Design, fabrication and sensing application of hierarchical microstructures based on micro/nano fibers

-

摘要: 微结构化是提高柔性压力传感器性能的重要技术手段之一,本文提出一种基于微纳米纤维的多层次微结构设计与快速制备方法。首先采用近场直写与熔融沉积成型一体化成形工艺制备出具有多尺度纤维的牺牲支架,在聚二甲基硅氧烷(Polydimethylsiloxane,PDMS)中掺杂碳纳米管(Carbon nanotubes,CNTs)作为柔性传感器的介电层材料,通过牺牲模板法制备出具有多层次微结构的CNTs/PDMS柔性介电层;进一步研究了多层次微结构的设计参数对其传感性能的影响。实验结果表明:设计的微结构能显著增强柔性传感器的输出电性能。其中高度为1.3 mm、间距为1.5 mm的多层次微结构在频率为3 Hz、压力载荷为14 N下输出电性能最为优异;此外,制备的传感器经过20000次循环测试,表现出良好的稳定性与耐久性。最后,设计了一款用于观察足底压力分布及步态检测的柔性压力传感鞋垫,结果表现出良好灵敏度和稳定性。本文为低成本快速制备多层次微结构提供新的思路,为制备高性能柔性压力传感器提供参考与借鉴。Abstract: Microstructuring is one of the important techniques to improve the performance of flexible pressure sensors. In this paper, a method for designing and fabricating hierarchical microstructures based on micro/nano fibers was proposed. First, a sacrificial mold with hierarchical microstructures was prepared by integrating near-field direct writing and fused deposition modeling. Carbon nanotubes (CNTs) were doped into polydimethylsiloxane (PDMS) as the dielectric layer material for the flexible sensor. The CNTs/PDMS flexible dielectric layer with hierarchical microstructures was then prepared by sacrificial template method. Furthermore, the effect of design parameters of hierarchical microstructures on the sensing performance was studied. The experimental results show that the designed microstructures can significantly enhance the output electrical performance of the flexible sensor. Among them, the hierarchical microstructure with a height of 1.3 mm and a spacing of 1.5 mm exhibits the best output electrical performance under a pressure load of 14 N at a frequency of 3 Hz. In addition, the fabricated sensor exhibits good stability and durability after 20000 cycles of testing. Finally, a flexible pressure sensing insole was designed for observing the distribution of foot pressure and gait detection, which demonstrates good sensitivity and stability. This study provides a new approach for low-cost and rapid fabrication of hierarchical microstructures and serves as a reference for the development of high-performance flexible pressure sensors.

-

图 1 (a) 垂直接触分离式摩擦纳米发电机(TENG)压力传感器结构图;(b) 传感原理示意图;(c) 微结构层压缩变形应力云图

Figure 1. (a) Composition of vertical contact separation-type triboelectric nanogenerator (TENG) structure; (b) Diagram of sensing principle; (c) Stress cloud of dielectric layer with microstructures

PET—Polyethylene terephthalate; CNTs—Carbon nanotubes; PDMS—Polydimethylsiloxane

图 4 (a) 粗纤维微结构(高度0.15 mm);(b) 粗细纤维结合微结构(高度0.15 mm);(c) 粗纤维微结构(高度1.30 mm);(d) 粗细纤维结合微结构(高度1.30 mm,间距2.50 mm);(e) 粗细纤维结合微结构(高度1.30 mm,间距2.00 mm);(f) 粗细纤维结合微结构(高度1.30 mm,间距1.50 mm);(g) CNTs/PDMS薄膜截面微观形貌SEM图像;(h) 拉伸弯曲测试示意图

Figure 4. (a) Coarse fiber pattern with height of 0.15 mm; (b) Pattern of combined fiber with height of 0.15 mm; (c) Coarse fiber pattern with height of 1.30 mm; (d) Pattern of combined fiber with height of 1.30 mm and spacing of 2.50 mm; (e) Pattern of combined fiber with height of 1.30 mm and spacing of 2.00 mm; (f) Pattern of combined fiber with height of 1.30 mm and spacing of 1.50 mm; (g) SEM images of microstructure morphology in the cross-section of CNTs/PDMS thin film; (h) Tensile and bending test

图 10 微结构传感单元的足底压力分布与步态检测:(a) 传感单元分布示意图;(b) 负摩擦面实物图;(c) 触地期;(d) 支撑期;(e) 离地期

Figure 10. Plantar pressure distribution and gait detection of microstructured sensor unit: (a) Schematic diagram of sensor unit distribution; (b) Photo of negative friction surface; (c) Contact phase; (d) Support phase; (e) Swing phase

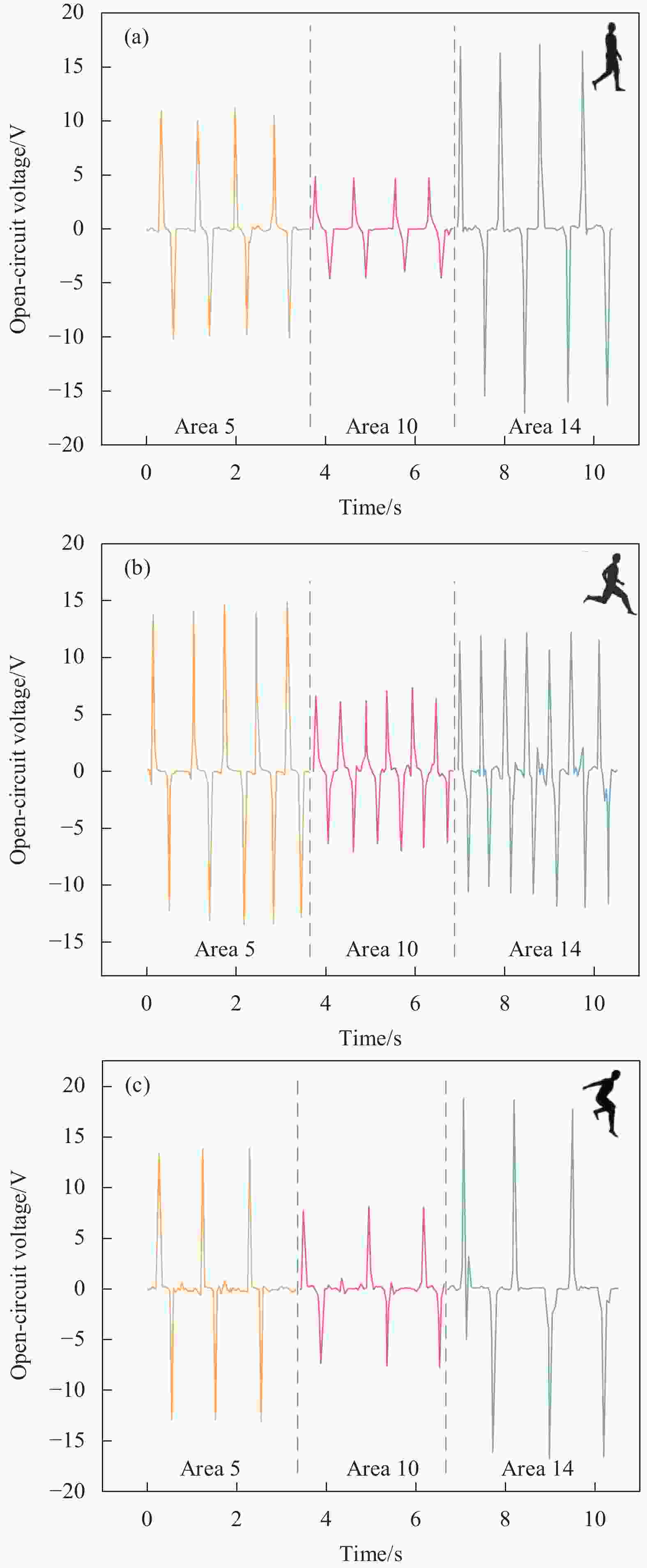

图 11 不同运动状态下微结构传感单元的压力分布与输出电压:(a) 行走时输出电压信号;(b) 奔跑时输出电压信号;(c) 跳跃时输出电压信号

Figure 11. Pressure distribution and output voltage of microstructured sensor unit under different motion states: (a) Output voltage signal during walking; (b) Output voltage signal during running; (c) Output voltage signal during jumping

表 1 多层次微结构CNTs/PDMS传感器与其他同类压力传感器的性能比较

Table 1. Performance comparison between hierarchical microstructured CNTs/PDMS sensors and other similar pressure sensors

Key material Sensitivity Open-circuit voltage/V Short-circuit current/μA Cycle Ref. CNT/PDMS 0.5 V/kPa 4.0 3.0 10000 [28] CNT/PDMS 0.122 V/kPa 31 — 10000 [35] CNT/PDMS — 42 1.6 — [36] Polyacrylamide (PAAm)-LiCl 0.013 V/kPa 4.0 1.5 5000 [37] Fluorinated ethylene propylene (FEP) 0.04 V/kPa 15 — 10000 [38] PDMS — 16.2 0.512 — [30] CNTs/PDMS 0.437 V/kPa, 0.015 μA/kPa 50.8 1.85 20000 This work -

[1] TERADA T, TOYOURA M, SATO T, et al. Functional fabric pattern-examining the case of pressure detection and localization[J]. IEEE Transactions on Industrial Electronics,2019,66(10):8224-8234. doi: 10.1109/TIE.2018.2885692 [2] TESSAROLO M, GUALANDI I, FRABONI B. Recent progress in wearable fully textile chemical sensors[J]. Advanced Materials Technologies,2018,3(8):1-7. [3] PAN M, YUAN C G, ANPALAGAN H, et al. Soft controllable carbon fibre-based piezoresistive self-sensing actuators[J]. Actuators,2020,9(3):79. doi: 10.3390/act9030079 [4] WANG H Y, LIU Z F, DING J N, et al. Downsized sheath-core conducting fibers for weavable superelastic wires, biosensors, supercapacitors, and strain sensors[J]. Advanced Materials,2016,28(25):4998-5007. doi: 10.1002/adma.201600405 [5] PANG Y, TIAN H, TAO L Q, et al. Flexible, highly sensitive, and wearable pressure and strain sensors with graphene porous network structure[J]. ACS Applied Materials & Interfaces,2016,8(40):26458-26462. doi: 10.1021/acsami.6b08172 [6] HAMMOCK M L, CHORTOS A, TEE B C K, et al. The evolution of electronic skin (e-skin): A brief history, design considerations, and recent progress[J]. Advanced Materials,2013,25(42):5997-6038. doi: 10.1002/adma.201302240 [7] 金凡, 吕大伍, 张天成, 等. 基于微结构的柔性压力传感器设计、制备及性能[J]. 复合材料学报, 2021, 38(10):3133-3150.JIN Fan, LYU Dawu, ZHANG Tiancheng, et al. Design, fabrication and performance of flexible pressure sensors based on microstructures[J]. Acta Materiae Compositae Sinica,2021,38(10):3133-3150(in Chinese). [8] BAUER S, BAUER-GOGONEA S, GRAZ I, et al. A soft future: From robots and sensor skin to energy harvesters[J]. Advanced Materials,2014,26(1):149-162. doi: 10.1002/adma.201303349 [9] WANG S H, NIU S M, YANG J, et al. Quantitative measurements of vibration amplitude using a contact-mode freestanding triboelectric nanogenerator[J]. ACS Nano,2014,8(12):12004-12013. doi: 10.1021/nn5054365 [10] ZHENG Q, SHI B J, FAN F R, et al. In vivo powering of pacemaker by breathing-driven implanted triboelectric nanogenerator[J]. Advanced Materials,2014,26(33):5851-5856. doi: 10.1002/adma.201402064 [11] PARK J, LEE Y, HONG J, et al. Giant tunneling piezoresistance of composite elastomers with interlocked microdome arrays for ultrasensitive and multimodal electronic skins[J]. ACS Nano,2014,8(5):4689-4697. doi: 10.1021/nn500441k [12] ZANG Y P, ZHANG F J, DI C A, et al. Advances of flexible pressure sensors toward artificial intelligence and health care applications[J]. Materials Horizons,2015,2(2):140-156. doi: 10.1039/C4MH00147H [13] TRESSLER J F, ALKOY S, NEWNHAM R E. Piezoelectric sensors and sensor materials[J]. Journal of Electroceramics,1998,2(4):257-272. doi: 10.1023/A:1009926623551 [14] HA M, PARK J, LEE Y, et al. Triboelectric generators and sensors for self-powered wearable electronics[J]. ACS Nano,2015,9(4):3421-3427. doi: 10.1021/acsnano.5b01478 [15] LIN Z H, XIE Y N, YANG Y, et al. Enhanced triboelectric nanogenerators and triboelectric nanosensor using chemically modified TiO2 nanomaterials[J]. ACS Nano,2013,7(5):4554-4560. doi: 10.1021/nn401256w [16] XIA X N, LIU G L, GUO H Y, et al. Honeycomb-like three electrodes based triboelectric generator for harvesting energy in full space and as a self-powered vibration alertor[J]. Nano Energy,2015,15:766-775. doi: 10.1016/j.nanoen.2015.05.033 [17] WANG C F, PAN C F, WANG Z L. Electronic skin for closed-loop systems[J]. ACS Nano,2019,13(11):12287-12293. doi: 10.1021/acsnano.9b06576 [18] WANG S H, XIE Y N, NIU S M, et al. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes[J]. Advanced Materials,2014,26(18):2818-2824. doi: 10.1002/adma.201305303 [19] FAN F R, TIAN Z Q, WANG Z L. Flexible triboelectric generator[J]. Nano Energy,2012,1(2):328-334. doi: 10.1016/j.nanoen.2012.01.004 [20] MENG X S, ZHU G A, WANG Z L. Robust thin-film generator based on segmented contact-electrification for harvesting wind energy[J]. ACS Applied Materials & Interfaces,2014,6(11):8011-8016. doi: 10.1021/am501782f [21] ZHU G A, SU Y J, BAI P, et al. Harvesting water wave energy by asymmetric screening of electrostatic charges on a nanostructured hydrophobic thin-film surface[J]. ACS Nano,2014,8(6):6031-6037. doi: 10.1021/nn5012732 [22] HU Y F, YANG J, JING Q S, et al. Triboelectric nanogenerator built on suspended 3D spiral structure as vibration and positioning sensor and wave energy harvester[J]. ACS Nano,2013,7(11):10424-10432. doi: 10.1021/nn405209u [23] YANG J, CHEN J, LIU Y, et al. Triboelectrification-based organic film nanogenerator for acoustic energy harvesting and self-powered active acoustic sensing[J]. ACS Nano,2014,8(3):2649-2657. doi: 10.1021/nn4063616 [24] YANG W Q, CHEN J, ZHU G A, et al. Harvesting energy from the natural vibration of human walking[J]. ACS Nano,2013,7(12):11317-11324. doi: 10.1021/nn405175z [25] PARK J H, WU C, SUNG S, et al. Ingenious use of natural triboelectrification on the human body for versatile applications in walking energy harvesting and body action monitoring[J]. Nano Energy,2019,57:872-878. doi: 10.1016/j.nanoen.2019.01.001 [26] ZHAO L M, ZHENG Q, OUYANG H, et al. A size-unlimited surface microstructure modification method for achieving high performance triboelectric nanogenerator[J]. Nano Energy,2016,28:172-178. doi: 10.1016/j.nanoen.2016.08.024 [27] 刘荆堰, 陈子航, 姜啟恒, 等. PVDF/SBS柔性复合纤维薄膜压电-摩擦电纳米发电机[J]. 复合材料学报, 2023, 40(7):4022-4029.LIU Jingyan, CHEN Zihang, JIANG Qiheng, et al. Piezoelectric/triboelectric nanogenerator based on PVDF/SBS flexible composite fiber film[J]. Acta Materiae Compositae Sinica,2023,40(7):4022-4029(in Chinese). [28] RASEL M S, MAHARJAN P, SALAUDDIN M, et al. An impedance tunable and highly efficient triboelectric nanogenerator for large-scale, ultra-sensitive pressure sensing applications[J]. Nano Energy,2018,49:603-613. doi: 10.1016/j.nanoen.2018.04.060 [29] ZHANG X S, HAN M D, WANG R X, et al. Frequency-multiplication high-output triboelectric nanogenerator for sustainably powering biomedical microsystems[J]. Nano Letters,2013,13(3):1168-1172. doi: 10.1021/nl3045684 [30] UDDIN A S M I, CHUNG G S. A self-powered active hydrogen sensor based on a high-performance triboelectric nanogenerator using a wrinkle-micropatterned PDMS film[J]. RSC Advances,2016,6(67):63030-63036. doi: 10.1039/C6RA07179A [31] FAN F R, LIN L, ZHU G, et al. Transparent triboelectric nanogenerators and self-powered pressure sensors based on micropatterned plastic films[J]. Nano Letters,2012,12(6):3109-3114. doi: 10.1021/nl300988z [32] DAGDEVIREN C, LI Z, WANG Z L. Energy harvesting from the animal-human body for self-powered electronics[J]. Annual Review of Biomedical Engineering,2017,19:85-108. doi: 10.1146/annurev-bioeng-071516-044517 [33] NIU S M, WANG S H, LIN L, et al. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source[J]. Energy and Environmental Science,2013,6(12):3576-3583. doi: 10.1039/c3ee42571a [34] CHEN J E, GUO H Y, HE X M, et al. Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge PDMS film[J]. ACS Applied Materials & Interfaces,2016,8(1):736-744. doi: 10.1021/acsami.5b09907 [35] 肖渊, 刘进超, 吕晓来, 等. CNT/PDMS介电层微结构成型及摩擦纳米发电机制备[J]. 机械工程学报, 2021, 57(15):177-185. doi: 10.3901/JME.2021.15.177XIAO Yuan, LIU Jinchao, LYU Xiaolai, et al. Preparation of triboelectric nanogenerators with CNT-containing and micro-structure PDMS composite films[J]. Journal of Mechanical Engineering,2021,57(15):177-185(in Chinese). doi: 10.3901/JME.2021.15.177 [36] VAFAIEE M, EJEHI F, MOHAMMADPOUR R. CNT-PDMS foams as self-powered humidity sensors based on triboelectric nanogenerators driven by finger tapping[J]. Scientific Reports, 2023, 13: 370. [37] HAN X, JIANG D J, QU X C, et al. A stretchable, self-healable triboelectric nanogenerator as electronic skin for energy harvesting and tactile sensing[J]. Science Advances,2021,14(7):1689. doi: 10.3390/ma14071689 [38] BAI P, ZHU G, JING Q S, et al. Membrane-based self-powered triboelectric sensors for pressure change detection and its uses in security surveillance and healthcare monitoring[J]. Advanced Functional Materials,2014,24(37):5807-5813. doi: 10.1002/adfm.201401267 [39] LIEBERMAN D E, VENKADESAN M, WERBEL W A, et al. Foot strike patterns and collision forces in habitually barefoot versus shod runners[J]. Nature,2010,463(7280):531-535. doi: 10.1038/nature08723 -

下载:

下载: