Thermal degradation behaviors of phosphorus-containing liquid oxygen-compatible epoxy resin

-

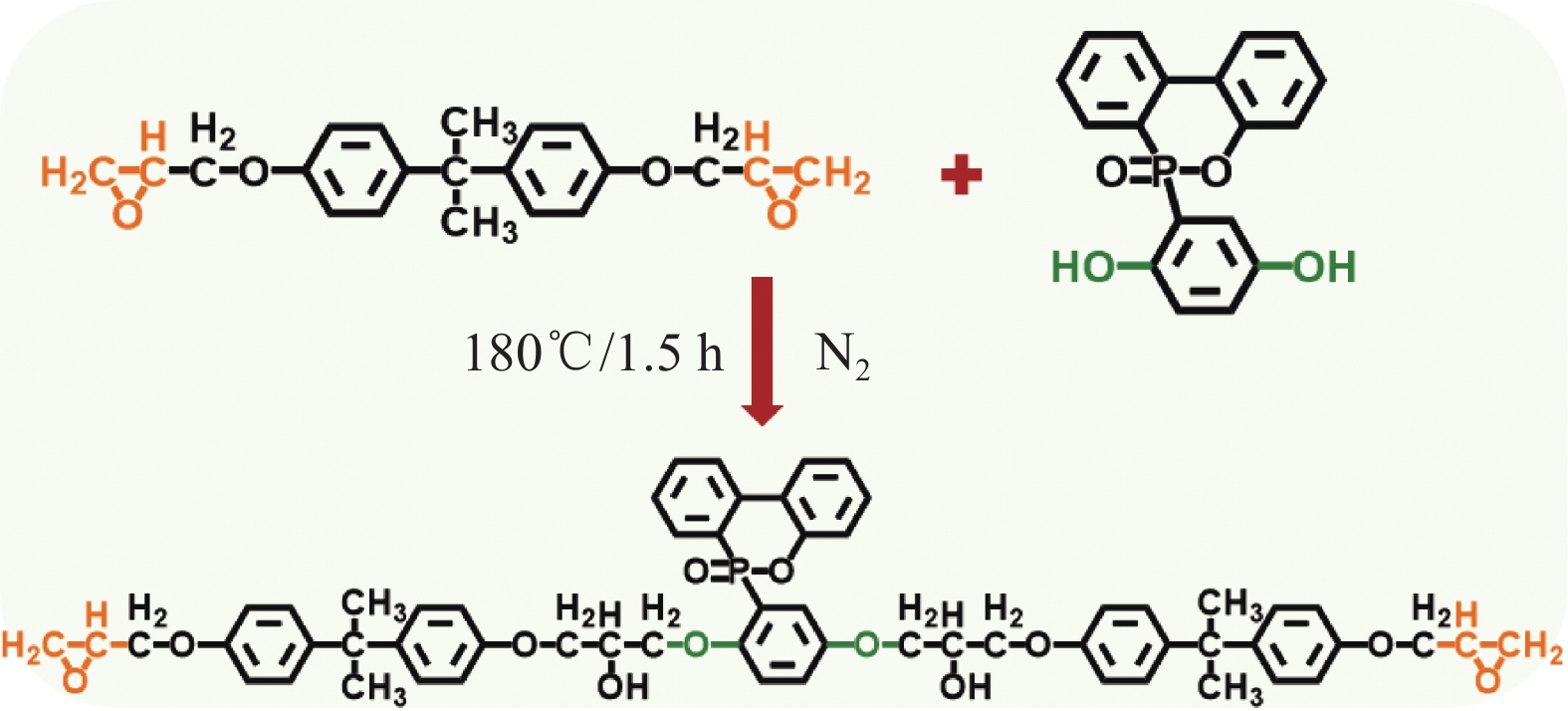

摘要: 碳纤维/环氧树脂复合材料液氧贮箱对重型火箭和空天飞机等新一代航天器减重具有重要意义。然而,环氧树脂与液氧不相容制约了其应用。采用热重分析、Kissinger方法、Coasts-Redfern方法、热重-红外-气质联用技术对10-(2, 5-二羟基苯基)-10-氢-9-氧杂-10-磷杂菲-10-氧化物(ODOPB)改性液氧相容环氧树脂(ODOPB-EP)的热降解行为及机制进行了研究。结果表明:ODOPB-EP的热降解机制为相边界反应,对应的降解机制函数g(α)=1−(1−α)1/3,α为转化率。在热降解过程中,树脂先从C—N和C—O弱键处断裂,随着温度升高,释放出苯酚及其衍生物等芳香类物质,且ODOPB在树脂中会分解产生联苯等物质,在这个过程中会伴随着含磷自由基的释放,在气相能起到淬灭作用,有利于提高树脂的液氧相容性,为探明聚合物的液氧相容机制提供了理论基础。

-

关键词:

- 环氧树脂 /

- 液氧相容性 /

- 热降解 /

- 热重-红外-气质联用 /

- 相容机制

Abstract: The liquid oxygen tanks that made of carbon fiber/epoxy resin composites are vital for weight reduction in new generation spacecraft such as heavy rockets and space shuttles. However, the incompatibility of epoxy resin with liquid oxygen limits their application. Thermogravimetric analyser, the Kissinger method, the Coasts-Redfern method and thermogravimetric-infrared-gas chromatography/mass spectrometry were used to investigate the thermal degradation behaviors and mechanism of 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphafi-10-oxide (ODOPB)-modified liquid oxygen-compatible epoxy resin (ODOPB-EP). The results show that the thermal degradation mechanism of ODOPB-EP is a phase boundary reaction, corresponding to the degradation mechanism function g(α)=1−(1−α)1/3, α is conversion rate. During the thermal degradation process, the resin breaks from the weak bonds of C—N and C—O. With the increase of temperature, aromatic substances such as phenol and its derivatives are released. Besides, ODOPB part in resin produces biphenyl and other substances, accompanied by the release of phosphorus-containing radicals. The phosphorus-containing radicals could exert quenching effects, which is conducive to improving the compatibility of the resin with liquid oxygen. This study provides a theoretic basis for verifying the compatible mechanism of polymers with liquid oxygen.-

Key words:

- epoxy resin /

- liquid oxygen compatibility /

- thermal degradation /

- TG-FTIR-GC/MS /

- compatible mechanism

-

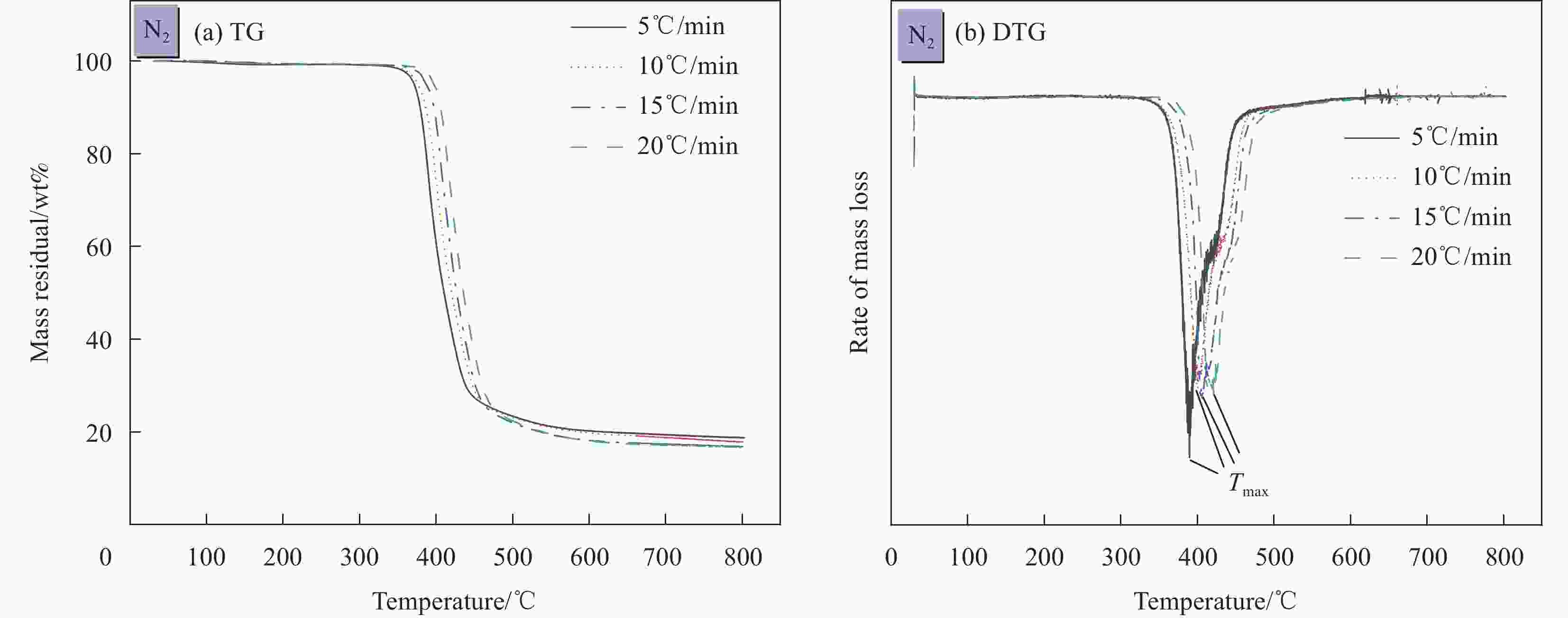

表 1 ODOPB-EP在氮气和空气下的热重数据

Table 1. TG and DTG data of ODOPB-EP under N2 and air atmosphere

Atmosphere Heating rate/

(℃·min−1)T5%/℃ Tmax/℃ Residue at

800℃/%Tmax1 Tmax2 N2 5 371.1 389.4 — 18.7 10 376.1 400.6 — 17.8 15 388.3 405.8 — 16.8 20 397.6 421.3 — 16.6 Air 5 319.4 382.7 581.7 0.70 10 335.6 394.6 599.7 0.72 15 353.3 405.3 618.2 0.88 20 358.1 415.6 627.3 1.52 Note: T5%—Temperature corresponding to mass loss 5% of material. 表 2 Coasts-Redfern方法计算不同机制模型的活化能及相关系数[22- 23]

Table 2. Activation energy and correlation coefficient calculated by Coasts-Redfern method[22-23]

Kinetic mechanism models g(α) 5℃/min 10℃/min 15℃/min 20℃/min E/(kJ·mol−1) r E/(kJ·mol−1) r E/(kJ·mol−1) r E/(kJ·mol−1) r F1 −ln(1−α) 158.71 0.875 157.11 0.915 180.91 0.911 186.19 0.906 F2 1/(1-α) 58.89 0.986 56.94 0.974 65.85 0.978 68.02 0.980 F3 1/(1−α)2 129.07 0.988 124.82 0.976 144.33 0.980 149.08 0.983 A2 [−ln(1−α)]1/2 73.72 0.856 73.08 0.900 84.13 0.896 86.58 0.891 A3 [−ln(1−α)]1/3 45.39 0.835 45.07 0.882 51.88 0.878 53.37 0.873 A4 [−ln(1−α)]1/4 31.22 0.808 31.07 0.860 35.75 0.855 36.77 0.849 R2 1−(1−α)1/2 142.04 0.843 140.97 0.889 162.24 0.885 166.93 0.879 R3 1−(1−α)1/3 147.40 0.854 146.17 0.872 168.25 0.894 173.13 0.889 D1 α2 265.41 0.822 263.87 0.872 303.57 0.867 312.26 0.862 D2 (1−α)ln(1-α)+α 284.33 0.842 282.23 0.888 324.80 0.884 334.17 0.879 D3 [1−(1−α)1/3]2 306.08 0.864 303.28 0.906 349.14 0.902 359.31 0.897 D4 (1−2α/3)−(1−α)2/3 291.55 0.849 289.22 0.895 332.88 0.890 342.51 0.885 Notes: g(α)—Degradation mechanism function; α—Conversion rate; E—Activation energy; r—Degree of fit. 表 3 不同温度下ODOPB-EP的热分解气相产物

Table 3. Pyrolytic compounds of ODOPB-EP under different temperatures

Peak Compounds m/z Peak Compounds m/z 1

92 9

121 2

106 10

136 3

94 11

160 4

108 12

134 5

107 13

158 6

121 14

174 7

122 15

154 8

122 16

172 Note: m/z—Mass-to-charge ratio. -

[1] GUO F L, TAN D, WU T, et al. Experimental characterization and molecular dynamics simulation of thermal stability, mechanical properties and liquid oxygen compatibility of multiple epoxy systems for cryotank applications[J]. Extreme Mechanics Letters,2021,44:101227. doi: 10.1016/j.eml.2021.101227 [2] LI S C, LI J Z, CUI Y G, et al. Liquid oxygen compatibility of epoxy matrix and carbon fiber reinforced epoxy composite[J]. Composites Part A: Applied Science and Manufacturing,2022,154:106771. doi: 10.1016/j.compositesa.2021.106771 [3] 湛利华, 关成龙, 黄诚, 等. 航天低温复合材料贮箱国内外研究现状分析[J]. 航空制造技术, 2019, 62(16):79-87. doi: 10.16080/j.issn1671-833x.2019.16.079ZHAN Lihua, GUAN Chenglong, HUANG Cheng, et al. Analysis of research status of composite cryotank for space[J]. Aeronautical Manufacturing Technology,2019,62(16):79-87(in Chinese). doi: 10.16080/j.issn1671-833x.2019.16.079 [4] VICKERS J. NASA composite cryotank technology project game changing program[EB/OL]. (2015-12-1)[2023-11-19]. https://ntrs.nasa.gov/citations/20160000466. [5] WANG H H, LI C, HOU Z, et al. A phosphorus-containing imidazole derivative towards the liquid oxygen compatibility and toughness of epoxy resin[J]. RSC Advances,2022,12(12):7046-7054. doi: 10.1039/D1RA09049F [6] American Society for Testing and Materials. Standard test method for determining ignition sensitivity of materials to mechanical impact in ambient liquid oxygen and pressurized liquid and gaseous oxygen environments: ASTM G86—17[S]. West Conshohocken: American Society for Testing and Materials International, 2017. [7] ROBINSON M J, STOLTZFUS J M, OWENS T N, et al. Composite material compatibility with liquid oxygen[C]//38th AIAA Structures, Structural Dynamics, and Materials Conference. Seattle: American Institute of Aeronautics and Astronautics, 1997. [8] LIU N, MA B, LIU F, et al. Progress in research on composite cryogenic propellant tank for large aerospace vehicles[J]. Composites Part A: Applied Science and Manufacturing,2021,143:106297. doi: 10.1016/j.compositesa.2021.106297 [9] AMSTER A B, MILL T, CHAMBERLAIN D L, et al. Investigation of reactivity of launch vehicle materials with liquid oxygen[R]. Huntsville: National Aeronautics and Space Administration, 1967. [10] MILL T, CHANBERLAIN D L, STRINGHAM R S, et al. Investigation of reactivity of launch vehicle materials with liquid oxygen[R]. Alabama: National Aeronautics and Space Administration, 1969. [11] 李家亮. 环氧树脂液氧相容性和低温力学性能研究[D]. 大连: 大连理工大学, 2017.LI Jialiang. Study on liquid oxygen compatibility and cryogenic mechanical properties of epoxy resins[D]. Dalian: Dalian University of Technology, 2017(in Chinese). [12] LI J, LIU X, WU Z, et al. The effect of 10-(2, 5-dihydroxyphenyl)-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide on liquid oxygen compatibility and cryogenic mechanical properties of epoxy resins[J]. High Performance Polymers, 2016, 28(7): 820-830. [13] CAO Y F, WANG Z R, WANG J L, et al. Chitosan-bridged synthesis of 2D/2D hierarchical nanostructure towards promoting the fire safety and mechanical property of epoxy resin[J]. Composites Part A: Applied Science and Manufacturing,2022,158:106958. doi: 10.1016/j.compositesa.2022.106958 [14] HUO S Q, YANG S, WANG J, et al. A liquid phosphorus-containing imidazole derivative as flame-retardant curing agent for epoxy resin with enhanced thermal latency, mechanical, and flame-retardant performances[J]. Journal of Hazardous Materials,2020,386:121984. doi: 10.1016/j.jhazmat.2019.121984 [15] TENG N, DAI J Y, WANG S P, et al. Hyperbranched flame retardant for epoxy resin modification: Simultaneously improved flame retardancy, toughness and strength as well as glass transition temperature[J]. Chemical Engineering Journal,2022,428:131226. doi: 10.1016/j.cej.2021.131226 [16] 史路飞. 抗氧剂对管材用TPEE热降解动力学研究[J]. 聚酯工业, 2022, 35(4): 32-35.SHI Lufei. Kinetics of thermal degradation for effect of antioxidant on TPEE for pipes[J]. Polyester Industry, 2022, 35(4): 32-35(in Chinese). [17] LI H, WANG N, HAN X F, et al. Mechanism identification and kinetics analysis of thermal degradation for carbon fiber/epoxy resin[J]. Polymers,2021,13(4):569. doi: 10.3390/polym13040569 [18] MA C, SANCHEZ-RODRIGUEZ D, KAMO T. A comprehensive study on the oxidative pyrolysis of epoxy resin from fiber/epoxy composites: Product characteristics and kinetics[J]. Journal of Hazardous Materials,2021,412:125329. doi: 10.1016/j.jhazmat.2021.125329 [19] KISSINGER H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry,1957,29:1702-1706. doi: 10.1021/ac60131a045 [20] COATS A W, REDFERN J P. Kinetic parameters from thermogravimetric data[J]. Nature,1964,201(4914):68-69. doi: 10.1038/201068a0 [21] COATS A W, REDFERN J P. Kinetic parameters from thermogravimetric data. II[J]. Journal of Polymer Science Part B: Polymer Letters,1965,3(11):917-920. doi: 10.1002/pol.1965.110031106 [22] QIAO Y H, DAS O, ZHAO S N, et al. Pyrolysis kinetic study and reaction mechanism of epoxy glass fiber reinforced plastic by thermogravimetric analyzer (TG) and TG-FTIR (Fourier-transform infrared) techniques[J]. Polymers,2020,12(11):739. [23] 杨婷婷, 高远博, 郑毅, 等. 生物基聚酰胺56纤维的热降解动力学及其热解产物[J]. 纺织学报, 2021, 42(4):1-7. doi: 10.13475/j.fzxb.20200908307YANG Tingting, GAO Yuanbo, ZHENG Yi, et al. Thermal degradation kinetics and pyrolysis products of bio-based polyamide 56 fiber[J]. Jouranl of Textile Research,2021,42(4):1-7(in Chinese). doi: 10.13475/j.fzxb.20200908307 [24] MU X W, ZHAN J, MA C, et al. Integrated effect of flame retardant wrapped macromolecular covalent organic nanosheet on reduction of fire hazards of epoxy resin[J]. Composites Part A: Applied Science and Manufacturing,2019,117:23-33. doi: 10.1016/j.compositesa.2018.11.005 [25] PENG W, NIE S B, XU Y X, et al. A tetra-DOPO derivative as highly efficient flame retardant for epoxy resins[J]. Polymer Degradation and Stability,2021,193:109715. doi: 10.1016/j.polymdegradstab.2021.109715 [26] LIU X F, XIAO Y F, LUO X, et al. Flame-retardant multifunctional epoxy resin with high performances[J]. Chemical Engineering Journal,2022,427:132031. doi: 10.1016/j.cej.2021.132031 [27] 许松江, 许志彦, 侯泽明, 等. 环氧树脂/DOPS衍生物复合材料的阻燃性能及热降解行为[J]. 材料导报, 2023, 37(22):1-15.XU Songjiang, XU Zhiyan, HOU Zeming, et al. Flame retardant and thermal degradation behaviors of epoxy resin/DOPS derivative composites[J]. Materials Reports,2023,37(22):1-15(in Chinese). [28] LEVCHIK S V, WEIL E D. Thermal decomposition, combustion and flame-retardancy of epoxy resins—A review of the recent literature[J]. Polymer International,2004,53(12):1901-1929. doi: 10.1002/pi.1473 [29] GRASSIE N, GUY M I. Degradation of epoxy polymers: Part 4—Thermal degradation of bisphenol-A diglycidyl ether cured with ethylene diamine[J]. Polymer Degradation and Stability,1986,14:125-137. doi: 10.1016/0141-3910(86)90011-X [30] GUO Y, RONG H, CHEN Z W, et al. A novel DOPO derivative containing multifunctional groups aiming to improve fire safety, thermal stability and curing state towards epoxy resin[J]. Polymer Degradation and Stability,2022,205:110142. doi: 10.1016/j.polymdegradstab.2022.110142 [31] DUAN H J, CHEN Y S, JI S, et al. A novel phosphorus/nitrogen-containing polycarboxylic acid endowing epoxy resin with excellent flame retardance and mechanical properties[J]. Chemical Engineering Journal,2019,375:121916. doi: 10.1016/j.cej.2019.121916 [32] MA X, GUO W Q, XU Z J, et al. Synthesis of degradable hyperbranched epoxy resins with high tensile, elongation, modulus and low-temperature resistance[J]. Composites Part B: Engineering,2020,192:108005. doi: 10.1016/j.compositesb.2020.108005 [33] 吕明哲, 李普旺, 黄茂芳, 等. 用动态热机械分析仪研究橡胶的低温动态力学性能[J]. 中国测试技术, 2007, 33(3):27-29.LYU Mingzhe, LI Puwang, HUANG Maofang, et al. Studies on dynamic mechanical property of natural rubber at low temperature by using dunamical mechanical analyzer[J]. China Mesurement Technology,2007,33(3):27-29(in Chinese). -

下载:

下载: