Impact localization on stiffened composite plate based on adaptive time reversal focusing

-

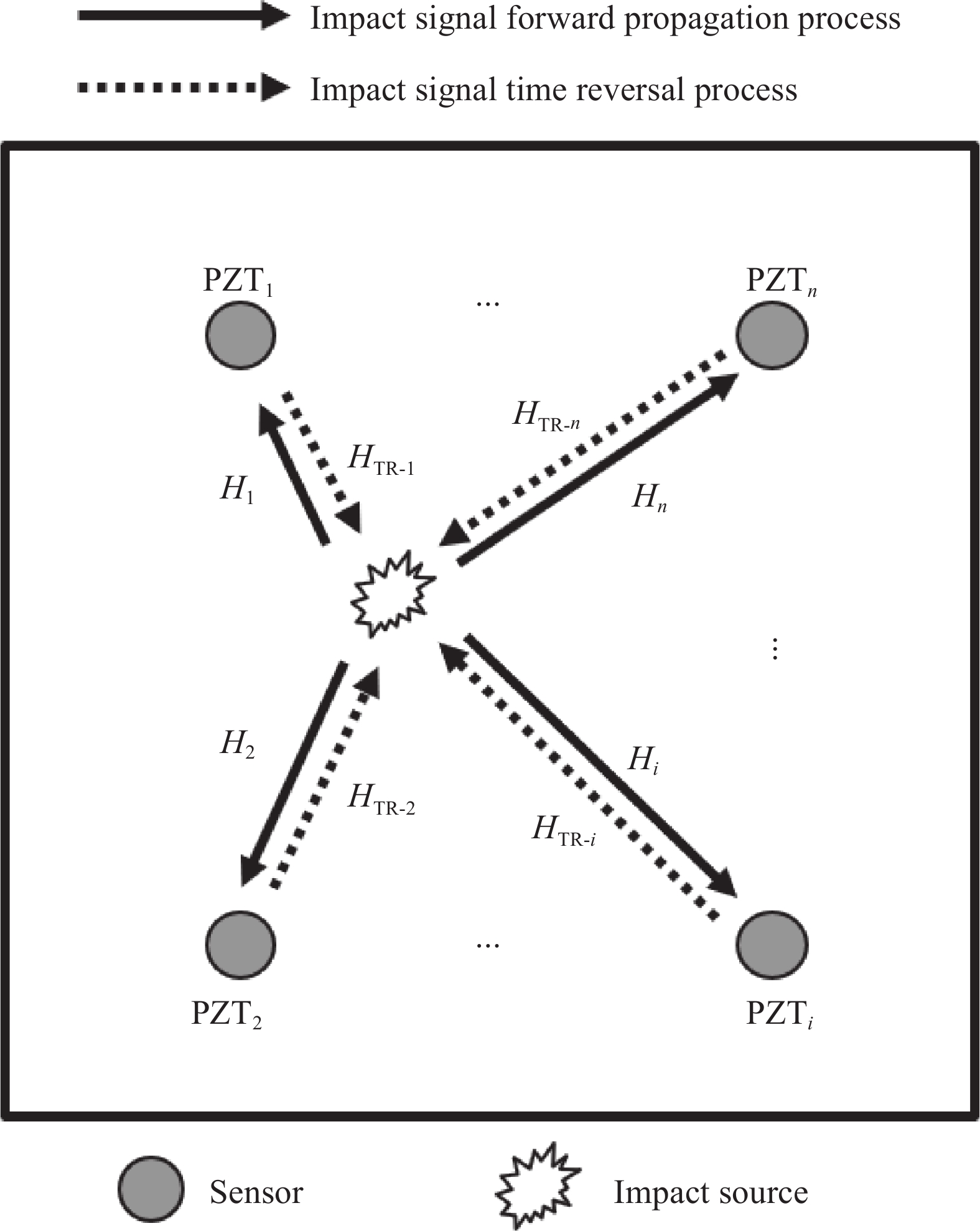

摘要: 复合材料结构在航空航天、海洋工程和轨道交通等领域中占有重要地位。但由于复合材料在抗冲击性能方面存在缺陷,实时在线的冲击监测技术越来越受到关注。本文提出了基于自适应时间反转聚焦的加筋复材板冲击定位方法。首先,利用结构表面布置的压电传感器网络接收冲击响应信号;然后,利用连续小波变换提取冲击响应信号的窄带Lamb波信号,使用窄带Lamb波信号的包络特征,根据时间反转聚焦原理,构建以冲击位置坐标和窄带Lamb波群速度为变量的虚拟时间反转成像函数;最后,迭代计算不同群速度下对应的虚拟时间反转成像结果,根据不同群速度对应的图像最大像素曲线获得自适应时间反转聚焦图像,从而实现冲击定位。利用尺寸为800 mm×400 mm (长×宽)的加筋编织复材板进行落球冲击实验,验证该方法的有效性。结果表明该方法可以准确的识别冲击位置,且在引入噪声、传感器数量减少和变温情况下仍然具有较好的精度。Abstract: Composite structures play an important role in the fields of aerospace, ocean engineering and rail transit. Due to their defects in impact resistance, real-time on-line impact monitoring technology has attracted more and more attention. In this paper, an impact localization method for stiffened composite plates based on adaptive time reversal focusing imaging was proposed. Firstly, the impact response signal was received by piezoelectric sensor network arranged on the surface of the structure. Then, the narrowband Lamb wave signal of impact response signal was extracted by continuous wavelet transform. And a virtual time-reversal imaging function with impact position coordinates and narrowband Lamb wave group velocity as variables was constructed according to the time-reversal focusing principle. Finally, the virtual time reversal imaging results corresponding to different group velocities were iteratively calculated, and the adaptive time reversal focusing image was obtained according to the maximum pixel curve corresponding to different group velocities to realize impact localization. Drop ball impact experiments were carried out on a stiffened braided composite plate of 800 mm×400 mm (length×width) to verify the effectiveness of the method. The results show that this method can accurately identify the impact location and has a good accuracy in the cases of noise, reducing the number of sensors, and changing temperature.

-

图 3 冲击定位算法流程图

Figure 3. Flow chart of impact localization algorithm

k—Iteration step number; Cg—Group velocity; Cg min and Cg max—Minimum and maximum values of the iteration group velocity; ΔCg—Iteration step size; (x, y)—Coordinates of the pixel point assumed to be the position of the impact source; (Sxi, Syi)—Coordinates of the sensor PZTi ; Vi—Narrowband Lamb wave signal of the impact signal; P(t)—Synthesized signal at the pixel poin; "~" indicates that the signal is taken as an envelope; $ \mathop {{C_{\rm{g}}}}\limits^ \wedge $—Determined group velocity of the narrowband Lamb; $ \hat{I}(x, y)$—Adaptive time reversal focusing image

图 6 复合材料加筋板冲击定位结果: (a) 不同群速度的虚拟时间反转成像结果;(b) 不同群速度对应的最大图像像素曲线;(c) 自适应时间反转聚焦图像

Figure 6. Impact localization results of the stiffened composite plate: (a) Virtual time reversal imaging results corresponding to different group velocities; (b) The curve of different group velocity and their corresponding maximum image pixel values; (c) Adaptive time reversal focusing image

表 1 传感器的位置坐标

Table 1. Position coordinates of the sensors

Number Coordinate/mm Number Coordinate/mm P1 (100, 50) P7 (500, 200) P2 (300, 50) P8 (700, 200) P3 (500, 50) P9 (100, 350) P4 (700, 50) P10 (300, 350) P5 (100, 200) P11 (500, 350) P6 (300, 200) P12 (700, 350) 表 2 复合材料加筋板预测冲击位置与实际冲击位置比较

Table 2. Comparison of predicted and actual impact positions of the stiffened composite plate

Number Actual impact position/mm Predicted impact position/mm Error/mm 1 (150, 150) (146, 160) 10.7 2 (150, 300) (148, 310) 10.2 3 (300, 275) (295, 270) 7.1 4 (400, 50) (402, 22) 28.1 5 (400, 275) (402, 280) 5.4 6 (500, 275) (506, 270) 7.8 7 (550, 300) (538, 310) 15.6 8 (600, 200) (590, 198) 10.2 9 (650, 270) (646, 266) 5.7 10 (700, 125) (714, 130) 14.9 表 3 复合材料加筋板两点冲击定位误差

Table 3. Impact localization error of two-point impact on the stiffened composite plate

Number Actual impact position/mm Predicted impact position/mm Error/

mmFig. 10(a) Impact 1 (250, 150) (250, 160) 10.0 Impact 2 (400, 275) (390, 305) 31.6 Fig. 10(b) Impact 1 (500, 125) (490, 130) 11.2 Impact 2 (650, 270) (675, 245) 35.4 表 4 考虑噪声情况下复合材料加筋板预测冲击位置与实际冲击位置比较

Table 4. Comparison between predicted and actual impact position of the stiffened composite plate under noise conditions

Number Actual impact position/mm Predicted impact position/mm Error/mm 1 (150, 150) (182, 148) 32.1 2 (150, 300) (141, 320) 21.9 3 (300, 275) (287, 264) 17.0 4 (400, 50) (366, 36) 36.8 5 (400, 275) (384, 290) 21.9 6 (500, 275) (513, 262) 18.4 7 (550, 300) (530, 315) 25.0 8 (600, 200) (577, 190) 25.1 9 (650, 270) (628, 262) 23.4 10 (700, 125) (722, 118) 23.1 表 5 减少传感器数量后复合材料加筋板预测冲击位置与实际冲击位置比较

Table 5. Comparison between predicted and actual impact position of the stiffened composite plate after reducing the number of sensors

Number Actual impact position/mm Predicted impact position/mm Error/mm 1 (150, 150) (135, 155) 15.8 2 (150, 300) (140, 310) 14.1 3 (300, 275) (290, 265) 14.1 4 (400, 50) (395, 90) 40.3 5 (400, 275) (410, 270) 11.1 6 (500, 275) (515, 260) 18.0 7 (550, 300) (545, 325) 25.5 8 (600, 200) (615, 200) 15.0 9 (650, 270) (660, 282) 15.6 10 (700, 125) (740, 120) 40.3 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12.DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). [2] 鲍益东, 何瑞, 宋云鹤, 等. 二维编织碳纤维增强树脂复合材料一步法铺层展开[J]. 复合材料学报, 2022, 39(7):3144-3155.BAO Yidong, HE Rui, SONG Yunhe, et al. One-step spreading for 2D woven carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica,2022,39(7):3144-3155(in Chinese). [3] SIKDAR S, KUDELA P, RADZIENSKI M, et al. Online detection of barely visible low-speed impact damage in 3D-core sandwich composite structure[J]. Composite Structures,2018,185:646-655. doi: 10.1016/j.compstruct.2017.11.067 [4] DIAMANTI K, SOUTIS C. Structural health monitoring techniques for aircraft composite structures[J]. Progress in Aerospace Sciences,2010,46(8):342-352. doi: 10.1016/j.paerosci.2010.05.001 [5] SIKDAR S, MIRGAL P, BANERJEE S. Low-velocity impact source localization in a composite sandwich structure using a broadband piezoelectric sensor network[J]. Composite Structures,2022,291:115619. doi: 10.1016/j.compstruct.2022.115619 [6] KIRKBY E, OLIVEIRA R, MICHAUD V, et al. Impact localisation with FBG for a self-healing carbon fibre composite structure[J]. Composite Structures,2011,94(1):8-14. doi: 10.1016/j.compstruct.2011.07.030 [7] GOUTAUDIER D, OSMOND G, GENDRE D. Impact localization on a composite fuselage with a sparse network of accelerometers[J]. Comptes Rendus Mecanique,2020,348:191-209. doi: 10.5802/crmeca.12 [8] SIMONE M E, CIAMPA F, BOCCARDI S, et al. Impact source localisation in aerospace composite structures[J]. Smart Materials and Structures,2017,26(12):125026. doi: 10.1088/1361-665X/aa973e [9] COLES A, CASTRO B A, ANDREADES C, et al. Impact localization in composites using time reversal, embedded PZT transducers, and topological algorithms[J]. Frontiers in Built Environment,2020,6:27. doi: 10.3389/fbuil.2020.00027 [10] SHRESTHA P, KIM J H, PARK Y, et al. Impact localization on composite wing using 1D array FBG sensor and RMS/correlation based reference database algorithm[J]. Composite Structures,2015,125:159-169. doi: 10.1016/j.compstruct.2015.01.029 [11] DIPIETRANGELO F, NICASSIO F, SCARSELLI G. Structural health monitoring for impact localisation via machine learning[J]. Mechanical Systems and Signal Processing,2023,183:109621. doi: 10.1016/j.ymssp.2022.109621 [12] TOBIAS A. Acoustic-emission source location in two dimensions by an array of three sensors[J]. Non-Destructive Testing,1976,9(1):9-12. doi: 10.1016/0029-1021(76)90027-X [13] CIAMPA F, MEO M. Acoustic emission source localization and velocity determination of the fundamental mode A0 using wavelet analysis and a newton-based optimization technique[J]. Smart Materials and Structures,2010,19(4):045027. doi: 10.1088/0964-1726/19/4/045027 [14] GORGIN R, WANG Z, WU Z, et al. Probability based impact localization in plate structures using an error index[J]. Mechanical Systems and Signal Processing,2021,157:107724. doi: 10.1016/j.ymssp.2021.107724 [15] MARINO M, ANDREA B, PIETRO G, et al. A novel differential time-of-arrival estimation technique for impact localization on carbon fiber laminate sheets[J]. Sensors,2017,17(10):2270. doi: 10.3390/s17102270 [16] QIU L, YUAN S, ZHANG X, et al. A time reversal focusing based impact imaging method and its evaluation on complex composite structures[J]. Smart Materials and Structures,2011,20(10):105014. doi: 10.1088/0964-1726/20/10/105014 [17] MINIACI M, MAZZOTTI M, RADZIEŃSKI M, et al. Application of a laser-based time reversal algorithm for impact localization in a stiffened aluminum plate[J]. Frontiers in Materials,2019,6:30. doi: 10.3389/fmats.2019.00030 [18] KIM M G, KIM S W. Impact localization for composite plate using the modified error-outlier algorithm with Pugh's concept selection under various temperatures[J]. Compo-site Structures,2021,272:114226. doi: 10.1016/j.compstruct.2021.114226 [19] WU Z, XU L, WANG Y, et al. Impact energy identification on a composite plate using basis vectors[J]. Smart Materials and Structures,2015,24(9):095007. doi: 10.1088/0964-1726/24/9/095007 [20] MASERAS-GUTIERREZ M A, STASZEWSKI W J, FOUND M S, et al. Detection of impacts in composite materials using piezoceramic sensors and neural networks[J]. Smart Structures,1998,3329:491-497. [21] LIU Q, WANG F, LI J, et al. A hybrid support vector regression with multi-domain features for low-velocity impact localization on composite plate structure[J]. Mechanical Systems and Signal Processing,2021,154:107547. doi: 10.1016/j.ymssp.2020.107547 [22] YAN G. A bayesian approach for damage localization in plate-like structures using Lamb waves[J]. Smart Materials & Structures,2013,22(3):035012. [23] CIAMPA F, MEO M, BARBIERI E. Impact localization in composite structures of arbitrary cross section[J]. Structural Health Monitoring—An International Journal,2012,11(6):643-655. doi: 10.1177/1475921712451951 [24] GIURGIUTIU V, SANTONI-BOTTAI G. Structural health monitoring of composite structures with piezoelectric-wafer active sensors[J]. AIAA Journal,2011,49(3):565-581. doi: 10.2514/1.J050641 [25] WANG S, WANG H, WANG D, et al. AE source localization and imaging on cylindrical shell structures based on six-AE-sensor monitoring network and VTR focusing imaging[J]. Nondestructive Testing and Evaluation,2021,36(1):35-61. doi: 10.1080/10589759.2019.1692012 [26] CHEN C, YUAN F. Impact source identification in finite isotropic plates using a time-reversal method: Theoretical study[J]. Smart Materials & Structures,2010,19(10):105028. [27] YANG Z, YANG L, ZHANG J, et al. Damage shape recognition algorithm of composite woven fabric plate based on guided waves[J]. Composite Structures, 2023, 303: 116351. [28] 胡宁, 刘瑶璐, 赵友选, 等. 基于低频动态信息和超声导波的复杂结构损伤的在线诊断技术[J]. 固体力学学报, 2017, 38(4):312-347.HU Ning, LIU Yaolu, ZHAO Youxuan, et al. On-line monitoring technologies for complex structural damage identification based on low-frequency structural dynamic signals and ultrasonic guided waves[J]. Chinese Journal of Solid Mechanics,2017,38(4):312-347(in Chinese). -

下载:

下载: