Fatigue performance analysis of composite joints based on hole deformation

-

摘要: 在复合材料的实际应用中,以装配组件或紧固件失效作为复合材料螺栓连接失效的判定准具有极大的风险性。在分析复合材料疲劳损伤发展特点的基础上,本文提出了一种基于连接孔变形的螺接结构疲劳寿命预测方法,并以碳纤维复合材料双钉单剪及单钉双剪连接拉-拉疲劳性能实验数据对模型进行了验证。结果表明:连接孔的变形量能很好地反映连接结构疲劳损伤的发展过程,本文所提的疲劳寿命预测模型的最大误差不超过−3.62%,装配间隙的存在可导致连接件疲劳寿命下降高达64.8%。Abstract: In the practical application of composite materials, using the failure of assembly components or faste-ners as a criterion for determining the failure of composite bolted joints brings great risks. After analysis of development characteristics of fatigue damage in composite materials, a method for predicting the fatigue life of composite bolted joints was proposed, which was based on the deformation of connection holes, and validated by using experimental data on tensile-tensile fatigue performance of double-bolt single-lap and single-bolt double-lap composite joints. The results show that the deformation of the connection hole can well reflect the development process of fatigue damage of the connection structure, and the maximum relative error of the fatigue life prediction model proposed in this paper does not exceed −3.62%. The existence of assembly gaps can lead to a decrease in the fatigue life of the connection member of up to 64.8%.

-

Key words:

- composites /

- bolted joints /

- fatigue life /

- hole deformation /

- assembly gap

-

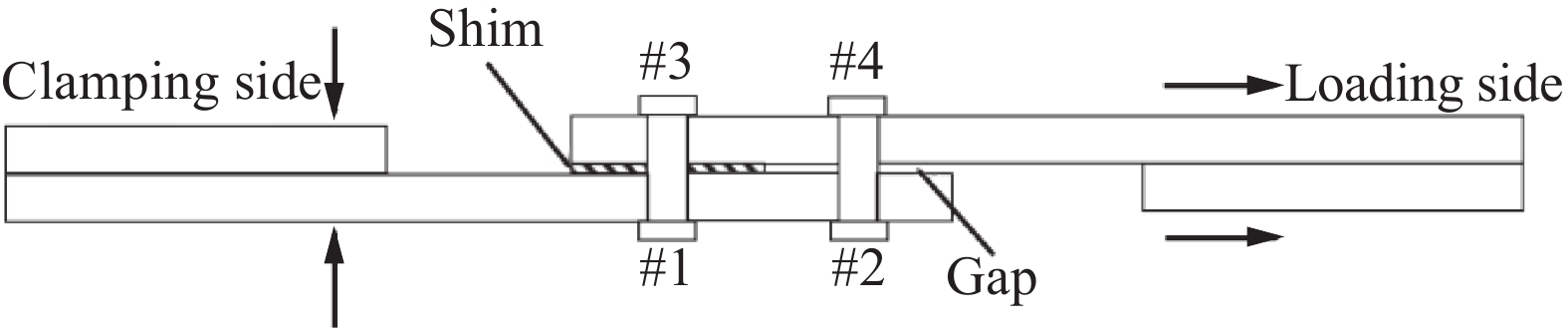

表 1 铺层顺序与单层板厚度

Table 1. Layup sequence and single layer board thickness

Laminate number Stacking sequence Single layer thickness/mm A [±45/0/45/0/−45/−45/90/45/0/±45] 0.15 B [45/90/−45/0/90/0/45/−45/90]s 0.2 表 2 层合板尺寸参数

Table 2. Laminate parameters

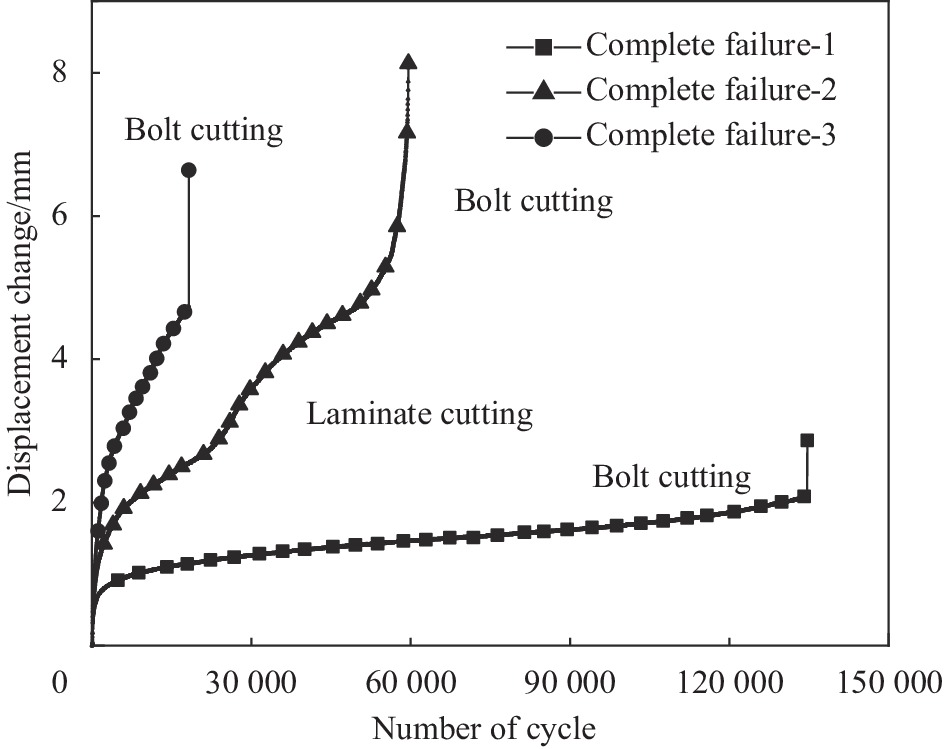

Laminate number d/mm L/mm W/mm A 4 140 24 B 6 135 36 Notes:d—Initial aperture; L—Laminate length; W—Laminate width. 表 3 构件完全失效时疲劳实验结果记录

Table 3. Record of fatigue test results when the component fails completely

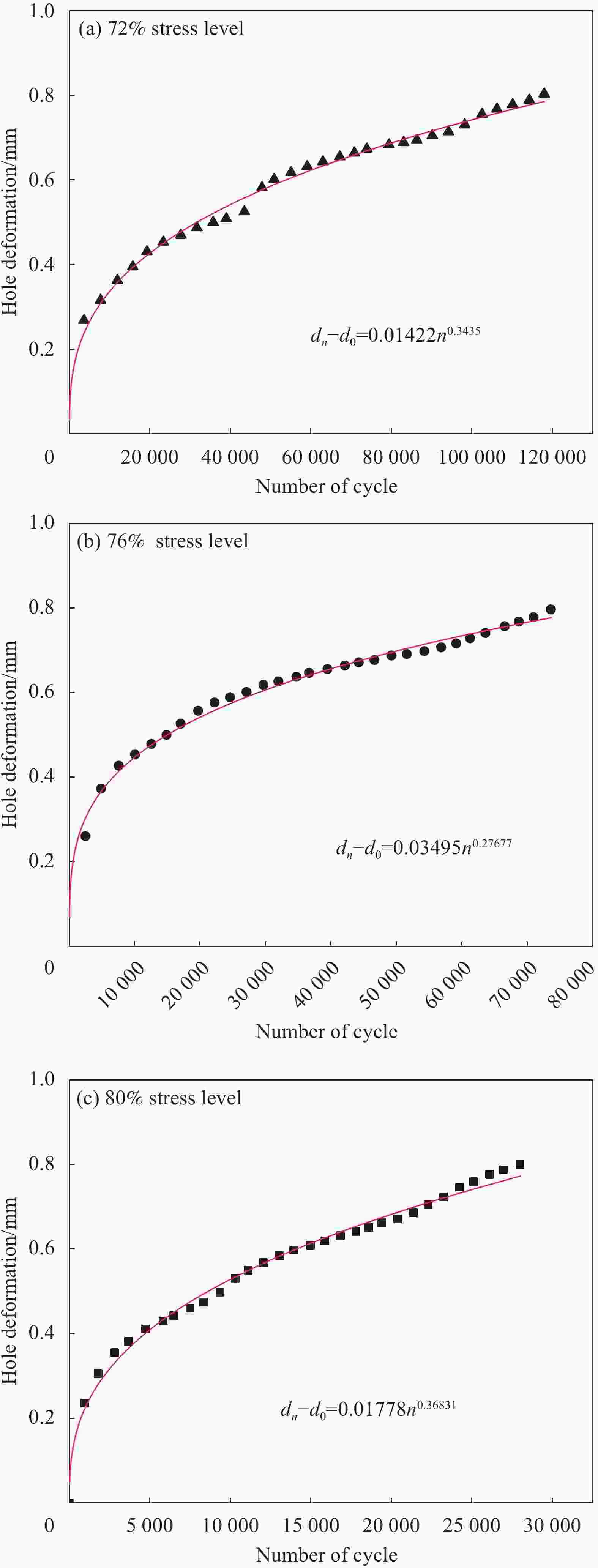

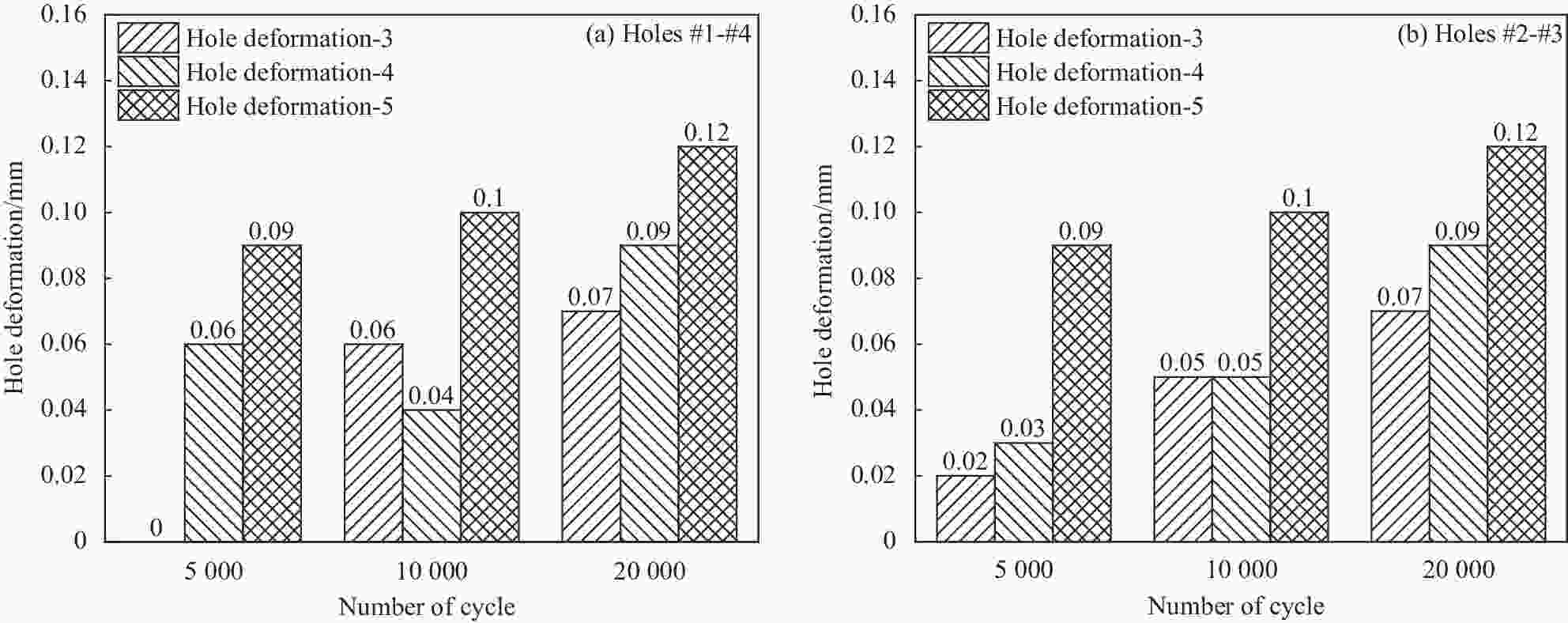

Number Gap height/mm Gap length/mm q/% s Complete failure-1 0 0 80 88696 Complete failure-2 0.5 12 80 59575 Complete failure-3 1.0 12 80 31221 Complete failure-4 0 0 70 126992 Complete failure-5 0.5 12 70 120713 Complete failure-6 1.0 12 70 121978 Notes:q—Stress level; s—Fatigue life. 表 4 固定循环次数孔变形测量结果记录

Table 4. Record of hole deformation measurement results with fixed number of cycles

Number Gap height/mm Gap length/mm q/% Number of cycle Hole deformation-1 0 0 80 20000 Hole deformation-2 0 0 75 20000 Hole deformation-3 0 0 70 60000 Hole deformation-4 0.5 12 70 20000 Hole deformation-5 1.0 12 70 20000 Hole deformation-6 0 0 65 20000 Hole deformation-7 0 0 60 20000 表 5 孔变形达到0.15d0时疲劳实验结果记录

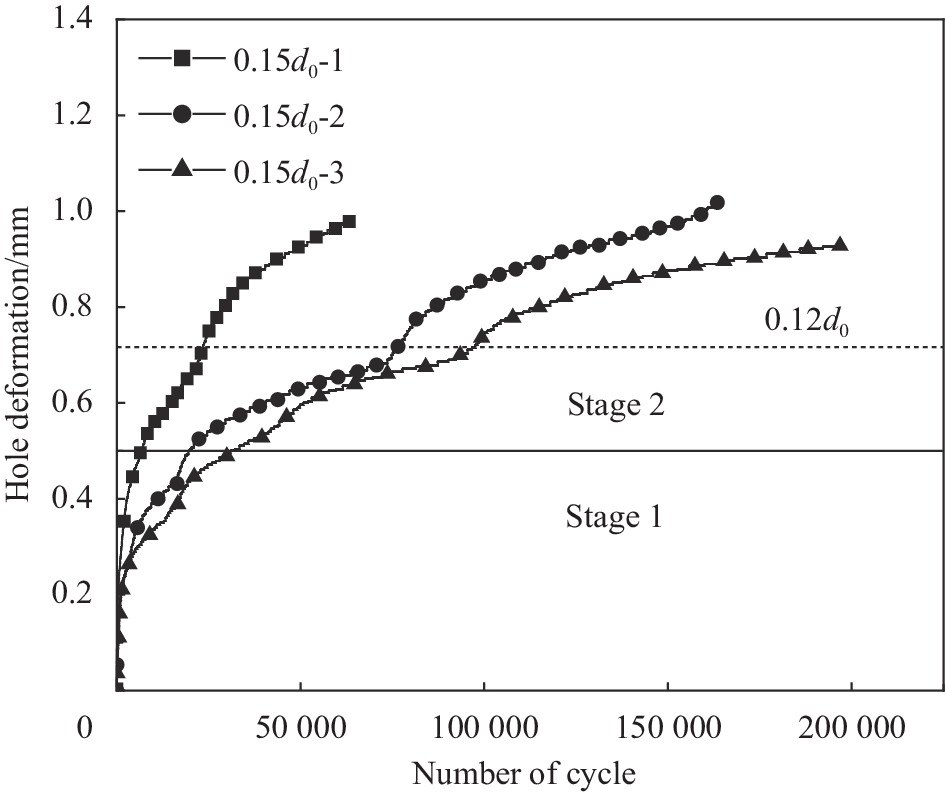

Table 5. Record of fatigue test results when hole deformation reaches 0.15d0

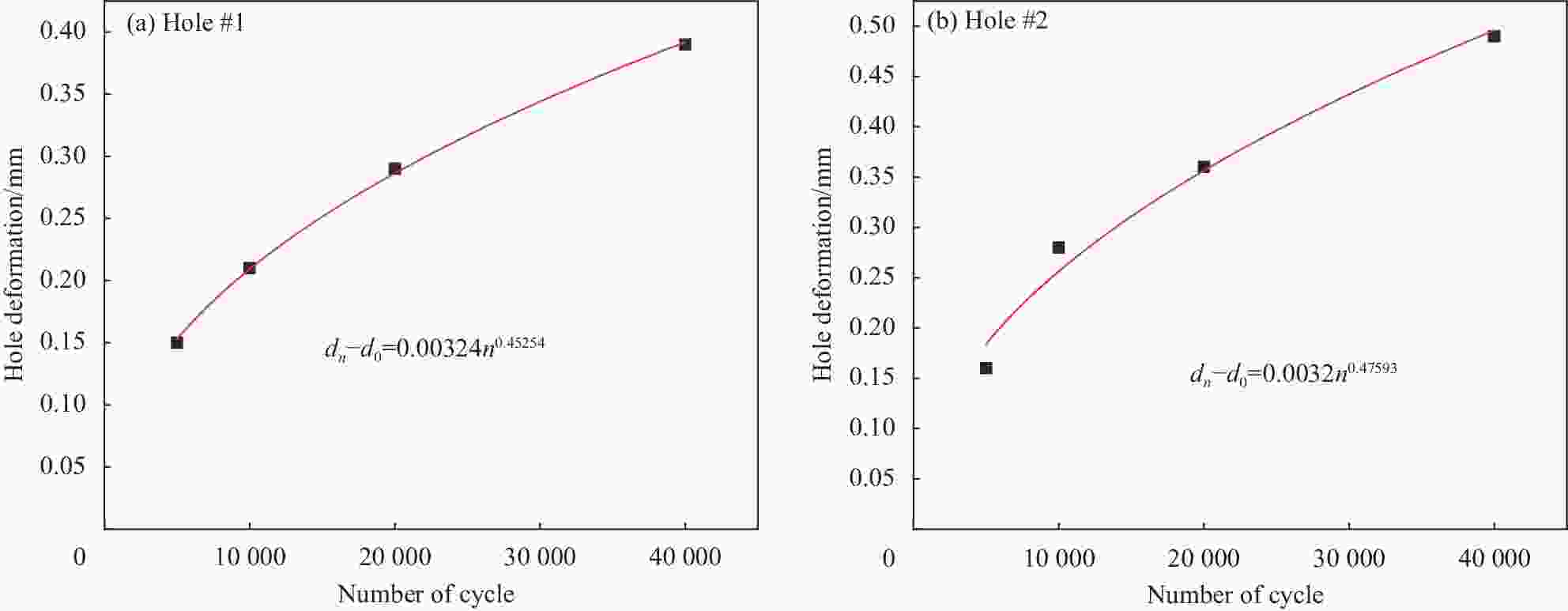

Number q/% Number of cycle 0.15d0-1 80 38420 0.15d0-2 76 73250 0.15d0-3 72 164401 Note:d0—Initial aperture. 表 6 #1孔和#2孔同应力水平预测模型验证结果

Table 6. Verification results of the same stress level prediction model for holes #1 and #2

Hole number Prediction model Number of cycle Predictive value/mm Actual value/mm Error #1 $ \Delta d=0.00324{n}^{0.45254} $ 60000 0.47 0.49 −3.92% #2 $ \Delta d=0.00320{n}^{0.47593} $ 60000 0.60 0.59 +1.98% Notes: Δd—Hole deformation; n—Number of time of fatigue load. 表 7 #1孔和#2孔同循环次数预测模型验证结果

Table 7. Verification results of the same number of cycles prediction model for holes #1 and #2

Hole number Prediction model Stress level/% Predictive value/mm Actual value/mm Error #1 $ \Delta d=6.61474{q}^{9.05923} $ 80 0.87 0.84 +3.57% #2 $ \Delta d=4.96697{q}^{7.74256} $ 80 0.88 0.89 −1.12% 表 8 3种应力水平下孔变形等应力水平预测模型验证结果

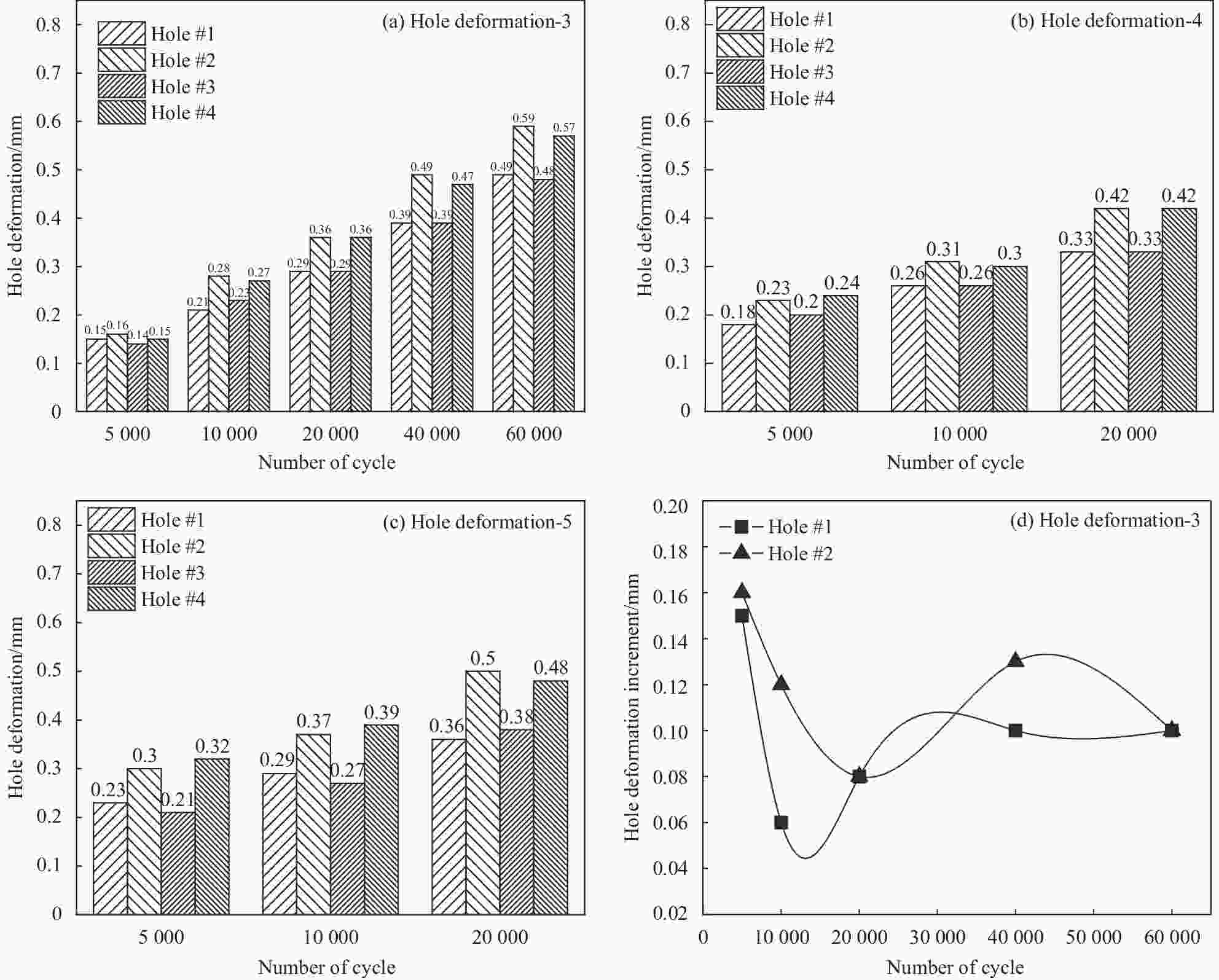

Table 8. Verification results of stress level prediction models for hole deformation under three different stress levels

Stress level/% Prediction model Number of cycle Predictive value/mm Actual value/mm Error 72 $ \Delta d=0.01422{n}^{0.34350} $ 140000 0.833 0.853 −2.36% 76 $ \Delta d=0.03495{n}^{0.27677} $ 100000 0.846 0.854 −0.96% 80 $ \Delta d=0.01778{n}^{0.36831} $ 40000 0.881 0.914 −3.62% 表 9 复合材料螺栓连接结构孔变形预测模型验证对比结果

Table 9. Verification and comparison results of hole deformation prediction models for composite bolted connection structures

Prediction model Number of cycle Predictive value/mm Actual value/mm Error $ \Delta d=4.46\times {10}^{-14}{n}^{3}-2.32\times {10}^{-9}{n}^{2}+5.23\times {10}^{-5}{n}^{}+0.19 $ 400000 1.424 0.914 55.80% $ \Delta d=-0.83318+0.34838{\rm{lg}}_{}n $ 400000 0.770 0.914 −15.75% $ \Delta d=0.01778{n}^{0.36831} $ 400000 0.881 0.914 −3.62% -

[1] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10.DU Shanyi, GUAN Zhidong. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). [2] 郝大贤, 王伟, 王琦珑, 等. 复合材料加工领域机器人的应用与发展趋势[J]. 机械工程学报, 2019, 55(3):1-17. doi: 10.3901/JME.2019.03.001HAO Daxian, WANG Wei, WANG Qilong, et al. Applications and development trend of robotics in composite material process[J]. Journal of Mechanical Engineering,2019,55(3):1-17(in Chinese). doi: 10.3901/JME.2019.03.001 [3] 王欢. 钛合金螺旋铣孔试验研究[D]. 大连: 大连理工大学, 2015.WANG Huan. Experimental study on helical milling of titanium alloy[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [4] 谢鸣九. 复合材料连接[M]. 上海: 上海交通大学出版社, 2011: 11-19.XIE Mingjiu. Composite material connection[M]. Shanghai: Shanghai Jiao Tong University Press, 2011: 11-19(in Chinese). [5] CAO Y J, ZUO D Q, ZHAO Y, et al. Experimental investigation on bearing behavior and failure mechanism of double-lap thin-ply composite bolted joints[J]. Composite Structures,2021,261:113565. doi: 10.1016/j.compstruct.2021.113565 [6] 武涛. 复合材料多钉干涉连接应力分布及损伤萌生研究[D]. 西安: 西北工业大学, 2017.WU Tao. Stress distribution and damage initiation analysis of composite multi-pin joints with interference fit[D]. Xi'an: Northwestern Polytechnical University, 2017(in Chinese). [7] ZHAO L B, FANG Z A, LIU F R, et al. A modified stiffness method considering effects of hole tensile deformation on bolt load distribution in multi-bolt composite joints[J]. Composites Part B: Engineering,2019,171:264-271. doi: 10.1016/j.compositesb.2019.05.010 [8] SU Z X, XIE C H, TANG Y. Stress distribution analysis and optimization for composite laminate containing hole of different shapes[J]. Aerospace Science and Technology,2018,76:466-470. doi: 10.1016/j.ast.2018.01.046 [9] HAEGER A, GRUDENIK M, HOFFMANN M J, et al. Effect of drilling-induced damage on the open hole flexural fatigue of carbon/epoxy composites[J]. Composite Structures,2019,215:238-248. doi: 10.1016/j.compstruct.2019.02.025 [10] HSU C W, HWU C. Correction of the existing solutions for hole/crack problems of composite laminates under coupled stretching-bending deformation[J]. Composite Structures,2021,260:113154. doi: 10.1016/j.compstruct.2020.113154 [11] 杨宇星. 虑及填隙装配的CFRP构件螺接性能研究[D]. 大连: 大连理工大学, 2019.YANG Yuxing. Research on bolted joint performance of CFRP components considering shimming assembly[D]. Dalian: Dalian University of Technology, 2019(in Chinese). [12] 窦亚冬. 飞机装配间隙协调及数字化加垫补偿技术研究[D]. 杭州: 浙江大学, 2018.DOU Yadong. Study on gap coordination and shim compensation in aircraft assembly[D]. Hangzhou: Zhejiang University, 2018(in Chinese). [13] CHANG J H, YANG Y X, LIU X S, et al. A mixed shimming method in eliminating the gaps during the assembly process of the complex structures[J]. IOP Conference Series: Materials Science and Engineering,2019,493(1):12140. [14] YANG Y X, WANG Y Q, LIU X S, et al. The effect of shimming material on flexural behavior for composite joints with assembly gap[J]. Composite Structures,2019,209:375-382. doi: 10.1016/j.compstruct.2018.10.086 [15] 邵远新, 王伟龙, 张磊, 等. 装配间隙对疲劳寿命影响的分析方法研究[J]. 飞机设计, 2017, 37(6):40-42.SHAO Yuanxin, WANG Weilong, ZHANG Lei, et al. Analy-sis method of the fatigue life affected by assembly clea-rance[J]. Aircraft Design,2017,37(6):40-42(in Chinese). [16] 吴富强, 姚卫星. 纤维增强复合材料剩余强度衰减模型[J]. 南京航空航天大学学报, 2008, 40(4):517-520.WU Fuqiang, YAO Weixing. Residual strength degradation model of fiber reinforced plastic[J]. Journal of Nanjing University of Aeronautics and Astronautics,2008,40(4):517-520(in Chinese). [17] 王军, 程小全, 张纪奎, 等. T700复合材料层合板拉-拉疲劳性能[J]. 航空材料学报, 2012, 32(3):85-90.WANG Jun, CHENG Xiaoquan, ZHANG Jikui, et al. Study on tension-tension fatigue properties of T700 composite laminates[J]. Journal of Aeronautical Materials,2012,32(3):85-90(in Chinese). [18] 中国国家标准管理委员会. 聚合物基复合材料疲劳性能测试方法 第3部分: 拉-拉疲劳: GB/T 35465.3—2017[S]. 北京: 中国标准出版社, 2017.Standardization Administration of the People's Republic of China. Test method for fatigue properties of polymer matrix composite materials—Part 3: Tension-tension fatigue: GB/T 35465.3—2017[S]. Beijing: Standards Press of China, 2017(in Chinese). [19] Amerian Society for Testing and Materials. Standard test method for bearing response of polymer matrix composite laminates: ASTM D5961/D5961M—2001[S]. Philadelphia: ASTM International, 2001. [20] 田昆. 纤维增强复合材料层合板强度与疲劳渐进损伤分析[D]. 哈尔滨: 哈尔滨工业大学, 2019.TIAN Kun. Strength and fatigue progressive damage analysis of fiber reinforced composite laminates[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [21] SUZUKI T, MAHFUZ H, TAKANASHI M. A new stiffness degradation model for fatigue life prediction of GFRPs under random loading[J]. International Journal of Fatigue,2019,119:220-228. doi: 10.1016/j.ijfatigue.2018.09.021 [22] 朱晓玲. 装配间隙对复材连接件力学性能影响研究[D]. 大连: 大连理工大学, 2020.ZHU Xiaoling. Study on the influence of assembly clea-rance on mechanical properties of composite joints[D]. Dalian: Dalian University of Technology, 2020(in Chinese). [23] 刘同, 许希武, 林智育. 复合材料厚板多钉连接[J]. 材料科学与工程学报, 2019, 37(5):768-778.LIU Tong, XU Xiwu, LIN Zhiyu. Research on multi-bolt composite laminate joint strength[J]. Journal of Materials Science and Engineering,2019,37(5):768-778(in Chinese). [24] 魏景超. 复合材料结构新型紧固件连接强度与失效机理[D]. 西安: 西北工业大学, 2014.WEI Jingchao. Strength and failure mechanism of bolted composite joints with new fastener[D]. Xi'an: Northwestern Polytechnical University, 2014(in Chinese). [25] LIU L Q, ZHANG J Q, CHEN K K, et al. Combined and interactive effects of interference fit and preloads on composite joints[J]. Chinese Journal of Aeronautics,2014,27(3):716-729. doi: 10.1016/j.cja.2014.04.014 -

下载:

下载: