Axial stress-strain behavior of CFRP-confined geopolymer concrete

-

摘要: 为了探究地质聚合物混凝土(GPC)在多轴应力状态下的应力-应变关系,开展了碳纤维增强树脂复合材料(CFRP)约束GPC圆柱的轴压试验,揭示了GPC在不同约束条件下的应力-应变曲线特征,据此建立了完整的轴向应力-应变模型、抗压强度模型和极限轴向压应变模型,特别是针对CFRP约束普通强度GPC,提出了新的模型参数表达式,并利用文献试验结果予以验证。结果表明:抗压强度模型具有良好的预测能力,预测值的平均绝对误差为3.55%;极限轴向压应变模型也能较精准地对其他研究的试验结果做出预测,预测值的平均绝对误差为17.03%。新的轴向应力-应变模型参数表达式不仅适用于CFRP约束高强GPC也适用于CFRP约束普通强度GPC。Abstract: To investigate the stress-strain behavior of geopolymer concrete (GPC) under multi-axial stress states, axial compression tests were conducted on GPC columns with and without carbon fiber reinforced polymer (CFRP) confinement. The characteristics of stress-strain curves for GPC under various confinement conditions were examined, and models for axial stress-strain, compressive strength, and ultimate axial compressive strain were established. Specifically, novel expressions for model parameters were proposed for CFRP-confined normal strength GPC, and the model was validated using experimental results from other studies. The results demonstrate that the compressive strength model has good predictive capability, with an average absolute error of 3.55%. Additionally, the ultimate axial compressive strain model accurately predicts experimental results from other studies, with an average absolute error of 17.03%. The newly proposed parameter expressions for the axial stress-strain model are applicable not only to CFRP-confined high-strength GPC but also to CFRP-confined normal strength GPC.

-

图 2 无约束试件和碳纤维增强树脂复合材料(CFRP)约束GPC试件的轴向应力-应变曲线

Figure 2. Axial stress-strain curves of unconfined and carbon fiber reinforced polymer (CFRP)-confined GPC specimens

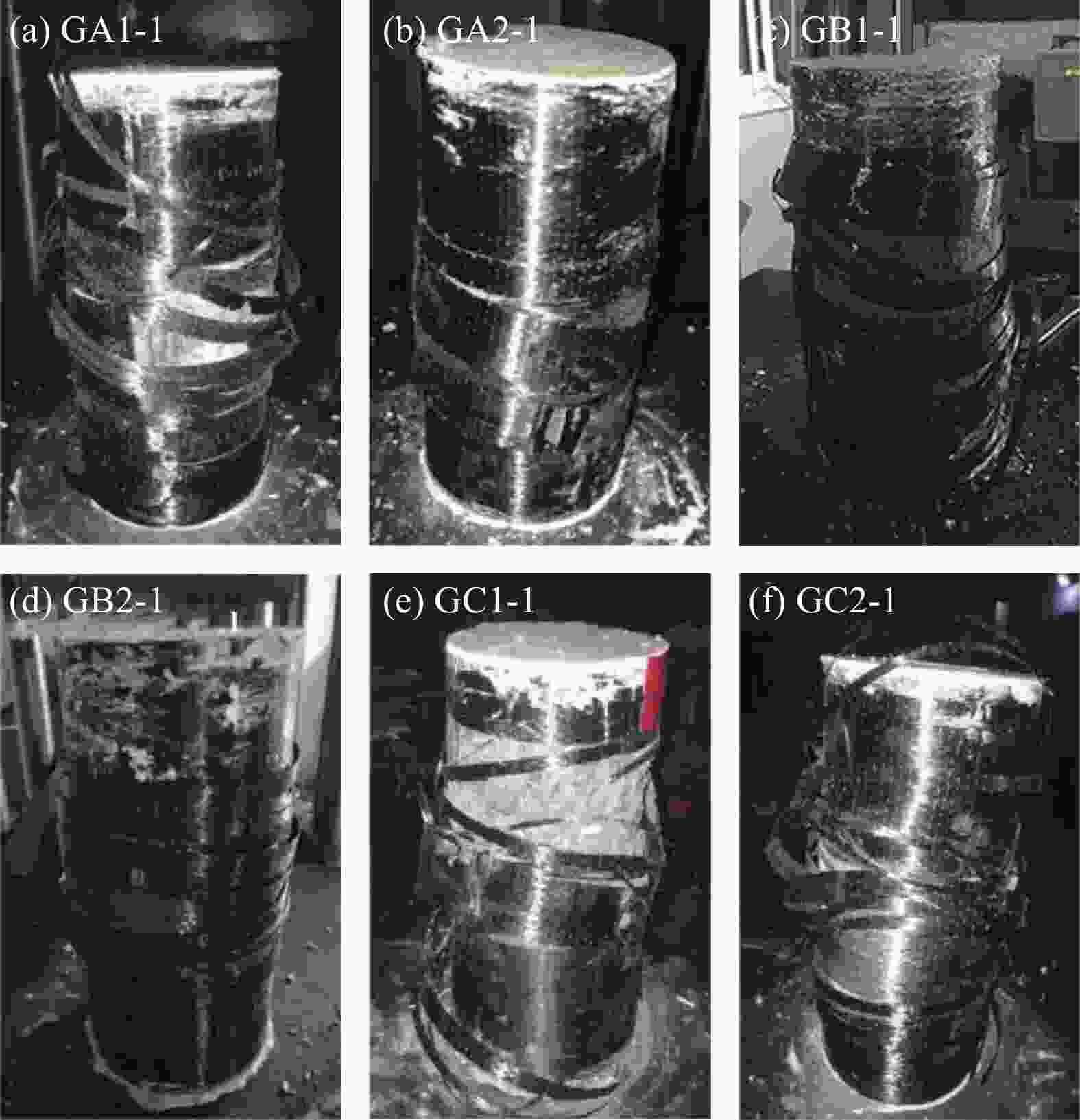

Labels of the specimens are as follows: The letter such as "GA" denotes the mixture of GPC; The first number such as "0" denotes the number of CFRP layers; The second number such as "2" differentiates the two nominally identical specimens. For example, "GC0-2" stands for the second specimen of the two nominally identical specimens of mix GC unconfined GPC; "GA1-1" stands for the first specimen of the two nominally identical specimens of 1 layer CFRP-confined GPC specimens

表 1 地质聚合物混凝土(GPC)配合比

Table 1. Mix proportions of geopolymer concrete (GPC)

Mixture Coarse aggregate/(kg·m−3) Fine aggregate/(kg·m−3) Fly ash/(kg·m−3) Silica fume/(kg·m−3) Alkaline activators/(kg·m−3) GA 1150 415 480 120 250 GB 1150 415 420 180 230 GC 1150 415 330 270 220 Note: GA, GB, GC—Three kinds of strength of GPC specimen. 表 2 粉煤灰和硅灰化学成分的X 射线荧光光谱(XRF)分析

Table 2. Chemical compositions of fly ash and silica fume obtained from X-ray fluorescence (XRF) analysis

SiO2/

wt%Al2O3/

wt%CaO/

wt%Fe2O3/

wt%TiO2/

wt%K2O/

wt%SO3/

wt%MgO/

wt%P2O5/

wt%Na2O/

wt%SrO/

wt%ZrO2/

wt%ZnO/

wt%LOI/

wt%Fly ash 49.10 36.70 4.96 3.67 1.39 0.94 0.49 0.37 0.26 0.20 0.18 0.12 0.02 2.08 Silica fume 84.69 0.39 1.37 3.77 — 1.25 0.42 3.73 0.16 1.05 0.01 — 1.18 1.30 Note:LOI—Loss of weight after ignition 表 3 无约束GPC的弹性模量

Table 3. Elasticity modulus of unconfined GPC

Specimen $ {E_{\text{c}}} $/GPa Measured Proposed GA0-1 14.88 15.79 GA0-2 16.54 16.05 GB0-1 18.82 19.01 GB0-2 17.93 18.62 GC0-1 21.49 21.59 GC0-2 22.61 20.88 Note: $ {E_{\text{c}}} $—Elasticity modulus of unconfined GPC. 表 4 无约束GPC试件的单轴抗压强度和对应的轴向应变

Table 4. Uniaxial compressive strengths and corresponding axial strains of unconfined GPC specimens

Specimen $ f_{{\text{co}}}' $/MPa $ {\varepsilon _{{\text{co}}}} $/% Average $ f_{{\text{co}}}' $/MPa $ {\varepsilon _{{\text{co}}}} $/% GA0-1 24.4 0.47 24.3 0.46 GA0-2 24.2 0.45 GB0-1 34.1 0.31 34.2 0.32 GB0-2 34.3 0.32 GC0-1 43.3 0.27 43.3 0.27 GC0-2 43.2 0.26 Note: $ f_{{\text{co}}}' $, $ {\varepsilon _{{\text{co}}}} $—Uniaxial compressive strengths and correspond-ing strains of unconfined GPC specimens. 表 5 CFRP约束GPC试件的抗压强度和极限轴向应变

Table 5. Compressive strengths and ultimate axial strains of CFRP-confined GPC specimens

Specimen $ f_{{\text{cc}}}' $/MPa $ f_{{\text{cc}}}'/f_{{\text{co}}}' $ $ {\varepsilon _{{\text{cu}}}} $/% $ {\varepsilon _{{\text{cu}}}}/{\varepsilon _{{\text{co}}}} $ GA1-1 40.0 1.65 1.58 3.36 GA1-2 39.8 1.64 1.45 3.09 GA2-1 49.5 2.04 1.83 3.89 GA2-2 48.6 2.00 2.07 4.50 GB1-1 47.7 1.39 0.83 2.59 GB1-2 49.3 1.44 0.79 2.47 GB2-1 64.1 1.87 1.34 4.19 GB2-2 65.7 1.92 1.27 3.97 GC1-1 52.9 1.22 0.59 2.19 GC1-2 52.2 1.21 0.58 2.15 GC2-1 66.1 1.53 0.86 3.19 GC2-2 69.1 1.60 0.99 3.67 Note: $ f_{{\text{cc}}}' $, $ {\varepsilon _{{\text{cu}}}} $—Compressive strengths and ultimate axial strains of CFRP-confined GPC specimens. 表 6 CFRP约束GPC极限状态模型的误差

Table 6. Reproduction and prediction errors in the ultimate condition model of CFRP-confined GPC

Ultimate condition $ f_{{\text{cc}}}' $ $ {\varepsilon _{{\text{cu}}}} $ $ \alpha = 3.334 $ $ \alpha = 2.651 + 0.026 f_{{\text{co}}}^\prime $ A/% S/% M A/% S/% M A/% S/% M Reproduction 6.95 8.94 0.99 6.11 8.10 1.01 7.75 9.95 1.02 Prediction 4.35 4.69 0.97 3.55 4.28 1.02 17.03 4.09 1.17 Notes: α—Strength enhancement coefficient; A—Average absolute error; S—Standard deviation; M—Mean value. 表 7 CFRP约束GPC的轴向应力-应变模型参数对比

Table 7. Comparison of parameters in axial stress-strain model of CFRP-confined GPC

Specimen Best fit Alrshoudi et al[19] Proposed $ {f_{{\text{ct}}}} $/MPa $ {\varepsilon _{{\text{ct}}}} $/% $ \lambda $ $ {f_{{\text{ct}}}} $/MPa $ {\varepsilon _{{\text{ct}}}} $/% $ \lambda $ $ {f_{{\text{ct}}}} $/MPa $ {\varepsilon _{{\text{ct}}}} $/% $ \lambda $ GA1-1 26.8 0.49 0.47 28.1 0.72 0.40 29.3 0.53 0.49 GA2-1 31.0 0.53 0.52 31.8 0.97 0.80 33.9 0.55 0.54 GB1-2 41.1 0.45 0.61 38.0 0.44 0.29 39.4 0.37 0.53 GB2-2 45.0 0.47 0.63 41.7 0.56 0.57 44.1 0.40 0.58 GC1-1 46.6 0.31 0.49 47.1 0.35 0.23 48.6 0.32 0.55 GC2-1 50.7 0.40 0.67 50.8 0.43 0.45 53.3 0.35 0.61 Notes: $ {f_{{\text{ct}}}} $ and $ {\varepsilon _{{\text{ct}}}} $—Axial strength and strain of transition point; $ \lambda $—Shape parameter of curve. -

[1] DING Y, DAI J G, SHI C J. Mechanical properties of alkali-activated concrete: A state-of-the-art review[J]. Construction and Building Materials,2016,127:68-79. doi: 10.1016/j.conbuildmat.2016.09.121 [2] HASSAN A, ARIF M, SHARIQ M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure[J]. Journal of Cleaner Production,2019,223:704-728. doi: 10.1016/j.jclepro.2019.03.051 [3] 张大旺, 王栋民. 地质聚合物混凝土研究现状[J]. 材料导报, 2018, 32(9):1519-1527, 1540. doi: 10.11896/j.issn.1005-023X.2018.09.017ZHANG Dawang, WANG Dongmin. Research status of geopolymer concrete[J]. Materials Reports,2018,32(9):1519-1527, 1540(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.09.017 [4] MCLELLAN B C, WILLIAMS R P, LAY J, et al. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement[J]. Journal of Cleaner Production,2011,19(9-10):1080-1090. doi: 10.1016/j.jclepro.2011.02.010 [5] DINDI A, QUANG D V, VEGA L F, et al. Applications of fly ash for CO2 capture, utilization, and storage[J]. Journal of CO2 Utilization,2019,29:82-102. doi: 10.1016/j.jcou.2018.11.011 [6] SETOODEH JAHROMY S, JORDAN C, AZAM M, et al. Fly ash from municipal solid waste incineration as a potential thermochemical energy storage material[J]. Energy & Fuels,2019,33(7):5810-5819. doi: 10.1021/acs.energyfuels.8b04106 [7] MUSHTAQ F, ZAHID M, BHATTI I A, et al. Possible applications of coal fly ash in wastewater treatment[J]. Journal of Environmental Management,2019,240:27-46. doi: 10.1016/j.jenvman.2019.03.054 [8] JUENGER M C G, SIDDIQUE R. Recent advances in understanding the role of supplementary cementitious materials in concrete[J]. Cement and Concrete Research,2015,78:71-80. doi: 10.1016/j.cemconres.2015.03.018 [9] THOMAS B S, YANG J, BAHURUDEEN A, et al. Geopolymer concrete incorporating recycled aggregates: A comprehensive review[J]. Cleaner Materials,2022,3:100056. doi: 10.1016/j.clema.2022.100056 [10] HUANG B, WANG X, KUA H, et al. Construction and demolition waste management in China through the 3R principle[J]. Resources, Conservation and Recycling,2018,129:36-44. doi: 10.1016/j.resconrec.2017.09.029 [11] 滕锦光. 新材料组合结构[J]. 土木工程学报, 2018, 51(12):1-11. doi: 10.15951/j.tmgcxb.2018.12.001TENG Jinguang. New-material hybrid structures[J]. China Civil Engineering Journal,2018,51(12):1-11(in Chinese). doi: 10.15951/j.tmgcxb.2018.12.001 [12] MA C K, APANDI N M, YUNG S C S, et al. Repair and rehabilitation of concrete structures using confinement: A review[J]. Construction and Building Materials,2017,133:502-515. doi: 10.1016/j.conbuildmat.2016.12.100 [13] AL-SAADI A U, ARAVINTHAN T, LOKUGE W. Structural applications of fibre reinforced polymer (FRP) composite tubes: A review of columns members[J]. Composite Structures,2018,204:513-524. doi: 10.1016/j.compstruct.2018.07.109 [14] PPATIL S, JOSHI D, MANGLA D, et al. Recent development in geopolymer concrete: A review [J/OL]. Materials Today: Proceedings, 2023-04-17. https://doi.org/10.1016/j.matpr. 2023.04.046. [15] 许凌云, 张祖华, 史才军, 等. 地质聚合物混凝土力学性能和结构性能的研究进展[J/OL]. 材料导报, 2022(7): 1-29[2023-12-07].XU Lingyun, ZHANG Zuhua, SHI Caijun, et al. Research progress on mechanical properties and structural performances of geopolymer concrete[J/OL]. Materials Reports, 2022(7): 1-29[2023-12-07](in Chinese). [16] ANVARI M, TOUFIGH V. Experimental and probabilistic investigation on the durability of geopolymer concrete confined with fiber reinforced polymer[J]. Construction and Building Materials,2022,334:127419. doi: 0.1016/j.conbuildmat.2022.127419 [17] OZBAKKALOGLU T, XIE T Y. Geopolymer concrete-filled FRP tubes: Behavior of circular and square columns under axial compression[J]. Composites Part B: Engineering,2016,96:215-230. doi: 10.1016/j.compositesb.2016.04.013 [18] TANG Z, LI W, TAM V W Y, et al. Mechanical behaviors of CFRP-confined sustainable geopolymeric recycled aggregate concrete under both static and cyclic compressions[J]. Composite Structures,2020,252:112750. doi: 10.1016/j.compstruct.2020.112750 [19] ALRSHOUDI F, ABBAS H, ABADEL A, et al. Compression behavior and modeling of FRP-confined high strength geopolymer concrete[J]. Construction and Building Materials,2021,283:122759. doi: 10.1016/j.conbuildmat.2021.122759 [20] HAIDER G M, SANJAYAN J G, RANJITH P G. Complete triaxial stress-strain curves for geopolymer[J]. Construction and Building Materials,2014,69:196-202. doi: 10.1016/j.conbuildmat.2014.07.058 [21] WANG H, WU Y, WEI M, et al. Hysteretic behavior of geopolymer concrete with active confinement subjected to monotonic and cyclic axial compression: An experimental study[J]. Materials,2020,13(18):3997. doi: 10.3390/ma13183997 [22] KHAN M Z N, HAO Y, HAO H, et al. Mechanical properties of ambient cured high-strength plain and hybrid fiber reinforced geopolymer composites from triaxial compressive tests[J]. Construction and Building Materials,2018,185:338-353. doi: 10.1016/j.conbuildmat.2018.07.092 [23] The American Society of Civil Engineers. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete: ASTM C618—22[S]. West Conshohocken: ASTM International, 2022. [24] 中国国家标准化管理委员会. 结构加固修复用碳纤维片材: JG/T 167—2016[S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People's Republic of China. Carbon fiber laminate for strengthening and restoring structures: JG/T 167—2016[S]. Beijing: China Standards Press, 2016(in Chinese). [25] 中国国家标准化管理委员会. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国标准出版社, 2012.Standardization Administration of the People's Republic of China. Standard for test method of concrete structures: GB/T 50152—2012[S]. Beijing: China Standards Press, 2012(in Chinese). [26] 中国国家标准化管理委员会. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [27] 中国国家标准化管理委员会. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国标准出版社, 2019.Standardization Administration of the People's Republic of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Standards Press, 2019(in Chinese). [28] THOMAS R J, PEETHAMPARAN S. Alkali-activated concrete: Engineering properties and stress-strain behavior[J]. Construction and Building Materials,2015,93:49-56. doi: 10.1016/j.conbuildmat.2015.04.039 [29] NATH P, SARKER P K. Flexural strength and elastic modulus of ambient-cured blended low-calcium fly ash geopolymer concrete[J]. Construction and Building Materials,2017,130:22-31. doi: 10.1016/j.conbuildmat.2016.11.034 [30] OZBAKKALOGLU T, LIM J C, VINCENT T. FRP-confined concrete in circular sections: Review and assessment of stress-strain models[J]. Engineering Structures,2013,49:1068-1088. doi: 10.1016/j.engstruct.2012.06.010 [31] RICHART F E, BRANDTZAG A, BROWN R L. A study of the failure of concrete under combined compressive stresses[M]. Illinois: University of Illinois at Urbana Champaign, 1928: 100-102. [32] POUR A F, OZBAKKALOGLU T, VINCENT T. Simplified design-oriented axial stress-strain model for FRP-confined normal- and high-strength concrete[J]. Engineering Structures,2018,175:501-516. doi: 10.1016/j.engstruct.2018.07.099 [33] DE OLIVEIRA D S, RAIZ V, CARRAZEDO R. Experimental study on normal-strength, high-strength and ultrahigh-strength concrete confined by carbon and glass FRP laminates[J]. Journal of Composites for Construction,2019,23(1):04018072. [34] LIM J C, OZBAKALOGLU T. Stress-strain model for normal- and light-weight concretes under uniaxial and triaxial compression[J]. Construction and Building Materials,2014,71:492-509. doi: 10.1016/j.conbuildmat.2014.08.050 [35] TENG J G, LAM L. Behavior and modeling of fiber reinforced polymer-confined concrete[J]. Journal of Structural Engineering,2004,130(11):1713-1723. [36] YANG J Q, FENG P. Analysis-oriented model for FRP confined high-strength concrete: 3D interpretation of path dependency[J]. Composite Structures,2021,278:114695. [37] TOUTANJI H. Stress-strain characteristics of concrete columns externally confined with advanced fiber composite sheets[J]. Materials Journal,1999,96(3):397-404. [38] SAAFI M, TOUTANJI H, LI Z. Behavior of concrete columns confined with fiber reinforced polymer tubes[J]. Materials Journal,1999,96(4):500-509. -

下载:

下载: