Effect of calcined wollastonite powder on mechanical properties of magnesium sulfade cement

-

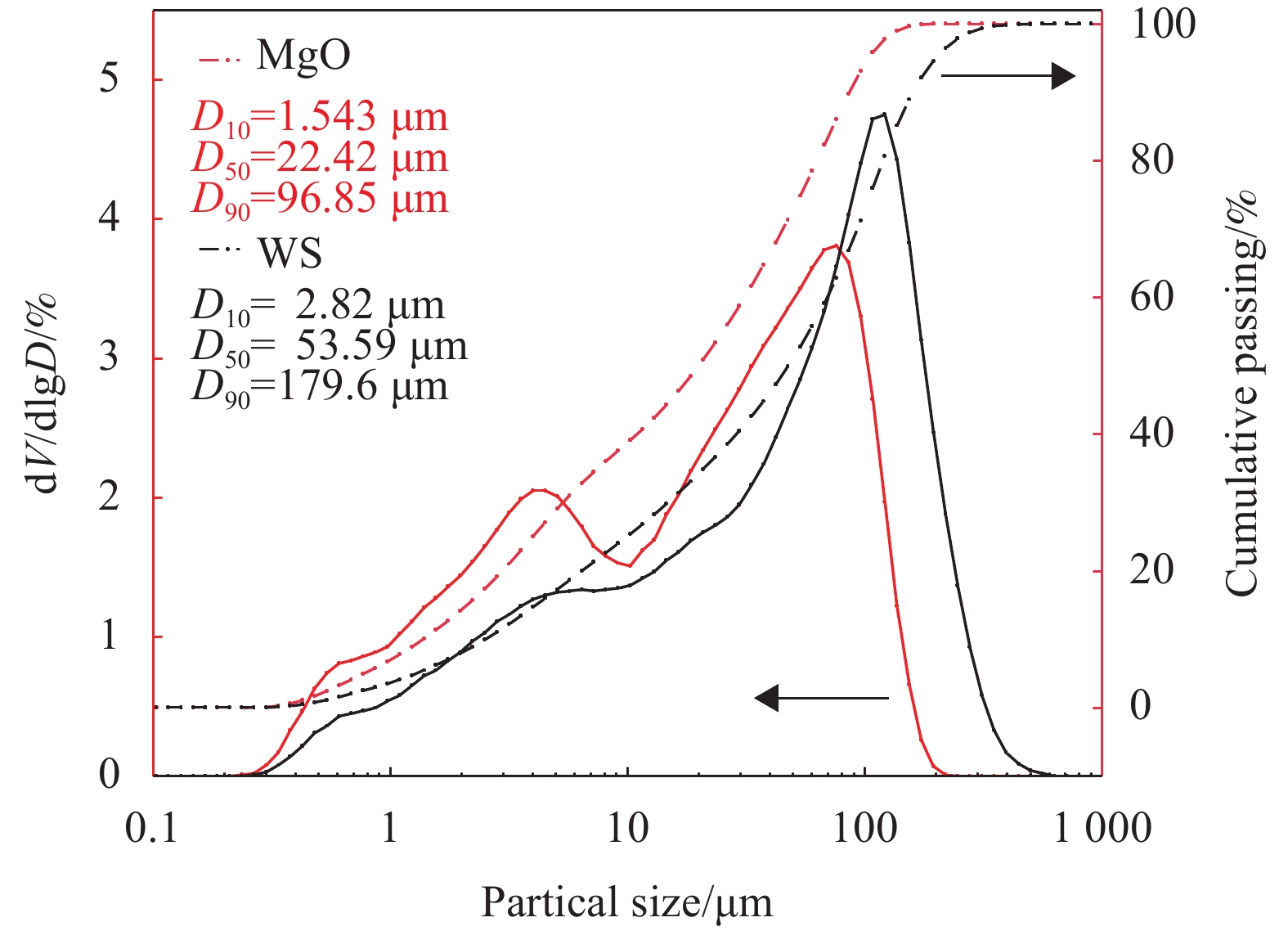

摘要: 为增强硫氧镁水泥(MOS)的力学性能,本文以煅烧前后硅灰石粉末(WS)作为外掺料,研究了其对 MOS 力学性能的影响,并利用DSC-TG、XRD、FTIR、NMR、SEM、压汞法(MIP)对煅烧前后(1000℃)的硅灰石粉和 WS/MOS 混合体系进行分析。试验表明,煅烧可以激发硅灰石粉中29Si的水化活性,并且煅烧后的硅灰石粉在镁碱环境中可以激发其水化活性导致WS/MOS复合材料的性能更优。硅灰石能增强MOS的力学性能,同时煅烧后的硅灰石粉对WS/MOS复合体系强度的增幅更明显,当煅烧后WS掺量为20wt%时,MOS 28天的抗折强度和抗压强度达到最大值,分别为11.4 MPa和63.4 MPa,增量可达71.4%和21.2%。WS优化了MOS孔隙结构,降低了MOS大于100 nm的孔的比例,煅烧后的WS与MOS具有良好的界面相容性,更有利于MOS的力学性能的提升。Abstract: To enhance the mechanical properties of magnesium oxysulfade (MOS) cement, wollastonite powder (WS) was utilized as an additive before and after calcination to study its effect on the mechanical properties of MOS. The WS and WS/MOS composite system before and after calcination (1000℃) were analyzed by DSC-TG, XRD, FTIR, NMR, SEM, and mercury intrusion porosimetry (MIP). The results show that calcination stimulates the hydration activity of 29Si in WS, and the calcined WS stimulates its hydration activity in magnesium alkali environment, resulting in better performance of WS/MOS composite materials. WS enhances the mechanical properties of MOS, and the strength of WS/MOS composite system with the calcined WS increases more significantly. The bending strength and compressive strength of MOS on the 28 days reach their maximum values when the after calcination WS content is 20wt%, which are 11.4 MPa and 63.4 MPa, respectively, with increments of 71.4% and 21.2%. WS optimizes the pore structure and reduces the proportion of pores larger than 100 nm in MOS. The calcined WS has good interface compatibility with MOS, which is more conducive to improving the mechanical properties of MOS.

-

Key words:

- wollastonite /

- calcination /

- MOS /

- mechanical properties /

- microstructure

-

表 1 轻烧氧化镁粉(LBM)和硅灰石粉(WS)的化学组成

Table 1. Chemical composition of light burned magnesium oxide powder (LBM) and wollastonite (WS)

Component MgO/wt% SiO2/wt% CaO/wt% Fe2O3/wt% Al2O3/wt% Others/wt% LBM 83.66 7.15 1.25 0.47 0.69 6.78 WS 1.11 51.34 45.74 0.28 0.59 0.94 表 2 试验配比

Table 2. Test ratio

SampleMolar ratio CA content/

wt%WS content/

wt%n(α-MgO)∶n(MgSO4) n(H2O)∶n(MgSO4 ) 0%WS/MOS 8 20 0.3 — 5%CW/MOS 8 20 0.3 5 10%CW/MOS 8 20 0.3 10 15%CW/MOS 8 20 0.3 15 20%CW/MOS 8 20 0.3 20 25%CW/MOS 8 20 0.3 25 30%CW/MOS 8 20 0.3 30 5%CY/MOS 8 20 0.3 5 10%CY/MOS 8 20 0.3 10 15%CY/MOS 8 20 0.3 15 20%CY/MOS 8 20 0.3 20 25%CY/MOS 8 20 0.3 25 30%CY/MOS 8 20 0.3 30 Notes: CW—WS not calcined; CA—Citric acid; CY—WS calcined at 1000℃ for 2 h; MOS—Magnesium oxysulfade. 表 3 WS/MOS 养护至 28天的孔径分布

Table 3. Pore size distribution of WS/MOS cured to 28 days

Sample Total intruded

volume/

(mL·g−1)Total porosity/% Volume of pore in each range/% >100 nm 10-100 nm <10 nm 0%WS/MOS 0.1294 12.9132 34.63 64.05 1.32 10%CW/MOS 0.1220 12.2003 28.88 68.54 2.58 20%CW/MOS 0.1285 12.8457 23.49 75.04 1.47 10%CY/MOS 0.1100 11.0001 26.05 71.02 2.93 20%CY/MOS 0.1101 11.0141 18.46 79.63 1.91 -

[1] WU C, YU H, ZHANG H, et al. Effects of phosphoric acid and phosphates on magnesium oxysulfate cement[J]. Materials and Structures,2015,48:907-917. doi: 10.1617/s11527-013-0202-6 [2] 柳俊哲, 孙武, 巴明芳, 等. 碳化对水泥石中硫元素分布的影响[J]. 建筑材料学报, 2015, 18(3): 477-481.LIU Junzhe, SUN Wu, BA Mingfang, et al. The effect of carbonization on the distribution of sulfur elements in cement paste[J]. Journal of Building Materials, 2015, 18(3): 477-481(in Chinese). [3] URWONGSE L, SORRELL C A. Phase relations in magnesium oxysulfate cements[J]. Journal of the American Ceramic Society,1980,63(9-10):523-526. [4] WANG R, QIN L, GAO X. Mechanical strength and water resistance of magnesium oxysulfate cement based lightweight materials[J]. Cement and Concrete Composites,2020,109:103554. doi: 10.1016/j.cemconcomp.2020.103554 [5] WANG N, YU H, BI W, et al. Effects of sodium citrate and citric acid on the properties of magnesium oxysulfate cement[J]. Construction and Building Materials,2018,169:697-704. doi: 10.1016/j.conbuildmat.2018.02.208 [6] LIU H, YU Y, LIU H, et al. Hybrid effects of nano-silica and graphene oxide on mechanical properties and hydration products of oil well cement[J]. Construction and Building Materials,2018,191:311-319. doi: 10.1016/j.conbuildmat.2018.10.029 [7] GU K, MAIERDAN Y, CHEN B. Effects of ethylenediamine tetra-acetic acid (EDTA) and its disodium salt derivative (EDTA-Na) on the characteristics of magnesium oxysulfate (MOS) cement[J]. Composites Part B: Engineering,2022,232:109654. doi: 10.1016/j.compositesb.2022.109654 [8] BA M, GAO Q, MA Y, et al. Improved hydration and properties of magnesium oxysulfate (MOS) cement using sodium silicate as an additive[J]. Construction and Building Materials,2021,267:120988. doi: 10.1016/j.conbuildmat.2020.120988 [9] ZHANG N, YU H, GONG W, et al. Effects of low-and high-calcium fly ash on the water resistance of magnesium oxysulfate cement[J]. Construction and Building Materials,2020,230:116951. doi: 10.1016/j.conbuildmat.2019.116951 [10] 靳凯戎, 许星星, 陈啸洋, 等. 花岗岩石粉对硫氧镁水泥耐压强度和耐水性的影响[J]. 建筑材料学报, 2022, 25(8): 767-772, 780.JIN Kairong, XU Xingxing, CHEN Xiaoyang, et al. The effect of granite powder on the water resistance of magnesium oxysulfide cement[J]. Journal of Building Materials, 2022, 25(8): 767-772, 780(in Chinese). [11] GUO T, WANG H, YANG H, et al. The mechanical properties of magnesium oxysulfate cement enhanced with 517 phase magnesium oxysulfate whiskers[J]. Construction and Building Materials,2017,150:844-850. doi: 10.1016/j.conbuildmat.2017.06.024 [12] RUNCEVSKI T, WU C, YU H, et al. Structural characterization of a new magnesium oxysulfate hydrate cement phase and its surface reactions with atmospheric carbon dioxide[J]. Journal of the American Ceramic Society,2013,96(11):3609-3616. doi: 10.1111/jace.12556 [13] 胡智淇, 关岩, 毕万利. 含镁碳酸盐矿物对硫氧镁水泥耐水性的影响[J]. 建筑材料学报, 2022, 25(2): 184-190.HU Zhiqi, GUAN Yan, BI Wanli. The effect of magnesium carbonate minerals on the water resistance of magnesium oxysulfide cement[J]. Journal of Building Materials, 2022, 25(2): 184-190(in Chinese). [14] 房卉, 毕万利, 张婷婷, 等. 铝酸盐水泥对硫氧镁水泥强度和耐水性的影响[J]. 建筑材料学报, 2022, 25(4): 367-374.FANG Hui, BI Wanli, ZHANG Tingting, et al. Effect of aluminate cement on strength and water resistance of magnesium oxysulfide cement[J]. Journal of Building Materials, 2022, 25(4): 367-374(in Chinese). [15] 李振国, 王博, 刘博, 等. 玻璃纤维增强碱式硫酸镁水泥耐久性研究[J]. 硅酸盐通报, 2018, 37(9): 2904-2907.LI Zhenguo, WANG Bo, LIU Bo, et al. Study on the durability of glass fiber reinforced alkaline magnesium sulfate cement[J]. Silicate Bulletin, 2018, 37(9): 2904-2907(in Chinese). [16] 汪先三. 硅灰石开发利用及发展趋势[J]. 中国非金属矿工业导刊, 2016(1):13-15.WANG Xiansan. Development, utilization and development trend of wollastonite[J]. Introduction to China's Non-metallic Mining Industry,2016(1):13-15(in Chinese). [17] 李渴, 彭春艳, 魏博, 等. 国外硅灰石资源开发利用情况[J]. 建材世界, 2019, 40(5): 12-16.LI Ke, PENG Chunyan, WEI Bo, et al. Development and utilization of wollastonite resources abroad[J]. Building Materials World, 2019, 40(5): 12-16(in Chinese). [18] WAHAB M A, LATIF I A, KOHAIL M, et al. The use of wollastonite to enhance the mechanical properties of mortar mixes[J]. Construction and Building Materials,2017,152:304-309. doi: 10.1016/j.conbuildmat.2017.07.005 [19] HE Z, SHEN A, LYU Z, et al. Effect of wollastonite microfibers as cement replacement on the properties of cementitious composites: A review[J]. Construction and Building Materials,2020,261:119920. doi: 10.1016/j.conbuildmat.2020.119920 [20] 骆超群. 煅烧硅灰石的结构与特性研究[D]. 重庆: 重庆大学, 2018.LUO Chaoqun. Study on the structure and characteristics of calcined wollastonite[D]. Chongqing: Chongqing University, 2018(in Chinese). [21] ZHENG Y, WANG C, ZHOU S, et al. The self-gelation pro-perties of calcined wollastonite powder[J]. Construction and Building Materials,2021,290:123061. doi: 10.1016/j.conbuildmat.2021.123061 [22] 中华人民共和国住房和城乡建设部. 混凝土用水标准: JGJ 63—2006[S]. 北京: 中国建筑工业出版社, 2006.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Concrete water standard: JGJ 63—2006[S]. Beijing: China Architecture & Building Press, 2006(in Chinese). [23] 国家质量技术监督局. 水泥胶砂强度检验方法 (ISO 法): GB/T 17671—1999[S]. 北京: 中国标准出版社, 1999.State Bureau of Quality and Technical Supervision. Method of testing cements—Determination of strength: GB/T 17671—1999[S]. Beijing: Standards Press of China, 1999(in Chinese). [24] GUAN Y, HU Z, ZHANG Z, et al. Effect of hydromagnesite addition on the properties and water resistance of magnesium oxysulfate (MOS) cement[J]. Cement and Concrete Research,2021,143:106387. doi: 10.1016/j.cemconres.2021.106387 [25] BENHELAL E, HOOK J M, RASHID M I, et al. Insights into chemical stability of Mg-silicates and silica in aqueous systems using 25Mg and 29Si solid-state MAS NMR spectroscopy: Applications for CO2 capture and utilisation[J]. Chemical Engineering Journal,2021,420:127656. doi: 10.1016/j.cej.2020.127656 [26] DUNG N T, HOOPER T J N, UNLUER C. Enhancing the performance of MgO-activated slag-fly ash mixes by accelerated carbonation[J]. Journal of CO2 Utilization,2020,42:101356. doi: 10.1016/j.jcou.2020.101356 [27] ZHANG Y, ZHAO Q, GAO Z, et al. Nanostructural evolution of Al(OH)3 gel formed by the cubic and orthorhombic ye'elimite clinkers of calcium sulfoaluminate cements in an ultra-wide hydration temperature range[J]. Cement and Concrete Research,2021,150:106607. doi: 10.1016/j.cemconres.2021.106607 -

下载:

下载: