High temperature mechanical behavior and damage mechanism of 2.5D woven carbon fiber-glass fiber/bismaleimide resin composite

-

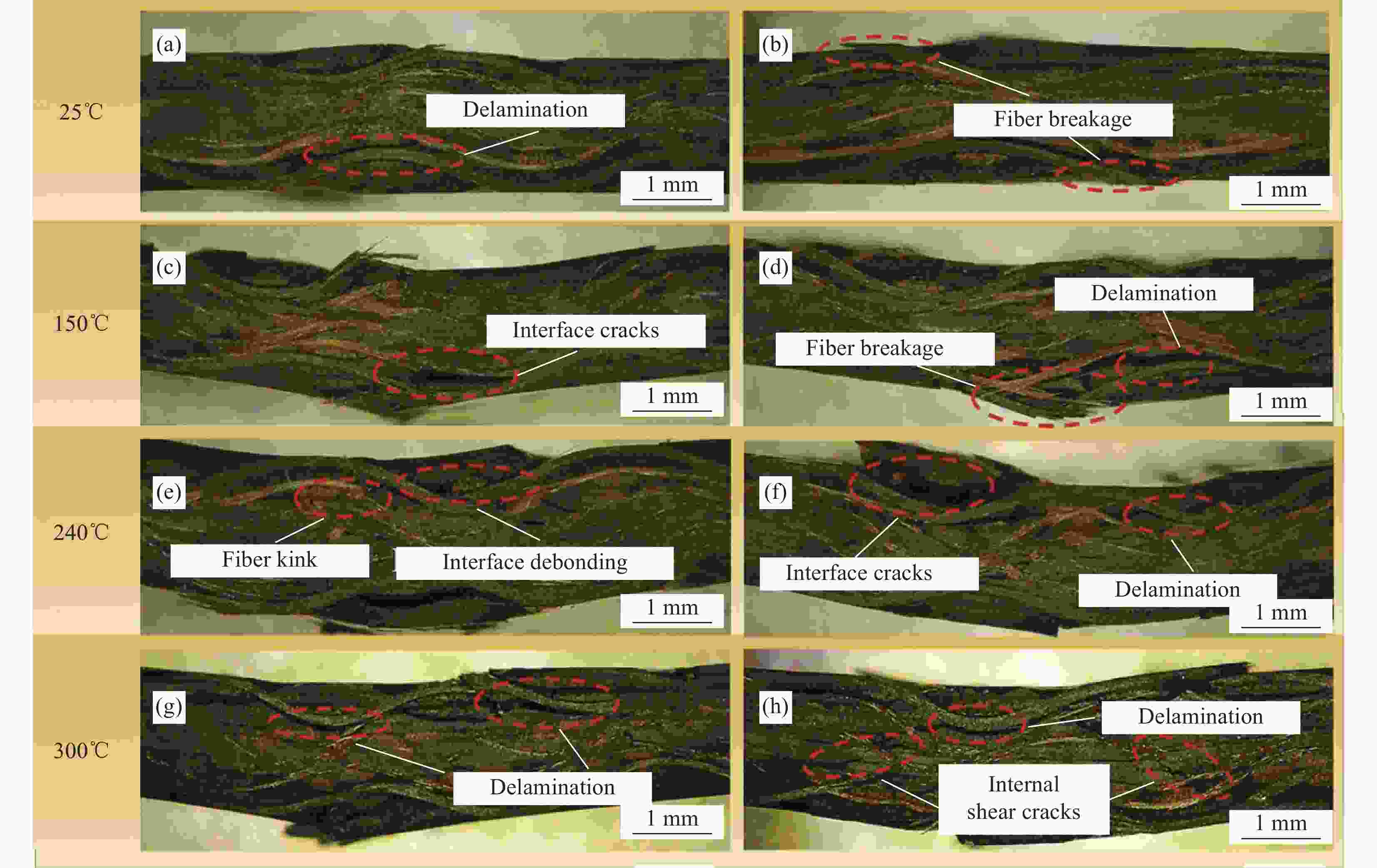

摘要: 采用三维纺织技术与树脂传递模塑工艺(RTM)制备了2.5D机织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料,分别在室温(25℃)和高温(150℃、240℃、300℃)环境下对复合材料进行了三点弯曲和层间剪切力学性能测试,探究了温度对复合材料力学行为及损伤机制的影响。结果表明:温度对2.5D机织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料的力学特性和损伤模式均有显著影响。温度上升导致纤维/基体界面结合力减弱,复合材料在300℃下的弯曲强度、弯曲模量和层间剪切强度相比室温环境分别降低了23.06%、70.01%和18.93%。弯曲载荷下,2.5D机织混杂复合材料的室温破坏模式主要以局部的纤维断裂和基体开裂为主,而高温损伤则以纤维/基体界面脱粘为主导。剪切载荷下,2.5D机织混杂复合材料的室温破坏模式主要为分层破坏,而随着温度升高,复合材料因基体软化出现塑性变形,基体开裂、界面脱粘及分层破坏决定了材料的最终失效。

-

关键词:

- 2.5D机织复合材料 /

- 混杂纤维 /

- 温度 /

- 力学行为 /

- 损伤机制

Abstract: 2.5D woven carbon fiber-glass fiber/bismaleimide resin composite was prepared by three-dimensional textile technology and resin transfer molding (RTM), and the mechanical properties of three-point bending and interlaminar shear were tested at room temperature (25℃) and high temperature (150℃, 240℃, 300℃), respectively, and the influence of temperature on the mechanical behavior and damage mechanism of the composites was explored. The results show that temperature has a significant effect on the mechanical properties and damage mode of 2.5D woven carbon fiber-glass fiber/bismaleimide resin composites. Temperature rise leads to weakening of fiber/matrix interface adhesion. Compared with the room temperature environment, the flexural strength, flexural modulus and interlaminar shear strength of the composite at 300℃ decrease by 23.06%, 70.01% and 18.93%. Under bending load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly dominated by local fiber fracture and matrix cracking, while high temperature damage is dominated by fiber/matrix interface debonding. Under shear load, the failure mode of 2.5D woven hybrid composites at room temperature is mainly stratified failure. With the increase of temperature, the composites appear plastic deformation due to the softening of matrix, matrix cracking, interface debonding and stratified failure determine the final failure of the material.-

Key words:

- 2.5D woven composite materials /

- hybrid fibers /

- temperature /

- mechanical behavior /

- mechanism of injury

-

表 1 复合材料各组分性能参数

Table 1. Performance parameters of each component of composite materials

Material Type Tensile strength/MPa Tensile modulus/GPa Elongation at break/% Density/(g·cm−3) Carbon fiber (CF) T300-3 K 3530 230 2.1 1.8 Glass fiber (GF) E 3400 73 4.8 2.54 Bismaleimide R801 90 4.2 2.5 1.25 表 2 2.5D机织混杂复合材料参数

Table 2. 2.5D woven hybrid composite material parameters

Yarn Fiber linear

density/texLayer Preformed unit

density/(yarn·cm−1)Composite

thickness/mmFiber volume

fraction/vol%Warp (CF) 200 2 8 1.85 49.87 Warp (GF) 144 4 8 Weft (CF) 200 3 4 Weft (GF) 144 4 8 -

[1] 李昱霖, 安庆升, 杨坤好, 等. 防热承载一体化复合材料电缆罩分析及验证[J]. 空天防御, 2019, 2(3):1-7. doi: 10.3969/j.issn.2096-4641.2019.03.001LI Yulin, AN Qingsheng, YANG Kunhao, et al. Analysis and validation of integrated thermal protection and load bearing for composite material cable cover[J]. Air&Space Defense,2019,2(3):1-7(in Chinese). doi: 10.3969/j.issn.2096-4641.2019.03.001 [2] 周世豪, 倪楠楠, 刘彬, 等. 结构热防护一体化复合材料研究进展[J]. 航空材料学报, 2022, 42(4):1-15. doi: 10.11868/j.issn.1005-5053.2020.000053ZHOU Shihao, NI Nannan, LIU Bin, et al. Research progress on structural thermal protection integration composite[J]. Journal of Aeronautical Materials,2022,42(4):1-15(in Chinese). doi: 10.11868/j.issn.1005-5053.2020.000053 [3] LI W J, ZHANG Z W, ZHU M D, et al. Novel strategy and multi-scale modelling of integrated multifunctional composite for thermal protection under extreme environment[J]. Applied Thermal Engineering,2022,209:118313. doi: 10.1016/j.applthermaleng.2022.118313 [4] 杨智勇, 张东, 顾春辉, 等. 国外空天往返飞行器用先进树脂基复合材料研究与应用进展[J]. 复合材料学报, 2022, 39(7):3029-3043.YANG Zhiyong, ZHANG Dong, GU Chunhui, et al. Research and application of advanced resin matrix composites for aerospace shuttle vehicles abroad[J]. Acta Materiae Compositae Sinica,2022,39(7):3029-3043(in Chinese). [5] 高军鹏, 白江波, 邓华, 等. 间隙率对平纹及三轴向织物复合材料弹性性能的影响[J]. 宇航材料工艺, 2014, 44(5):20-24,35. doi: 10.3969/j.issn.1007-2330.2014.05.005GAO Junpeng, BAI Jiangbo DENG Hua, et al. Effect of gap ratio on elastic properties of plain weave fabric and laminate with triaxial weave fabric composites[J]. Aerospace Materials & Technology,2014,44(5):20-24,35(in Chinese). doi: 10.3969/j.issn.1007-2330.2014.05.005 [6] FAN W, DANG W, LIU T, et al. Fatigue behavior of the 3D orthogonal carbon/glass fibers hybrid composite under three-point bending load[J]. Materials & Design,2019,183:108112. [7] PANKOW M, RIOSBASS M, JUSTUSSON B, et al. Effect of fiber hybridization on tensile fracture of 3D woven textile composites[J]. Composites Part A: Applied Science and Manufacturing,2023,165:107306. doi: 10.1016/j.compositesa.2022.107306 [8] 龚亮, 薛利利. 热氧老化对三向正交碳/玻璃纤维/双马复合材料力学性能的影响[J]. 材料工程, 2021, 49(10):144-155. doi: 10.11868/j.issn.1001-4381.2021.000045GONG Liang, XUE Lili. Influence of thermo-oxidative aging on mechanical performance of three-dimensional orthogonal carbon/glass fiber/bismaleimide composites[J]. Journal of Materials Engineering,2021,49(10):144-155(in Chinese). doi: 10.11868/j.issn.1001-4381.2021.000045 [9] PAPA I, BOCCARUSSO L, LANGELLA A, et al. Carbon/glass hybrid composite laminates in vinylester resin: Bending and low velocity impact tests[J]. Composite Structures,2020,232:111571. doi: 10.1016/j.compstruct.2019.111571 [10] 王忠远, 蔡长春, 王振军, 等. 三维角联锁机织铝基复合材料面内拉伸力学行为与失效机制[J]. 复合材料学报, 2021, 38(9):2989-2999. doi: 10.13801/j.cnki.fhclxb.20201116.007WANG Zhongyuan, CAI Changchun, WANG Zhenjun, et al. In-plane tensile mechanical behavior and failure mechanism of three-dimensional angle interlocking woven aluminum matrix composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2989-2999(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201116.007 [11] LI T, CHEN L, SHEN W, et al. Quasi-static compression response of carbon fiber reinforced 2.5D woven composites at different loading directions[J]. Materials,2022,15(11):3953. doi: 10.3390/ma15113953 [12] 翟军军, 王露晨, 孔祥霞. 三维多向编织复合材料温度效应综述:热传导、热膨胀性质和力学响应[J]. 复合材料学报, 2021, 38(8):2459-2478.ZHAI Junjun, WANG Luchen, KONG Xiangxia. A review on temperature effect of 3D multi-directional braided composites: Heat conduction, thermal expansion properties and mechanical response[J]. Acta Materiae Compositae Sinica,2021,38(8):2459-2478(in Chinese). [13] DONG F, WANG X, ZHANG C, et al. Ablation behavior and damage mechanisms of carbon/boron-modified phenolic 2.5D woven composite[J]. Polymer Degradation and Stability,2023,209:110279. doi: 10.1016/j.polymdegradstab.2023.110279 [14] RUGGLES-WRENN M B, ALNATIFAT S A. Fully-reversed tension-compression fatigue of 2D and 3D woven polymer matrix composites at elevated temperature[J]. Polymer Testing,2021,97:107179. doi: 10.1016/j.polymertesting.2021.107179 [15] ZHAO Y R, JIAN S, WEN W D, et al. Thermo-mechanical behaviors of 2.5D shallow straight-link-shaped woven composites under the warp direction fatigue loading at room and elevated temperatures[J]. Composite Structures,2022,289:115489. doi: 10.1016/j.compstruct.2022.115489 [16] SONG J, WEN W, CUI H. Experimental and numerical investigation of mechanical behaviors of 2.5D woven composites at ambient and un-ambient temperatures[J]. Composite Structures,2018,201:699-720. doi: 10.1016/j.compstruct.2018.06.054 [17] DANG M G, LI D S, LEI J. Temperature effects on mechanical response and failure mechanism of 3D angle-interlock woven carbon/epoxy composites[J]. Composites Communications,2020,18:37-42. doi: 10.1016/j.coco.2020.01.001 [18] 曹淼. 三维角联锁机织碳纤维/环氧树脂复合材料热氧老化效应及冲击后剩余强度[D]. 上海: 东华大学, 2020.CAO Miao. Residual strength of 3-D angle-interlock woven carbon fiber/epoxy resin composites after thermo-oxidative ageing and impact[D]. Shanghai: Donghua University, 2020(in Chinese). [19] RATHORE D K, PRUSTY R K, MOHANTY S C, et al. In-situ elevated temperature flexural and creep response of inter-ply glass/carbon hybrid FRP composites[J]. Mechanics of Materials,2017,105:99-111. doi: 10.1016/j.mechmat.2016.11.013 [20] 于洋, 樊威, 薛利利, 等. 热氧老化对三维编织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料力学性能的影响[J]. 复合材料学报, 2021, 38(12):4060-4072. doi: 10.13801/j.cnki.fhclxb.20210311.004YU Yang, FAN Wei, XUE Lili, et al. Influence of thermo-oxidative aging on the mechanical performance of three-dimensional braided carbonfiber-glass fiber/bismaleimide composites[J]. Acta Materiae Compositae Sinica,2021,38(12):4060-4072(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210311.004 [21] LIANG Q, LIU J, WANG X, et al. Flexural progressive failure mechanism of hybrid 3D woven composites: Combination of X-ray tomography, acoustic emission and digital image correlation[J]. Composite Structures,2022,280:114894. doi: 10.1016/j.compstruct.2021.114894 [22] 张雷, 李姗姗, 庄毅等. 碳纤维与玻-碳层间混杂2.5维机织复合材料的力学性能对比研究[J]. 材料导报, 2022, 36(S1):199-203.ZHANG Lei, LI Shanshan, ZHUANG Yi, et al. Comparative study on mechanical properties of carbon fiber and glass-carbon interlaminar hybrid 2.5D woven composites[J]. Materials Reports,2022,36(S1):199-203(in Chinese). [23] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Fibre-reinforced plastic composites—Dertermination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [24] 中国建筑材料联合会. 纤维增强塑料 短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国建材工业出版社, 2010.China Building Materials Federation. Fibre-reinforced plastics composites—Determination of apparent interlaminar shear strength by short-beam method: JC/T 773—2010[S]. Beijing: China Building Materials Industry Press, 2010(in Chinese). [25] 李紫伦, 杨安坤, 覃小红, 等. 三维编织玻璃纤维/环氧树脂复合材料薄壁管轴向压缩性能的温度效应[J]. 复合材料学报, 2023, 40(10): 5588-5600.LI Zilun, YANG Ankun, QIN Xiaohong, et al. Temperature effect on axial compressive properties of three-dimensional glass fiber/epoxy resin braided composite thin-walled tubes[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5588-5600(in Chinese). [26] LI J, FAN W, TAO L, et al. The temperature effect on the inter-laminar shear properties and failure mechanism of 3D orthogonal woven composites[J]. Textile Research Journal,2020,90(23-24):2806-2817. doi: 10.1177/0040517520927009 [27] YANG B, YUE Z, GENG X, et al. Temperature effects on transverse failure modes of carbon fiber/bismaleimides composites[J]. Journal of Composite Materials,2017,51(2):261-272. doi: 10.1177/0021998316639122 [28] 双超, 刘璐璐, 赵振华, 等. 湿热老化后碳纤维复合材料层间剪切强度实验方法对比研究[J]. 航空材料学报, 2017, 37(5):90-98. doi: 10.11868/j.issn.1001-4381.2016.000226SHUANG Chao, LIU Lulu, ZHAO Zhenhua, et al. Comparison study on interlaminar shear strength testing methods of CFRP under hygrothermal aging conditions[J]. Journal of Aeronautical Materials,2017,37(5):90-98(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.000226 [29] HE Y, MEI M, WEI K, et al. Interlaminar shear behaviour and meso damage suppression mechanism of stitched composite under short beam shear using X-ray CT[J]. Composites Science and Technology,2022,218:109189. doi: 10.1016/j.compscitech.2021.109189 -

下载:

下载: