Effect of polymer derived SiBN ceramic components on thermal stability and electromagnetic wave transparency

-

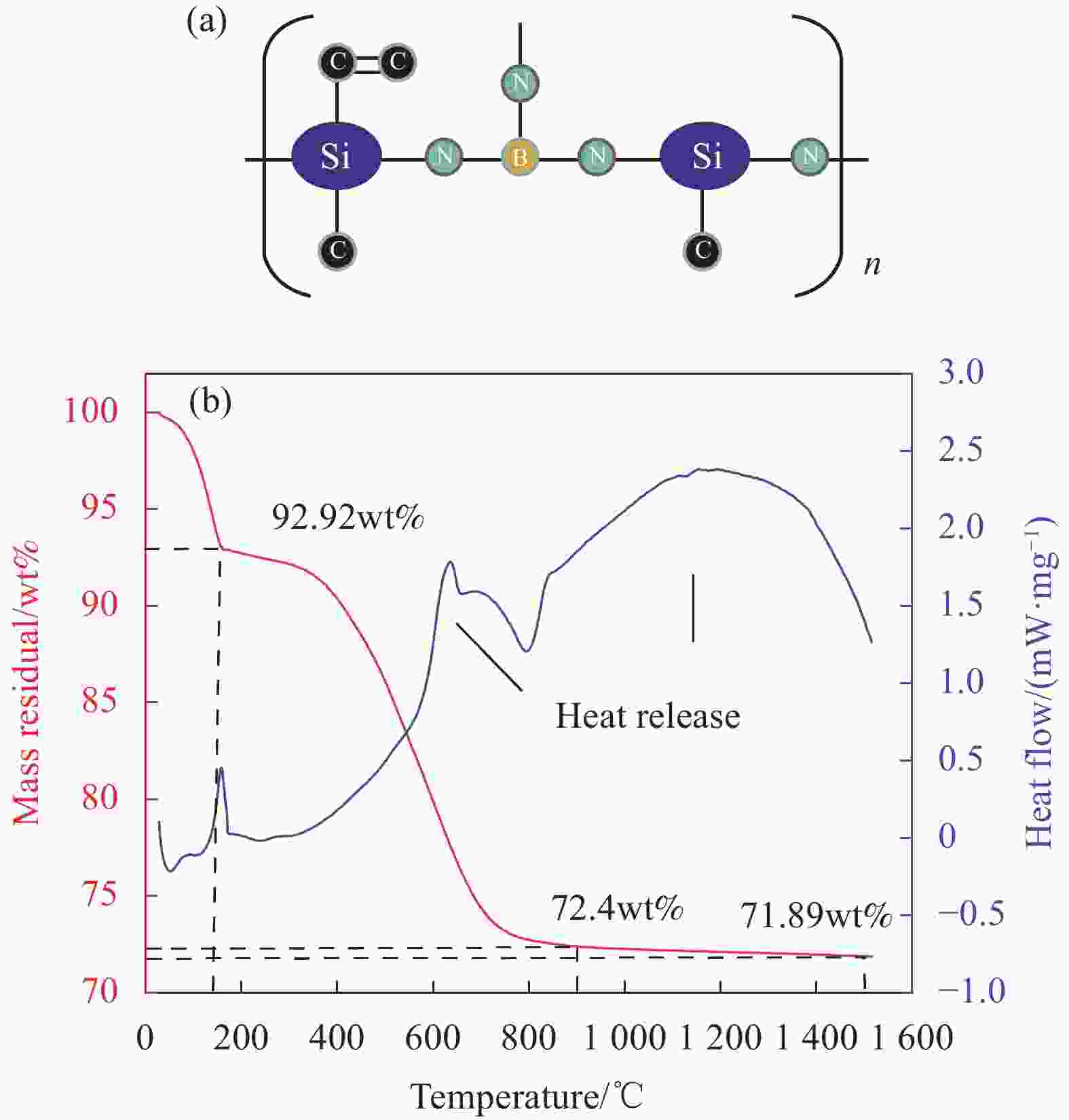

摘要: 对聚硅硼氮烷(PSNB)、三甲胺环硼氮烷(PBN)及混合先驱体陶瓷化过程分别进行了研究,掌握了热处理温度对先驱体转化陶瓷微结构及性能的影响规律。经NH3裂解后,聚合物转化陶瓷(PDC)-SiBN中形成了B—Si—O—N多元网络,具有良好的抗析晶能力,经过不超过1500℃的热处理后,陶瓷抗吸潮能力提升,介电常数在3.0~3.6之间,损耗约0.003。经NH3裂解的PDC-BN中形成了B—N—O结构,随温度升高逐渐分解,转变为BN。将先驱体按照一定比例混合,可以实现对聚合物转化陶瓷元素组分的调控。混合先驱体转化陶瓷中由于异质界面的存在及多元网络减少,陶瓷热稳定性及介电性能均介于单种先驱体转化陶瓷之间,具有一定的性能可设计性。Abstract: The ceramization process of polyborosilazane (PSNB), tris(methylamino)borane (PBN) and mixed precursors were studied respectively, and the influence of heat treatment temperature on the microstructure and properties of polymer derived ceramics was mastered. After pyrolysis under NH3, the B—Si—O—N multielement network was formed in PDC-SiBN, which had good crystallization resistance. After heat treatment at less than 1500℃, the moisture resistance of ceramics was improved, the dielectric constant was between 3.0 and 3.6, and the loss was about 0.003. After pyrolysis under NH3, the B—N—O structure was formed in PDC-BN, which gradually decomposed into BN with the increase of temperature. The precursor can be mixed in a certain proportion to control the elements of polymer derived ceramics. Due to the existence of heterogeneous interfaces in the mixed precursor derived ceramics, the multiple networks were reduced. The thermal stability and dielectric properties of mixed polymer derived ceramics are between those of single polymer derived ceramics, which have certain performance designability.

-

Key words:

- polymer derived ceramics /

- electromagnetic wave transparency /

- thermal stability /

- PSNB /

- PBN

-

表 1 PSNB先驱体及在不同气氛下裂解后陶瓷(PDC)元素含量及产率

Table 1. Element contents and yields of PSNB and polymer derived ceramics (PDC) after pyrolysis in different atmospheres

Element content/wt% PDC

yield/%Si B N O C PSNB 34-36 5-7 24-26 1-2 27-29 — 900℃-N2 52.68 — 17.99 14.90 14.43 83.67 900℃-NH3 48.91 2.80 22.65 7.79 0.60 79.13 表 2 PBN先驱体及在NH3气氛下裂解后陶瓷元素含量及产率

Table 2. Element content and yield of PBN and PDC after pyrolysis under NH3

Element content/wt% PDC yield/% B N O C PBN 19.64 50 1-2 21.43 — 800℃-NH3 34.46 36.70 23.96 4.24 44.38 表 3 不同比例混合先驱体产率及裂解后陶瓷中B元素含量

Table 3. Yield and B element content of ceramics derived from mixed precursor with different proportions

Sample m(PSNB)/

m(PBN)Curing

yield/%PDC

yield/%B content/wt% S-SiBN 1∶0 98.65 79.13 2.80 S-31 3∶1 91.24 65.26 9.02 S-21 2∶1 85.68 59.38 12.13 S-11 1∶1 83.89 62.79 15.27 S-12 1∶2 68.65 60.94 20.05 S-13 1∶3 65.33 58.57 21.03 S-BN 0∶1 59.71 44.38 34.46 Note: m(PSNB)/m(PSN)—Mass ratio of PSNB precursor to PSN precursor. -

[1] SUZDAL'TSEV E I. Radio-transparent ceramics: Yesterday, today, tomorrow[J]. Refractories and Industrial Ceramics,2015,55(5):377-390. doi: 10.1007/s11148-015-9731-6 [2] 张大海, 黎义, 高文, 等. 高温天线罩材料研究进展[J]. 宇航材料工艺, 2001, 31(6):1-3.ZHANG Dahai, LI Yi, GAO Wen, et al. Development and application of high temperature radome materials[J]. Aerospace Materials & Technology,2001,31(6):1-3(in Chinese). [3] 张煜东, 苏勋家, 侯根良. 高温透波材料研究现状和展望[J]. 飞航导弹, 2006(3):56-58.ZHANG Yudong, SU Xunjia, HOU Genliang. Research status and prospect on high temperature wave transparent materials[J]. Aerodynamic Missile Journal,2006(3):56-58(in Chinese). [4] 崔雪峰, 李建平, 李明星, 等. 氮化物基陶瓷高温透波材料的研究进展[J]. 航空材料学报, 2020, 40(1):21-34.CUI Xuefeng, LI Jianping, LI Mingxing, et al. Research progress of nitride based ceramic high temperature wave transparent materials[J]. Journal of Aeronautical Materials,2020,40(1):21-34(in Chinese). [5] 孙聪. 高超声速飞行器强度技术的现状、挑战与发展趋势[J]. 航空学报, 2022, 43(6):8-27.SUN Cong. Development status, challenges and trends of strength technology for hypersonic vehicles[J]. Acta Aeronautica et Astronautica Sinica,2022,43(6):8-27(in Chinese). [6] 李燚. 短时高温工作的透波隔热天线罩设计[J]. 无线互联科技, 2017(13):62-65.LI Yi. Design of the microwave transparent and heat insolated antenna that works in short-time high-tempera-ture[J]. Wireless Internet Technology,2017(13):62-65(in Chinese). [7] 千粉玲, 谢志鹏, 孙加林, 等. Al2O3陶瓷微波介电性能的研究与进展[J]. 陶瓷学报, 2012, 33(4):519-527.QIAN Fenling, XIE Zhipeng, SUN Jialin, et al. Research status on microwave dielectric properties of Al2O3ceramics[J]. Journal of Ceramics,2012,33(4):519-527(in Chinese). [8] 孙银宝, 张宇民, 韩杰才. 耐高温透波材料及其性能研究进展[J]. 宇航材料工艺, 2008, 38(3):11-14.SUN Yinbao, ZHANG Yumin, HAN Jiecai. High-tempera-ture resistant microwave-transmitting materials and their properties[J]. Aerospace Materials & Technology,2008,38(3):11-14(in Chinese). [9] YANG X J, LI B, ZHANG C R, et al. Fabrication and properties of porous silicon nitride wave-transparent ceramics via gel-casting and pressureless sintering[J]. Materials Science and Engineering A,2016,663:174-180. doi: 10.1016/j.msea.2016.03.116 [10] YANG X J, LI B, LI D, et al. High-temperature properties and interface evolution of silicon nitride fiber reinforced silica matrix wave-transparent composite materials[J]. Journal of the European Ceramic Society,2019,39(2):240-248. [11] COLOMBO P, MERA G, RIEDEL R, et al. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics[J]. Journal of the American Ceramic Society,2010,93(7):1805-1837. [12] 李斌. 氮化物陶瓷基耐烧蚀、透波复合材料及其天线罩的制备与性能研究[D]. 长沙: 国防科学技术大学, 2007.LI Bin. Preparation and performance of ablation resistant, wave-transparent nitride ceramic matrix composites and radome[D]. Changsha: National University of Defense Technology, 2007(in Chinese). [13] TANG Y, WANG J, LI X D, et al. Polymer-derived SiBN fiber for high-temperature structural/functional applications[J]. Chemistry-A European Journal,2010,16(22):6458-6462. doi: 10.1002/chem.200902974 [14] 黄先华, 刘勇, 张晨宇, 等. SiBN陶瓷纤维的脱碳工艺研究[J]. 合成纤维工业, 2017, 40(2):1-5.HUANG Xianhua, LIU Yong, ZHANG Chenyu, et al. Decarburization research of SiBN ceramic fibers[J]. China Synthetic Fiber Industry,2017,40(2):1-5(in Chinese). [15] MAEDA M, MAKINO T. Low dielectric constant amorphous SiBN ternary films prepared by plasma-enhanced deposition[J]. Japanese Journal of Applied Physics,1987,26(5R):660. doi: 10.1143/JJAP.26.660 [16] BARTA J, MANELA M, FISCHER R. Si3N4 and Si2N2O for high performance radomes[J]. Materials Science and Engineering,1985,71:265-272. doi: 10.1016/0025-5416(85)90236-8 [17] GANESH I. Novel composites of β-SiAlON and radome manufacturing technology developed at ARCI, hyderabad, for hypervelocity vehicles[J]. Bulletin of Materials Science,2017,40(4):719-735. doi: 10.1007/s12034-017-1424-y [18] LONG X, SHAO C W, WANG Y D. Effects of boron content on the microwave-transparent property and high-temperature stability of continuous SiBN fibers[J]. Journal of the American Ceramic Society,2020,103(8):4436-4444. doi: 10.1111/jace.17151 [19] TAVAKOLI A H, GERSTEL P, GOLCZEWSKI J A, et al. Kinetic effect of boron on the crystallization of Si3N4 in Si-B-C-N polymer-derived ceramics[J]. Journal of Materials Research,2011,26(4):600-608. doi: 10.1557/jmr.2010.53 [20] 李贞, 殷小玮, 成来飞, 等. 液态聚硼硅氮烷的陶瓷化过程[J]. 硅酸盐学报, 2012, 40(7):979-982.LI Zhen, YIN Xiaowei, CHENG Laifei, et al. Polymer-ceramic conversion of liquid polyborosilazanes[J]. Journal of the Chinese Ceramic Society,2012,40(7):979-982(in Chinese). [21] 国家质量技术监督局. 致密定形耐火制品体积密度、显气孔率和真气孔率试验方法: GB/T 2997—2000[S]. 北京: 中国标准出版社, 2000.State Bureau of Quality and Technical Supervision of China. Test method for bulk density, apparent porosity and true porosity of dense shaped refractory products: GB/T 2997—2000[S]. Beijing: China Standards Press, 2000(in Chinese). [22] GALUSEK D, RESCHKE S, RIEDEL R, et al. In-situ carbon content adjustment in polysilazane derived amorphous SiCN bulk ceramics[J]. Journal of the European Ceramic Society,1999,19(10):1911-1921. doi: 10.1016/S0955-2219(98)00288-X [23] YE F, ZHANG L T, YIN X W, et al. Dielectric and EMW absorbing properties of PDCs-SiBCN annealed at different temperatures[J]. Journal of the European Ceramic Society,2013,33(8):1469-1477. doi: 10.1016/j.jeurceramsoc.2013.01.006 [24] XU Y, HU J, TAO M, et al. Study of pyrolysis mechanism of SiBCN polymer precursor[J]. Aerospace Materials & Technology,2018,48(1):44-48. [25] MO R, YIN X W, YE F, et al. Mechanical and microwave absorbing properties of Tyranno® ZMI fiber annealed at elevated temperatures[J]. Ceramics International,2017,43(12):8922-8931. doi: 10.1016/j.ceramint.2017.04.030 [26] ZHANG X W, YOU J B, CHEN N F. Recent advances in synthesis and properties of cubic boron nitride films[J]. Journal of Inorganic Materials,2007,22(3):385-390. -

下载:

下载: