Shear strength characteristics of sand solidified by enzyme-induced carbonate precipitation with waste face mask reinforcement

-

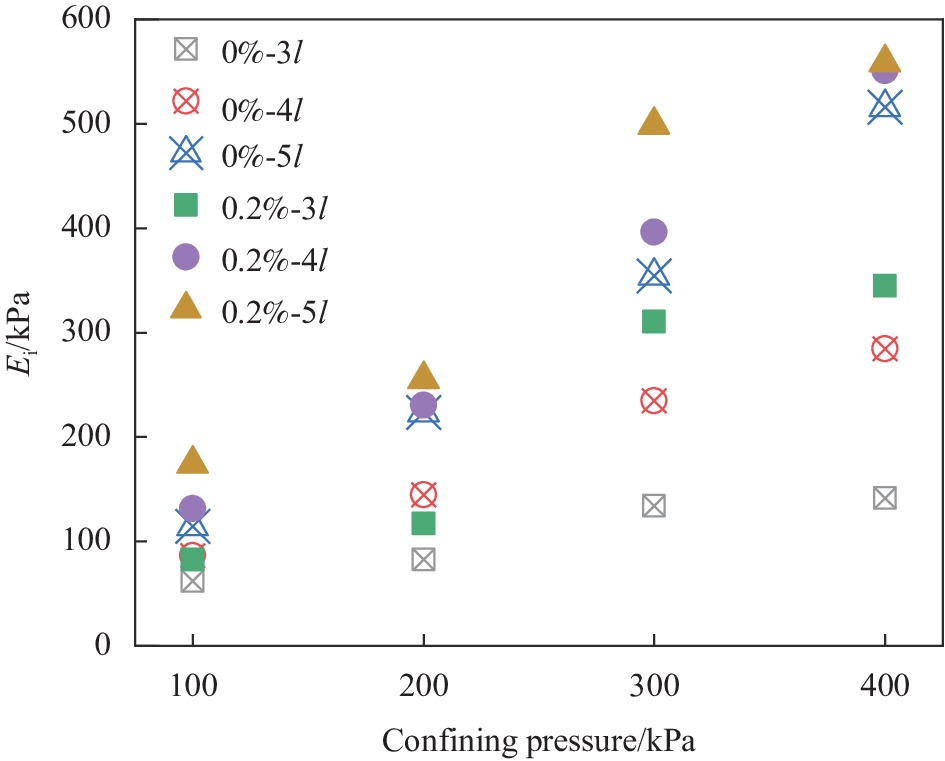

摘要: 为进一步提升酶诱导碳酸盐沉淀(EICP)固化砂土的抗剪强度特性,改善固化砂土的脆性破坏特征,向未固化砂土中添加废弃的一次性口罩进行改良。基于三轴压缩试验等,研究不同口罩纤维掺量对EICP固化砂土抗剪强度的影响,并分析改变EICP滴注轮次和砂土初始相对密实度后,改良砂土的抗剪强度特性和口罩加筋效益的变化情况。结果表明:口罩最优掺量为0.2%,不同围压下可以使改良砂土的峰值偏应力提高59.9%~34%,黏聚力提高188%,内摩擦角提高14.5%,且能有效减少峰后强度损失,改善固化砂土的脆性破坏特征;增加滴注轮次和相对密实度可以提高峰值偏应力、黏聚力和内摩擦角,但口罩的加筋效果略微减弱;碳酸钙生成率随滴注轮次增加而增大,随相对密实度增加而减小,加筋可以提高碳酸钙生成率。Abstract: To further enhance the shear strength characteristics of sandy soils cured by enzyme-induced carbonate precipitation (EICP) technology, and to improve the brittle damage characteristics of the cured sandy soils, the abandoned disposable masks were blended into the sandy soils for improvement. Based on the triaxial compression test, the influence of different contents of the mask on the shear strength of EICP solidified sand was studied. However, the change of the shear strength characteristics of improved sand and the benefit of mask reinforcement were analyzed after changing the EICP drip rounds and the initial relative compactness of sand. The results show that the best content of the mask is 0.2%. At this time, the peak partial stress of improved sandy soil increases by 59.9%-34% under different confining pressures, the cohesive force increases by 188%, and the internal friction angle increases by 14.5%. The post-peak strength loss is effectively reduced and the brittle damage of cured sand is improved. However, increasing the number of drip rounds and relative compactness could increase the peak partial stress, cohesive force and internal friction angle, but the effect of mask reinforcement is slightly weakened. Finally, mask reinforcement can improve the calcium carbonate generation rate, and the calcium carbonate generation rate increases with the increase of drip rounds, but decreases with the increase of relative compactness.

-

表 1 标准砂的物理力学性质

Table 1. Physical-mechanical properties of sand

Effective particle size/mm Specific gravity Curvature coefficient Nonuniformity coefficient D10 D30 D60 0.13 0.3 0.66 2.65 1.05 5.07 Note: Dn means the mass of particles smaller than this particle size accounts for n% of the total mass of soil particles. 表 2 口罩的物理力学性质

Table 2. Physical-mechanical properties of face masks

Nonuniformity

coefficientMelting point/

℃Water absorption/

%Tensile strength/

MPaElongation at break/

%Tensile strength at break/

MPa0.91 160 9.5 4.25 118.9 4.18 表 3 工况设置

Table 3. Working conditions setting

Test Mask fiber content/% Number of EICP drops/drop Relative density/% Confining pressure/kPa C1 0 4 50 100, 200

300, 400C2 0.1 4 50 C3 0.15 4 50 C4 0.2 4 50 C5 0.25 4 50 C6 0.3 4 50 L1 0 3 50 L2 0 5 50 L3 0.2 3 50 L4 0.2 5 50 D1 0 4 30 D2 0 4 80 D3 0.2 4 30 D4 0.2 4 80 Note: EICP—Enzyme-induced carbonate precipitation. -

[1] SHU S, YAN B, MENG H, et al. Comparative study of EICP treatment methods on the mechanical properties of sandy soil[J]. Soils and Foundations,2022,62(6):101246. doi: 10.1016/j.sandf.2022.101246 [2] 张建伟, 李贝贝, 边汉亮, 等. 钙源对酶诱导碳酸钙沉淀影响的试验研究[J]. 应用基础与工程科学学报, 2022, 30(5):1245-1255.ZHANG Jianwei, LI Beibei, BIAN Hanliang, et al. Influence and evaluation analysis of different fibers on the performance of recycled aggregate pervious concrete[J]. Journal of Basic Science and Engineering,2022,30(5):1245-1255(in Chinese). [3] LIU L, LIU H L, STUEDLEIN A W, et al. Strength, stiffness, and microstructure characteristics of biocemented calcareous sand[J]. Canadian Geotechnical Journal,2019,56(10):1502-1513. doi: 10.1139/cgj-2018-0007 [4] 赵志峰, 邵光辉. 微生物诱导碳酸钙沉积加固海相粉土的试验研究[J]. 应用基础与工程科学学报, 2021, 29(1):231-238. doi: 10.16058/j.issn.1005-0930.2021.01.020ZHAO Zhifeng, SHAO Guanghui. Experimental study on marine silt reinforcement by microbial induced calcium precipitation[J]. Journal of Basic Science and Engineering,2021,29(1):231-238(in Chinese). doi: 10.16058/j.issn.1005-0930.2021.01.020 [5] PHILLIPS A J, LAUCHNOR E, ELDRING J J, et al. Potential CO2 leakage reduction through biofilm-induced calcium carbonate precipitation[J]. Environmental Science & Technology,2013,47(1):142-149. [6] 许朝阳, 杨贺, 黄建璋, 等. 生物修复Cu2+、Pb2+污染土的稳定性[J]. 工业建筑, 2018, 48(7):33-37.XU Zhaoyang, YANG He, HUANG Jianzhang, et al. Stability of bioremediated soil contaminated by Cu2+ or Pb2+[J]. Industrial Construction,2018,48(7):33-37(in Chinese). [7] KHODADADI T H, KAVAZANJIAN E, VAN PAASSEN L, et al. Bio-grout materials: A review[C]//American Society of Civil Engineers (ASCE). Virginia: ASCE Publications, 2017: 1-12. [8] 董瑾, 刘效彬. 脲酶诱导碳酸钙沉淀技术改良传统三合土的性能[J]. 建筑材料学报, 2022, 25(8):853-859. doi: 10.3969/j.issn.1007-9629.2022.08.012DONG Jin, LIU Xiaobin. Performance of traditional tabia improved by enzyme induced calcite precipitation technology[J]. Journal of Building Materials,2022,25(8):853-859(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.08.012 [9] YASUHARA H, NEUPANE D, HAYASHI K, et al. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation[J]. Soils and Foundations,2012,52(3):539-549. doi: 10.1016/j.sandf.2012.05.011 [10] MIFTAH A, KHODADADI TIRKOLAEI H, BILSEL H, et al. Erodibility improvement and scour mitigation of beach sand by enzymatic induced carbonate precipitation[J]. Geomechanics for Energy and the Environment,2022,32:100354. doi: 10.1016/j.gete.2022.100354 [11] HE J, YANG F, QI Y, et al. Improvement in silty sand with enzyme-induced carbonate precipitation: Laboratory model experiment[J]. Acta Geotechnica,2022,17(7):2895-2905. doi: 10.1007/s11440-021-01361-z [12] DAKHANE A, DAS S, HANSEN H, et al. Crack healing in cementitious mortars using enzyme-induced carbonate precipitation: Quantification based on fracture response[J]. Journal of Materials in Civil Engineering,2018,30(4):4018035. doi: 10.1061/(ASCE)MT.1943-5533.0002218 [13] 刘阳, 高玉峰, 何稼, 等. 大豆脲酶诱导碳酸钙沉积技术的防风固沙试验研究[J]. 河南科学, 2019, 37(11):1784-1789. doi: 10.3969/j.issn.1004-3918.2019.11.012LIU Yang, GAO Yufeng, HE Jia, et al. Experimental study on the windbreak and sand fixation effect using soybean urease induced calcium carbonate precipitation[J]. Henan Science,2019,37(11):1784-1789(in Chinese). doi: 10.3969/j.issn.1004-3918.2019.11.012 [14] 边汉亮, 张旭钢, 韩一, 等. 大豆脲酶对Zn2+污染土的修复试验研究[J]. 工业建筑, 2022, 52(11):67-70.BIAN Hanliang, ZHANG Xugang, HAN Yi, et al. Remediation tests of Zn2+ contaminated soil by soybean urease[J]. Industrial Construction,2022,52(11):67-70(in Chinese). [15] NOORZAD R, AMINI P F. Liquefaction resistance of babolsar sand reinforced with randomly distributed fibers under cyclic loading[J]. Soil Dynamics and Earthquake Engineering,2014,66:281-292. doi: 10.1016/j.soildyn.2014.07.011 [16] 李丽华, 万畅, 刘永莉, 等. 玻璃纤维加筋砂土剪切强度特性研究[J]. 武汉大学学报(工学版), 2017, 50(1):102-106. doi: 10.14188/j.1671-8844.2017-01-015LI Lihua, WAN Chang, LIU Yongli, et al. Shear strength characteristics of glass fiber reinforced sandy soil[J]. Engineering Journal of Wuhan University,2017,50(1):102-106(in Chinese). doi: 10.14188/j.1671-8844.2017-01-015 [17] 高磊, 胡国辉, 杨晨, 等. 玄武岩纤维加筋黏土的剪切强度特性[J]. 岩土工程学报, 2016, 38(S1):231-237. doi: 10.11779/CJGE2016S1043GAO Lei, HU Guohui, YANG Chen, et al. Shear strength characteristics of basalt fiber-reinforced clay[J]. Chinese Journal of Geotechnical Engineering,2016,38(S1):231-237(in Chinese). doi: 10.11779/CJGE2016S1043 [18] SHAO W, CETIN B, LI Y D, et al. Experimental investigation of mechanical properties of sands reinforced with discrete randomly distributed fiber[J]. Geotechnical and Geological Engineering,2014,32(4):901-910. doi: 10.1007/s10706-014-9766-3 [19] 钟汉林, 刘春辉, 张俊, 等. 随机分布剑麻纤维对砂土力学特性的影响[J]. 烟台大学学报(自然科学与工程版), 2019, 32(4):391-396. doi: 10.13951/j.cnki.37-1213/n.2019.04.015ZHONG Hanlin, LIU Chunhui, ZHANG Jun, et al. Effect of randomly distributed sisal fibers on static mechanical properties of sand[J]. Journal of Yantai University (Natural Science and Engineering Edition),2019,32(4):391-396(in Chinese). doi: 10.13951/j.cnki.37-1213/n.2019.04.015 [20] CHOI S G, WANG K J, CHU J. Properties of biocemented, fiber reinforced sand[J]. Construction and Buildinding Materials,2016,120:623-629. doi: 10.1016/j.conbuildmat.2016.05.124 [21] LI M, LI L, OGBONNAYA U, et al. Influence of fiber addition on mechanical properties of MICP-treated sand[J]. Journal of Materials in Civil Engineering,2016,28(4):268. doi: 10.1061/(ASCE)MT.1943-5533.0001442 [22] FANG X W, YANG Y, CHEN Z, et al. Influence of fiber content and length on engineering properties of MICP-treated coral sand[J]. Geomicrobiology Journal,2020,37(6):582-594. doi: 10.1080/01490451.2020.1743392 [23] SABERIAN M, LI J, KILMARTIN-LYNCH S, et al. Repurposing of COVID-19 single-use face masks for pavements base/subbase[J]. Science of the Total Environment,2021,769:145527. doi: 10.1016/j.scitotenv.2021.145527 [24] 闭东民, 孔纲强, 陈庚, 等. 废弃口罩加筋固化土的强度特性与破坏模式[J]. 防灾减灾工程学报, 2022, 42(5):993-998, 1009.BI Dongmin, KONG Gangqiang, CHEN Geng, et al. Strength characteristics and failure mode of solidified soil reinforced by waste masks[J]. Journal of Disaster Prevention and Mitigation Engineering,2022,42(5):993-998, 1009(in Chinese). [25] REHMAN Z U, KHALID U. Reuse of COVID-19 face mask for the amelioration of mechanical properties of fat clay: A novel solution to an emerging waste problem[J]. Science of the Total Environment,2021,794:148746. doi: 10.1016/j.scitotenv.2021.148746 [26] AKBULUT S, ARASAN S, KALKAN E. Modification of clayey soils using scrap tire rubber and synthetic fibers[J]. Applied Clay Science,2007,38(1):23-32. [27] WHIFFIN V S. Microbial CaCO3 precipitation for the production of biocement[D]. Perth: Murdoch University, 2004. [28] 陈翔. 钙质砂不固结不排水剪切特性研究[D]. 南宁: 广西大学, 2022.CHEN Xiang. Research on unconsolidated undrained shear characteristics of calcareous sand[D]. Nanning: Guangxi University, 2022(in Chinese). [29] 程富阳, 黄英, 周志伟, 等. 干湿循环下饱和红土不排水三轴试验研究[J]. 工程地质学报, 2017, 25(4):1017-1026. doi: 10.13544/j.cnki.jeg.2017.04.016CHENG Fuyang, HUANG Ying, ZHOU Zhiwei, et al. Undrained triaxial test of saturated laterite under drying-wetting cycle[J]. Journal of Engineering Geology,2017,25(4):1017-1026(in Chinese). doi: 10.13544/j.cnki.jeg.2017.04.016 [30] 李驰, 刘世慧, 周团结, 等. 微生物矿化风沙土强度及孔隙特性的试验研究[J]. 力学与实践, 2017, 39(2):165-171, 184. doi: 10.6052/1000-0879-16-286LI Chi, LIU Shihui, ZHOU Tuanjie, et al. The strength and porosity properties of MICP-treated aeolian sandy soil[J]. Mechanics in Engineering,2017,39(2):165-171, 184(in Chinese). doi: 10.6052/1000-0879-16-286 [31] 郑俊杰, 宋杨, 赖汉江, 等. 微生物固化纤维加筋砂土抗剪强度试验研究[J]. 土木与环境工程学报(中英文), 2019, 41(1):15-21.ZHENG Junjie, SONG Yang, LAI Hanjiang, et al. Experimental study on the shear behavior of fiber-reinforced bio-cemented sand[J]. Journal of Civil and Environmental Engineering,2019,41(1):15-21(in Chinese). [32] 徐日庆, 王兴陈, 朱剑锋, 等. 初始相对密实度对砂土强度特性影响的试验[J]. 江苏大学学报(自然科学版), 2012, 33(3):345-349.XU Riqing, WANG Xingchen, ZHU Jianfeng, et al. Experiment of initial relative density effects on sand strength[J]. Journal of Jiangsu University (Natural Science Edition),2012,33(3):345-349(in Chinese). -

下载:

下载: