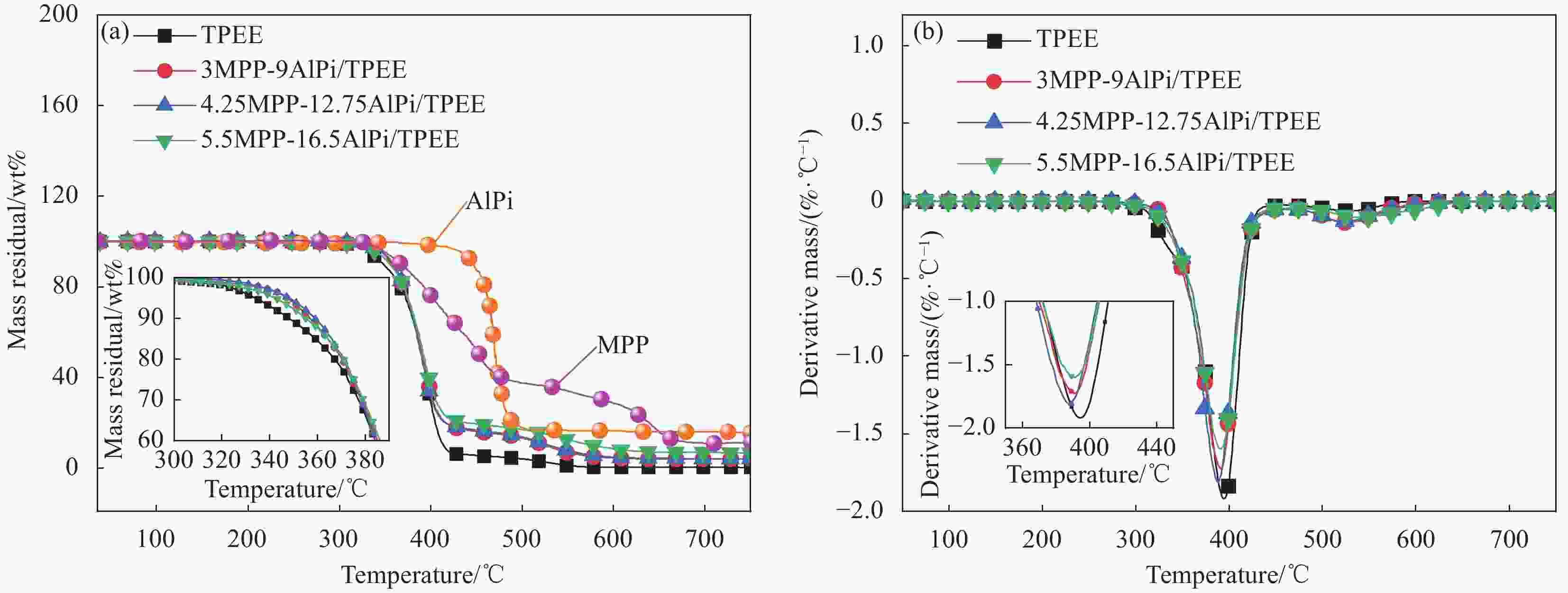

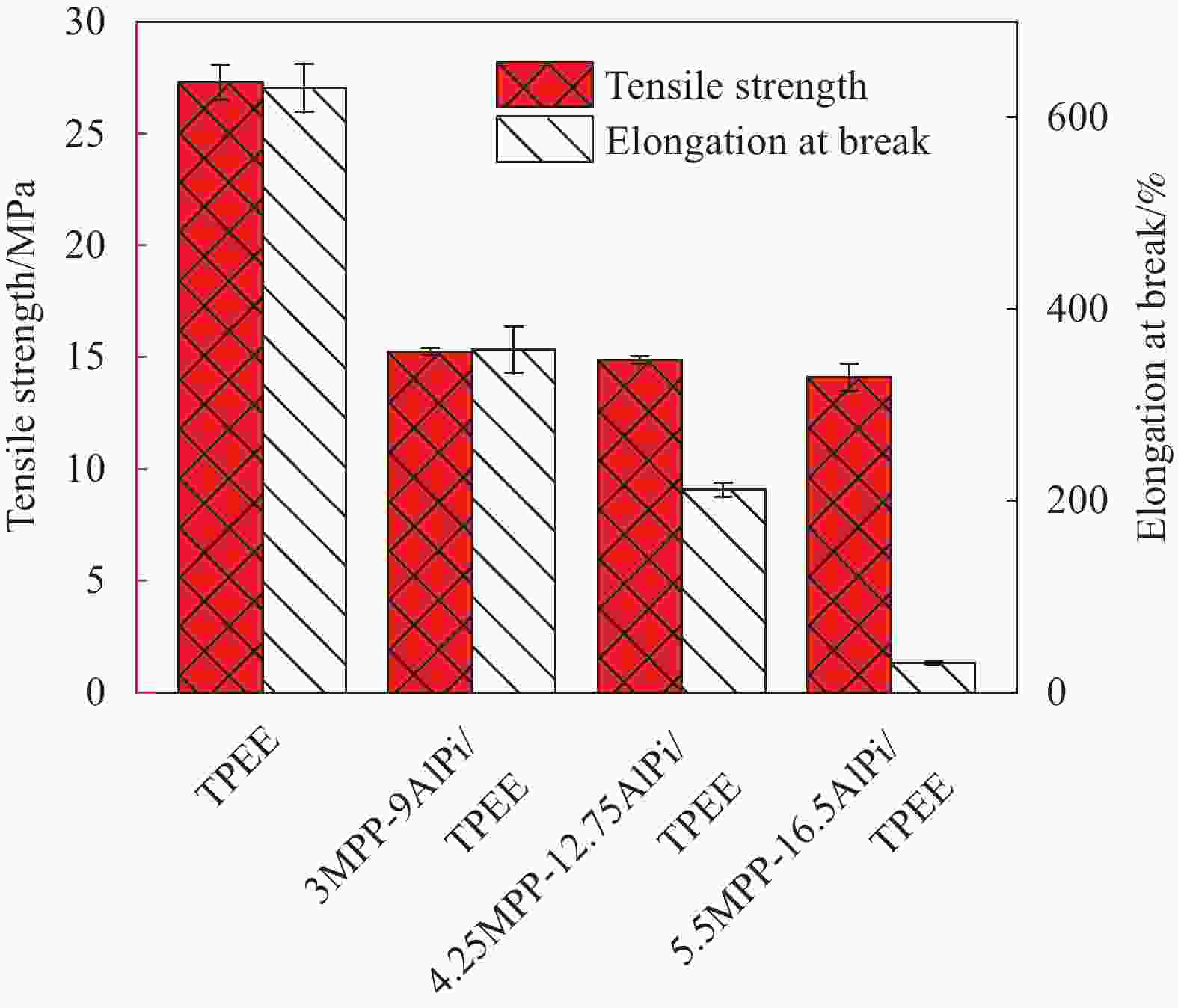

摘要: 由于热塑性聚酯弹性体(TPEE)极易燃烧,严重阻碍了其在电子电气、电线护套、充电桩等领域的应用,为解决此问题,以二乙基次磷酸铝(AlPi)和三聚氰胺聚磷酸盐(MPP)为阻燃剂,添加到TPEE中,采用密炼和热压成型方法制备出高阻燃性TPEE复合材料。采用极限氧指数(LOI)测试、垂直燃烧(UL-94)测试、锥形量热(CONE)测试等对TPEE复合材料的阻燃性能进行了测试。结果表明:AlPi和MPP复配可以实现TPEE的高效阻燃,添加22wt%复配阻燃剂的TPEE材料的LOI由19.3%提升至31.5%,UL-94达到V-0级,总热释放和峰值热释放速率下降27.6%和64.8%。采用热失重分析仪(TGA)、扫描电子显微镜、力学性能测试仪及电绝缘性能测试仪等对TPEE材料的热稳定性、力学性能、电性能及其烧蚀前后的微观形貌进行了表征。结果表明:复配阻燃剂的阻燃机制为膨胀炭层凝聚相阻隔型阻燃,且促进了TPEE分解成炭;力学性能、电绝缘性能和微观形貌测试表明复配的AlPi和MPP能够提升TPEE材料的电绝缘性,但其与TPEE相容性较差,导致TPEE材料的力学性能下降。Abstract: Thermoplastic polyester elastomer (TPEE) is extremely flammable, which seriously hinders its application in the fields of electronics and electrical, wire sheath, charging station, etc. TPEE composites with high flame retardancy were prepared by adding aluminum diethylphosphinate (AlPi) and melamine polyphosphate (MPP) flame retardant into TPEE matrix through internal mixing and hot pressing process. The flame retardancy of the TPEE composites was studied by limiting oxygen index (LOI), vertical burning (UL-94) and cone calorimeter (CONE) tests. The results show that AlPi combined with MPP can achieve high-efficiency flame retardancy of TPEE composites. In addition, the TPEE composite with 22wt%AlPi and MPP passed the UL-94 V-0 rating and its LOI value increase from 19.3% to 31.5%, accompanied with 27.6% reduction in the total heat release and 64.8% reduction of the peak heat release rate compared to pure TPEE. The thermal stabilities, mechanical properties, and electrical properties of the TPEE composites, as well as the microscopic morphology of the composites before and after ablation were studied by thermogravimetric analyzer (TGA), SEM, universal testing machine and electrical insulation test. The results indicate that the flame retardant mechanism of the composite flame retardant system is the barrier action of intumescent char layer in the condense phase. The composite flame retardant system can promote the decomposition of TPEE into carbon. The mechanical properties, electrical insulation properties and microtopography tests show that the combination of AlPi and MPP can improve the electrical insulation performance, but reduce the mechanical properties of TPEE composites due to their poor compatibility with TPEE matrix.

-

图 3 MPP-AlPi/TPEE复合材料的热释放率(HRR) (a)、总热释放(THR) (b)、质量损失率(MLR) (c)和TPEE (d)、3MPP-9AlPi/TPEE (e)、4.25MPP-12.75AlPi/TPEE (f)、5.5MPP-16.5AlPi/TPEE (g)复合材料在锥形量热实验后的残炭照片

Figure 3. Heat release rate (HRR) (a), total heat release (THR) (b), mass loss rate (MLR) (c) of MPP-AlPi/TPEE composite materials and carbon residue photos of TPEE (d), 3MPP-9AlPi/TPEE (e), 4.25MPP-12.75AlPi/TPEE (f) and 5.5MPP-16.5AlPi/TPEE (g) after cone calorimetry test

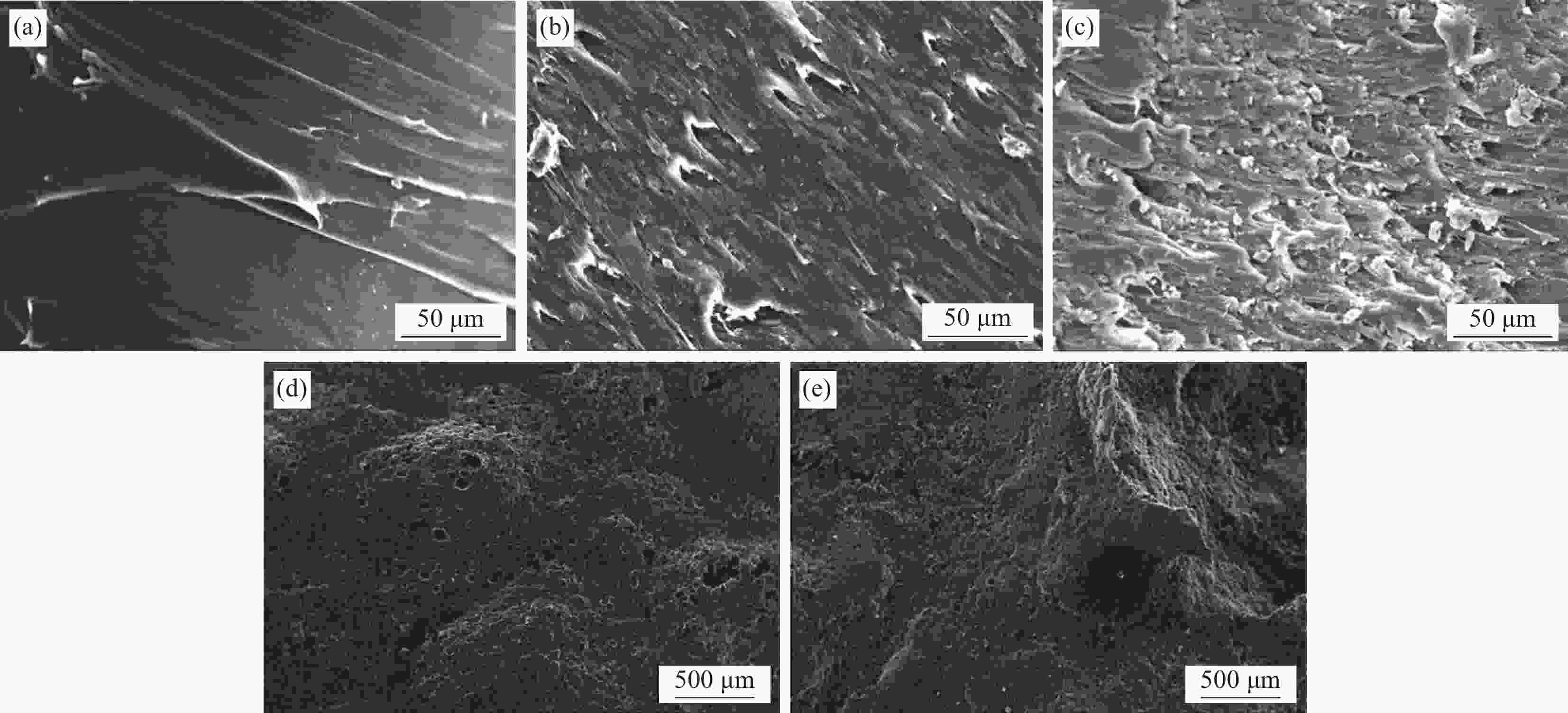

图 5 TPEE (a)、3MPP-9AlPi/TPEE (b)和5.5MPP-16.5AlPi/TPEE (c)的断面微观形貌及4.25MPP-12.75AlPi/TPEE (d)和5.5MPP-16.5AlPi/TPEE (e)在锥形量热实验后的微观形态

Figure 5. SEM images of shear cross-section microstructure of TPEE (a), 3MPP-9AlPi/TPEE (b), 5.5MPP-16.5AlPi/TPEE (c) and micromorphology of carbon layer of 4.25MPP-12.75AlPi/TPEE (d) and 5.5MPP-16.5AlPi/TPEE (e) after cone calorimetry test

表 1 三聚氰胺聚磷酸盐(MPP)-二乙基次磷酸铝(AlPi)/热塑性聚酯弹性体(TPEE)复合材料的配方

Table 1. Formulations of melamine polyphosphate (MPP)-aluminum diethylphosphinate (AlPi)/thermoplastic polyester elastomer (TPEE) composites

Sample TPEE/wt% AlPi/wt% MPP/wt% TPEE

3MPP-9AlPi/TPEE

4.25MPP-12.75AlPi/TPEE

5.5MPP-16.5AlPi/TPEE100

88

83

780.00

9.00

12.75

16.500.00

3.00

4.25

5.50Note: Each sample contains an additional 2% antioxidant 1010. 表 2 不同MPP-AlPi/TPEE复合材料的极限氧指数(LOI)及垂直燃烧(UL-94)测试结果

Table 2. Limiting oxygen index (LOI) and vertical burning (UL-94) test results of different MPP-AlPi/TPEE composites

Sample LOI/% UL-94 Driping t1/s t2/s TPEE 19.3 No rating Yes —a —a 3MPP-9AlPi/TPEE 26.3 No rating Yes —a —a 4.25MPP-12.75AlPi/TPEE 27.6 V-0 No 2.3 5.7 5.5MPP-16.5AlPi/TPEE 31.5 V-0 No 0.0 1.1 Notes: t1—Self-extinguishing time after the first ignition; t2—Self-extinguishing time after the second ignition; —a: After ignition, the sample continues to burn until it is completely burned out. 表 3 不同MPP-AlPi/TPEE复合材料的锥形量热数据

Table 3. Cone calorimetric data of different MPP-AlPi/TPEE composites

Sample TTI/s Tp/s PHRR/

(kW·m–2)THR/

(MJ·m–2)CO yield/

(kg·kg–1)CO2 yield/

(kg·kg–1)Residue/

%FGI FPI TPEE 33 65 529.0±5.8 41.4±2.6 0.04±0.01 1.82±0.01 4.2±0.1 8.1 0.06 3MPP-9AlPi/TPEE 40 105 277.1±3.2 34.9±2.1 0.18±0.02 1.43±0.02 10.1±0.1 2.6 0.14 4.25MPP-12.75AlPi/TPEE 39 116 260.7±2.8 36.0±2.3 0.21±0.01 1.43±0.01 10.6±0.2 2.3 0.15 5.5MPP-16.5AlPi/TPEE 41 114 186.3±2.4 30.0±1.8 0.20±0.01 1.43±0.01 28.0±0.1 1.6 0.22 Notes: TTI—Ignition time; Tp—Time to reach peak heat release rate; PHRR—Peak heat release rate; FGI—Fire growth index; FPI—Fire performance index. 表 4 MPP-AlPi/TPEE复合材料在空气中的TGA数据

Table 4. TGA data of MPP-AlPi/TPEE composites in air

Sample T5%/℃ Tmax/℃ DTGmax/(%·℃–1) Residue at 700℃ (Exp.)/wt% Residue at 700℃ (Cal.)/wt% TPEE 333.1 393.1 1.9 0.5 — AlPi 435.6 445.6 2.2 24.0 — MPP 351.7 411.1 1.0 21.0 — 3MPP-9AlPi/TPEE 342.1 390.0 1.8 4.1 3.2 4.25MPP-12.75AlPi/TPEE 347.1 391.2 1.7 5.1 4.4 5.5MPP-16.5AlPi/TPEE 348.2 392.2 1.6 7.0 5.5 Notes: T5%—Initial degradation temperature of the composite; Tmax—Temperature at maximum mass loss rate; DTGmax—Maximum mass loss rate; Exp.—Experimental value; Cal.—Calculated value.

表 5 MPP-AlPi/TPEE复合材料的杨氏模量

Table 5. Young's modulus of MPP-AlPi/TPEE composites

Sample Young's modulus/MPa TPEE 4.32±0.23 3MPP-9AlPi/TPEE 4.26±0.26 4.25MPP-12.75AlPi/TPEE 7.01±0.55 5.5MPP-16.5AlPi/TPEE 45.48±1.58 表 6 MPP-AlPi/TPEE复合材料的体积电阻率

Table 6. Volume resistivity of MPP-AlPi/TPEE composites

Sample Volume

resistivity/(1011 Ω·m)TPEE 3.41±0.34 3MPP-9AlPi/TPEE 6.21±0.46 4.25MPP-12.75AlPi/TPEE 8.59±0.57 5.5MPP-16.5AlPi/TPEE 16.90±8.90 -

[1] LIU C, ZHANG L C, MU L X, et al. Synergistic effects between a triazine-based charring agent and aluminum phosphinate on the intumescent flame retardance of thermoplastic polyether ester[J]. Journal of Macromolecular Science, Part A: Pure and Applied Chemistry,2019,56(7):723-732. [2] 郭正波, 夏利平, 何正宏, 等. 阻燃热塑性聚酯弹性体复合材料制备及性能[J]. 工程塑料应用, 2020, 48(4):20-24, 36. doi: 10.3969/j.issn.1001-3539.2020.04.004GUO Zhengbo, XIA Liping, HE Zhenghong, et al. Preparation and properties of flame-retardant thermoplastic polyester elastomer composites[J]. Engineering Plastics Application,2020,48(4):20-24, 36(in Chinese). doi: 10.3969/j.issn.1001-3539.2020.04.004 [3] 胡先海, 刘曼莉, 王射林, 等. 氮-磷无卤阻燃剂对热塑性聚酯弹性体性能的影响[J]. 材料科学与工程学报, 2019, 37(1):126-130.HU Xianhai, LIU Manli, WANG Shelin, et al. Effect of halogen-free nitrogen phosphorus flame retardant on thermoplastic polyester elastomer[J]. Journal of Materials Science and Engineering,2019,37(1):126-130(in Chinese). [4] ZOU L, ZHOU M, LIU J, et al. Flame-retardant thermoplastic polyester based on multiarm aluminum phosphinate for improving anti-dripping[J]. Thermochimica Acta,2018,664:118-127. doi: 10.1016/j.tca.2018.04.016 [5] ZHANG L, WU W, ZHONG Y, et al. Synergistic effects of BHDB-IPC with AlPi/MCA on flame retarding TPEE[J]. RSC Advances,2015,5(106):87609-87615. doi: 10.1039/C5RA13677F [6] KIM S, LINH P T H, KANG J, et al. Phosphorus-containing thermoplastic poly(ether ester) elastomers showing intrinsic flame retardancy[J]. Journal of Applied Polymer Science,2017,134:45478. doi: 10.1002/app.45478 [7] 吴唯, 钟宇华, 吴仁, 等. 磷-氮阻燃剂与酚醛成炭剂复配阻燃热塑性聚醚酯弹性体[J]. 高分子材料科学与工程, 2015, 31(1):153-157.WU Wei, ZHONG Yuhua, WU Ren, et al. Preparation of flame retarded thermoplastic polyester-ether elastomer by adding halogen-free additives and novolac[J]. Polymer Materials Science and Engineering,2015,31(1):153-157(in Chinese). [8] ZHU Z M, WANG L X, LIN X B, et al. Synthesis of a novel phosphorus-nitrogen flame retardant and its application in epoxy resin[J]. Polymer Degradation and Stability,2019,169:108981. doi: 10.1016/j.polymdegradstab.2019.108981 [9] 唐启恒, 郭文静. 三聚氰胺聚磷酸盐/次磷酸铝对高密度纤维板阻燃和力学性能的影响[J]. 材料导报, 2021, 35(16):16166-16171. doi: 10.11896/cldb.20030040TANG Qiheng, GUO Wenjing. Effect of the melamine polyphosphate and aluminum hypophosphite on themechanical and flame-retardant properties of high density fiberboard[J]. Materials Reports,2021,35(16):16166-16171(in Chinese). doi: 10.11896/cldb.20030040 [10] 赵依纯, 卢珊, 熊高燕, 等. 含季戊四醇基烷基次膦酸盐与MCA复配膨胀阻燃热塑性聚酯弹性体[J]. 塑料工业, 2018, 46(2):92-97. doi: 10.3969/j.issn.1005-5770.2018.02.022ZHAO Yichun, LU Shan, XIONG Gaoyan, et al. Preparation of intumescent flame retarded thermoplastic polyester elastomer with pentaerythritol-based alkyl phosphinate and MCA[J]. China Plastics Industry,2018,46(2):92-97(in Chinese). doi: 10.3969/j.issn.1005-5770.2018.02.022 [11] LUO D, SHI Y, WANG Q. The properties of flame retardant and heat conduction polyamide 66 based on melamine cyanurate/aluminum diethylphosphinate/graphene[J]. Journal of Polymer Research,2019,26:216. [12] ZHANG L, WU W, LI J H, et al. New insight into the preparation of flame-retardant thermoplastic polyether ester utilizing β-cyclodextrin as a charring agent[J]. High Performance Polymers,2017,29(4):422-430. doi: 10.1177/0954008316648004 [13] JIANG H P, BI M S, MA D Q, et al. Flame suppression mechanism of aluminum dust cloud by melamine cyanurate and melamine polyphosphate[J]. Journal of Hazardous Materials,2019,368(15):797-810. [14] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 塑料-用氧指数法测定燃烧行为-第2部分: 室温试验: GB/T 2406.2—2009[S]. 北京: 中国质检出版社, 2009.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Plastics−Determination of burning behaviour by oxygen index method−Part 2: Ambient temperature test: GB/T 2406.2—2009[S]. Beijing: China Quality Inspection Press, 2009(in Chinese). [15] ASTM. Standard test method for measuring the comparative burning characteristics of solid plastics in a vertical position: ASTM D3801-20 A[S]. West Conshohocken: ASTM, 2020. [16] ISO. Reaction-to-fire tests−Heat release, smoke production and mass loss rate−Part 1: Heat release rate (Cone calorimeter method) and smoke production rate (Dynamic measurement): ISO 5660-1: 2015 [S]. Geneva: ISO, 2015. [17] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 塑料-拉伸性能的测定-第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2—2006[S]. 北京: 中国质检出版社, 2006.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Plastics−Determination of tensile properties−Part 2: Test conditions for moulding and extrusion plastics: GB/T 1040.2—2006[S]. Beijing: China Quality Inspection Press, 2006(in Chinese). [18] JIA P, ZHU Y, LU J, et al. Multifunctional fireproof electromagnetic shielding polyurethane films with thermal management performance[J]. Chemical Engineering Journal,2022,439:135673. doi: 10.1016/j.cej.2022.135673 [19] YIN Z, LU J, HONG N, et al. Functionalizing Ti3C2Tx for enhancing fire resistance and reducing toxic gases of flexible polyurethane foam composites with reinforced mechanical properties[J]. Journal of Colloid and Interface Science,2022,607:1300-1312. doi: 10.1016/j.jcis.2021.09.027 [20] LIU W, DING L, WANG L, et al. A rational design of functionalized black phosphorus cooperates with piperazine pyrophosphate to significantly suppress the fire hazards of polypropylene[J]. Chemosphere,2023,314:137686. doi: 10.1016/j.chemosphere.2022.137686 [21] 王飞跃, 廖家浩, 颜龙. 二氨基二苯甲烷改性聚磷酸铵的合成及在环氧树脂中的应用[J]. 高分子材料科学与工程, 2022, 38(2):24-31. doi: 10.16865/j.cnki.1000-7555.2022.0039WANG Feiyue, LIAO Jiahao, YAN Long. Synthesis of diamino diphenyl methane modified ammonium polyphosphate and its application in epoxy resin[J]. Polymer Materials Science and Engineering,2022,38(2):24-31(in Chinese). doi: 10.16865/j.cnki.1000-7555.2022.0039 [22] 唐启恒, 任一萍, 王戈, 等. 三聚氰胺聚磷酸盐对竹纤维/聚丙烯复合材料力学及阻燃性能的影响[J]. 复合材料学报, 2020, 37(3):553-561. doi: 10.13801/j.cnki.fhclxb.20190611.006TANG Qiheng, REN Yiping, WANG Ge, et al. Effects of melamine pyrophosphate on mechanical and flame retardant properties of bamboo fiber/polypropylene composites[J]. Acta Materiae Compositae Sinica,2020,37(3):553-561(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190611.006 [23] 唐启恒, 任一萍, 郭文静. 三聚氰胺聚磷酸盐和次磷酸铝协效阻燃高密度纤维板复合材料[J]. 复合材料学报, 2021, 38(1):84-92. doi: 10.13801/j.cnki.fhclxb.20200727.004TANG Qiheng, REN Yiping, GUO Wenjing. Melamine polyphosphate and aluminium phosphinate synergistic flame retardant high density fiberboard composite[J]. Acta Materiae Compositae Sinica,2021,38(1):84-92(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200727.004 [24] 王金泳, 王兴旺. 无卤阻燃剂二乙基次磷酸铝的热降解和阻燃机理[J]. 中国塑料, 2019, 33(2):82-95, 130. doi: 10.19491/j.issn.1001-9278.2019.02.015WANG Jinyong, WANG Xingwang. Study on thermal degradation and flame retardant mechanisms of aluminum diethylphosphinate[J]. China Plastics,2019,33(2):82-95, 130(in Chinese). doi: 10.19491/j.issn.1001-9278.2019.02.015 [25] 王晓慧, 程瑞香, 李胜. 蜜胺甲醛树脂包覆聚磷酸铵/三聚氰胺/硼酸锌复合阻燃剂对环氧树脂胶黏剂阻燃性能的影响[J]. 高分子材料科学与工程, 2020, 36(10):86-93.WANG Xiaohui, CHENG Ruixiang, LI Sheng. Effect of ammonium polyphosphate coated with melamine formaldehyde resin/melamine/linc borate composite flame retardant on flame retardant properties of epoxy resin adhesive[J]. Polymer Materials Science and Engineering,2020,36(10):86-93(in Chinese). -

下载:

下载: