Molecular dynamics simulation of thermodynamic properties of polypropylene modified by nano-ZnO

-

摘要: 聚丙烯(PP)作为环境友好型热塑性材料,在超特高压电缆线路的应用中具有巨大潜力。但其在实际应用中,热、力学性能难以协同提升,所处的潮湿环境加速了水树枝的引发,严重掣肘了PP的快速发展。为此,基于分子动力学模拟技术,搭建纯PP、半径分别为0.4 nm和0.6 nm的球型纳米粒子ZnO/PP复合模型及含水分子的模型,利用热、力学性能等参数指标的变化情况,从分子层面研究球型纳米ZnO对PP性能的影响。结果表明:纳米ZnO能够在提高PP热稳定性的同时,改善其力学性能,且不同半径的ZnO颗粒提升效果有所不同。其中,半径为0.6 nm的纳米ZnO使PP的玻璃化转变温度提高56 K,能够明显降低其杨氏模量和剪切模量,对PP分子链运动和水分子运动具有较好的抑制作用。水分子使均方位移有明显的提高,玻璃化转变温度和力学参数均下降,扩散能力随着温度的升高不断增强;由于纳米ZnO与水分子之间的氢键作用,该复合体系中水分子运动受限,从而保持良好的热稳定性。研究结果对抑制PP水树枝生长、老化及开发实用型和环境友好型电缆料提供了微观层面的参考。Abstract: Polypropylene (PP), as an environment-friendly thermoplastic material, has great potential in the application of ultra high voltage cable lines. However, in practical applications, the thermal and mechanical properties are difficult to improve in coordination, and the humid environment accelerates the initiation of water branches, which seriously hampers the rapid development of PP. To this end, based on molecular dynamics simulation technology, pure PP, composite model of ZnO/PP with sphericalnanoparticles with radius of 0.4 nm and 0.6 nm and water-containing molecular models were built, and the effects of spherical nano-ZnO on the properties of PP were studied from the molecular level by using the changes of thermal and mechanical properties and other parameters. The results show that nano-ZnO can improve the thermal stability of PP and its mechanical properties, and the lifting effect of ZnO particles with different radii is different. Among them, the glass transition temperature of PP increases by 56 K with nano-ZnO with a radius of 0.6 nm, which can significantly reduce its Young's modulus and shear modulus, and has a good inhibition effect on the movement of PP molecular chain and water molecules. Water molecules significantly increase the average azimuthal shift, reduce the glass transition temperature and mechanical parameters, and enhance the diffusion ability with the increase of temperature. Due to the hydrogen bonding between nano ZnO and water molecules, the movement of water molecules in the composite system is limited, thus maintaining good thermal stability. The research results provide micro-level reference for inhibiting the growth and aging of PP water tree and developing practical and environment-friendly cable materials.

-

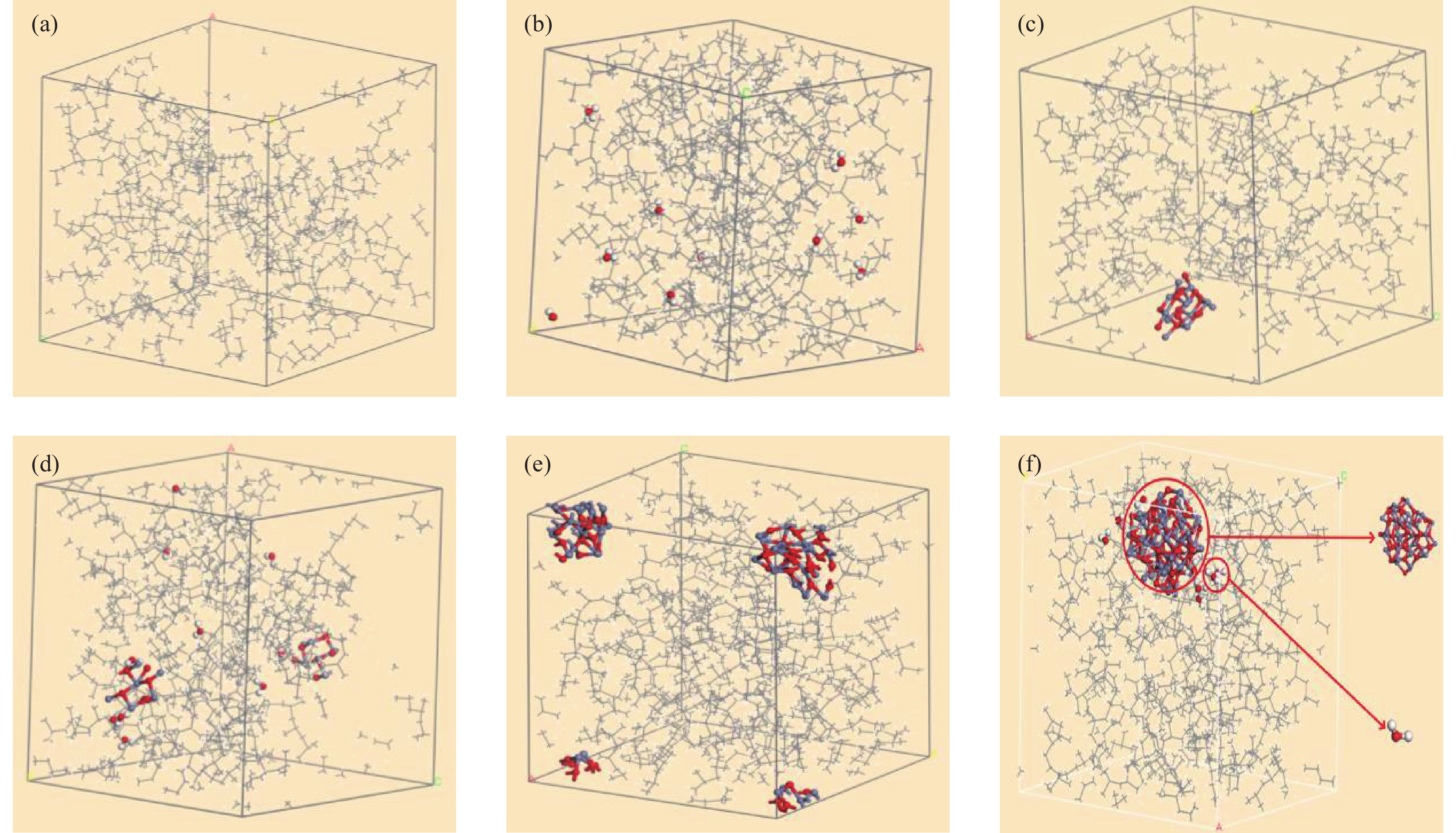

图 1 (a) 聚丙烯(PP)模型分子构象;(b) PP/10H2O模型分子构象;(c) ZnO(0.4 nm)/PP模型分子构象;(d) ZnO(0.4 nm)/PP/10H2O模型分子构象;(e) ZnO(0.6 nm)/PP模型分子构象;(f) ZnO(0.6 nm)/PP/10H2O模型分子构象

Figure 1. (a) Polypropylene (PP) model molecular conformation; (b) PP/10H2O model molecular conformation; (c) ZnO(0.4 nm)/PP model molecular conformation; (d) ZnO(0.4 nm)/PP/10H2O model molecular conformation; (e) ZnO(0.6 nm)/PP model molecular conformation; (f) ZnO(0.6 nm)/PP/10H2O model molecular conformation

表 1 250 K温度下PP及其复合材料的自由体积VFree、占有体积VOcucupied和自由体积分数f

Table 1. Free volume VFree, occupied volume VOccupied and free volume fraction f of PP and its composite materials at 250 K

System VFree/

(10−3 nm3)VOccupied/

(10−3 nm3)f/% PP 5463.79 20708.08 20.88 PP/10H2O 5627.56 20821.13 21.28 ZnO(0.4 nm)/PP 4458.44 21770.09 17.00 ZnO(0.4 nm)/PP/10H2O 4843.20 21428.15 18.44 ZnO(0.6 nm)/PP 3957.96 22485.71 14.97 ZnO(0.6 nm)/PP/10H2O 4605.22 22645.34 16.90 表 2 PP及其复合材料的扩散系数

Table 2. Diffusion coefficient of PP and its composite materials

Model Diffusion coefficient /(10−11 m2/s) 100 K 150 K 200 K 250 K 300 K 350 K 400 K 450 K 500 K 550 K PP/10H2O 16.44 21.12 52.00 57.43 148.20 372.77 703.50 454.08 3434.14 3070.43 ZnO(0.4 nm)/PP/10H2O 0.76 1.28 2.65 36.51 66.43 216.91 364.04 400.47 581.43 2466.70 ZnO(0.6 nm)/PP/10H2O 0.22 1.14 1.88 21.39 18.41 75.34 85.99 98.19 740.30 865.94 -

[1] 何金良, 彭琳, 周垚. 环保型高压直流电缆绝缘材料研究进展[J]. 高电压技术, 2017, 43(2):337-343. doi: 10.13336/j.1003-6520.hve.20170123001HE Jinliang, PENG Lin, ZHOU Yao. Research progress of environment/friendly HVDC power cable insulation materials[J]. High Voltage Engineering,2017,43(2):337-343(in Chinese). doi: 10.13336/j.1003-6520.hve.20170123001 [2] 李盛涛, 王诗航, 杨柳青, 等. 高压电缆交联聚乙烯绝缘的关键性能与基础问题[J]. 中国电机工程学报, 2022, 42(11):4247-4255. doi: 10.13334/J.0258-8013.PCSEE.212553LI Shengtao, WANG Shihang, YANG Liuqing, et al. Important properties and fundamental issues of the crosslinked polyethylene insulating materials used in high/voltage cable[J]. Proceedings of the CSEE,2022,42(11):4247-4255(in Chinese). doi: 10.13334/J.0258-8013.PCSEE.212553 [3] 朱乐为, 杜伯学. 环境友好型直流电缆料聚丙烯绝缘的电树枝研究进展[J]. 电气工程学报, 2018, 13(11):21-29. doi: 10.11985/2018.11.003ZHU Lewei, DU Boxue. Research status on electrical tree of polymer insulation materials in HVDC cables[J]. Journal of Electrical Engineering,2018,13(11):21-29(in Chinese). doi: 10.11985/2018.11.003 [4] 杜伯学, 侯兆豪, 徐航, 等. 高压直流电缆绝缘用聚丙烯及其纳米复合材料的研究进展[J]. 高电压技术, 2017, 43(9):2769-2780. doi: 10.13336/j.1003-6520.hve.20170831001DU Boxue, HOU Zhaohao, XU Hang, et al. Research achievements in polypropylene and polypropylene/inorganic nanocomposites for HVDC cable insulation[J]. High Voltage Engineering,2017,43(9):2769-2780(in Chinese). doi: 10.13336/j.1003-6520.hve.20170831001 [5] 沈鑫甫. 中学教师实用化学辞典[M]. 北京: 北京科学技术出版社, 2002: 782.SHEN Xinfu. Dictionary of practical chemistry for middle school teachers[M]. Beijing: Beijing Science and Technology Press, 2002: 782(in Chinese). [6] 杨凯, 任颙若, 李建英, 等. 乙烯共聚调控晶态结构对聚丙烯电缆绝缘料电气性能的影响[J]. 高电压技术, 2023, 49(3):982-989. doi: 10.13336/j.1003-6520.hve.20220519YANG Kai, REN Yongruo, LI Jianying, et al. Effect of regulating crystalline structure by copolymerizing with ethylene on the electrical performance of polypropylene cable insulation materials[J]. High Voltage Engineering,2023,49(3):982-989(in Chinese). doi: 10.13336/j.1003-6520.hve.20220519 [7] YOSHINO K, UEDA A, DEMURA T, et al. Property of syndiotactic polypropylene and its application to insulation of electric power cable/property, manufacturing and characteristics[C]//Manufacturing and Characteristics Proceedings of the 7th lntemational Conference on Properties and Applications of Dielectric Materials. Nagoya: Proceedings of the Asian Test Symposium, 2003: 175-178. [8] LIN X, SIEW W H, LIGGAT J, et al. Octavinyl polyhedral oligomeric silsesquioxane on tailoring the DC electrical characteristics of polypropylene[J]. High Voltage,2022,7(1):137-146. doi: 10.1049/hve2.12146 [9] 周垚, 党斌, 胡军, 等. 纳米氧化镁颗粒对聚丙烯的性能调控[J]. 中国电机工程学报, 2016, 36(24):6619-6626, 6914. doi: 10.13334/j.0258-8013.pcsee.161814ZHOU Yao, DANG Bin, HU Jun, et al. Effect of magnesium oxide nanoparticles on tailoring the properties of polypropylene[J]. Proceedings of the CSEE,2016,36(24):6619-6626, 6914(in Chinese). doi: 10.13334/j.0258-8013.pcsee.161814 [10] 高铭泽, 赵洪, 吕洪雷, 等. SEBS/PP复合材料抗水树枝性能研究[J]. 电工技术学报, 2019, 34(24):5252-5261. doi: 10.19595/j.cnki.1000-6753.tces.181671GAO Mingze, ZHAO Hong, LYU Honglei, et al. Study on anti/water/treeing performance of SEBS/PP composites[J]. Transactions of China Electrotechnical Society,2019,34(24):5252-5261(in Chinese). doi: 10.19595/j.cnki.1000-6753.tces.181671 [11] LAO S, HE H, WANG L, et al. Simulation and analysis of polypropylene dielectric constant based on molecular simulation method[C]//22nd International Symposium on High Voltage Engineering (ISH 2021). Xi'an: IET, 2021: 1831-1834. [12] 杨瑞成, 吴量, 牛绍蕊, 等. 纳米蒙脱土/聚丙烯复合材料热氧老化动力学[J]. 复合材料学报, 2010, 27(6):70-75. doi: 10.13801/j.cnki.fhclxb.2010.06.005YANG Ruicheng, WU Liang, NIU Shaorui, et al. Thermal-oxidative aging kinetics of montmorillonite/polypropylene nanocomposites[J]. Acta Materiae Compositae Sinica,2010,27(6):70-75(in Chinese). doi: 10.13801/j.cnki.fhclxb.2010.06.005 [13] 付一政, 刘亚青, 张丽燕, 等. 不同构型聚丙烯的玻璃化转变温度的分子模拟[J]. 分子科学学报, 2009, 25(1):1-4. doi: 10.3969/j.issn.1000-9035.2009.01.001FU Yizheng, LIU Yaqing, ZHANG Liyan, et al. Molecular simulation of glass transition temperature of polypropylene with different configurations[J]. Journal of Molecular Science,2009,25(1):1-4(in Chinese). doi: 10.3969/j.issn.1000-9035.2009.01.001 [14] 王乐, 孙颖, 汪辉平, 等. 绝缘材料水树产生及发展机理的研究现状[J]. 电线电缆, 2006(6):5-8. doi: 10.3969/j.issn.1672-6901.2006.06.002WANG Le, SUN Ying, WANG Huiping, et al. Status-quo of the study on water-tree generation and growth in insulating materials[J]. Electric Wire and Cable,2006(6):5-8(in Chinese). doi: 10.3969/j.issn.1672-6901.2006.06.002 [15] 李霞. 不同形状微、纳米氧化锌/低密度聚乙烯复合材料介电性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2019.LI Xia. Investigation of dielectric properties of micro-nano ZnO/LDPE composites with different shapes[D]. Harbin: Harbin University of Science and Technology, 2019(in Chinese). [16] GUAN W, WANG J, ZHU X, et al. Exploration on structure and stability of polypropylene during heating and cooling processes in terms of molecular dynamics simulations[J]. Computational and Theoretical Chemistry,2014,1027:142-150. doi: 10.1016/j.comptc.2013.11.014 [17] 李亚莎, 胡豁然, 夏宇, 等. 纳米MgO掺杂聚乙烯微观特性的分子动力学模拟研究[J]. 原子与分子物理学报, 2022, 39(2):52-60. doi: 10.19855/j.1000-0364.2022.022001LI Yasha, HU Huoran, XIA Yu, et al. Molecular dynamics simulation of the microscopic properties of nano-MgO-doped polyethylene[J]. Journal of Atomic and Molecular Physics,2022,39(2):52-60(in Chinese). doi: 10.19855/j.1000-0364.2022.022001 [18] 程伟, 孙伟, 王雯霏, 等. 丙烯腈含量对丁腈橡胶玻璃化转变过程中结构与动力学特性影响的分子模拟[J]. 高分子材料科学与工程, 2022, 38(11):110-117. doi: 10.16865/j.cnki.1000-7555.2022.0258CHENG Wei, SUN Wei, WANG Wenfei, et al. Molecular dynamics simulation on effect of acrylonitrile content on static and dynamic properties of nitrile rubber during glass transition[J]. Polymer Materials Science and Engineering,2022,38(11):110-117(in Chinese). doi: 10.16865/j.cnki.1000-7555.2022.0258 [19] 凡朋, 周登波, 严海健, 等. 纳米二氧化硅掺杂低密度聚乙烯微观特性的分子模拟[J]. 高电压技术, 2017, 43(9):2875-2880. doi: 10.13336/j.1003-6520.hve.20170831014FAN Peng, ZHOU Dengbo, YAN Haijian, et al. Microcosmic properties of LDPE/SiO2 nano/composite by molecular simulation[J]. High Voltage Engineering,2017,43(9):2875-2880(in Chinese). doi: 10.13336/j.1003-6520.hve.20170831014 [20] 李加才, 刘红剑, 王诗航, 等. 交联剂和抗氧剂对低密度聚乙烯绝缘料熔体黏弹特性的影响[J]. 中国电机工程学报, 2023, 43(1):368-380. doi: 10.13334/j.0258-8013.pcsee.213089LI Jiacai, LIU Hongjian, WANG Shihang, et al. Effect of crosslinking agent and antioxidants on the melt viscoelastic properties of low-density polyethylene insulating materials[J]. Proceedings of the CSEE,2023,43(1):368-380(in Chinese). doi: 10.13334/j.0258-8013.pcsee.213089 [21] 韩智云, 邹亮, 辛喆, 等. 直流GIL绝缘子环氧树脂/碳纳米管复合涂层关键物理性能的分子动力学模拟[J]. 电工技术学报, 2018, 33(20):4692-4703, 4721. doi: 10.19595/j.cnki.1000-6753.tces.180811HAN Zhiyun, ZOU Liang, XIN Zhe, et al. Molecular dynamics simulation of vital physical properties of epoxy/carbon nanotube composite coatings on DC GIL insulators[J]. Transactions of China Electrotechnical Society,2018,33(20):4692-4703, 4721(in Chinese). doi: 10.19595/j.cnki.1000-6753.tces.180811 [22] 刘晓辉, 范家起, 李强, 等. 聚丙烯/蒙脱土纳米复合材料I: 制备、表征及动态力学性能[J]. 高分子学报, 2000(5):563-567. doi: 10.3321/j.issn:1000-3304.2000.05.009LIU Xiaohui, FAN Jiaqi, LI Qiang, et al. Polypropylene/montmorillonite nanocomposites I: Preparation characterization and dynamic mechnical properties[J]. Acta Polymerica Sinica,2000(5):563-567(in Chinese). doi: 10.3321/j.issn:1000-3304.2000.05.009 [23] 王霞, 余栋, 段胜杰, 等. 高压电缆附件设计环节中几个关键问题探讨[J]. 高电压技术, 2018, 44(8):2710-2716. doi: 10.13336/j.1003-6520.hve.20180731030WANG Xia, YU Dong, DUAN Shengjie, et al. Dealing with some key design problems in HV cable accessory[J]. High Voltage Engineering,2018,44(8):2710-2716(in Chinese). doi: 10.13336/j.1003-6520.hve.20180731030 [24] 张永霞, 谢昕, 王庆涛, 等. 聚丙烯共混增韧改性研究进展[J]. 合成材料老化与应用, 2018, 47(1):85-90, 136. doi: 10.16584/j.cnki.issn1671-5381.2018.01.017ZHANG Yongxia, XIE Xin, WANG Qingtao, et al. Research progress of polypropylene blending toughening modification[J]. Synthetic Materials Aging and Application,2018,47(1):85-90, 136(in Chinese). doi: 10.16584/j.cnki.issn1671-5381.2018.01.017 [25] 李良钊, 张秀芹, 罗发亮, 等. 改性纳米碳酸钙-聚丙烯复合材料的结构与性能研究[J]. 高分子学报, 2011(10):1218-1223.LI Liangzhao, ZHANG Xiuqin, LUO Faliang, et al. Structure and properties of IPP/modified nano-CaCO3 composites[J]. Acta Polymerica Sinica,2011(10):1218-1223(in Chinese). [26] ALLEN M P, TILDESLEY D J. Computer simulation of liquids[M]. Oxford: Clarendon Press, 1987: 9-11. [27] 刘亚丽. PP/MMT纳米复合材料结晶形态与介电性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2010.LIU Yali. Investigation on crystalline morphology and dielectric properties of PP/MMT nanocomposites[D]. Harbin: Harbin University of Science and Technology, 2010(in Chinese). -

下载:

下载: