Dynamic characteristics of polyurethane reinforced sea sand under traffic loads

-

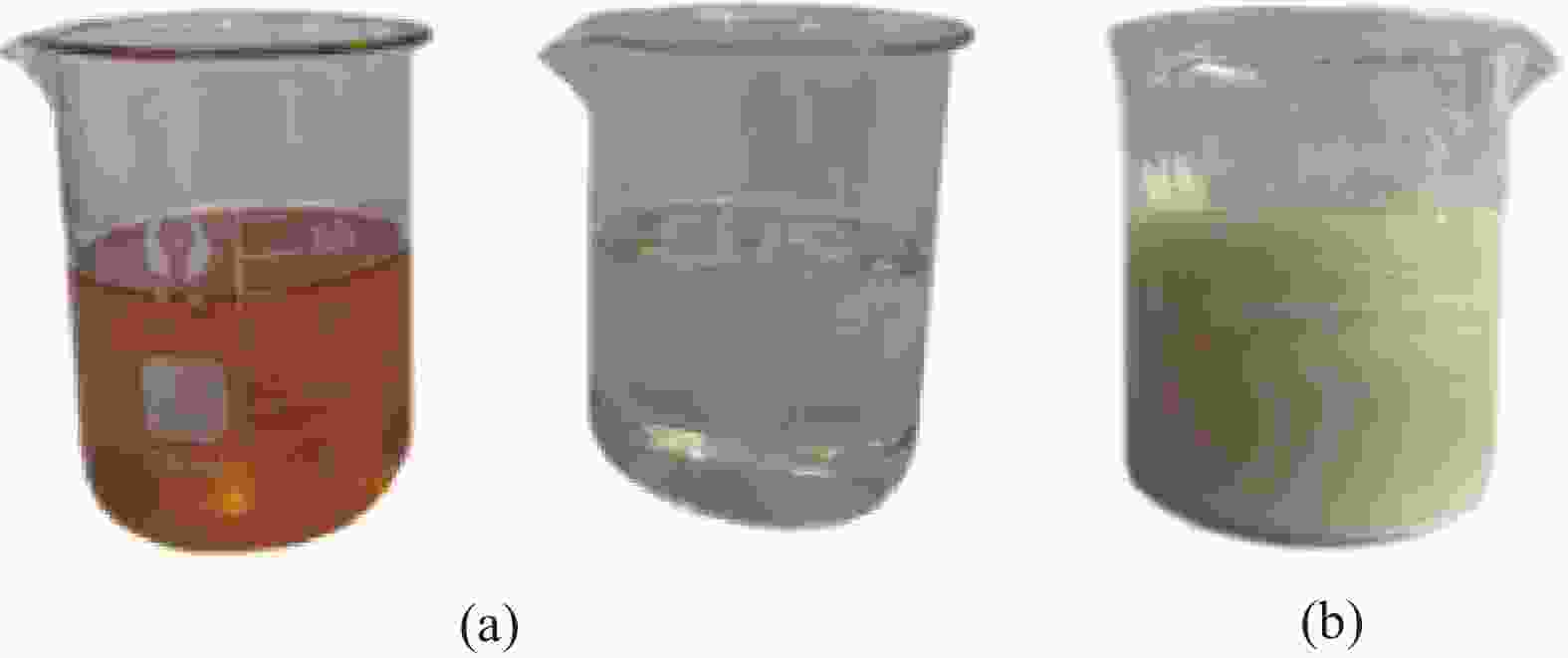

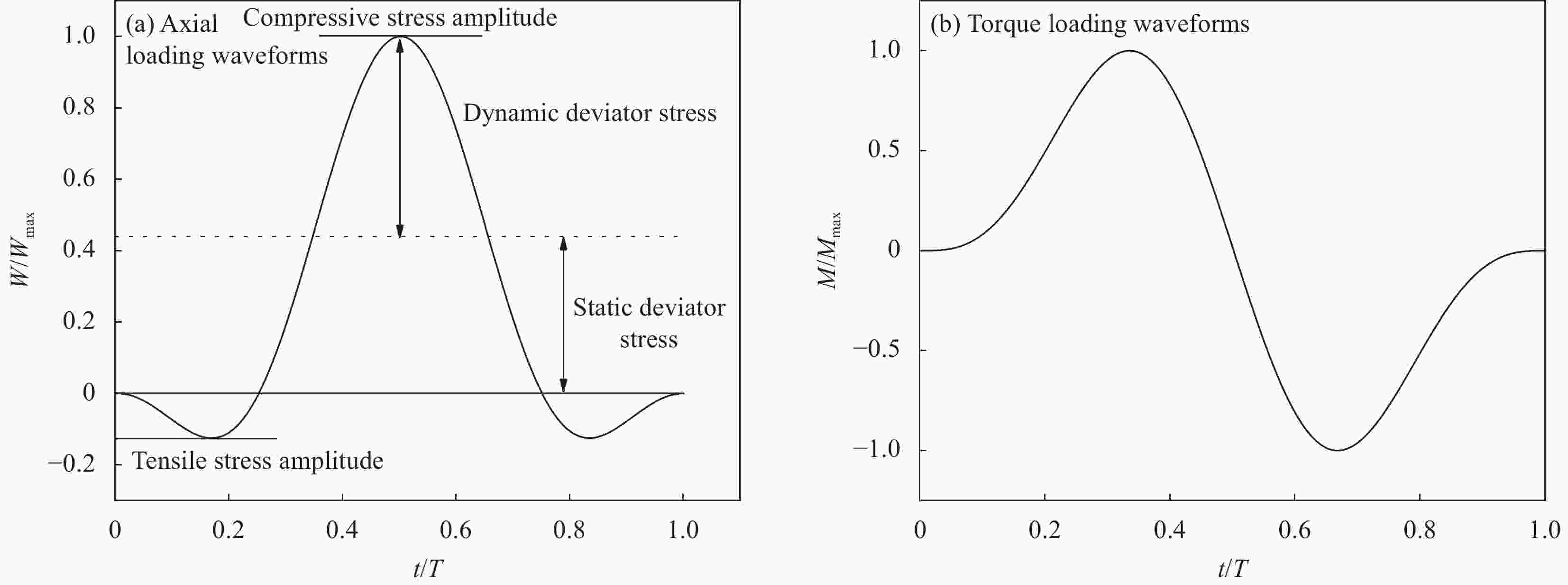

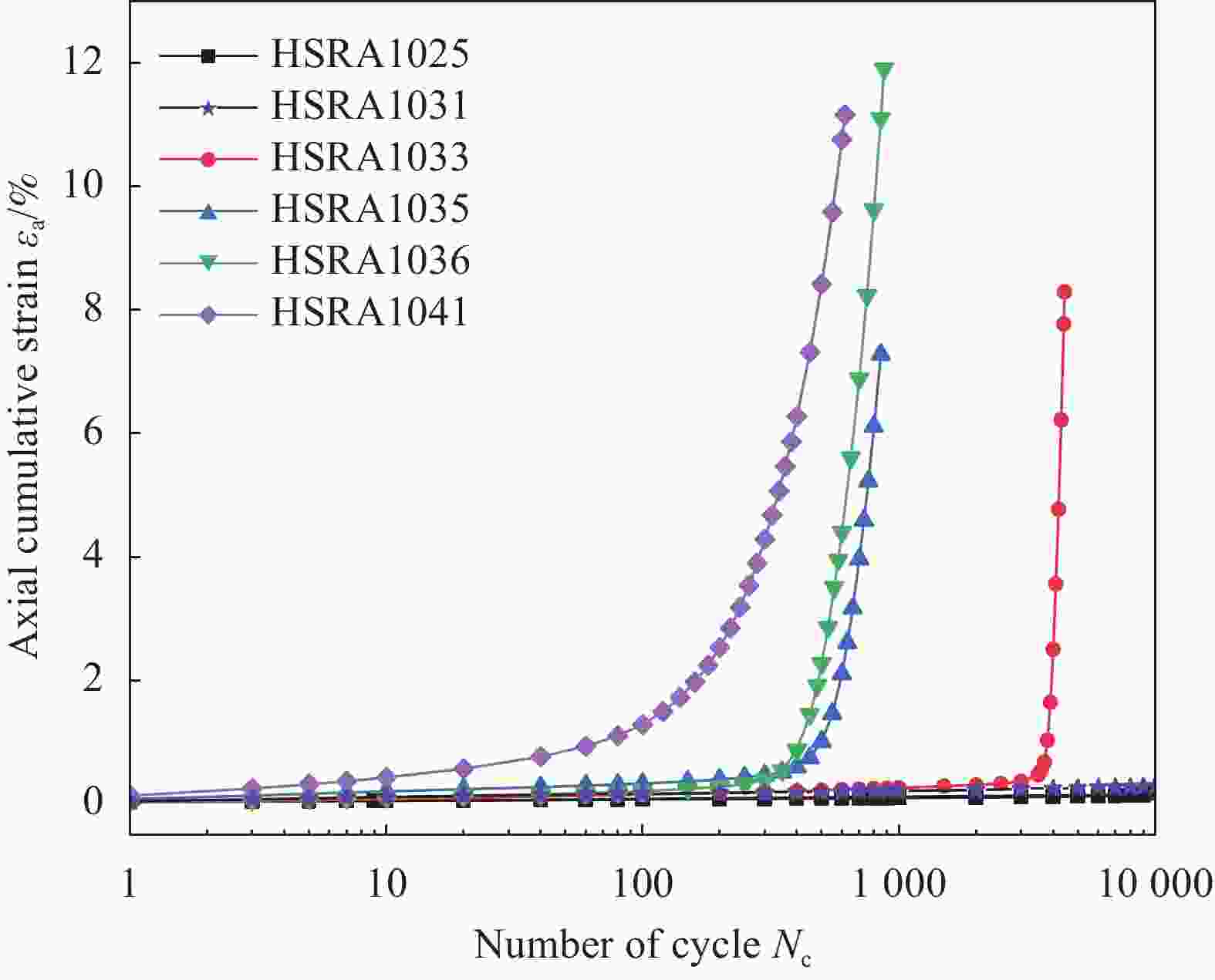

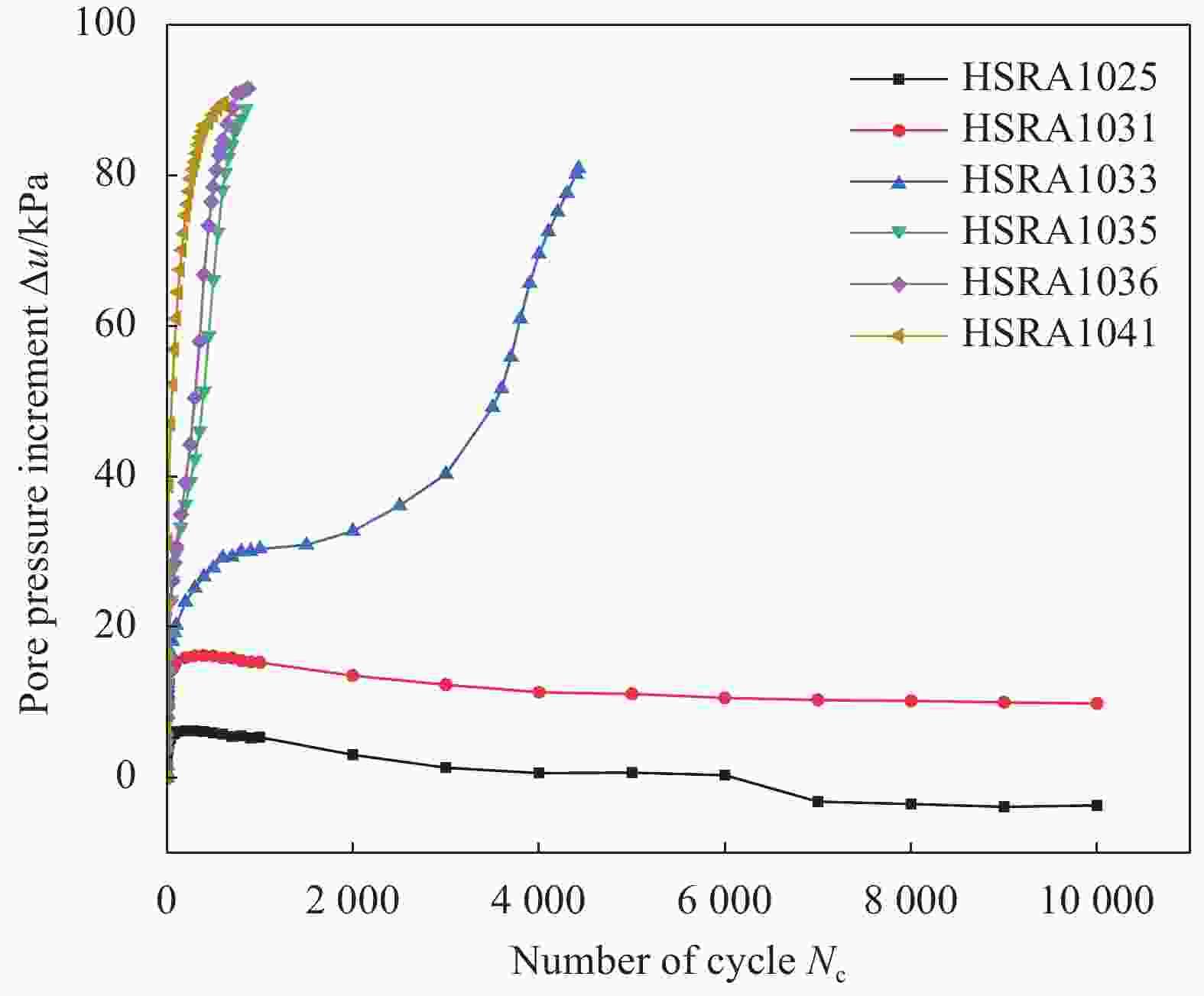

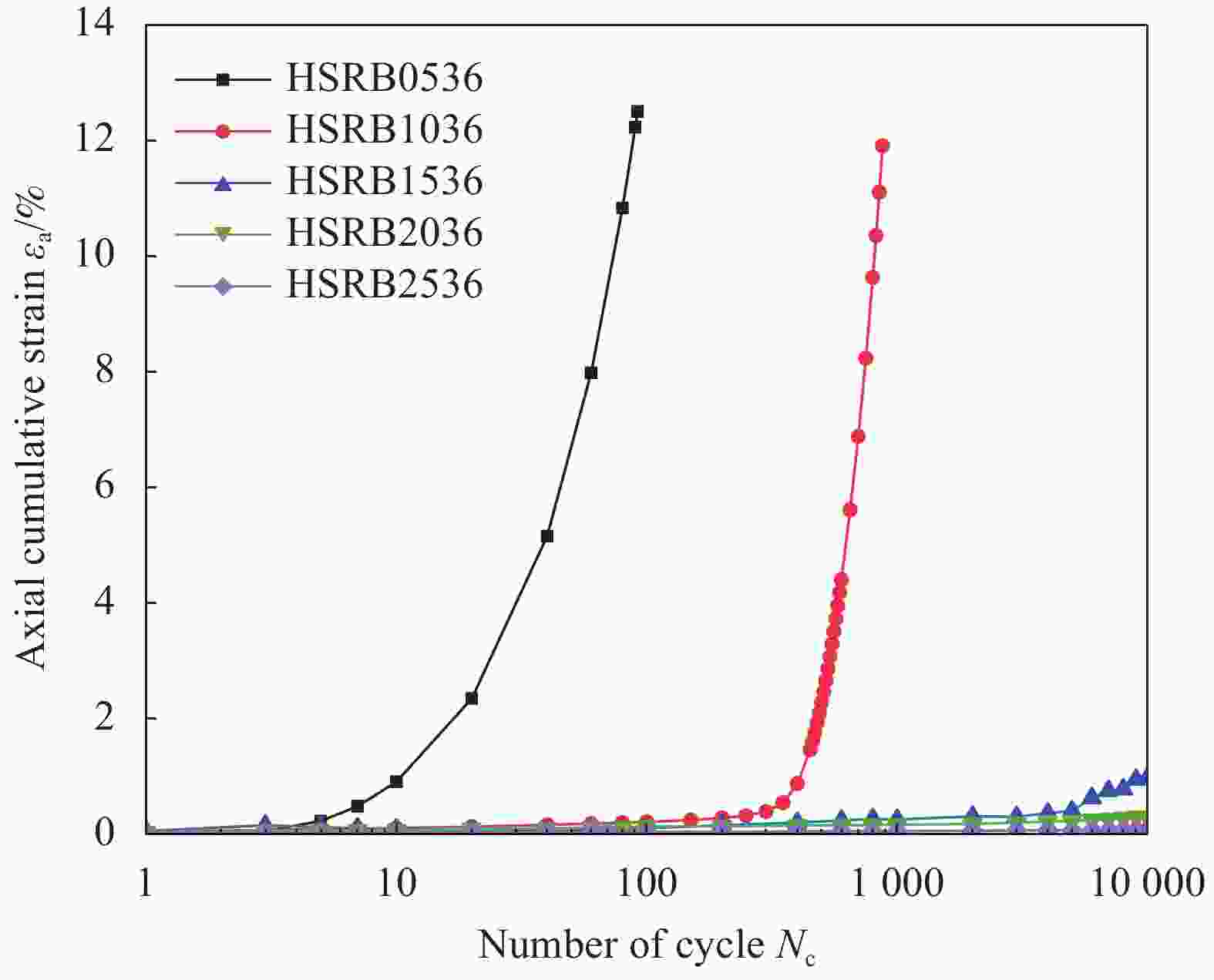

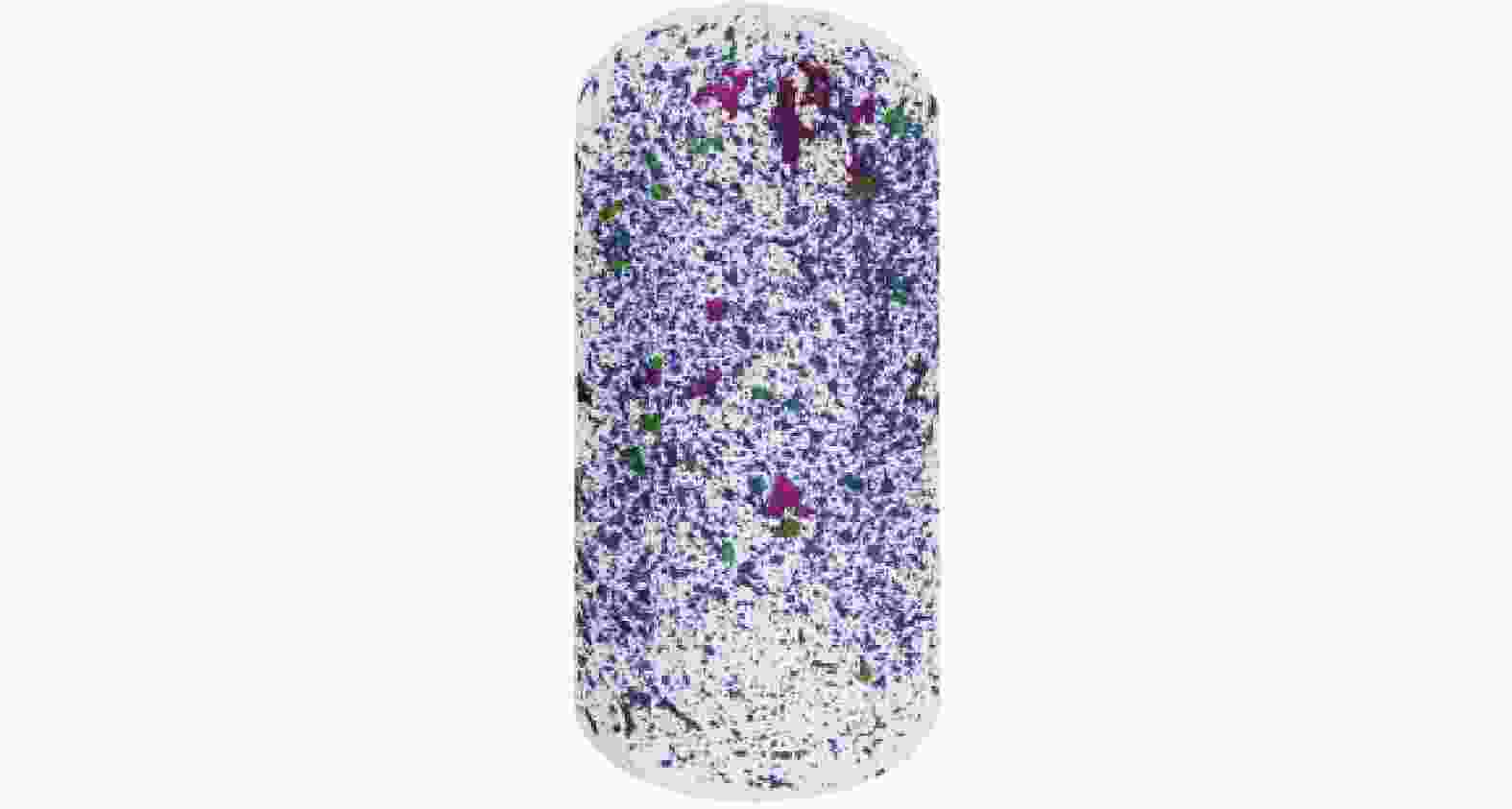

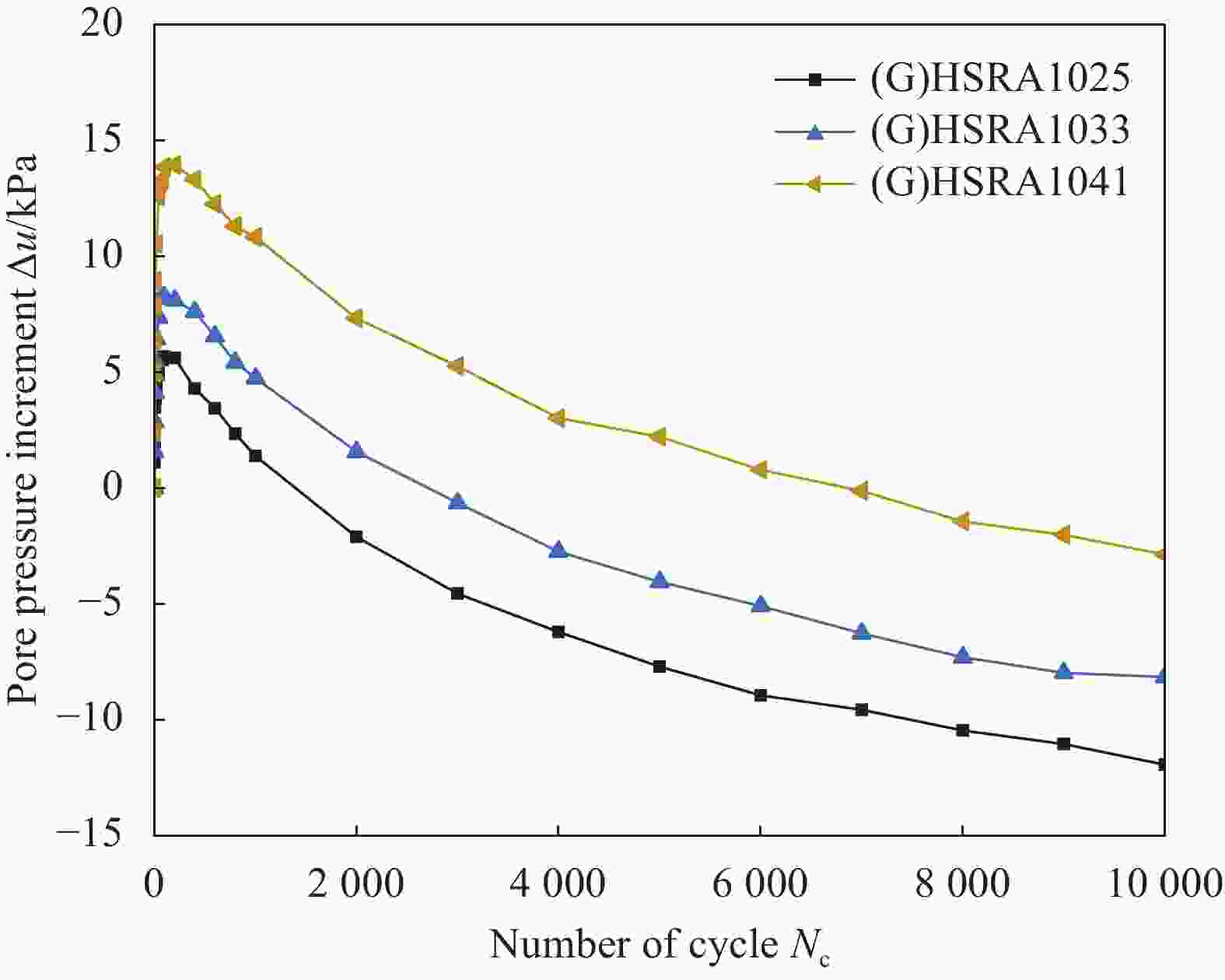

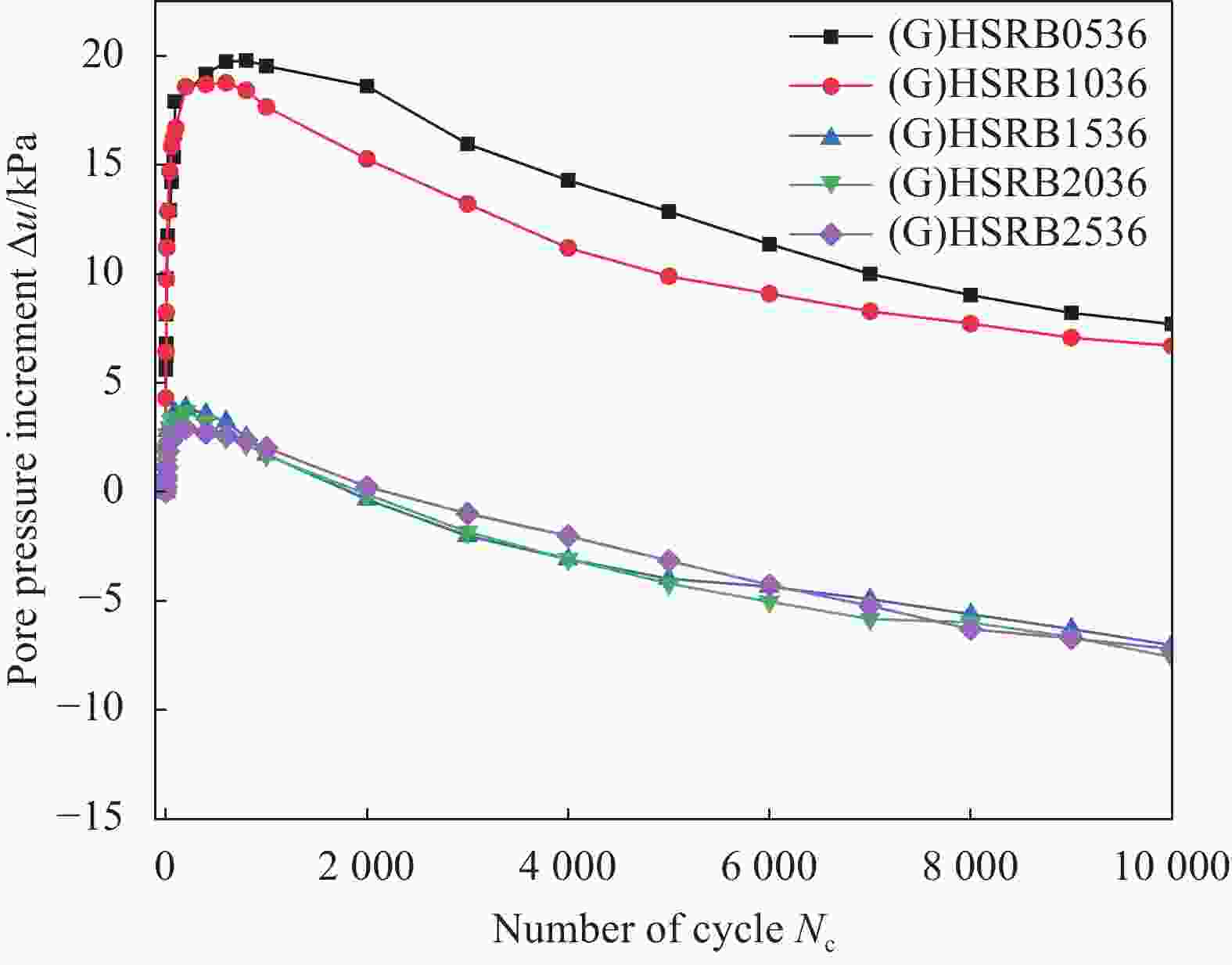

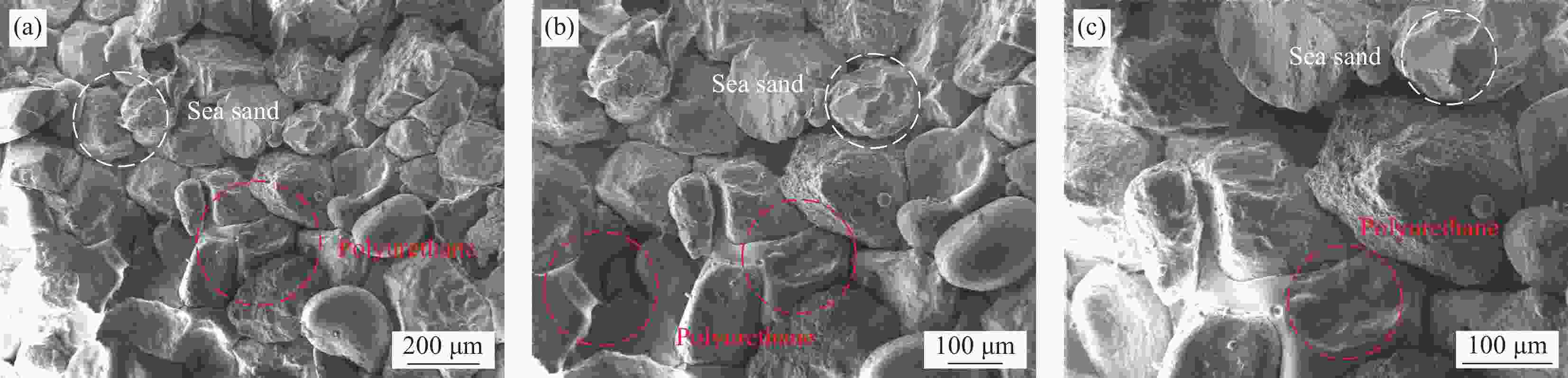

摘要: 采用聚氨酯型固化剂对我国某地海砂进行改良处理,以快速提升其浅层地基承载能力,为定量评价其固化性能,研发适用于聚氨酯固化海砂的空心圆柱制样方法,开展了不同动应力比及加载频率下的固化前后海砂的空心圆柱扭剪试验,并结合SEM结果分析微观加固机制。试验表明:未固化试样的应变及孔压发展随动应力比的变化呈现3种形式,试验所得围压频率一定时临界动应力比η'=0.33。固化前的海砂在不同频率条件下,频率f越小,循环荷载的累积效应越明显,应变与孔压的发展速率越快,并以f=1.5 Hz为界,呈现两种发展趋势。固化后的海砂抗变形能力大大加强,在改变动应力比及频率两组加载条件下的轴向累积应变均不超过0.7%,且孔压发展限制均不超过20 kPa,部分加载条件孔压出现负值,产生剪胀现象。SEM结果分析表明,固化剂反应后占据了砂土内部的部分孔隙,反应生成的固化膜联结在一起,与砂颗粒形成了一种“砂粒嵌裹于固化膜”的稳定的空间结构,同时增加了试样的相对密实度,使颗粒重新排列阻力增大,从而极大提升了固化试样的力学性能。Abstract: In order to improve the bearing capacity of sea sand foundation in China, a treatment method for curing of sea sand foundation using polyurethane has been studied. The cyclic traffic load tests on the pure sand and reinforced sand were carried out by using hollow cylinder apparatus under different dynamic stress ratios and loading frequencies. A hollow cylindrical sample preparation method which is suitable for polyurethane rapid and efficient curing sea sand was innovatively designed for the study. And the micro-reinforcement mechanism was analyzed based on SEM results. The experimental results show that: The strain curve and pore pressure development of pure sand are divided into three development trends with the change of dynamic stress ratios, the critical dynamic stress ratio η' obtained by the test is 0.33. The smaller the frequency f under different frequency conditions is, the more obvious the cumulative effect of cyclic load is, the more obvious the development of strain and pore pressure are, bounded by the condition f=1.5 Hz, showing two development trends. The axial cumulative strain of the cured sea sand under the two sets of loading conditions did not exceed 0.7%, and the pore pressure development limit did not exceed 20 kPa. In some conditions, pore pressure eventually turned to be negative, resulting in shear dilatation. The analysis of SEM results shows that the curing agent takes up part of the pores in the sand after reaction. And as a consequence, the curing agent and sea sand forms a stable spatial structure, which leads to an increase of the resistance of particle rearrangement, thereby greatly improving the mechanical properties of the cured sample.

-

Key words:

- polyurethane /

- sea sand /

- traffic loads /

- axial cumulative strain /

- pore pressure development

-

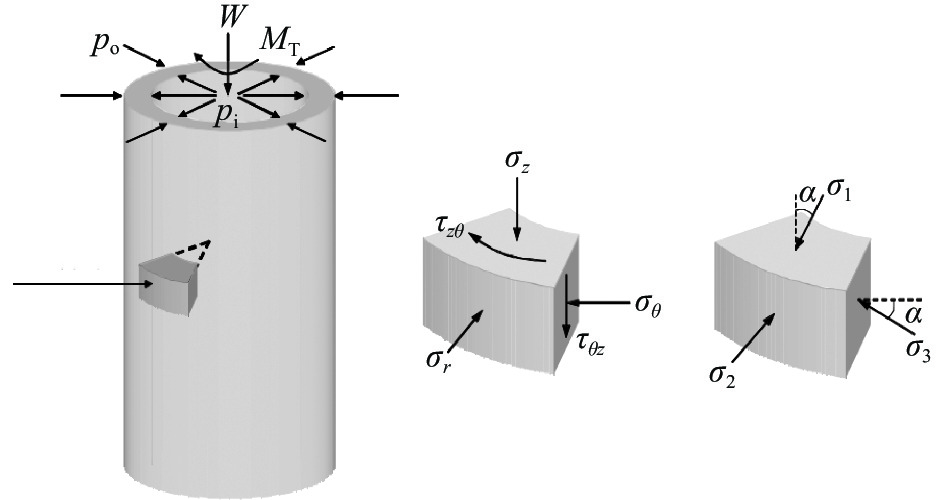

图 4 空心圆柱试样薄壁单元体受力状态

Figure 4. Force acting on a hollow cylindrical specimen

pi—Internal confining pressure; po—External confining pressure; W—Axial force; MT—Torque; $ {\sigma _z} $—Axial stress; $ {\sigma _r} $—Radial stress; $ {\sigma _\theta } $—Ring stress; $ {\tau _{z\theta }} $, τθz—Torsional shear stress, same quantity, different directions; $ \theta $—Torsion angle; $ \alpha $—Angle at which the large principal stress deviates from the original direction; $ {\sigma _1} $, $ {\sigma _2} $, $ {\sigma _3} $—Large, medium and small principal stresses

图 8 空心圆柱试样不同循环动应力比下的实际应力路径

Figure 8. Actual stress path diagrams of hollow cylindrical sample under different cyclic dynamic stress ratios

$ ({\sigma _z} - {\sigma _\theta })/2 $—Half the difference between axial stress and ring stress; The different cyclic dynamic stress ratios of the internal to external are 0.25, 0.31, 0.33, 0.35, 0.36 and 0.41, respectively

表 1 海砂的物理性质指标

Table 1. Physical parameters of the sea sand

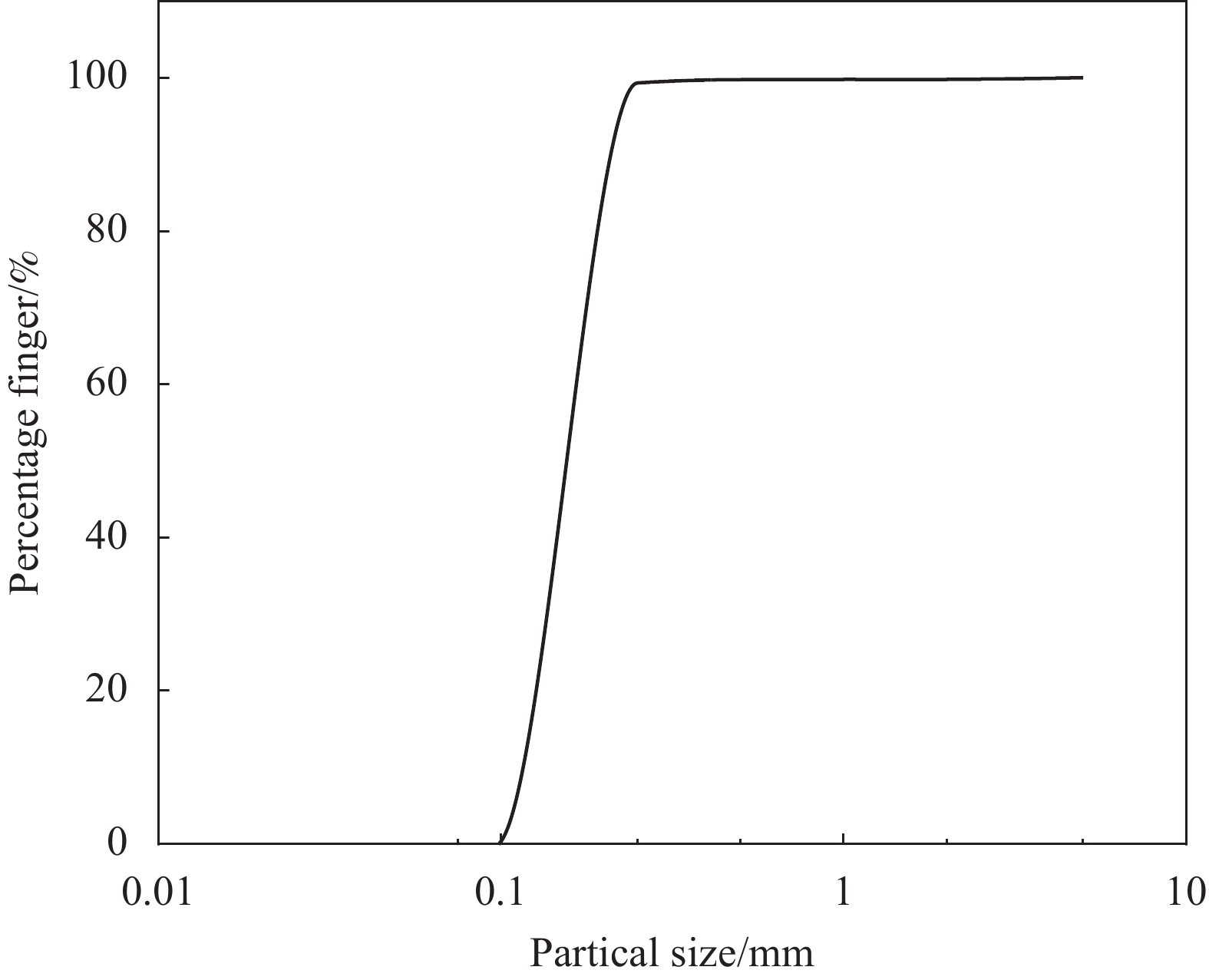

Specimen Gs Cu Cc D50 D10 D30 D60 ρdmax/(kg·cm−3) ρdmin/(kg·cm−3) Sea sand 2.66 1.47 0.95 0.174 0.122 0.155 0.184 1654 1410 Notes:Gs—Specific gravity of solid particles; Cu—Coefficient of uniformity; Cc—Compression index; Dx—Particle size corresponding to the cumulative distribution percentage reaching x, x is the cumulative distribution percentage; ρdmax—Maximum dry density; ρdmin—Minimum dry density. 表 2 试验采用的应力路径加载

Table 2. Stress paths used in tests

p0/kPa f/Hz Number η0 p0/kPa η0 Number f/Hz 100 1 (G)HSRA1025 0.25 100 0.36 (G)HSRB0536 0.5 HSRA1031 0.31 (G)HSRB1036 1 (G)HSRA1033 0.33 (G)HSRB1536 1.5 HSRA1035 0.35 (G)HSRB2036 2 HSRA1036 0.36 (G)HSRB2536 2.5 (G)HSRA1041 0.41 Notes: The addition of "G" before the number indicates the number of the cured sample; HSRA stands for the heart stress ratio loading test group A, HSRB stands for heart stress ratio loading test group B, the last four numbers represent the frequency and dynamic stress ratio; p0—Effective confining pressure; f—Frequency; η0—Initial dynamic stress ratio. -

[1] 范威. 真空联合堆载预压法在滩涂软基加固工程中的应用研究[D]. 舟山: 浙江海洋大学, 2022.FAN Wei. Application of vacuum combined surcharge preloading method in shoal soft foundation reinforcement engineering[D]. Zhoushan: Zhejiang Ocean University, 2022(in Chinese). [2] 龚贵林. 换填法与灰土挤密桩法处理湿陷性黄土地基试验研究[D]. 兰州: 兰州交通大学, 2015.GONG Guilin. The experimental research on handling collapsible loess foundation with replacement cushion and lime-loess compaction pile[D]. Lanzhou: Lanzhou Jiaotong University, 2015(in Chinese). [3] 徐文涛, 董宝志, 于永堂, 等. 直接强夯法处理低含水量大厚度湿陷性黄土的效果分析[J]. 地基处理, 2022, 4(S1):134-143.XU Wentao, DONG Baozhi, YU Yongtang, et al. Effect analysis of direct dynamic compaction on collapsible loess with low moisture content and large thickness[J]. Journal of Ground Improvement,2022,4(S1):134-143(in Chinese). [4] 张丽娟. 强夯法地基加固数值模拟及工程案例分析[D]. 杭州: 浙江大学, 2020.ZHANG Lijuan. Numerical simulation and engineering case analysis of dynamic consolidation method for reinforcing foundations[D]. Hangzhou: Zhejiang University, 2020(in Chinese). [5] 吴民晖, 刘海旺. 强夯法处理吹填海砂地基现场试验研究[J]. 地基处理, 2022, 4(4):322-328.WU Minhui, LIU Haiwang. Field test on the treatment of hydraulic reclamation sand foundation by dynamic compaction[J]. Journal of Ground Improvement,2022,4(4):322-328(in Chinese). [6] 苏亮, 时伟, 水伟厚, 等. 高能级强夯法处理深厚吹填砂土地基现场试验[J]. 吉林大学学报(地球科学版), 2021, 51(5):1560-1569. doi: 10.13278/j.cnki.jjuese.20200296SU Liang, SHI Wei, SHUI Weihou, et al. Field test of high energy dynamic compaction on hydraulic sandy filling[J]. Journal of Jilin University (Earth Science Edition),2021,51(5):1560-1569(in Chinese). doi: 10.13278/j.cnki.jjuese.20200296 [7] 陈兴城. 大面积吹填滩涂淤泥地基真空预压处理技术试验研究[D]. 赣州: 江西理工大学, 2013.CHEN Xingcheng. Experimental study on vacuum precompression treatment technology of large-area beach blowing and filling mudflat[D]. Ganzhou: Jiangxi University of Science and Technology, 2013(in Chinese). [8] 王春茶. 真空联合堆载预压在沿海滩涂地基处理中的应用[J]. 长春工程学院学报(自然科学版), 2021, 22(3):9-12.WANG Chuncha. The application of vacuum combined surcharge preloading in foundation treatment of coastal beach[J]. Journal of Changchun Institute of Technology (Natural Sciences Edition),2021,22(3):9-12(in Chinese). [9] 黄涛, 彭典华. 强夯-排水板联合加固河漫滩吹填料场地基的试验研究与应用[J]. 建筑结构, 2014, 44(1):92-97. doi: 10.19701/j.jzjg.2014.01.019HUANG Tao, PENG Dianhua. Experimental study and application of combination consolidation of dynamic consolidation and drainage plate in floodplain blow-fill foundation[J]. Building Structure,2014,44(1):92-97(in Chinese). doi: 10.19701/j.jzjg.2014.01.019 [10] 吴怀娜, 马庆雷, 孟凡衍, 等. 滩涂极软地基托板桩法处理技术研究[J]. 湖南大学学报(自然科学版), 2021, 48(1):37-45. doi: 10.16339/j.cnki.hdxbzkb.2021.01.005WU Huaina, MA Qinglei, MENG Fanyan, et al. Research on treatment technology of cap-pile method in extremely soft ground[J]. Journal of Hunan University (Natural Sciences),2021,48(1):37-45(in Chinese). doi: 10.16339/j.cnki.hdxbzkb.2021.01.005 [11] 朱剑锋, 杨浩, 徐日庆, 等. 硫氧镁水泥固化沿海风电场滩涂软土加固机理及微观特性分析[J]. 太阳能学报, 2022, 43(7):276-283.ZHU Jianfeng, YANG Hao, XU Riqing, et al. Mechanism of mudflat soft clay stabilized by magnsia oxysulfate cement and analysis on its micro-behavior for offshore wind farm[J]. Acta Energiae Solaris Sinica,2022,43(7):276-283(in Chinese). [12] XIAO P, LIU H L, XIAO Y, et al. Liquefaction resistance of bio-cemented calcareous sand[J]. Soil Dynamics and Earthquake Engineering,2018,107:9-19. doi: 10.1016/j.soildyn.2018.01.008 [13] XIAO P, LIU H L, STUEDLEIN A W, et al. Effect of relative density and bio-cementation on the cyclic response of calcareous sand[J]. Canadian Geotechnical Journal,2019,56(12):1849-1862. doi: 10.1139/cgj-2018-0573 [14] 肖鹏, 刘汉龙, 史金权, 等. 微生物加固钙质砂地基动力响应特性研究[J]. 岩土工程学报, 2023, 45(6):1303-1313. doi: 10.11779/CJGE20220455XIAO Peng, LIU Hanlong, SHI Jinquan, et al. Dynamic response of calcareous foundation reinforced by microbially induced calcite precipitation[J]. Chinese Journal of Geotechnical Engineering,2023,45(6):1303-1313(in Chinese). doi: 10.11779/CJGE20220455 [15] 刘汉龙, 马国梁, 赵常, 等. 微生物加固钙质砂的宏微观力学机理[J]. 土木与环境工程学报, 2020, 42(4):205-206.LIU Hanlong, MA Guoliang, ZHAO Chang, et al. Macro-and micro-mechanical regime of biotreated calcareous sand[J]. Journal of Civil and Environmental Engineering,2020,42(4):205-206(in Chinese). [16] 陈育民, 张书航, 丁绚晨, 等. 微生物加固钙质砂强度演化过程的环剪试验研究[J]. 土木与环境工程学报, 2022, 44(4):10-17.CHEN Yumin, ZHANG Shuhang, DING Xuanchen, et al. Ring shear test study on strength evolution process of microbial reinforced calcareous sand[J]. Journal of Civil and Environmental Engineering,2022,44(4):10-17(in Chinese). [17] 刘瑾, 冯巧, 孙少锐, 等. 聚氨酯型固化剂加固砂性土抗压试验及破坏模式[J]. 地球科学与环境学报, 2017, 39(5):704-710. doi: 10.3969/j.issn.1672-6561.2017.05.008LIU Jin, FENG Qiao, SUN Shaorui, et al. Unconfined compression test and failure mode of sandy soil stabilized by polyurethane soil stabilizer[J]. Journal of Earth Sciences and Environment,2017,39(5):704-710(in Chinese). doi: 10.3969/j.issn.1672-6561.2017.05.008 [18] 冯巧, 刘瑾, 卢毅, 等. 一种复合加固剂改良砂土的强度试验研究[J]. 工程地质学报, 2017, 25(4):903-911. doi: 10.13544/j.cnki.jeg.2017.04.002FENG Qiao, LIU Jin, LU Yi, et al. Experimental study on strength of sand reinforced with composite reinforcement agent[J]. Journal of Engineering Geology,2017,25(4):903-911(in Chinese). doi: 10.13544/j.cnki.jeg.2017.04.002 [19] 张柏源. 海水环境用聚氨酯仿生胶粘剂的设计与制备研究[D]. 吉林: 东北电力大学, 2022.ZHANG Baiyuan . Design and preparation of polyurethane bionic adhesive for seawater environment[D]. Jilin: Northeast Electric Power University, 2022(in Chinese). [20] BAI Y, LIU J, CUI Y J, et al. Mechanical behavior of polymer stabilized sand under different temperatures[J]. Construction and Building Materials,2021,290:123237. doi: 10.1016/j.conbuildmat.2021.123237 [21] LIU J, CHEN Z H, ZENG Z J, et al. Influence of polyurethane polymer on the strength and mechanical behavior of sand-root composite[J]. Fibers and Polymers,2020,21(4):829-839. doi: 10.1007/s12221-020-9331-z [22] LIU J, BU F, BAI Y X, et al. Study on engineering properties of sand strengthened by mixed fibers and polyurethane organic polymer[J]. Bulletin of Engineering Geology and the Environment,2020,79:3049-3062. doi: 10.1007/s10064-020-01751-9 [23] 王颖, 刘瑾, 马晓凡, 等. 基于核磁共振的聚氨酯固化砂土浸水作用分析[J]. 岩土工程学报, 2020, 42(12):2342-2349. doi: 10.11779/CJGE202012023WANG Ying, LIU Jin, MA Xiaofan, et al. Immersion effect of polyurethane-reinforced sand based on NMR[J]. Chinese Journal of Geotechnical Engineering,2020,42(12):2342-2349(in Chinese). doi: 10.11779/CJGE202012023 [24] CHEN Q S, YU R H, TAO G L, et al. Shear behavior of polyurethane foam adhesive improved calcareous sand under large-scale triaxial test[J]. Marine Georesources and Geotechnology,2021,39(12):1449-1458. doi: 10.1080/1064119X.2020.1849473 [25] XIAO J H, JUANG C H, WEI K, et al. Effects of principal stress rotation on the cumulative deformation of normally consolidated soft clay under subway traffic loading[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2014, 140(4): 04013046. [26] 翁效林, 胡继波, 贾阳, 等. 循环交通荷载作用下饱和重塑黄土变形特性研究[J]. 岩土工程学报, 2022, 44(9):1617-1625.WENG Xiaolin, HU Jibo, JIA Yang, et al. Deformation characteristics of saturated remolded loess under cyclic traffic loads[J]. Chinese Journal of Geotechnical Engineering,2022,44(9):1617-1625(in Chinese). [27] 沈礼伟, 庄海洋, 陈磊, 等. 列车振动荷载作用下南京细砂累积变形预测公式对比分析[J]. 岩土力学, 2014, 35(11):3170-3176. doi: 10.16285/j.rsm.2014.11.023SHEN Liwei, ZHUANG Haiyang, CHEN Lei, et al. Prediction formula for dynamic accumulated deformation of Nanjing fine sand under train-induced vibration load[J]. Rock and Soil Mechanics,2014,35(11):3170-3176(in Chinese). doi: 10.16285/j.rsm.2014.11.023 [28] 孙奇, 董全杨, 蔡袁强, 等. 扭剪荷载作用下饱和南京砂不排水特性试验研究[J]. 岩土力学, 2017, 38(1):41-48. doi: 10.16285/j.rsm.2017.01.006SUN Qi, DONG Quanyang, CAI Yuanqiang, et al. Experimental study of undrained properties of saturated Nanjing sand under torsional shear loading[J]. Rock and Soil Mechanics,2017,38(1):41-48(in Chinese). doi: 10.16285/j.rsm.2017.01.006 [29] 沈扬, 徐海东, 王保光, 等. 列车荷载引起心形应力路径下软土非共轴应变特征研究[J]. 岩土力学, 2017, 38(1):1-9. doi: 10.16285/j.rsm.2017.01.001SHEN Yang, XU Haidong, WANG Baoguang, et al. Strain characteristics of non-coaxiality under heart-shaped stress path caused by train loads in soft clay[J]. Rock and Soil Mechanics,2017,38(1):1-9(in Chinese). doi: 10.16285/j.rsm.2017.01.001 [30] 关伟, 吴红刚, 余仕江, 等. 列车荷载下螺杆桩复合地基动力特性及承载性状试验研究[J]. 岩石力学与工程学报, 2023, 42(2):508-520. doi: 10.13722/j.cnki.jrme.2022.0475GUAN Wei, WU Honggang, YU Shijiang, et al. Experimental study on dynamic and bearing characteristics of part-screw pile composite foundations under train loads[J]. Rock and Soil Mechanics,2023,42(2):508-520(in Chinese). doi: 10.13722/j.cnki.jrme.2022.0475 [31] 陈平, 廖明义. 高分子合成材料学[M]. 第3版. 北京: 化学工业出版社, 2017: 126-147.CHEN Ping, LIAO Mingyi. Polymer synthetic materials science[M]. 3rd edition. Beijing: Chemical Industry Press, 2017: 126-147(in Chinese). -

下载:

下载: